Does recipe management seem a challenging task to you? Do you want to seek the help of technological developments to ease that process, while also increasing your profit margins and customer loyalty? If your answer to these questions is yes, then you are on the right page.

In the dynamic and competitive landscape of the food and beverage industry, effective recipe management is essential for maintaining product consistency, ensuring compliance with regulatory standards, and driving operational efficiency.

Leveraging advanced technology solutions such as food and beverage ERP systems can significantly simplify recipe management processes, streamline operations, and enhance overall productivity.

In this era of digital transformation, businesses are increasingly turning to food and beverage ERP systems to centralize and optimize their recipe management workflows.

These comprehensive software solutions offer a wide range of features and functionalities tailored specifically to the unique requirements of the food and beverage industry.

In this article, we will explore in-depth how food and beverage ERP systems can revolutionize recipe management, streamline operations, ensure compliance, and drive business success in the food and beverage industry.

From recipe creation to production planning, inventory management, quality control, and beyond, we will delve into the various features and functionalities of these systems and examine their real-world applications and benefits for businesses of all sizes.

The topics covered in this article are:

- What is Recipe Management?

- Importance of Recipe Management in the Food and Beverage Industry

- What is Food and Beverage ERP?

- Recipe Management Made Easy - Leveraging Food and Beverage ERP

- How can Deskera Help in Making Recipe Management Easy as a Food and Beverage ERP?

- Key Takeaways

- Related Articles

What is Recipe Management?

Recipe management refers to the systematic process of creating, organizing, storing, and managing recipes within a culinary or food production environment.

It involves the efficient handling of recipe-related information, including ingredients, quantities, instructions, variations, and nutritional data. Recipe management is essential for various industries, including food and beverage manufacturing, hospitality, catering, and retail.

The key aspects of recipe management include:

- Creation and Formulation: Developing new recipes or modifying existing ones to meet specific requirements, such as taste preferences, dietary restrictions, or cost constraints.

- Standardization: Establishing standardized recipes with precise measurements and instructions to ensure consistency in flavor, texture, and quality across multiple batches or locations.

- Ingredient Management: Managing ingredient inventory, procurement, and usage to ensure that necessary ingredients are available when needed and to minimize waste.

- Version Control: Tracking revisions and updates to recipes over time, including changes to ingredients, quantities, or preparation methods, to maintain an accurate record of recipe evolution.

- Production Planning: Planning and scheduling production activities based on recipe requirements, production capacity, and demand forecasts to optimize resource utilization and meet customer demand.

- Quality Control: Implementing quality control measures to ensure that recipes meet established standards for taste, appearance, nutritional content, and safety.

- Costing and Pricing: Analyzing the cost of ingredients, labor, and overhead associated with recipes to determine the overall cost of production and set pricing strategies that ensure profitability.

- Compliance and Regulations: Ensuring that recipes comply with relevant food safety regulations, labeling requirements, and industry standards to maintain legal compliance and consumer trust.

- Batch Tracking and Traceability: Tracking the movement of ingredients and products throughout the production process to enable traceability in the event of quality issues, recalls, or audits.

- Documentation and Reporting: Maintaining comprehensive documentation of recipes, production processes, and quality control measures, and generating reports to analyze recipe performance, production efficiency, and compliance metrics.

Effective recipe management is essential for optimizing operational efficiency, maintaining product consistency and quality, meeting regulatory requirements, and satisfying customer expectations.

It requires the use of specialized software tools, such as Recipe Management Systems (RMS) or Enterprise Resource Planning (ERP) systems tailored to the needs of the food and beverage industry.

These systems facilitate the centralized storage, retrieval, and analysis of recipe data, streamlining recipe management processes and enabling informed decision-making.

Importance of Recipe Management in the Food and Beverage Industry

Recipe management plays a pivotal role in the food and beverage industry for several reasons:

- Consistency in Product Quality: Standardized recipes ensure consistency in the taste, texture, and appearance of food and beverage products. By following precise measurements and instructions, businesses can replicate the same quality across multiple batches or locations, enhancing customer satisfaction and customer loyalty.

- Operational Efficiency: Efficient recipe management streamlines production processes by providing clear guidelines for ingredient procurement, preparation, and assembly. This reduces the risk of errors, minimizes waste, and optimizes resource utilization, leading to cost savings and improved profitability.

- Regulatory Compliance: Recipe management helps businesses comply with food safety regulations, labeling requirements, and industry standards. By documenting ingredients, nutritional information, allergens, and production processes, businesses can ensure that their products meet legal requirements and consumer expectations.

- Inventory Management: Managing recipes involves tracking ingredient inventory levels, forecasting demand, and optimizing stock levels to ensure that necessary ingredients are available when needed. This minimizes stockouts, reduces excess inventory holding costs, and improves cash flow management.

- Product Innovation: Recipe management fosters creativity and innovation by providing a framework for recipe development and experimentation. By analyzing customer feedback, market trends, and ingredient availability, businesses can create new recipes or modify existing ones to meet evolving consumer preferences and market demands.

- Cost Control and Pricing Strategy: Analyzing recipe costs, including ingredient costs, labor expenses, and overheads, enables businesses to determine the profitability of each recipe and set appropriate pricing strategies. This helps businesses remain competitive in the market while maintaining profit margins.

- Quality Control and Assurance: Recipe management includes implementing quality control measures to ensure that products meet established quality standards for taste, safety, and nutritional content. By conducting regular quality checks and inspections, businesses can identify and address issues promptly, maintaining product quality and consumer trust.

- Customer Satisfaction: Consistently delivering high-quality products that meet or exceed customer expectations is essential for building a loyal customer base and achieving long-term success in the food and beverage industry. Effective recipe management plays a crucial role in meeting this objective by ensuring product consistency, safety, and taste.

Overall, recipe management is integral to the success of businesses in the food and beverage industry. By implementing efficient recipe management processes and utilizing technology solutions such as Recipe Management Systems (RMS) or Enterprise Resource Planning (ERP) systems, businesses can streamline operations, ensure regulatory compliance, drive product innovation, and enhance customer satisfaction, ultimately leading to sustainable growth and profitability.

What is Food and Beverage ERP?

A food and beverage ERP system is a specialized software solution designed to address the unique needs and challenges of the food and beverage industry.

It integrates various business functions and processes into a single, centralized platform, providing comprehensive management of resources, operations, and data across the entire food and beverage supply chain.

Key features of a food and beverage ERP system typically include:

- Recipe Management: Comprehensive management of recipes, including creation, version control, ingredient tracking, nutritional analysis, and production scaling.

- Inventory Management: Efficient tracking and management of ingredient inventory, including procurement, storage, usage, and replenishment to optimize stock levels and minimize waste.

- Production Planning and Scheduling: Planning and scheduling of production activities based on demand forecasts, resource availability, production capacity, and recipe requirements to ensure timely and efficient production.

- Quality Control and Assurance: Implementation of quality control measures to ensure compliance with regulatory standards, product specifications, and customer requirements, including batch tracking, inspection, and testing.

- Supply Chain Management: Integration with suppliers, distributors, and other partners to streamline procurement, logistics, and distribution processes, ensuring timely delivery of ingredients and products.

- Compliance and Regulatory Reporting: Generation of reports and documentation to demonstrate compliance with food safety regulations, labeling requirements, and industry standards, facilitating regulatory audits and inspections.

- Costing and Pricing Analysis: Analysis of recipe costs, including ingredient costs, labor expenses, and overheads, to determine the profitability of products and set pricing strategies that maximize profitability.

- Financial Management: Comprehensive financial management capabilities, including budgeting, forecasting, accounting, and financial reporting, to ensure financial stability and transparency in operations.

- Customer Relationship Management (CRM): Management of customer interactions, orders, and preferences to enhance customer satisfaction, loyalty, and retention.

- Business Intelligence and Analytics: Advanced analytics and reporting capabilities to analyze data, identify trends, and make informed decisions to drive business growth and performance improvement.

Food and beverage ERP systems are typically tailored to the specific requirements of the food and beverage industry, incorporating industry-specific features, regulations, and best practices.

They help businesses streamline operations, improve efficiency, ensure compliance, and enhance competitiveness in a complex and highly regulated industry landscape.

Recipe Management Made Easy - Leveraging Food and Beverage ERP

Managing recipes efficiently is crucial in the food and beverage industry to ensure consistent quality, cost control, and compliance with regulations. Leveraging food and beverage ERP systems can greatly simplify and enhance recipe management.

Here's a guide on how to make recipe management easy using an ERP system:

Centralized Recipe Database

In the realm of food and beverage production, maintaining an organized and accessible recipe database is pivotal for operational efficiency and product consistency.

This is where the integration of a robust food and beverage ERP system proves indispensable. At the heart of this manufacturing software solution lies a centralized recipe database, a cornerstone of recipe management made easy in the food and beverage industry.

Importance of Centralization: A centralized recipe database serves as the nucleus of recipe management operations within a food and beverage ERP system.

Here's how it streamlines the process:

- Single Source of Truth: By consolidating all recipes into one centralized location, the MRP software system ensures that every stakeholder accesses the most up-to-date and accurate recipe versions. This minimizes confusion and errors stemming from outdated or conflicting recipe documents.

- Efficient Collaboration: Whether it's chefs devising new recipes or production managers fine-tuning existing ones, a centralized database fosters seamless collaboration. Team members can easily access, edit, and contribute to recipes, enhancing teamwork and innovation.

- Accessibility and Availability: With a food and beverage ERP system, accessing the recipe database becomes a breeze. Whether on-site or remotely, authorized personnel can retrieve recipes swiftly, enabling agile decision-making and reducing downtime.

Integration with ERP Features: The beauty of a centralized recipe database lies in its integration with other features inherent in food and beverage ERP systems, amplifying its efficacy:

- Costing and Pricing: Linking recipes to cost calculation tools allows for real-time cost updates, empowering businesses to make informed pricing decisions.

- Supplier Integration: Seamless integration with suppliers ensures that ingredient prices and availability are automatically updated, facilitating accurate recipe costing and procurement decisions.

- Compliance and Regulations: Centralized recipe management simplifies compliance adherence by enabling swift updates to recipes in line with regulatory requirements. This ensures that products meet industry standards and certifications effortlessly.

Scalability and Future-Proofing: A food and beverage ERP system equipped with a centralized recipe database is not just a solution for the present but a foundation for future growth:

- Scalability: As businesses expand their product lines or operations, a centralized recipe database scales seamlessly within the manufacturing ERP system, accommodating a growing repertoire of recipes without compromising efficiency or performance.

- Flexibility and Adaptability: With evolving consumer preferences and industry trends, the ability to swiftly modify and adapt recipes is paramount. A centralized database within a food and beverage ERP system empowers businesses to stay agile and responsive to market demands.

In essence, the centralized recipe database facilitated by a food and beverage ERP system epitomizes recipe management made easy. It serves as a dynamic hub where creativity meets efficiency, enabling businesses to innovate, collaborate, and thrive in the ever-evolving landscape of the food and beverage industry.

Version Control

In the dynamic landscape of food and beverage production, where recipes undergo iterative improvements and adjustments, version control emerges as a crucial feature within a food and beverage ERP system.

Here's how it simplifies recipe management and boosts operational efficiency:

Ensuring Accuracy and Consistency:

- Track Changes Effectively: With version control in place, every modification made to a recipe is meticulously recorded. This ensures transparency and accountability, allowing stakeholders to track the evolution of recipes over time.

- Preventing Errors and Duplication: Version control mitigates the risks associated with manual tracking of recipe changes. Maintaining a clear record of revisions minimizes the likelihood of errors, such as duplicate or conflicting recipe versions.

Facilitating Collaboration and Innovation:

- Promoting Collaboration: In a collaborative environment, where chefs, food technologists, and production managers work together to refine recipes, version control fosters seamless collaboration. It enables stakeholders to contribute insights and modifications, driving continuous improvement.

- Encouraging Innovation: By providing a structured framework for experimentation and iteration, version control encourages innovation. Chefs can explore new ingredients or techniques with confidence, knowing that their revisions are meticulously documented and can be reverted if necessary.

Enhancing Compliance and Quality Assurance:

- Regulatory Compliance: In the food and beverage industry, adherence to regulatory standards is paramount. Version control ensures that recipes are always up-to-date with the latest compliance requirements, minimizing the risk of non-compliance and associated penalties.

- Quality Assurance: By tracking changes to recipes, version control supports robust quality assurance processes. Any modifications that impact product quality can be identified and analyzed, facilitating prompt corrective actions and maintaining high standards of quality.

Integration with ERP Features: Version control seamlessly integrates with other features within a food and beverage ERP system, amplifying its impact on recipe management:

- Costing and Pricing: Version control ensures that cost calculations remain accurate, even as recipes undergo revisions. This enables businesses to make informed pricing decisions based on the latest recipe iterations.

- Batch Tracking and Traceability: Version control enhances traceability by documenting changes to recipes and linking them to specific batches of products. This facilitates comprehensive batch tracking, enabling swift recall actions if necessary.

Scalability and Future-Proofing: As businesses evolve and expand, version control within a food and beverage ERP system adapts to meet growing needs:

- Scalability: Whether managing a handful of recipes or a vast portfolio, version control scales seamlessly within the ERP system. Businesses can continue to innovate and iterate without constraints, confident in their ability to manage recipe revisions effectively.

- Future-Proofing: In an industry characterized by rapid change, version control future-proofs recipe management processes. It equips businesses with the agility and flexibility to adapt to emerging trends and consumer preferences, ensuring continued relevance and competitiveness.

In essence, version control is a cornerstone of recipe management made easy with a food and beverage ERP system. By providing a structured framework for tracking and managing recipe revisions, it empowers businesses to drive innovation, ensure compliance, and maintain uncompromising standards of quality in their culinary creations.

Costing and Pricing

In the intricate world of food and beverage production, accurate costing and pricing are paramount for maintaining profitability and competitiveness.

A food and beverage ERP system offers robust tools and functionalities to simplify these tasks, making recipe management a seamless process.

Here's how:

Accurate Cost Calculation:

- Real-Time Ingredient Cost Updates: Food and beverage ERP systems integrate with suppliers and databases to fetch real-time ingredient prices. This ensures that cost calculations are precise, reflecting the latest market rates for each component of the recipe.

- Comprehensive Cost Analysis: With built-in cost calculation tools, MRP software systems provide a comprehensive breakdown of recipe costs, including direct and indirect expenses. This enables businesses to understand the true cost of each recipe, factoring in labor, overheads, and other expenses.

Informed Pricing Strategies:

- Dynamic Pricing Adjustments: Leveraging the cost data generated by the manufacturing software system, businesses can devise dynamic pricing strategies. They can set prices based on desired profit margins, competitor pricing, or market demand, ensuring optimal profitability without sacrificing competitiveness.

- Price Optimization: By analyzing cost data alongside sales performance and market trends, food and beverage ERP systems support price optimization efforts. Businesses can identify opportunities to adjust pricing for maximum revenue generation while maintaining customer satisfaction.

Integration with Recipe Management:

- Seamless Recipe Costing: Recipe management modules within food and beverage ERP systems seamlessly integrate with costing features. As recipes are created or modified, the system automatically calculates the cost implications, providing instant insights into the financial impact of recipe changes.

- Cost-Sensitive Recipe Development: Chefs and product developers can leverage cost data during recipe creation to make informed decisions. They can select ingredients and formulations that align with cost targets without compromising on quality or flavor, optimizing recipe development processes.

Compliance and Reporting:

- Regulatory Compliance: Food and beverage ERP systems ensure that recipe costing and pricing practices comply with regulatory standards. They facilitate accurate labeling and pricing information, helping businesses meet legal requirements and avoid compliance issues.

- Reporting and Analysis: Comprehensive reporting capabilities within manufacturing ERP systems enable businesses to track recipe costs, pricing strategies, and profitability metrics over time. This data-driven approach empowers informed decision-making and facilitates continuous improvement efforts.

Scalability and Efficiency:

- Scalable Solutions: Whether managing a small artisanal operation or a large-scale production facility, food and beverage ERP systems offer scalable solutions for recipe costing and pricing. They can accommodate growing recipe databases and production volumes without sacrificing performance or accuracy.

- Efficient Resource Allocation: By optimizing recipe costing and pricing processes, MRP software systems enable efficient resource allocation. Businesses can allocate resources judiciously based on the profitability of each recipe, maximizing returns on investment and minimizing waste.

In essence, the integration of costing and pricing features within a food and beverage ERP system transforms recipe management into a streamlined and data-driven process.

By providing accurate cost calculations, supporting informed pricing strategies, and facilitating compliance and reporting, these systems empower businesses to achieve profitability and competitiveness in the dynamic food and beverage market.

Supplier Integration

In the complex ecosystem of food and beverage production, seamless collaboration with suppliers is essential for sourcing high-quality ingredients at optimal prices.

A food and beverage ERP system facilitates this collaboration through robust supplier integration features, making recipe management easy and efficient.

Here's how:

Real-Time Ingredient Updates:

- Automatic Price and Availability Updates: Food and beverage ERP systems integrate seamlessly with suppliers' databases, enabling automatic updates of ingredient prices and availability in real time. This ensures that recipe costing remains accurate and reflects current market conditions.

- Timely Notification of Changes: Through supplier integration, businesses receive timely notifications of any changes in ingredient prices, availability, or specifications. This proactive approach allows for swift adjustments to recipes, minimizing supply chain disruptions in production and procurement processes.

Streamlined Procurement Processes:

- Efficient Order Placement: With supplier integration, manufacturing ERP systems streamline the procurement process by facilitating electronic order placement directly from within the system. This reduces manual effort and eliminates the risk of errors associated with traditional procurement methods.

- Optimized Inventory Management: By maintaining up-to-date information on ingredient availability, food and beverage ERP systems support optimized inventory management. Businesses can ensure adequate stock levels without overstocking, thereby reducing carrying costs and minimizing wastage.

Cost-effective Sourcing:

- Comparison of Supplier Quotes: Supplier integration enables businesses to compare quotes from multiple suppliers effortlessly. This allows for informed decision-making based on factors such as price, quality, and delivery terms, ensuring cost-effective sourcing of ingredients.

- Negotiation and Contract Management: Manufacturing ERP systems equipped with supplier integration features facilitate negotiation and contract management processes. Businesses can negotiate favorable terms with suppliers and manage contracts effectively, further optimizing procurement costs.

Enhanced Traceability and Quality Assurance:

- Traceability of Ingredients: Supplier integration enhances traceability by providing visibility into the origin of ingredients. Businesses can trace ingredients back to their source, ensuring compliance with regulatory requirements and quality standards.

- Quality Assurance: By collaborating closely with trusted suppliers, businesses can maintain consistent quality across their supply chain. Supplier integration facilitates communication regarding quality specifications and certifications, ensuring that only approved ingredients are used in recipes.

Seamless Recipe Updates:

- Automatic Adjustment of Recipes: When ingredient prices or availability change, food and beverage ERP systems automatically adjust recipes accordingly. This ensures that recipe costing remains accurate, allowing businesses to make informed decisions about recipe formulations and pricing.

- Efficient Version Control: Supplier integration supports efficient version control of recipes by capturing changes in ingredient specifications or substitutions. This ensures that recipe versions are always up-to-date and reflect the latest information from suppliers.

Scalability and Collaboration:

- Scalable Solutions: Whether managing a small-scale operation or a large-scale production facility, food and beverage ERP systems offer scalable solutions for supplier integration. They can accommodate the growing needs of businesses and support collaboration with an expanding network of suppliers.

- Enhanced Collaboration: Supplier integration fosters collaboration between businesses and their suppliers, promoting transparency and mutual understanding. By sharing information seamlessly, both parties can work together to optimize procurement processes and drive mutual success.

In summary, supplier integration within a food and beverage ERP system is integral to recipe management, offering numerous benefits such as real-time ingredient updates, streamlined procurement processes, cost-effective sourcing, enhanced traceability, and seamless collaboration.

By leveraging these features, businesses can optimize their recipe management processes, drive operational efficiency, and maintain competitiveness in the dynamic food and beverage market.

Compliance and Regulations

In the highly regulated landscape of the food and beverage industry, compliance with various standards and regulations is non-negotiable.

A food and beverage ERP system offers robust features to streamline compliance efforts, making recipe management easy and ensuring adherence to regulatory requirements.

Here's how:

Regulatory Adherence:

- Built-in Compliance Checks: Food and beverage ERP systems come equipped with built-in compliance checks that ensure recipes adhere to regulatory standards and guidelines. This includes requirements related to ingredient labeling, nutritional information, allergen declarations, and food safety regulations.

- Automated Compliance Updates: With constant updates to regulations and standards, staying compliant can be challenging. Food and beverage ERP systems simplify this process by providing automated updates on regulatory changes relevant to recipe management. This ensures that recipes are always up-to-date and compliant with the latest requirements.

Labeling and Documentation:

- Accurate Labeling: Food and beverage ERP systems enable accurate labeling of products by incorporating labeling requirements directly into recipe management processes. Businesses can generate labels that include ingredient lists, nutritional information, allergen declarations, and other mandatory details effortlessly.

- Documentation Management: Documentation is a critical aspect of compliance, and manufacturing ERP systems offer centralized repositories for storing and managing compliance-related documents. This includes certificates of analysis, supplier documentation, and regulatory approvals, ensuring easy access during audits or inspections.

Allergen Tracking:

- Comprehensive Allergen Management: Allergen management is a key consideration in recipe management, especially with the rise in food allergies and intolerances. Food and beverage ERP systems facilitate comprehensive allergen tracking by associating allergen information with ingredients and recipes, ensuring accurate labeling and risk assessment.

- Alerts and Notifications: Manufacturing ERP systems can be configured to generate alerts and notifications for allergen-related issues, such as changes in ingredient formulations or potential cross-contamination risks. This proactive approach helps businesses mitigate allergen-related hazards and ensures consumer safety.

Quality Control:

- Adherence to Quality Standards: Quality control is integral to compliance with regulatory requirements and maintaining product integrity. Food and beverage ERP systems support robust quality control processes by implementing checks and procedures to ensure recipes meet predefined quality standards.

- Documentation of Quality Metrics: MRP software systems capture and document quality metrics related to recipe management, including batch testing results, sensory evaluations, and production deviations. This data provides valuable insights into product quality and supports continuous improvement initiatives.

Audit Preparedness:

- Centralized Audit Trails: Food and beverage ERP systems maintain centralized audit trails that track all changes and activities related to recipe management. This ensures transparency and accountability, facilitating smooth audits and inspections by regulatory authorities or certification bodies.

- On-Demand Reporting: Manufacturing ERP systems enable on-demand reporting of compliance-related data, allowing businesses to generate comprehensive reports for audits or regulatory submissions quickly. This saves time and effort while ensuring compliance documentation is readily available when needed.

Scalability and Adaptability:

- Scalable Compliance Solutions: Whether operating on a small scale or managing a global supply chain, food and beverage ERP systems offer scalable compliance solutions that can accommodate the unique needs of businesses of all sizes. They can adapt to evolving regulatory requirements and support compliance efforts across diverse markets.

- Continuous Compliance Monitoring: Manufacturing software systems enable continuous monitoring of compliance metrics and performance indicators, helping businesses identify potential issues or areas for improvement proactively. This proactive approach ensures ongoing compliance and reduces the risk of non-compliance penalties or sanctions.

In summary, compliance and regulations are central to recipe management in the food and beverage industry, and leveraging a food and beverage ERP system simplifies adherence to these standards.

By automating compliance checks, facilitating accurate labeling, enabling allergen tracking, supporting quality control processes, ensuring audit preparedness, and offering scalable solutions, manufacturing ERP systems streamline compliance efforts and enhance recipe management capabilities.

Batch Tracking and Traceability

In the intricate web of food and beverage production, batch tracking and traceability play a pivotal role in ensuring product quality, safety, and regulatory compliance.

A food and beverage ERP system offers robust features to streamline these processes, making recipe management easy and facilitating efficient tracking of ingredients and products throughout the supply chain.

Here's how:

Comprehensive Tracking:

- Ingredient Sourcing: Food and beverage ERP systems enable businesses to track ingredients from their source to production. By recording supplier information, lot numbers, and receiving dates, businesses can trace the origin of each ingredient used in recipes, ensuring quality and compliance with regulatory standards.

- Production Processes: MRP software systems capture detailed information about production processes, including batch numbers, manufacturing dates, and equipment used. This allows businesses to track the movement of ingredients through each stage of production, ensuring consistency and quality control.

Traceability Across the Supply Chain:

- Forward and Backward Traceability: Food and beverage ERP systems facilitate both forward and backward traceability, allowing businesses to trace ingredients and products from production to distribution and vice versa. This capability is invaluable for conducting recalls, investigating quality issues, and ensuring product integrity.

- Lot Tracking: Manufacturing ERP systems support lot tracking, enabling businesses to assign unique identifiers to batches of ingredients and products. This allows for precise identification and tracing of specific batches throughout the supply chain, minimizing the scope of recalls and enhancing efficiency in managing inventory.

Compliance with Regulations:

- Regulatory Compliance: Batch tracking and traceability are essential for compliance with regulatory requirements in the food and beverage industry. Food and beverage ERP systems help businesses meet these requirements by providing comprehensive documentation and audit trails that demonstrate adherence to regulatory standards.

- Labeling and Documentation: Manufacturing software systems facilitate accurate labeling and documentation of batch-related information, including lot numbers, expiration dates, and production timestamps. This ensures compliance with labeling regulations and provides essential information for consumers and regulatory authorities.

Rapid Response to Issues:

- Recall Management: In the event of a product recall or quality issue, food and beverage ERP systems enable businesses to initiate rapid recalls by identifying affected batches and tracing their distribution channels. This minimizes the impact on consumers and helps businesses mitigate reputational damage.

- Root Cause Analysis: Manufacturing ERP systems support root cause analysis by providing detailed data on batch tracking and production processes. Businesses can identify the source of quality issues or deviations, implement corrective actions, and prevent similar issues from recurring in the future.

Integration with Recipe Management:

- Seamless Integration: Batch tracking and traceability features seamlessly integrate with recipe management modules within food and beverage ERP systems. This ensures that batch-related information is linked directly to recipes, enabling businesses to maintain accurate records and track changes over time.

- Automatic Updates: When recipes are modified or updated, MRP software systems automatically update batch-related information to reflect these changes. This ensures that batch tracking remains synchronized with recipe management processes, minimizing discrepancies and ensuring data integrity.

Scalability and Adaptability:

- Scalable Solutions: Food and beverage ERP systems offer scalable solutions for batch tracking and traceability, allowing businesses to accommodate growing production volumes and evolving regulatory requirements. They can adapt to changes in the business environment while maintaining robust tracking capabilities.

- Continuous Improvement: Manufacturing software systems support continuous improvement efforts by providing insights into batch performance and production processes. Businesses can analyze data related to batch tracking and traceability to identify opportunities for optimization and enhance operational efficiency.

In summary, batch tracking and traceability are essential components of recipe management in the food and beverage industry, and leveraging a food and beverage ERP system enhances these capabilities.

By facilitating comprehensive tracking, ensuring compliance with regulations, enabling rapid response to issues, integrating seamlessly with recipe management, and offering scalable solutions, manufacturing ERP systems streamline batch tracking and traceability processes, making recipe management easy and efficient.

Production Planning and Scheduling

Efficient production planning and scheduling are essential for optimizing resource utilization, meeting customer demand, and ensuring timely delivery of products in the food and beverage industry.

A food and beverage ERP system offers robust tools and functionalities to streamline these processes, making recipe management easy and enhancing operational efficiency.

Here's how:

Demand Forecasting and Capacity Planning:

- Accurate Demand Forecasting: Food and beverage ERP systems leverage historical data and market trends to generate accurate demand forecasts for products. This enables businesses to anticipate customer demand and plan production schedules accordingly, minimizing stockouts and excess inventory.

- Capacity Planning: MRP software systems facilitate capacity planning by analyzing production capacities, resource availability, and order volumes. Businesses can optimize production schedules to maximize resource utilization while meeting customer demand and maintaining efficiency.

Recipe Integration into Production Plans:

- Seamless Integration: Recipe management modules within food and beverage ERP systems seamlessly integrate with production planning and scheduling processes. This allows businesses to incorporate recipes into production plans, ensuring that the necessary ingredients and resources are allocated efficiently.

- Automated Recipe Selection: Manufacturing ERP systems automate the process of selecting recipes based on production requirements and customer orders. This streamlines production planning by eliminating manual efforts and ensuring that the right recipes are scheduled for production at the right time.

Just-in-Time Production:

- Optimized Inventory Management: Food and beverage ERP systems support just-in-time production by synchronizing production schedules with inventory levels and order demand. This minimizes inventory holding costs and reduces the risk of obsolete or expired ingredients.

- Efficient Resource Allocation: Manufacturing software systems allocate resources judiciously based on production requirements and recipe specifications. This ensures that ingredients, equipment, and labor are deployed efficiently, maximizing productivity and minimizing waste.

Real-Time Monitoring and Adjustments:

- Real-Time Visibility: Food and beverage ERP systems provide real-time visibility into production schedules, allowing businesses to monitor progress and identify bottlenecks or delays promptly. This enables proactive decision-making to optimize production efficiency.

- Dynamic Scheduling: Manufacturing ERP systems support dynamic scheduling capabilities, allowing businesses to adjust production plans in response to changing demand, resource availability, or other factors. This agility ensures that production schedules remain flexible and responsive to market conditions.

Collaboration and Communication:

- Cross-Functional Collaboration: Manufacturing ERP systems facilitate collaboration between different departments involved in production planning and scheduling, such as production, procurement, and sales. This ensures alignment of goals and priorities, minimizing conflicts and maximizing efficiency.

- Communication Tools: Food and beverage ERP systems include communication tools, such as messaging systems or notifications, to keep stakeholders informed about production schedules, recipe changes, or other relevant updates. This promotes transparency and coordination across the organization.

Compliance and Quality Control:

- Adherence to Standards: MRP software systems ensure that production plans and schedules comply with regulatory standards, quality requirements, and safety protocols. This mitigates the risk of non-compliance issues and ensures that products meet the necessary quality standards.

- Quality Assurance Checks: Manufacturing software systems incorporate quality assurance checks into production schedules, such as batch testing or inspection checkpoints. This ensures that products meet quality specifications before they are released to the market, minimizing the risk of defects or recalls.

Scalability and Adaptability:

- Scalable Solutions: Food and beverage ERP systems offer scalable solutions for production planning and scheduling, allowing businesses to accommodate growing production volumes or changes in demand. This scalability ensures that production processes remain efficient and responsive to business needs.

- Continuous Improvement: Manufacturing ERP systems support continuous improvement initiatives by providing insights into production performance, efficiency metrics, and other key performance indicators. Businesses can analyze data to identify opportunities for optimization and implement process improvements accordingly.

In summary, production planning and scheduling are integral components of recipe management in the food and beverage industry, and leveraging a food and beverage ERP system enhances these capabilities.

By facilitating demand forecasting, capacity planning, recipe integration, just-in-time production, real-time monitoring, collaboration, compliance, and scalability, MRP software systems streamline production processes, making recipe management easy and ensuring operational excellence.

Quality Control and Testing

Maintaining product quality is paramount in the food and beverage industry to uphold brand reputation, meet customer expectations, and comply with regulatory standards.

A food and beverage ERP system offers robust quality control and testing features to streamline these processes, making recipe management easy and ensuring adherence to quality standards.

Here's how:

Comprehensive Quality Parameters:

- Defined Quality Standards: Food and beverage ERP systems enable businesses to define comprehensive quality standards for ingredients, intermediate products, and finished goods. These standards encompass attributes such as taste, texture, appearance, and nutritional content, ensuring consistent product quality.

- Specification Management: Manufacturing ERP systems facilitate specification management by centralizing and maintaining detailed specifications for ingredients, recipes, and products. This ensures that all stakeholders have access to up-to-date information and can adhere to established quality parameters.

Quality Assurance Checks:

- Automated Quality Checks: Food and beverage ERP systems automate quality assurance checks throughout the production process, from raw material inspection to finished product testing. This minimizes manual effort, reduces human error, and ensures that products meet predefined quality criteria.

- Real-Time Monitoring: MRP software systems provide real-time monitoring of quality parameters during production, allowing businesses to detect deviations or anomalies promptly. This proactive approach enables corrective actions to be taken immediately, preventing quality issues from escalating.

Batch Testing and Sampling:

- Batch Testing Protocols: Food and beverage ERP systems establish batch-testing protocols to ensure product consistency and safety. These protocols define sampling procedures, testing methodologies, and acceptance criteria for each batch, facilitating standardized testing procedures.

- Sampling Plans: Manufacturing software systems support the creation of sampling plans based on statistical principles, ensuring representative sampling of batches. This minimizes the risk of sampling bias and ensures that test results accurately reflect the quality of the entire batch.

Integration with Laboratory Systems:

- Seamless Data Exchange: Food and beverage ERP systems seamlessly integrate with laboratory information management systems (LIMS) or quality management systems (QMS), enabling efficient data exchange between production and testing facilities. This ensures that test results are captured and recorded accurately within the manufacturing ERP system.

- Automated Test Result Analysis: MRP software systems automate the analysis of test results, comparing them against predefined acceptance criteria and generating alerts for out-of-specification results. This expedites decision-making and enables prompt corrective actions to be taken to maintain product quality.

Compliance with Regulations:

- Regulatory Compliance Checks: Food and beverage ERP systems incorporate regulatory compliance checks into quality control processes, ensuring that products meet relevant food safety standards and labeling requirements. This minimizes the risk of non-compliance issues and helps businesses avoid regulatory penalties.

- Documentation and Reporting: Manufacturing ERP systems facilitate documentation and reporting of quality control activities, including test results, compliance certificates, and audit trails. This ensures transparency and traceability, enabling businesses to demonstrate adherence to regulatory requirements during audits or inspections.

Continuous Improvement:

- Root Cause Analysis: Food and beverage ERP systems support root cause analysis of quality issues by providing detailed data on production processes and test results. This enables businesses to identify the underlying causes of quality deviations and implement corrective actions to prevent recurrence.

- Trend Analysis: MRP software systems enable trend analysis of quality data over time, identifying patterns or recurring issues that may indicate systemic problems. This data-driven approach empowers businesses to proactively address quality issues and drive continuous improvement in their operations.

Scalability and Adaptability:

- Scalable Solutions: Food and beverage ERP systems offer scalable quality control solutions that can accommodate growing production volumes or changes in product portfolios. This scalability ensures that quality management processes remain effective and efficient as businesses expand.

- Adaptive Compliance: Manufacturing software systems adapt to changes in regulatory requirements or industry standards, ensuring ongoing compliance with evolving quality regulations. This adaptability future-proofs quality management processes and helps businesses stay ahead of regulatory changes.

In summary, quality control and testing are critical components of recipe management in the food and beverage industry, and leveraging a food and beverage ERP system enhances these processes.

By facilitating comprehensive quality parameters, automated quality checks, batch testing and sampling, integration with laboratory systems, compliance with regulations, continuous improvement, scalability, and adaptability, manufacturing ERP systems streamline quality management processes, making recipe management easy and ensuring consistent product quality.

Mobile Accessibility

In today's interconnected world, mobile devices have become indispensable tools for professionals across various industries, including food and beverage.

Food and beverage ERP systems with mobile accessibility empower businesses to manage recipes effectively on the go, facilitating seamless collaboration, real-time updates, and improved decision-making.

Here's how:

Flexible Access Anytime, Anywhere:

- Remote Access to Recipe Data: Food and beverage ERP systems with mobile accessibility allow users to access recipe data from anywhere, at any time, using their smartphones or tablets. This flexibility enables chefs, production managers, and other stakeholders to stay connected to recipe information, even when they are away from the office or production facility.

- On-the-Go Decision-Making: With mobile access to recipe management tools, decision-makers can review, approve, or modify recipes on the go, without being tied to a desktop computer. This agility enhances decision-making processes and ensures that recipe-related tasks can be addressed promptly, regardless of location.

Real-Time Collaboration:

- Instant Communication and Updates: Mobile accessibility enables real-time communication and collaboration among team members involved in recipe management. Users can exchange messages, share feedback, and collaborate on recipe development or modifications seamlessly, enhancing teamwork and productivity.

- Simultaneous Access to Data: Food and beverage ERP systems with mobile accessibility allow multiple users to access recipe data simultaneously, regardless of their location. This promotes transparency and facilitates concurrent work on recipes, leading to faster turnaround times and improved efficiency.

Rapid Response to Changes:

- Immediate Updates to Recipes: Mobile accessibility enables users to make immediate updates to recipes in response to changing requirements, customer feedback, or market trends. This agility ensures that recipes remain up-to-date and reflective of the latest information, facilitating quick adaptation to evolving circumstances.

- Prompt Resolution of Issues: In the event of quality issues or production disruptions, mobile accessibility enables rapid response and resolution. Users can access recipe data, review production processes, and initiate corrective actions promptly, minimizing downtime and mitigating the impact on operations.

Enhanced Efficiency in Operations:

- Streamlined Workflow Management: Food and beverage ERP systems with mobile accessibility streamline workflow management by providing users with tools to track recipe progress, monitor production schedules, and allocate resources efficiently. This ensures that tasks are completed promptly and production runs smoothly.

- Optimized Inventory Management: Mobile access to recipe data allows inventory managers to monitor ingredient levels, track usage, and place orders as needed, directly from their mobile devices. This optimizes inventory management processes and helps prevent stock outs or overstocking of ingredients.

Secure Data Access:

- Role-Based Permissions: Food and beverage ERP systems enforce role-based permissions to ensure that only authorized users can access sensitive recipe data via mobile devices. This safeguards against unauthorized access and protects confidential recipe formulations or proprietary information.

- Data Encryption and Security Measures: Mobile accessibility features of manufacturing ERP systems employ data encryption and other security measures to protect recipe data transmitted between devices and servers. This ensures that recipe information remains secure and confidential, even when accessed remotely.

User-Friendly Interface:

- Intuitive Mobile App Design: Food and beverage ERP systems offer mobile apps with user-friendly interfaces designed specifically for ease of use on smartphones and tablets. This ensures that users can navigate recipe management tools seamlessly, with minimal training or technical expertise required.

- Responsive Design Across Devices: Mobile accessibility features ensure that food and beverage ERP systems are compatible with a wide range of mobile devices and screen sizes. Whether using a smartphone or tablet, users can enjoy a consistent and responsive experience when accessing recipe data on the go.

In summary, mobile accessibility enhances recipe management processes in the food and beverage industry by providing flexible access to recipe data, facilitating real-time collaboration, enabling rapid response to changes, enhancing operational efficiency, ensuring secure data access, and offering a user-friendly interface.

By leveraging food and beverage ERP systems with mobile accessibility, businesses can streamline recipe management tasks, improve productivity, and maintain a competitive edge in a fast-paced industry.

Analytics and Reporting

In the competitive landscape of the food and beverage industry, data-driven insights are invaluable for optimizing recipe management processes, improving operational efficiency, and driving business growth.

A food and beverage ERP system offers robust analytics and reporting functionalities that enable businesses to gain actionable insights from recipe-related data.

Here's how:

Comprehensive Data Analysis:

- Ingredient Usage Patterns: Food and beverage ERP systems analyze ingredient usage patterns across recipes, enabling businesses to identify trends, variations, and opportunities for optimization. This insight helps in managing inventory effectively, reducing waste, and optimizing procurement processes.

- Recipe Performance Metrics: MRP software systems track recipe performance metrics such as production yield, quality attributes, and customer feedback. By analyzing this data, businesses can assess the popularity of recipes, identify high-performing formulations, and make data-driven decisions about recipe modifications or discontinuations.

Cost Analysis and Profitability:

- Recipe Costing Insights: Food and beverage ERP systems provide detailed cost analysis for each recipe, including ingredient costs, labor expenses, overheads, and more. Businesses can evaluate the profitability of recipes, identify cost-saving opportunities, and optimize pricing strategies to maximize profitability.

- Profit Margin Optimization: Manufacturing software systems enable businesses to analyze profit margins for individual recipes or product lines, helping them identify opportunities to increase profitability. By adjusting ingredient formulations, pricing strategies, or production processes, businesses can optimize profit margins and drive financial success.

Production Efficiency Metrics:

- Production Yield and Efficiency: Food and beverage ERP systems track production yield, efficiency metrics, and downtime events associated with recipe production. By analyzing this data, businesses can identify bottlenecks, streamline production processes, and improve overall efficiency in recipe management.

- Resource Utilization: Manufacturing ERP systems analyze resource utilization metrics such as equipment downtime, labor productivity, and ingredient usage rates. This insight helps businesses optimize resource allocation, minimize waste, and maximize the utilization of production assets.

Compliance and Quality Metrics:

- Compliance Reporting: Food and beverage ERP systems generate compliance reports that document adherence to regulatory standards, quality specifications, and labeling requirements. Businesses can demonstrate compliance with food safety regulations, certifications, and customer specifications through comprehensive reporting.

- Quality Control Analytics: MRP software systems analyze quality control data, including batch testing results, inspection findings, and customer complaints. By identifying trends or recurring issues, businesses can implement corrective actions, improve product quality, and enhance consumer satisfaction.

Forecasting and Demand Planning:

- Demand Forecasting Accuracy: Food and beverage ERP systems leverage historical data and predictive analytics to forecast demand for recipes accurately. This enables businesses to plan production schedules, manage inventory levels, and meet customer demand more effectively.

- Inventory Optimization: Manufacturing ERP systems analyze inventory data to optimize stock levels, minimize carrying costs, and prevent stock outs or overstocking of ingredients. By aligning inventory levels with production requirements and demand forecasts, businesses can reduce inventory holding costs and improve cash flow.

Customizable Reporting:

- Tailored Report Generation: Food and beverage ERP systems offer customizable reporting capabilities that allow businesses to generate tailored reports based on specific requirements. Whether analyzing recipe performance, cost trends, or compliance metrics, businesses can create reports that provide actionable insights for decision-making.

- Scheduled Reporting: MRP software systems automate the generation and distribution of scheduled reports, ensuring that key stakeholders receive timely updates on recipe management metrics. This streamlines communication promotes transparency, and facilitates informed decision-making across the organization.

Scalability and Adaptability:

- Scalable Analytics Solutions: Food and beverage ERP systems offer scalable analytics solutions that can accommodate growing data volumes and evolving business needs. Whether managing a small-scale operation or a global enterprise, businesses can scale their analytics capabilities to support recipe management processes effectively.

- Adaptive Insights: Manufacturing software systems adapt to changes in the business environment, market conditions, or regulatory requirements, ensuring that analytics and reporting capabilities remain relevant and actionable. This adaptability enables businesses to stay ahead of industry trends, anticipate challenges, and drive continuous improvement in recipe management.

In summary, analytics and reporting are essential components of recipe management in the food and beverage industry, and leveraging a food and beverage ERP system enhances these capabilities.

By providing comprehensive data analysis, cost analysis, production efficiency metrics, compliance reporting, demand forecasting, customizable reporting, scalability, and adaptability, manufacturing ERP systems empower businesses to make informed decisions, optimize recipe management processes, and drive business success.

Training and Documentation

Implementing a food and beverage ERP system for recipe management requires comprehensive training and documentation to ensure that users can effectively utilize the system's capabilities.

Here's how training and documentation contribute to making recipe management easy:

User Training:

- System Familiarization: Training sessions familiarize users with the features and functionalities of the food and beverage ERP system, including recipe management modules. Users learn how to navigate the system, input recipe data, and perform essential tasks such as recipe creation, modification, and version control.

- Role-Specific Training: Training is tailored to the specific roles and responsibilities of users involved in recipe management, such as chefs, production managers, quality control personnel, and procurement specialists. Role-specific training ensures that users understand how to perform tasks relevant to their job functions effectively.

Hands-On Practice:

- Interactive Training Exercises: Training sessions include hands-on exercises and simulations that allow users to practice using the food and beverage ERP system in a controlled environment. This practical experience reinforces learning and builds confidence in using the system for recipe management tasks.

- Scenario-Based Learning: Users are presented with real-world scenarios and case studies during training to demonstrate how the food and beverage ERP system can be used to address common challenges in recipe management. This helps users understand the practical applications of the system and how it can streamline their workflow.

Continuous Support:

- On-Going Assistance: After the initial training period, users have access to ongoing support resources, such as help desks, online forums, and user communities. This ensures that users can seek assistance or clarification whenever they encounter difficulties or have questions about using the food and beverage ERP system for recipe management.

- Refresher Training: Periodic refresher training sessions are conducted to reinforce learning and introduce users to new features or updates in the food and beverage ERP system. Refresher training helps users stay up-to-date with best practices and optimize their use of the system for recipe management.

Comprehensive Documentation:

- User Manuals and Guides: Food and beverage ERP systems provide comprehensive user manuals and guides that cover all aspects of recipe management, from basic tasks to advanced functionalities. These documents serve as valuable references for users to consult when they need assistance or guidance.

- Training Materials: Training materials, such as presentation slides, training videos, and interactive tutorials, are provided to supplement user training sessions. These materials reinforce key concepts covered during training and provide additional resources for self-paced learning.

Troubleshooting Resources:

- FAQs and Troubleshooting Guides: Food and beverage ERP systems include FAQs and troubleshooting guides that address common user queries and issues related to recipe management. These resources help users troubleshoot problems independently and resolve issues quickly without the need for extensive support.

- Online Help Resources: Online help resources, such as knowledge bases and support portals, are available to users for accessing additional information, tips, and best practices for using the food and beverage ERP system effectively for recipe management. These resources supplement training and documentation and provide on-demand assistance whenever needed.

Customized Training Programs:

- Tailored Training Sessions: Food and beverage ERP vendors offer customized training programs tailored to the specific needs and requirements of each organization. This ensures that training content aligns with the organization's business processes and recipe management workflows.

- Training for New Employees: Organizations provide training for new employees who join the company after the initial implementation of the food and beverage ERP system. This ensures that new hires are proficient in using the system for recipe management tasks and can contribute effectively to the organization's operations.

Compliance and Regulatory Training:

- Training on Regulatory Requirements: Food and beverage ERP systems include training modules on regulatory requirements and compliance standards relevant to recipe management, such as food safety regulations, labeling requirements, and quality control protocols. This ensures that users understand their responsibilities in maintaining compliance when managing recipes.

- Certification Programs: Some food and beverage ERP vendors offer certification programs that validate users' proficiency in using the system for recipe management and compliance tasks. Certification programs provide formal recognition of users' skills and knowledge in utilizing the system effectively.

In summary, training and documentation play a crucial role in making recipe management easy when leveraging a food and beverage ERP system.

Through comprehensive user training, hands-on practice, continuous support, comprehensive documentation, troubleshooting resources, customized training programs, and compliance training, organizations ensure that users are equipped with the knowledge and resources they need to effectively utilize the system for recipe management tasks.

This empowers users to optimize their workflow, streamline operations, and achieve success in recipe management within the food and beverage industry.

Scalability

In the competitive environment of the food and beverage industry, businesses must be able to scale their recipe management processes to meet evolving demands, accommodate growth, and capitalize on new opportunities.

A food and beverage ERP system that offers scalability provides the flexibility and agility needed to support these requirements.

Here's how scalability contributes to making recipe management easy:

Flexible Infrastructure:

- Adaptable Architecture: Food and beverage ERP systems with scalable architecture can easily accommodate changes in data volume, user traffic, and processing requirements. This adaptability ensures that the system can scale up or down as needed to support recipe management processes without compromising performance.

- Cloud-Based Solutions: Cloud-based food and beverage ERP systems offer scalability by allowing businesses to scale resources such as storage, computing power, and bandwidth on demand. This flexibility ensures that recipe management processes can scale seamlessly to meet growing demand or seasonal fluctuations.

Growing Product Portfolios:

- Recipe Portfolio Expansion: As businesses expand their product portfolios or introduce new recipes, scalability becomes essential to accommodate the increased data volume and complexity. Food and beverage ERP systems with scalable databases and data management capabilities can easily handle the addition of new recipes without impacting performance.

- Multi-Location Operations: For food and beverage companies with multiple locations or production facilities, scalability is crucial for ensuring consistency and efficiency in recipe management across all sites. Scalable manufacturing ERP systems allow for centralized management of recipes while providing the flexibility to support diverse operational needs.

Increased Production Volumes:

- Production Scaling: Food and beverage ERP systems enable businesses to scale production volumes seamlessly to meet fluctuating demand. Scalability ensures that recipe management processes can handle increased production volumes without causing bottlenecks or delays in recipe formulation, production planning, or inventory management.

- Supply Chain Integration: Scalable MRP software systems facilitate integration with suppliers and third-party partners, enabling businesses to scale their supply chain operations in line with production requirements. This ensures that ingredients can be sourced efficiently to support recipe production at scale.

Global Expansion:

- International Operations: Food and beverage ERP systems that support scalability are essential for businesses expanding into new markets or operating globally. Scalable solutions accommodate the diverse needs of international operations, such as multi-language support, currency conversion, and compliance with local regulations.

- Localized Recipe Management: Scalable manufacturing ERP systems allow for localized recipe management, enabling businesses to tailor recipes to suit regional preferences, regulations, and cultural differences. This flexibility ensures that recipe management processes can be adapted to meet the unique requirements of each market.

Customization and Integration:

- Modular Architecture: Food and beverage ERP systems with modular architectures allow businesses to customize and extend functionality as needed to support recipe management processes. This scalability enables businesses to add or remove modules, integrate with third-party applications, and adapt the system to evolving business needs.

- API Integration: Scalable manufacturing software systems offer Application Programming Interfaces (APIs) that facilitate seamless integration with other software applications, equipment, or IoT devices used in recipe management processes. This interoperability ensures that businesses can leverage existing tools and systems while scaling their recipe management capabilities.

Future-Proofing:

- Technology Evolution: Scalable food and beverage ERP systems are designed to evolve with changing technology trends and industry standards. This ensures that businesses can future-proof their recipe management processes by adopting new technologies, such as AI, machine learning, or blockchain, as they become available.

- Continuous Improvement: Scalable manufacturing ERP systems support continuous improvement initiatives by providing the flexibility to refine and optimize recipe management processes over time. Businesses can adapt workflows, implement best practices, and incorporate feedback to enhance efficiency and effectiveness in recipe management.

In summary, scalability is essential for making recipe management easy when leveraging a food and beverage ERP system.

By offering flexible infrastructure, accommodating growing product portfolios and production volumes, supporting global expansion, enabling customization and integration, and future-proofing recipe management processes, scalable MRP software systems empower businesses to adapt, grow, and succeed in the dynamic environment of the food and beverage industry.

How can Deskera Help in Making Recipe Management Easy as a Food and Beverage ERP?

Deskera, as a food and beverage ERP solution, can significantly simplify recipe management processes through its comprehensive features and functionalities tailored to the specific needs of the industry.

Here's how Deskera can help in making recipe management easy:

- Recipe Creation and Standardization: Deskera provides tools for creating and standardizing recipes with precise measurements, ingredient lists, and instructions. Users can easily input recipe details, including ingredient quantities, preparation methods, and nutritional information, ensuring consistency in product quality across batches and locations.

- Version Control and Revision History: Deskera offers version control capabilities that allow users to track revisions and updates to recipes over time. This ensures that users can maintain an accurate record of recipe changes, review previous versions, and revert to earlier versions if needed, thereby enhancing recipe traceability and compliance.

- Ingredient Management and Procurement: Deskera facilitates efficient ingredient management by enabling users to track ingredient inventory levels, manage suppliers, and streamline procurement processes. Users can monitor ingredient availability, forecast demand, and automate purchase orders to ensure that necessary ingredients are always on hand for recipe production.

- Production Planning and Scheduling: Deskera helps businesses optimize production planning and scheduling by providing tools to plan production activities based on recipe requirements, production capacity, and demand forecasts. Users can create production schedules, allocate resources, and monitor production progress in real time, ensuring efficient utilization of resources and timely delivery of products.

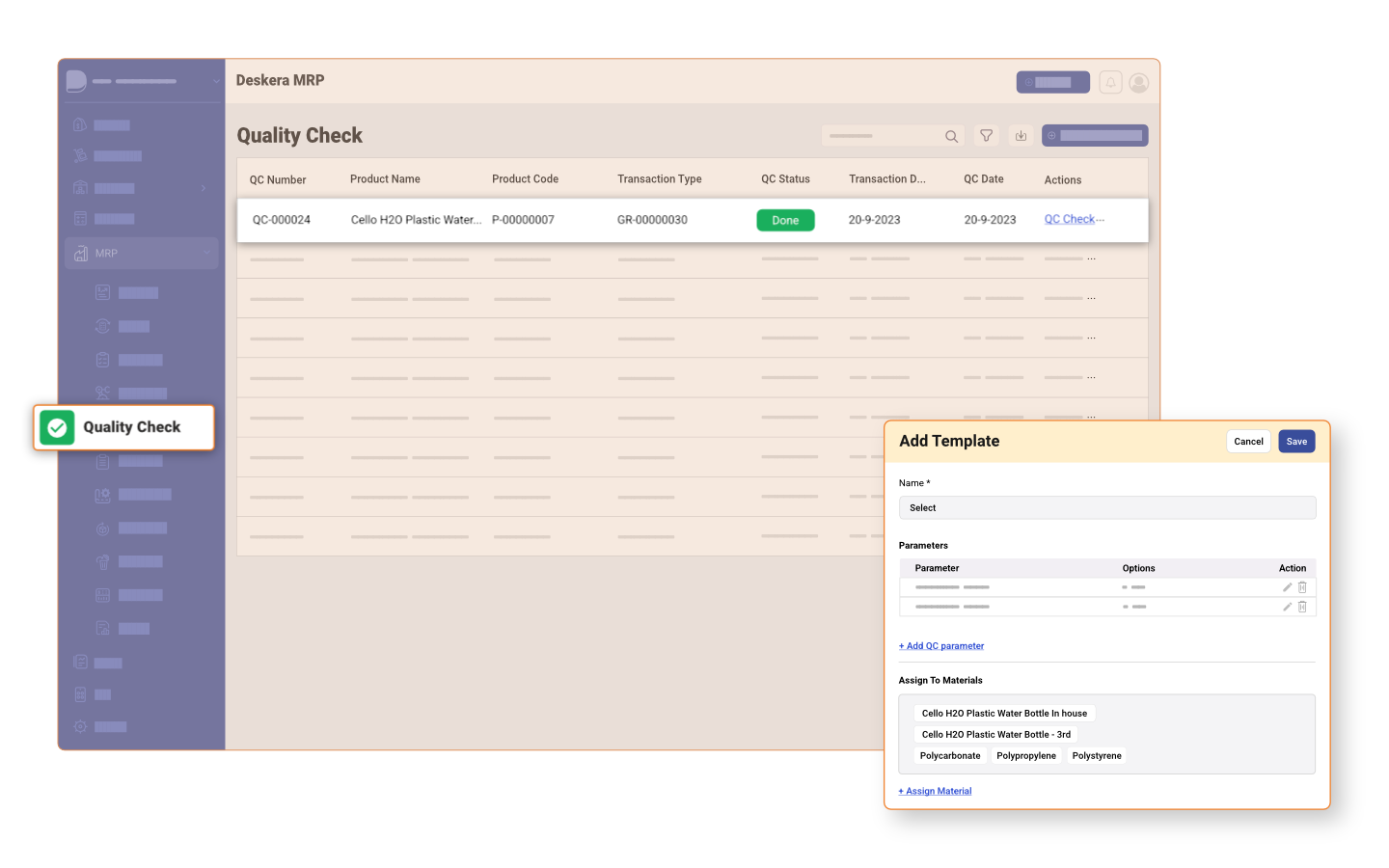

- Quality Control and Assurance: Deskera includes quality control and assurance features to ensure that recipes meet established quality standards and regulatory requirements. Users can conduct quality checks, record inspection results, and generate compliance reports to demonstrate adherence to food safety regulations and industry standards.

- Cost Analysis and Pricing: Deskera offers cost analysis and pricing tools that enable businesses to analyze recipe costs, including ingredient costs, labor expenses, and overheads. Users can determine the profitability of recipes, set appropriate pricing strategies, and optimize product margins to maximize profitability while remaining competitive in the market.

- Compliance and Regulatory Reporting: Deskera helps businesses ensure compliance with food safety regulations, labeling requirements, and industry standards by generating compliance reports and documentation. Users can track regulatory changes, implement necessary updates to recipes, and generate audit-ready reports to demonstrate compliance during regulatory inspections.

- Mobile Accessibility: Deskera provides mobile accessibility, allowing users to access recipe management features on the go using smartphones or tablets. This enables chefs, production managers, and other stakeholders to review recipes, make updates, and monitor production processes remotely, enhancing flexibility and efficiency in recipe management.

Overall, Deskera's comprehensive suite of features and functionalities tailored to the food and beverage industry can significantly streamline recipe management processes, improve operational efficiency, ensure compliance, and drive business growth.

By leveraging Deskera as a food and beverage ERP solution, businesses can simplify recipe management, reduce costs, and enhance competitiveness in a dynamic and highly regulated industry landscape.

Key Takeaways

Leveraging food and beverage ERP systems revolutionizes the way businesses in the food and beverage industry manage recipes, streamline operations, and ensure compliance.

The 11 ways in which food and beverage ERP helps in making recipe management easy are:

Centralized Recipe Database:

- Implement a centralized database within the manufacturing ERP system to store all recipes. This ensures a single source of truth, minimizing errors and discrepancies.

- Include detailed information such as ingredients, quantities, units of measurement, preparation steps, and nutritional information.

Version Control:

- Use version control features to track changes in recipes over time. This is crucial for maintaining consistency and allows for easy rollback to previous versions if needed.

- Document reasons for changes and track who made them to ensure accountability.

Costing and Pricing:

- Integrate cost calculation tools into the ERP system to accurately determine the cost of each recipe.

- Link recipes to current ingredient prices, enabling real-time cost updates and helping with accurate pricing strategies.

Supplier Integration:

- Connect the MRP software system with suppliers to automatically update ingredient prices and availability.

- Enable alerts for ingredient shortages or price fluctuations to make informed decisions and maintain uninterrupted production.

Compliance and Regulations:

- Ensure that the manufacturing software system is equipped to handle regulatory compliance requirements for food and beverage products.

- Include features for labeling, allergen tracking, and adherence to industry standards and certifications.

Batch Tracking and Traceability:

- Implement batch tracking functionality to trace ingredients back to their source and forward them to the final product.

- This aids in quality control, recalls, and compliance with safety regulations.

Production Planning and Scheduling:

- Integrate recipe management with production planning and scheduling modules.

- Optimize production schedules based on recipe requirements, ensuring efficient resource utilization.

Quality Control and Testing:

- Include quality control parameters in the manufacturing ERP system to monitor and enforce quality standards.

- Integrate testing results into the system to identify and address quality issues promptly.

Mobile Accessibility:

- Enable mobile access to the MRP software system for chefs and production staff.

- This allows real-time access to recipes, ingredient availability, and production updates, improving collaboration and responsiveness.

Analytics and Reporting:

- Implement robust analytics and reporting tools to gain insights into recipe performance, production efficiency, and cost trends.

- Use these insights to make data-driven decisions for continuous improvement.

Training and Documentation:

- Provide training resources within the manufacturing software system for new and existing staff.

- Document standard operating procedures for recipe management to ensure consistency and ease of use.

Scalability:

- Choose a manufacturing software system that can scale with the growing needs of your business.

- Ensure that the system can handle an expanding recipe database and increased production volume.

Leveraging a food and beverage ERP system for recipe management streamlines operations enhances collaboration, and ensures compliance with industry standards.

By integrating various modules and functionalities, businesses can achieve greater efficiency, reduce costs, and maintain high-quality standards in their food and beverage production processes.

Thus, as businesses continue to embrace digital transformation, food and beverage ERP systems emerge as indispensable tools for recipe management, offering scalability, flexibility, and real-time insights that enable businesses to adapt to evolving market dynamics, seize opportunities, and stay ahead of the competition.

Deskera's comprehensive suite of features and functionalities tailored to the food and beverage industry can significantly streamline recipe management processes, improve operational efficiency, ensure compliance, and drive business growth.

By leveraging Deskera as a food and beverage ERP solution, businesses can simplify recipe management, reduce costs, and enhance competitiveness in a dynamic and highly regulated industry landscape.

Related Articles