Once the manufacturer gets the raw materials in-house, the process for making the finished products begin. But, does it mean as business owners your job’s done and you don’t have a role in the manufacturing process? As a business owner, the production cycle is where you can make or lose money. That’s why it’s so important to track your production costs throughout the cycle and not just when you buy materials or sell products.

Your role as a business owner is to keep tabs on the work-in-progress (WIP) inventory at work. Don’t know what WIP inventory is and why is it important to your business? We will tell you all you need to know about WIP inventory in this article.

By the end of the article, you will have answers to the following questions on WIP Inventory:

- What is WIP Inventory?

- Difference between Work in Progress Inventory and Work in Process Inventory

- How to calculate WIP inventory?

- What are the pros of WIP inventory?

- Tips to reduce WIP Inventory

What is WIP Inventory?

Work-in-progress (WIP) inventory, as the term suggests, are the goods that are at present in the production stage, getting ready into a finished good for sale.

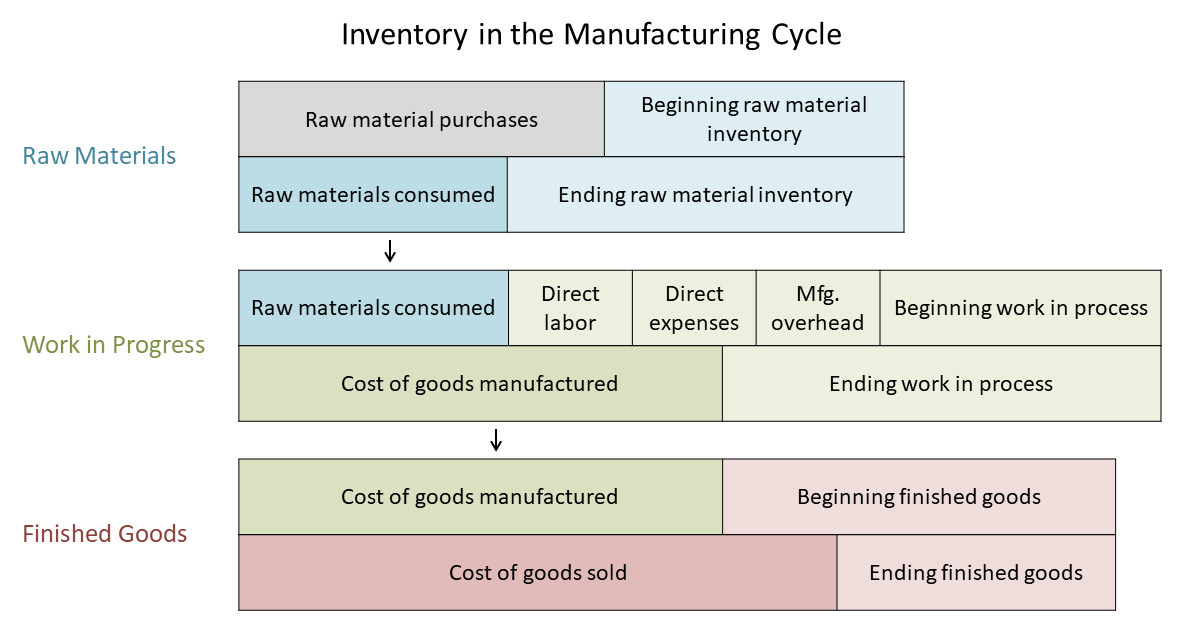

WIP inventory includes the expense of raw materials, labor, and any overhead costs during production. It excludes any raw materials which are yet to be utilized for the production of the goods and the products which are ready to be sold in the market.Its important as a business manager to monitor & manage a company's inventory and warehouse by keeping up the stock at desired levels via inventory control.

The concept of WIP inventory is mainly concerned with industries involved in manufacturing, construction, consultancy, etc. Generally, it is advised that your inventory should be calculated frequently, like biweekly, month-end, or quarterly.

A point to note is, another title for work in progress inventory is work in process inventory, both abbreviated as WIP inventory. The question is, are these terms synonymous with each other or hold separate meanings? Let’s find out.

Work in Progress Inventory vs Work in Process Inventory

Work in progress inventory and work in process inventory are two terms that literally hold the same meaning but the terms are perceived differently in different industries.

Work in process inventory is used to describe raw materials that are converted into finished goods over a short duration of time. On the other hand, work-in-progress inventory is often used in construction and other service businesses and refers to the progress of a project as a whole and how much it is costing compared to the percentage of completion. And when these terms are used by businesses selling a physical product, both mean the same thing.

We hope that the difference between work-in-progress inventory and work-in-process inventory is clear. Now let’s look at a few terms you should be familiar with before you start calculating your WIP inventory.

Terms & Formulas You Must Know Before Calculating WIP Inventory

Similar to any other calculations, calculating WIP inventory also consists of many components. Without these components, it is impossible to calculate your WIP Inventory. Let’s learn about these components so that you can quickly do your inventory calculations.

Beginning WIP Inventory Cost

Beginning WIP inventory cost is the asset section of the previous accounting period that you will find in your balance sheet. To calculate your beginning WIP inventory cost, you have to determine the ending WIPs inventory from the previous accounting period and carry it forward as the beginning WIP inventory for the new financial year. You will find your ending WIP inventory under the current asset on your balance sheet.

Manufacturing Cost

The manufacturing cost of your products includes all the expenses required to make a finished product for sale. It includes the cost of raw material, labor, and any overhead costs during the production process.

The manufacturing cost goes up with the amount of WIP inventory in stock. Higher the amount of WIP inventory, the higher the manufacturing cost. This as a result adds to the costs of the manufactured goods.

Formula to calculate the manufacturing cost:

Manufacturing Costs= Raw Materials + Direct Labor Costs + Manufacturing Overhead Costs

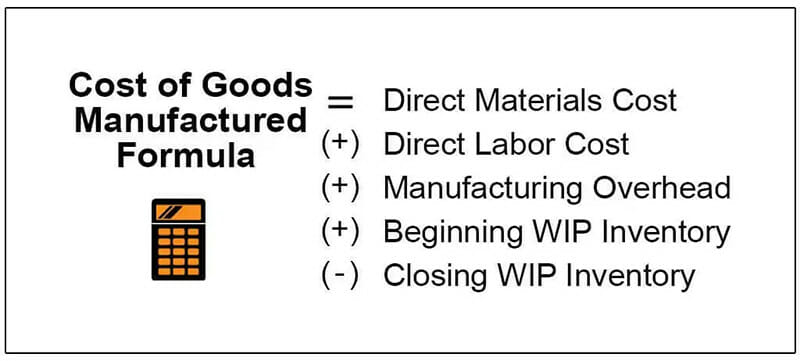

Cost of Manufactured Goods (COGM)

COGM is the total cost of manufacturing the final product. You will require the final COGM to calculate the value of your current WIP inventory.

Formula to calculate COGM:

COGM= Total Manufacturing Costs + Beginning WIP Inventory - Ending WIP Inventory

Now that we have understood all about the components required to calculate WIP inventory, let’s learn about how to calculate WIP inventory.

How to Calculate WIP inventory?

To calculate your WIP inventory you will need to first calculate your beginning WIP inventory, manufacturing cost, and COGM. Once you have determined these, you can easily calculate your WIP inventory by using the following formula.

The formula for WIP Inventory:

Beginning WIP Inventory + Manufacturing Cost - COGM = Ending WIP Inventory

Let us look at an example to understand how to calculate WIP inventory better.

Imagine your company’s beginning WIP inventory is $15,000 for in the new year. In the same year, you spend $2,00,000 on manufacturing costs, and your COGM is $2,50, 000. So your ending WIP Inventory would be:

Beginning WIP Inventory + Manufacturing Costs - COGM = Ending WIP Inventory

$15000 + $200,000 - $300,000 = $35,000

Thus, your ending WIP inventory would be $35,000

We hope you have learned how to calculate WIP inventory. Let us learn more about the pros of WIP inventory.

Pros of WIP Inventory

Accurately calculating WIP inventory will keep your balance sheet updated with the latest development in your inventory and not just the goods sold. Moreover, if you offer customized products, it is all the more essential to know how WIP inventory works. It helps you to understand what goes into the production cost and how to calculate it by the end of the accounting period. This also gives you an idea of the cost of goods sold (COGS).

Here are several pros of the WIP Inventory that you must make a note of:

- One of the major benefits of calculating your WIP inventory is that in case you are noticing high WIP inventory, it indicates that there can be some obstructions in the production process. As a result of this, you can immediately improve the production process by resolving those issues sitting as roadblocks in the process.

- When you are aware of the inventory in progress to be ready into a finished product, you can accelerate the process. This will help you to reach your demand at the right time.

- Since production is a constant process, by calculating the WIP inventory you will not

- As production is a constant process, by calculating the WIP inventory, there won't be any raw materials secured and unused.

- Calculating WIP inventory additionally helps in managing the production of your goods as per the lead time in obtaining the raw materials from your supplier.

- WIP inventory is an asset of your business, rather an important one. Not valuing your WIP inventory might result in undervaluation of inventory and the cost of goods manufactured will be exaggerated directly impacting your bottom line.

- If you are dealing with a lot of inventory, there is a risk of your inventory getting damaged sitting in the warehouse waiting to be utilized for production. In this case, when you have updated WIP inventory you will be able able to prevent the wastage of goods from happening.

- These are some compelling reasons why you must calculate your WIP inventory frequently. Now let’s flip the coin and look at some cons of WIP inventory too.

Hope this encourages you to get yourself a WIP inventory tracking system.

A fact that is now clear, you cannot afford to have a lot of WIP inventory. But how do you maintain an optimal level? We have a few tips that will help you reduce your WIP inventory.

Tips to Reduce WIP Inventory

Just in Time Inventory

Just in Time inventory is a method of production where the material is brought as they are required based on the demand. It is a go-to technique for many companies to reduce the wastage of resources and capital. The main purpose of this method is to do away with overproduction of goods, excess inventory, wastage of goods, control over storage costs, and so on.

Good Coordination

This tip is maybe not as technical, but as important as any technical method. Coordination is the key to run a good, successful, healthy business. If you aim to maintain an optimal amount of WIP inventory, you must make sure that your employees have one common goal of producing the most out of the resources available. They must be aware of each part of the manufacturing process so that they can work efficiently. This will not only help you maintain an optimal amount of WIP inventory but speed up the production and supply process.

Upgradation to New Machinery

When you have skilled employees it is essential to hand them the right tools and equipment too. They need the right machinery to maximize their productivity. By keeping equipment up to par are the most time-effective and cost-effective ways of reducing WIP.

How can Deskera help you with your WIP Inventory Management?

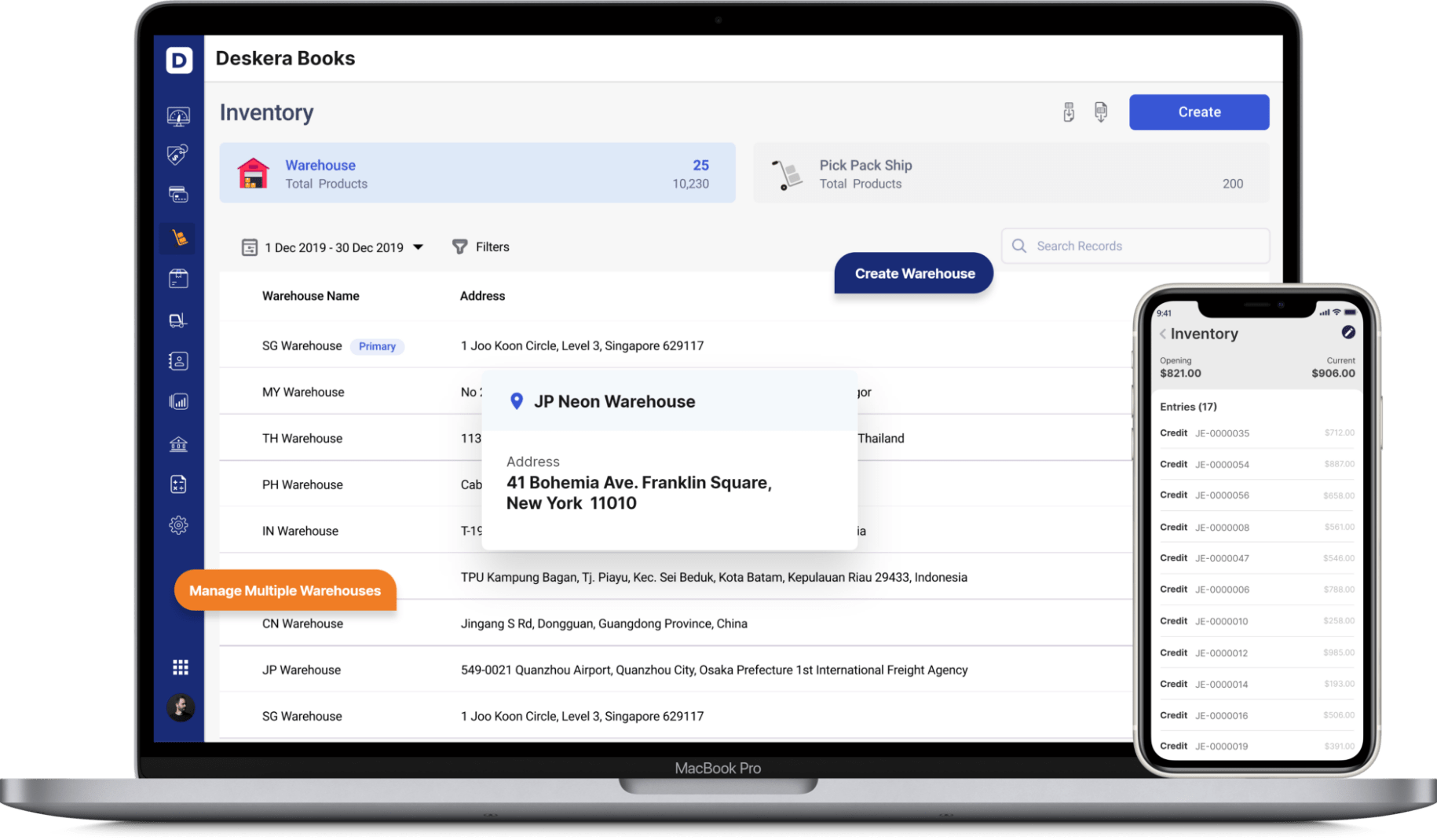

As a business owner, you can invest in inventory management softwares that can help you keep track of your progress and production costs.A successful business needs an efficient order fulfillment process that meets its specific needs. You can do a abc inventory analysis to see how you are managing your inventory.

You can use inventory management software like Deskera Books to help with your inventory management. Deskera's inventory management platform enables you to keep track of your inventory in real-time and optimize your stock levels to reduce holding costs and ordering costs tremendously.

Key Takeaways

In any business, supply chain, managing different types of inventory requires a lot of attention and expertise. In this article we learnt that:

- Work-in-progress (WIP) inventory are the goods that are at present in the production stage that is getting ready into a finished good for sale.

- WIP inventory includes the expense of raw materials, labor, and any overhead costs during production

- As production is a constant process, by calculating the WIP inventory, there won't be any raw materials secured and unused

- Calculating WIP inventory additionally helps in managing the production of your goods as per the lead time in obtaining the raw materials from your supplier

- Just in Time inventory is a method of production where the material is brought as they are required based on the demand.

By understanding WIP inventory, tracking your goods, and monitoring your work processes helps you improve your production capacity, and a but the obvious answer- inventory control.