Industry

Industrial Manufacturing

High Tech & Electronics

Footwear Manufacturing

Apparel & Textiles

Food & Beverage

Rubber & Plastics

Metal Fabrication

Industrial Machinery & Equipment

Construction & Engineering

Furnitures & Fixtures

Medical Device Manufacturing

Automotive Manufacturing

Aerospace And Defence

Screw Shop Manufacturing

Spring Shop Manufacturing

Solutions

Pricing

Resources

Company

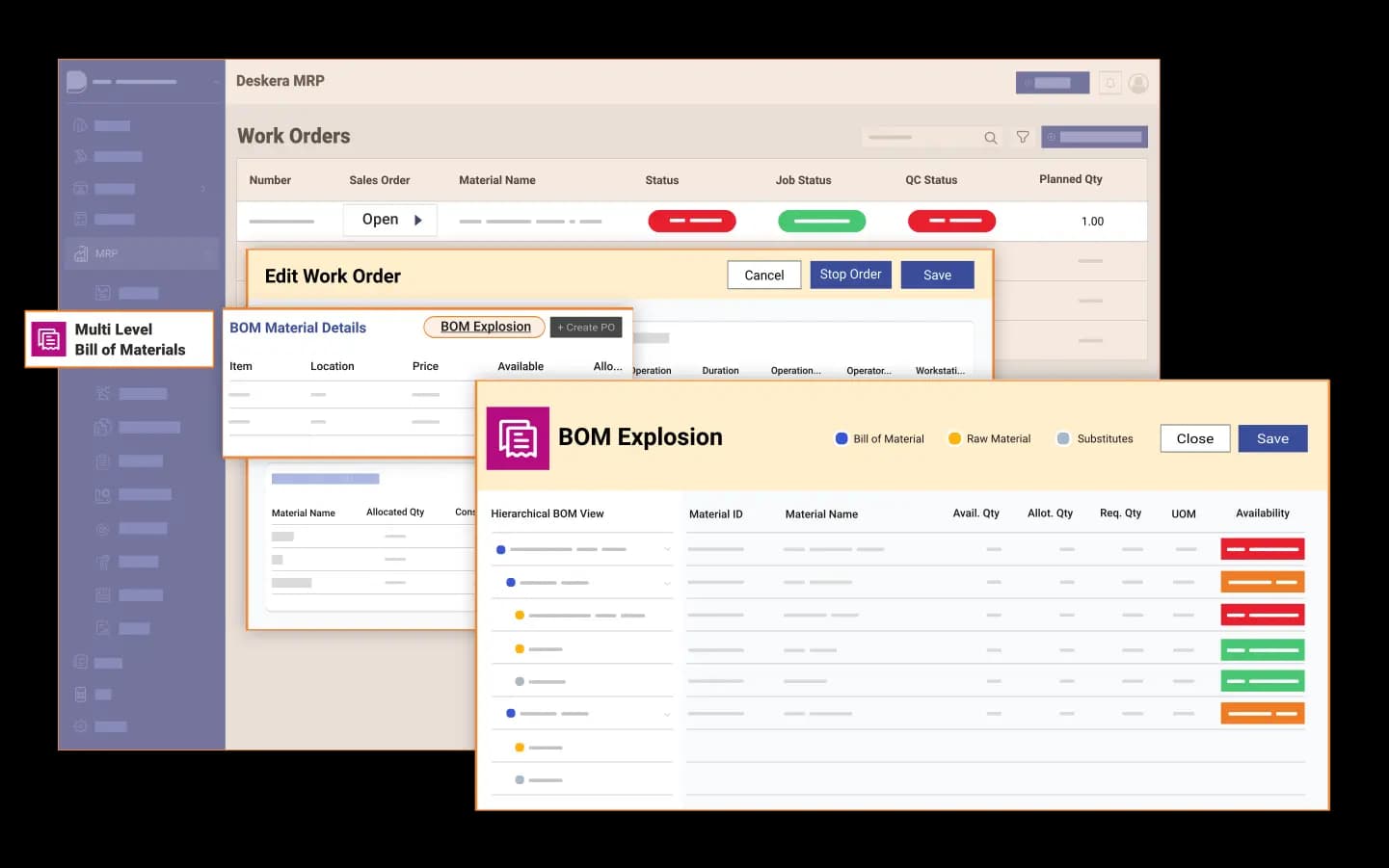

Multi Level Bill of Materials

Manage product structures with ease using Multi Level Bill of Materials. Assign multiple components to a single product. Identify components and subcomponents of each product and easily track their usage, movement, and costs.

Define the structure of a product and its components. Manage and track inventory for your production processes. Create multiple levels of subassemblies, components and parts to match the complexity of your products, track the quantity, cost, and suppliers of each item in the BOM, and identify discrepancies in inventory and production planning. Determine the most cost-effective way to use components and parts. Identify shortages and excesses in your inventory, and make adjustments accordingly.

Managers can create a hierarchical system of components and parts necessary to construct a final product, define the quantity of each component needed to assemble a finished product, and track the availability of components. With multi level bill of materials, managers can plan the entire production process in a detailed manne, track the cost of the components and parts used in the production process and ensure that they remain within the prescribed budget.

Maximize efficiency by reaching production goals faster through automatic generation of bill of materials. Automate the process of managing and maintaining multiple level bill of materials. Utilize the latest technology to keep up with the changing demands of the market.

Key Features of Multi Level Bill of Materials

with Deskera ERP.

Maximize Efficiency with Multi Level Bill of Materials

Utilize multi level bill of materials to ensure that all materials required for production are available

Create Detailed Material Requirements

Design detailed material requirements to ensure cost-effective production processes

Monitor Raw Material Inventory

Monitor raw material inventory levels to ensure that all necessary materials are available for production

Track Production Costs

Track production costs and identify areas for improvement with multi level bill of materials

Optimize Production Scheduling

Optimize production scheduling and reduce delivery times with multi level bill of materials

Automate Production Processes

Automate production processes and reduce manual labor with multi level bill of materials

Reduce Inventory Errors

Reduce inventory errors and improve traceability with multi level bill of materials

Monitor Supplier Performance

Monitor supplier performance to ensure quality of materials with multi level bill of materials

Streamline Production Planning

Streamline production planning and reduce lead times with multi level bill of materials

Improve Supply Chain Management

Improve supply chain management and increase efficiency with multi level bill of materials

Bulk Update Bills of Materials

Efficiently make mass changes to components, quantities, and other BOM details to quickly update product structures

Deskera Multi Level Bill of Materials

Products

Use Cases

, India

, India  , Singapore

, Singapore  , and Canada

, and Canada  with

with