Industry

Industrial Manufacturing

High Tech & Electronics

Footwear Manufacturing

Apparel & Textiles

Food & Beverage

Rubber & Plastics

Metal Fabrication

Industrial Machinery & Equipment

Construction & Engineering

Furnitures & Fixtures

Medical Device Manufacturing

Automotive Manufacturing

Aerospace And Defence

Screw Shop Manufacturing

Spring Shop Manufacturing

Solutions

Pricing

Resources

Company

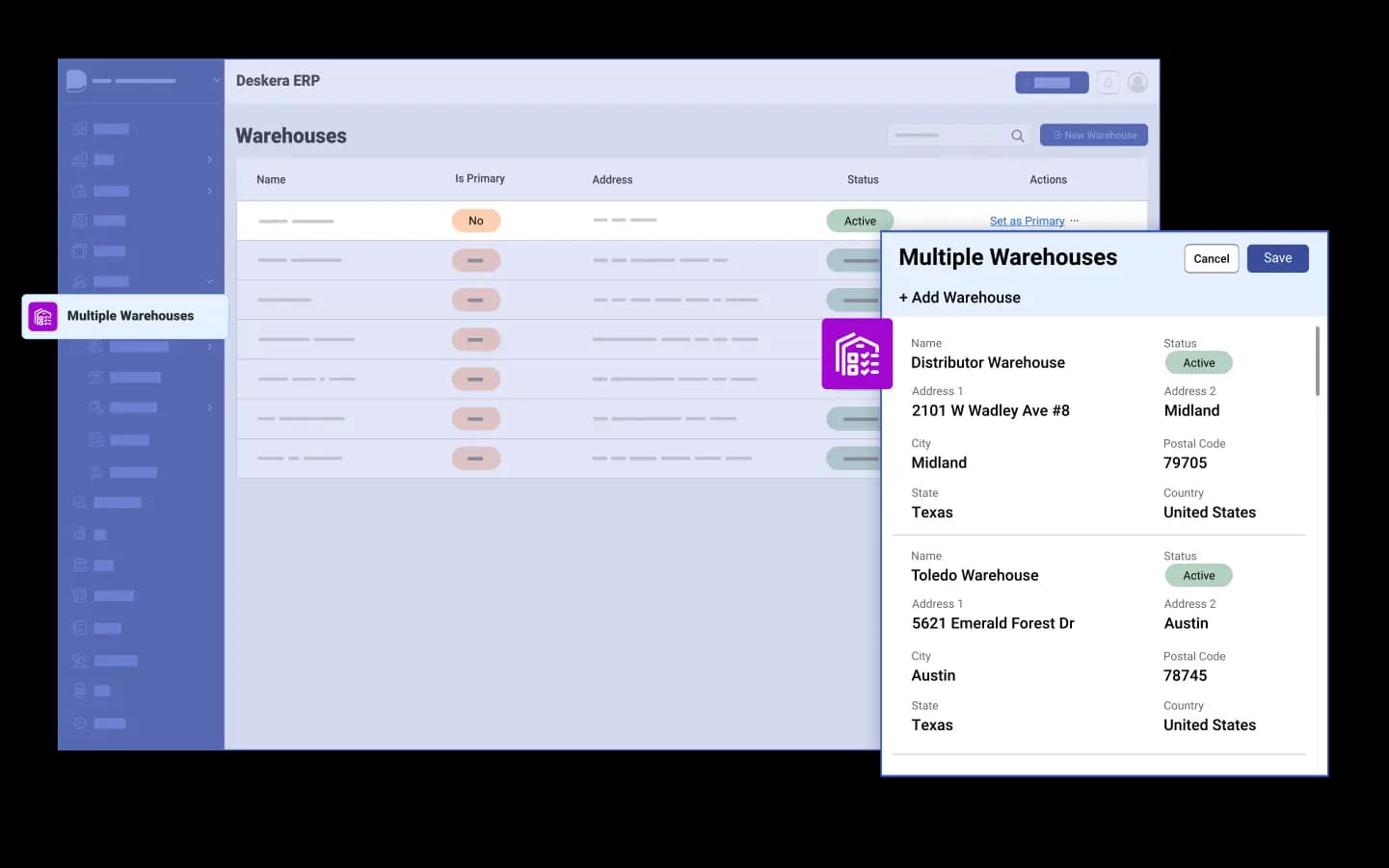

Multiple Warehouses

Assign stock to each location and keep track of inventory across all warehouses. Automate inventory tracking, stock allocation, and shipping processes across different warehouses. Access real-time inventory reports to maintain optimal stock levels.

Ensure smooth and efficient flow of goods and materials across multiple warehouses. Track the position of goods and materials in real-time. Monitor stock availability across multiple warehouses. Automatically generate order fulfillment instructions and redirect orders to the right warehouse based on stock availability. Benefit from increased visibility to stock status across multiple warehouses. Get an overview of inventory health and warehouse performance. Receive real-time alerts for low inventory levels and out-of-stock items.

Managers can track and manage multiple warehouses from one centralized location, and assign and manage specific warehouses to specific users and easily allocate products to each warehouse. They can also track the inventory levels of each warehouse, monitor stock availability, create automated replenishment orders, and monitor the storage capacity of each warehouse.

Automate the tracking of inventory levels across multiple warehouses.

Streamline inventory replenishment and stock transfers.

Reduce stockouts and ensure accurate stock records.

Key Features of Multiple Warehouses

with Deskera ERP.

Configure Multiple Warehouses

Easily set up and configure multiple warehouses

Optimize Inventory Allocation

Automatically assign inventory to the right warehouse and optimize stock allocation

Streamline Receiving and Put Away

Streamline the process of receiving and putting away goods at each warehouse

Monitor Warehouse Performance

Monitor warehouse performance and identify areas of improvement

Monitor Stock Levels

Keep track of stock levels across multiple warehouses and take corrective actions

Automate Replenishment

Automate replenishment process to ensure timely delivery of goods

Manage Warehouse Resources

Manage warehouse resources and personnel efficiently to maximize productivity

Improve Shipping Accuracy

Improve shipping accuracy by utilizing the most appropriate warehouse for each order

Track and Trace Shipments

Track and trace shipments to each warehouse and provide real-time updates

Automatically Generate Reports

Automatically generate reports to track warehouse performance and inventory levels

Deskera Multiple Warehouses

Products

Use Cases

, India

, India  , Singapore

, Singapore  , and Canada

, and Canada  with

with