Industry

Industrial Manufacturing

High Tech & Electronics

Footwear Manufacturing

Apparel & Textiles

Food & Beverage

Rubber & Plastics

Metal Fabrication

Industrial Machinery & Equipment

Construction & Engineering

Furnitures & Fixtures

Medical Device Manufacturing

Automotive Manufacturing

Aerospace And Defence

Screw Shop Manufacturing

Spring Shop Manufacturing

Solutions

Pricing

Resources

Company

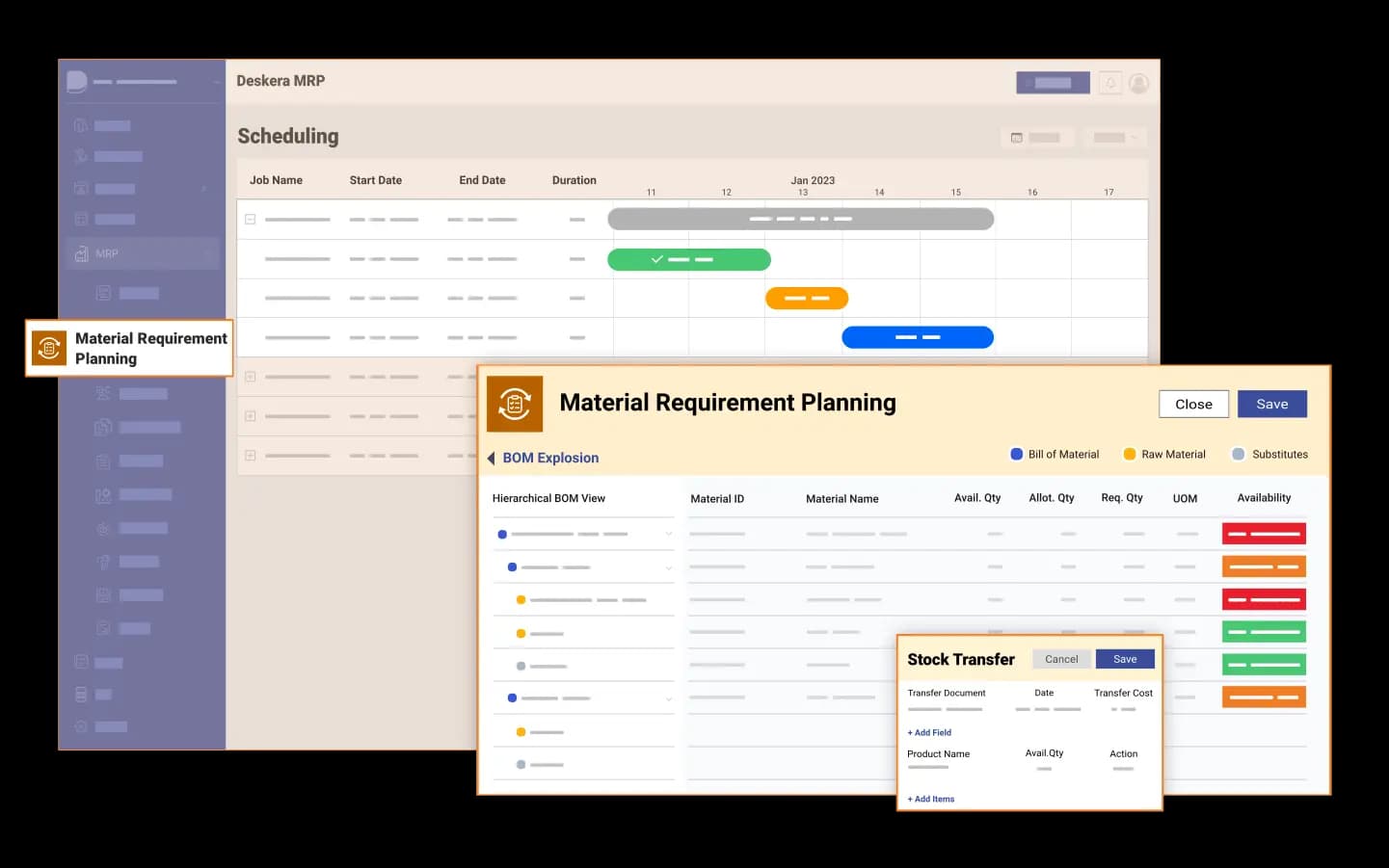

Material Requirement Planning

Plan and manage materials and inventory for production. Keep track of materials and components needed for production, track stock levels, plan orders, and optimize purchasing and production processes

Understand the current inventory levels to accurately plan the material requirements needed. Estimate the quantity of material required and the time it takes to procure it. Monitor the inventory levels and plan accordingly to meet customer demands. Analyze the material costs and establish a budget. Generate accurate and reliable reports that can help you plan your material requirements. Set safety stock levels to avoid any stock-outs. Get timely alerts and notifications about the inventory levels to stay informed. Monitor the material availability and take corrective action whenever needed. Managers can accurately track material requirements, from the moment they are ordered to the moment they are delivered, set realistic deadlines and goals for their material needs, accurately estimate their inventory needs for future projects, identify any potential problems in their material supply chain, and identify potential cost-saving opportunities

Monitor stock levels in real-time, enabling efficient ordering and re-ordering of materials.

Reduce the need for manual data entry, eliminating the potential for errors.

Automatically generate purchase orders based on the current inventory levels.

Key Features of Material Requirement Planning

with Deskera ERP.

Establish Material Requirements

Ensure your organization is aware of material needs and acquire the necessary supplies

Monitor Inventory Levels

Stay up to date on inventory levels and adjust as necessary

Forecast Future Requirements

Examine trends and anticipate future material needs

Assess Suppliers

Evaluate suppliers and select the best options for material procurement

Negotiate Agreements

Negotiate contracts and agreements with suppliers to get the best deals

Schedule Deliveries

Organize timely deliveries of materials to meet production needs

Track Incoming Shipments

Monitor all incoming shipments and ensure they meet quality standards

Implement Quality Control

Put in place quality control measures to guarantee material quality

Manage Storage

Properly store materials to extend shelf life and ensure safety

Monitor Performance

Track performance of material requirements to ensure objectives are met

Track Raw Material Lead Time

Accurately track lead time for timely procurement of raw material for efficient inventory management, and timely replenishment to ensure uninterrupted production

Deskera Material Requirement Planning

Products

Use Cases

, India

, India  , Singapore

, Singapore  , and Canada

, and Canada  with

with