A McKinsey study found that organizations that successfully optimize their production routing see up to a 20% reduction in production lead times, a 30% reduction in material waste, and an improvement of 10% in on-time delivery performance.

These figures demonstrate the significant influence of routing on production effectiveness and overall company performance.

Routing, in the context of manufacturing, refers to the systematic process of defining the sequence of operations, work centers, and resources required to transform raw materials into finished products. It encompasses the precise path that a product takes through the production process, including all the steps and resources involved at each stage.

Routing serves as a roadmap for manufacturing processes, providing clear instructions to production teams regarding the exact order of operations, the machines or workstations to be used, and the standard time required for each step.

It guides the flow of materials, ensures efficient utilization of resources, and supports consistent product quality and adherence to customer specifications.

In essence, routing is the backbone of production planning and control, enabling manufacturers to optimize production schedules, allocate resources effectively, and achieve operational excellence.

It facilitates seamless coordination among various departments, such as production, inventory, and procurement, ensuring a synchronized and streamlined manufacturing process.

Whether you are a production manager, an operations executive, or an aspiring manufacturing professional, this article will equip you with the knowledge and strategies needed to leverage routing as a powerful tool for success in the dynamic and competitive manufacturing landscape.

So let's start our journey to discover the importance of routing in manufacturing and uncover the possibilities for improved business outcomes and streamlined production operations.

Here is what we shall cover in this post:

- Introduction to Kitting in Inventory Management

- Benefits of Kitting for Efficient Inventory Control

- Kitting vs. Bundling: Understanding the Difference

- Steps Involved in Creating and Managing Kits

- How Kitting Impacts Inventory Accuracy

- Integrating Kitting With Other Inventory Strategies

- Future Trends in Kitting and Inventory Management

- Conclusion

- Key Takeaways

Introduction to Kitting in Inventory Management

Kitting is a valuable inventory management technique that plays a crucial role in optimizing supply chain processes and improving operational efficiency. It involves the process of grouping and packaging individual items, components, or parts together as a single unit or kit. These kits are then used to fulfill specific customer orders or production requirements.

Kitting helps streamline workflows, reduce handling time, and enhance order accuracy, making it an essential practice for businesses seeking to enhance their inventory control and meet customer demands effectively.

- The purpose of kitting is to improve efficiency and reduce the number of picking and handling tasks required in the production or order fulfillment process.

- Kitting is widely used in various industries, including manufacturing, electronics, automotive, aerospace, and e-commerce, among others, to optimize inventory management and improve overall operational efficiency.

- By pre-assembling components into kits, companies can reduce production lead times, minimize errors, and enhance the accuracy of order fulfillment.

- Kitting also enables businesses to better manage their inventory levels, as they can maintain a smaller stock of individual components while having a larger inventory of pre-assembled kits.

- The practice of kitting requires effective inventory tracking and management systems to ensure accurate stock levels of both individual components and assembled kits.

Types of Items Commonly Included in Kits

In inventory management, kitting is a process that involves grouping and packaging multiple items together as a single unit, commonly known as a "kit." These kits are created for various purposes, such as simplifying the assembly process, improving efficiency, reducing picking errors, and enhancing customer satisfaction.

The items included in kits can vary widely depending on the industry, the specific product being assembled, and the purpose of the kit.

Raw Materials: Raw materials are often the foundational components included in manufacturing kits. These materials serve as the building blocks for creating finished products. In industries like automotive, aerospace, and construction, kits may include raw materials such as metal sheets, plastic components, rubber parts, and fabric materials.

For example, in the automotive industry, a kit for assembling a specific car model may include metal panels, seats, dashboard components, and other raw materials required for production.

By bundling these raw materials into kits, manufacturers can streamline the production process and reduce the time and effort required to gather individual components.

Components and Parts: Kits frequently comprise various components and parts required to construct a particular product. These components can range from small electronic chips and circuit boards to large mechanical gears and pulleys. In industries like electronics, telecommunications, and machinery manufacturing, kitting is used to package all the necessary components for a specific product or repair service.

For instance, in the electronics industry, a kit for assembling a computer may include a motherboard, processor, memory modules, graphics card, power supply unit, and other components needed for the assembly.

By packaging these components together, manufacturers and technicians can save time and reduce the risk of missing essential parts during assembly or repair.

Fasteners and Hardware: Fasteners, such as screws, nuts, bolts, and washers, are crucial items included in kits across various industries. Fasteners are essential for securely connecting and fastening components together during assembly or repair processes.

In industries like manufacturing, construction, and machinery, kitting fasteners ensure that workers have all the necessary hardware at hand when assembling products or structures. By bundling fasteners in kits, businesses can minimize the risk of delays caused by missing or incorrect hardware during the assembly process.

Instruction Manuals and Documentation: In many cases, kits include instruction manuals or assembly guides that provide step-by-step instructions on how to put together the components. These manuals serve as a valuable resource for assemblers, technicians, or end-users to follow the correct assembly sequence and avoid errors.

In industries like consumer electronics, furniture manufacturing, and DIY kits, including detailed instruction manuals in the kit is essential for ensuring that customers can assemble the product correctly and efficiently.

Providing clear and concise documentation in the kit can also lead to higher customer satisfaction and reduced customer support inquiries.

Consumables and Supplies: Some kits may contain consumables and supplies that are used during the assembly or maintenance process. These can include adhesives, lubricants, cleaning agents, and other materials that may be necessary for the proper functioning or maintenance of the product.

In industries like electronics repair, vehicle maintenance, and equipment servicing, kitting consumables with other essential components simplifies the process for technicians and ensures they have everything they need to complete the task efficiently.

Accessories and Add-ons: Kits often include accessories and add-ons that enhance the functionality or appearance of the product. These may be optional items that customers can choose to include when purchasing a product, such as additional attachments, decorative elements, or customization options.

For example, in the consumer electronics industry, a camera kit may include optional lenses, carrying cases, and other accessories that users can select based on their specific needs.

Kitting these accessories with the main product provides customers with a convenient one-stop solution for all their requirements.

Spare Parts and Replacement Components: Kitting can be used to package spare parts and replacement components for future maintenance and repairs. Including spare parts in kits ensures that technicians have immediate access to critical components when performing repairs or servicing.

In industries like aviation, manufacturing, and heavy machinery, kits may contain spare parts like bearings, gaskets, sensors, and valves. This proactive approach to kitting can significantly reduce equipment downtime and improve overall operational efficiency.

Pre-Configured Solutions: In some cases, kits are pre-configured solutions that offer a specific combination of components or equipment designed to address particular customer needs or use cases. These pre-configured kits are typically designed for ease of use and are optimized for specific applications.

For example, in the IT industry, pre-configured server kits may include all the necessary components, including the server chassis, CPUs, memory modules, storage drives, and network interfaces, pre-assembled and ready to deploy.

These kits simplify the server deployment process for businesses, saving time and effort in configuring individual components.

Packaging and Labeling:

Packaging is a critical component of kitting. The items in the kit must be packaged securely to protect them from damage during storage and transportation. Additionally, clear labeling is essential to identify the contents of the kit accurately.

Proper packaging and labeling help ensure that the right kits are selected for specific orders and that the items can be easily identified and tracked in the inventory system. This level of organization and clarity contributes to the overall efficiency of inventory management and order fulfillment processes.

Specialty Items and Promotional Material:

In some cases, kits may include specialty items or promotional material to enhance the value of the product or create a unique customer experience. These items can vary widely, depending on the industry and the purpose of the kit.

For instance, a promotional kit for a new product launch may include samples of the product, marketing materials, and branded merchandise. Including these extra items in the kit can help businesses create a positive impression on customers and increase brand awareness.

Safety Equipment and Accessories:

In certain industries, kits may include safety equipment and accessories to ensure compliance with safety regulations and standards. This is particularly crucial in industries where workers are exposed to hazardous conditions or substances.

For example, a kit for construction workers may include safety goggles, gloves, hard hats, and other protective gear. By providing all the necessary safety equipment in a kit, businesses can ensure that workers have the required protection and reduce the risk of accidents and injuries.

Maintenance and Repair Kits:

In addition to assembly kits, there are maintenance and repair kits designed to support ongoing maintenance and repair activities. These kits typically include replacement parts and tools needed for routine maintenance and repairs.

For instance, in the automotive industry, a maintenance kit for a specific car model may include oil filters, spark plugs, belts, and other common replacement parts. By having these kits readily available, businesses can reduce downtime and keep products operating at peak performance.

Benefits of Kitting for Efficient Inventory Control

Kitting is a valuable inventory management strategy that involves grouping multiple items into a single package or kit. These kits are then treated as single units, making the process of inventory control and order fulfillment more efficient and streamlined.

Kitting is widely used across various industries, including manufacturing, electronics, automotive, retail, and more.

Improved Order Fulfillment

One of the significant benefits of kitting is that it leads to improved order fulfillment. By bundling multiple items together in a kit, businesses can reduce the time and effort required to pick individual items for each order.

Instead, warehouse staff can simply pick and pack the complete kit, ensuring that all the necessary items are included in the order. This results in faster and more accurate order processing, leading to higher customer satisfaction and retention.

Streamlined Inventory Management

Kitting also streamlines the inventory management process. Rather than managing individual SKUs for each item in the kit, businesses only need to track and manage a single SKU for the entire kit.

This simplifies inventory tracking and reduces the complexity of the inventory management system. Additionally, kitting allows businesses to maintain a smaller number of SKUs, leading to reduced storage space and lower operational costs.

Reduces Pick and Pack Errors

In traditional inventory management systems, there is a higher risk of pick and pack errors, leading to incorrect or incomplete orders. With kitting, this risk is significantly reduced because all the items needed for an order are pre-packaged in the kit.

This reduces the chance of human error during the picking and packing process, resulting in greater accuracy and fewer returns or exchanges due to incorrect orders.

Increased Productivity and Efficiency

Kitting can lead to increased productivity and efficiency in warehouse operations. Since all the items needed for a specific kit are grouped, warehouse staff can process orders more quickly and efficiently.

This leads to higher productivity levels and allows businesses to handle a larger volume of orders in a shorter amount of time. As a result, businesses can meet customer demands more effectively and even reduce order processing times.

Better Inventory Forecasting

By using kitting in inventory management, businesses can improve their inventory forecasting accuracy. Since kitted items are sold as single units, it is easier to predict demand for the complete kit rather than for individual components.

This allows businesses to optimize their inventory levels more effectively, ensuring that they have enough kits in stock to meet customer demands without overstocking individual items.

Enhanced Product Presentation

Kitting also enhances the presentation of products to customers. When items are packaged together in a kit, it creates a cohesive and aesthetically pleasing product package. This can have a positive impact on customers, making the product more attractive and appealing.

Additionally, businesses can use kitting to create promotional or gift kits, offering customers a bundle of related items at a discounted price. This can incentivize customers to make larger purchases and increase overall sales.

Customization and Personalization

Kitting allows businesses to offer customized and personalized products to customers. By assembling kits with different combinations of items, businesses can cater to specific customer preferences or needs.

For example, in the beauty industry, businesses can offer skincare or makeup kits tailored to different skin types or makeup looks. This level of customization can create a more personalized shopping experience for customers, leading to increased customer loyalty and repeat purchases.

Cost Savings

Kitting can also lead to cost savings for businesses. By bundling items together in a kit, businesses can take advantage of economies of scale and negotiate better deals with suppliers.

This can result in lower per-unit costs for the items included in the kit, allowing businesses to offer the kit at a competitive price while still maintaining a healthy profit margin. Additionally, kitting can reduce order processing and handling costs, further contributing to cost savings for the business.

Reduced Inventory Obsolescence

In industries where products have a limited shelf life or are subject to obsolescence, kitting can help reduce inventory obsolescence. By grouping items in kits, businesses can ensure that products are sold as complete units before they become outdated or expire.

This reduces the risk of having unsellable inventory and minimizes potential losses due to product obsolescence.

Better Inventory Turnover

Kitting can also lead to better inventory turnover rates. Since kitted items are sold as complete units, they tend to have higher turnover rates compared to individual items.

This means that inventory is moving faster, and businesses can replenish their stock more frequently. Higher inventory turnover rates contribute to a healthier cash flow and reduced carrying costs for inventory.

Kitting vs. Bundling: Understanding the Difference

Kitting and bundling are two terms often used in the context of inventory management and product packaging, but they refer to distinct practices. While they share similarities, it's essential to understand their differences to utilize each approach effectively.

Definition and Purpose:

Kitting: Kitting refers to the process of assembling multiple individual items or components into a single package, known as a kit. The primary purpose of kitting is to create a new product or package that includes everything needed to complete a specific task or project.

Kits are often sold as a single unit, making it convenient for customers to purchase all the necessary items in one package.

Bundling: Bundling involves combining two or more related products into a single offering for sale. The primary purpose of bundling is to increase sales and customer value by offering a package deal that includes complementary or related items at a discounted price.

Packaging and Composition:

Kitting: In kitting, the items included in the kit are individually packaged or labeled, and they remain separate within the larger package. Each item retains its identity and SKU, allowing for easy tracking and management of inventory. Kitting is common in industries where products need to be customized or assembled by the end user.

Bundling: Bundling involves packaging related items together, but unlike kitting, the bundled items are not individually packaged within the larger package.

Instead, the bundled items are combined into one package, and the package is given a new SKU to represent the bundled offering. Bundling is often used to promote related products or to offer discounts on items purchased together.

Flexibility and Customization:

Kitting: Kitting offers a high level of flexibility and customization since the individual items in the kit can be easily changed or modified based on customer preferences or specific requirements. Kits can be tailored to meet the unique needs of different customers or projects.

Bundling: Bundling is generally less flexible and customizable compared to kitting. The bundled items are predetermined and remain fixed in the package. While bundles can be offered in different configurations, the individual items within the bundle are not interchangeable.

Pricing Strategy:

Kitting: The pricing strategy for kitting is typically based on the cost of the individual items plus a premium for the convenience of having everything packaged together. Customers pay a higher price for the kit compared to purchasing the items separately.

Bundling: Bundling follows a different pricing strategy. The bundled items are offered at a discounted price compared to the sum of their prices. The discounted price encourages customers to purchase the bundle instead of buying the items separately.

Use Cases:

Kitting: Kitting is commonly used in industries such as electronics, manufacturing, and DIY projects. It is prevalent when products require assembly or when customers need multiple items to complete a specific task or project.

Bundling: Bundling is prevalent in retail, telecommunications, and the food industry. It is often used to promote related products, increase sales volume, and enhance customer value.

Implementing Kitting in Different Industries

Kitting is a versatile and valuable practice that can be implemented in various industries to streamline processes, enhance customer experiences, and improve overall efficiency.

Electronics Industry:

The electronics industry extensively utilizes kitting to assemble components and parts into ready-to-use kits for electronic devices. Electronic kits may include circuit boards, resistors, capacitors, connectors, and other components necessary for assembly.

Kitting in the electronics industry ensures that all the required parts are readily available, reducing assembly time and errors. It also simplifies inventory management by packaging components together, making it easier to track and reorder supplies.

Benefits:

- Improved assembly efficiency and reduced production time.

- Enhanced product quality by minimizing errors during assembly.

- Simplified inventory management and replenishment.

Manufacturing Industry:

Kitting plays a crucial role in the manufacturing sector by optimizing the production process and reducing material handling. Manufacturing kits may include raw materials, fasteners, tools, and instructions required to complete specific production tasks.

By creating pre-packaged kits, manufacturers can reduce the time spent searching for materials and ensure that workers have everything they need at their fingertips.

Benefits:

- Streamlined production process and reduced material waste.

- Increased productivity and reduced production downtime.

- Consistent and standardized production workflows.

Automotive Industry:

In the automotive industry, kitting is commonly used to prepare parts and components needed for vehicle assembly or repair. Automotive kits may include engine parts, filters, gaskets, and other components required for specific vehicle models.

Kitting allows automotive manufacturers and repair shops to efficiently manage inventory, reduce costs, and optimize workflow.

Benefits:

- Faster vehicle assembly and repair times.

- Enhanced accuracy in selecting the right parts for each vehicle.

- Improved organization and storage of automotive components.

Aerospace Industry:

The aerospace industry relies on kitting to prepare components and tools needed for aircraft assembly and maintenance. Aerospace kits may include nuts, bolts, washers, fasteners, and specialized tools for aircraft assembly.

Kitting ensures that all required parts are available at the right time and in the correct quantities, supporting efficient aircraft manufacturing and maintenance processes.

Benefits:

- Streamlined aircraft assembly and maintenance operations.

- Reduced risk of missing parts during critical processes.

- Increased worker efficiency and reduced downtime.

Healthcare Industry:

In the healthcare sector, kitting is employed to prepare medical kits for surgical procedures, patient care, and emergency response. Medical kits may contain various medical supplies, medications, and instruments needed for specific medical tasks.

Kitting in healthcare ensures that healthcare professionals have everything they need at hand, enabling them to provide efficient and effective care to patients.

Benefits:

- Improved patient care and reduced response time during emergencies.

- Simplified inventory management for medical supplies and medications.

- Enhanced organization and reduced risk of medical errors.

Retail Industry:

Kitting is utilized in the retail sector to create product bundles or gift sets. Retail kits may include multiple products bundled together at a discounted price, encouraging customers to purchase more items at once. Kitting in retail can also be used to create seasonal gift sets, promotional packages, or subscription boxes.

Benefits:

- Increased sales through cross-selling and upselling opportunities.

- Enhanced customer experience with curated product bundles.

- Improved inventory turnover and stock management.

E-commerce Industry:

In the e-commerce industry, kitting is used to create customized product bundles based on customer preferences. E-commerce kits may include complementary products or personalized items, providing customers with a unique and tailored shopping experience.

Kitting in e-commerce enhances customer satisfaction and encourages repeat purchases.

Benefits:

- Personalized shopping experiences for customers.

- Higher customer retention and loyalty.

- Increased sales through customized product offerings.

Steps Involved in Creating and Managing Kits

Creating and managing kits is a critical process in various industries, including manufacturing, electronics, healthcare, and retail. Kits are pre-assembled sets of items packaged together for convenience, efficiency, and better inventory control.

Whether it's assembling electronic components, preparing medical kits, or creating product bundles for retail sales, the steps involved in creating and managing kits are crucial for a smooth and streamlined workflow.

Define Kit Requirements:

The first step in creating and managing kits is to define the requirements for each kit. This involves understanding the purpose of the kit, the items that need to be included, and the quantity of each item. It is essential to clearly define the contents of the kit to ensure that all the necessary items are included, and there is no room for confusion during assembly.

For example, in the electronics industry, the kit requirements may include specific electronic components, circuit boards, connectors, and screws needed to assemble a particular product.

In the healthcare industry, the kit requirements may involve medical supplies, medications, and instruments needed for a surgical procedure.

Determine Kit Assembly Process:

Once the kit requirements are defined, the next step is to determine the assembly process for each kit. This involves creating a step-by-step guide or work instructions for assembling the kit. The assembly process should be clear, concise, and easy to follow to ensure that kits are assembled accurately and efficiently.

In some industries, kit assembly may involve complex processes that require specialized skills and tools. It is essential to provide adequate training and support to the assembly team to ensure the kits are assembled correctly.

Source and Procure Kit Components:

After defining the kit requirements and assembly process, the next step is to source and procure the components needed for the kits. This involves working with suppliers and vendors to ensure that all the required items are available in the right quantities and at the right time.

For efficient inventory management, it is essential to maintain an accurate record of the components used in each kit and regularly monitor stock levels to avoid shortages or overstocking.

Create Kit Assembly Workstation:

To streamline the kit assembly process, it is crucial to create a dedicated kit assembly workstation. The workstation should be well-organized and equipped with all the tools and equipment needed for kit assembly. This ensures that the assembly team can work efficiently and reduces the chances of errors or missing components.

In industries like manufacturing, creating a dedicated assembly line for kit production can significantly improve productivity and reduce lead times.

Test and Quality Control:

Before the kits are released for use or sale, it is essential to conduct testing and quality control checks to ensure that each kit meets the required standards and specifications. Testing may involve verifying that all the components are present and in good condition and that the kit functions as intended.

Quality control measures are especially crucial in industries like healthcare, where the accuracy and completeness of medical kits can directly impact patient care and safety.

Labeling and Packaging:

Proper labeling and packaging are critical for efficient kit management. Each kit should be clearly labeled with its contents, quantity, and any specific instructions. This makes it easy for the assembly team to identify the correct components and helps users quickly identify the kit they need.

For industries like retail, attractive and informative packaging can enhance the appeal of product bundles, leading to increased sales.

Inventory Management and Tracking:

Once the kits are assembled and ready for use or sale, it is essential to implement robust inventory management and tracking systems. This includes updating inventory records whenever kits are assembled or disbursed, and regularly reconciling stock levels to ensure accuracy.

In industries with high kit turnover, implementing barcode or RFID tracking can greatly improve inventory control and reduce the risk of stockouts.

Regular Kit Audits:

To maintain the integrity of the kits and ensure continued efficiency, regular kit audits should be conducted. Audits involve inspecting and verifying the contents of the kits against the defined requirements and addressing any discrepancies or issues.

Audits also provide an opportunity to identify any improvements or optimizations that can be made to the kit assembly process.

Kit Lifecycle Management:

Finally, managing the lifecycle of the kits is essential for effective kit management. This includes monitoring kit usage and demand patterns, updating kit contents as needed, and retiring obsolete kits.

Regularly reviewing and optimizing kit contents can help ensure that the kits remain relevant and valuable to end users.

Utilizing Kitting for Faster Order Fulfillment

Customers expect quick and accurate delivery of their orders, and delays or errors in fulfillment can lead to customer dissatisfaction and loss of business. Kitting, a process of pre-assembling and packaging related items together as a single unit, can significantly enhance order fulfillment speed and accuracy.

By bundling items that are commonly ordered together, kitting streamlines the picking and packing process, reducing handling time and increasing overall efficiency.

Streamlined Picking Process:

One of the primary advantages of kitting is that it streamlines the picking process. Instead of picking individual items for each order, warehouse staff can pick pre-assembled kits that contain all the necessary items for a specific order. This reduces the time and effort required for picking, as well as the risk of errors in picking the wrong items.

For example, in an electronics store, instead of picking individual electronic components for each customer order, the warehouse staff can pick pre-assembled kits containing all the components required for a particular project. This not only saves time but also ensures that all the correct components are included in the order.

Faster Packing Process:

Kitting also speeds up the packing process. Since the items in each kit are already pre-assembled and packaged together, warehouse staff can quickly pack the kits for shipment without the need to individually pack each item. This results in faster packing times and reduces the chances of errors in packing.

Faster packing also means that orders can be processed and shipped more quickly, leading to shorter delivery times and improved customer satisfaction.

Reduced Inventory Handling:

By bundling items together in kits, businesses can reduce the number of individual items they need to handle in their warehouse. This helps to free up storage space and reduces the time and effort required for inventory management.

For example, if a clothing retailer creates pre-packaged outfits as kits, they can store the kits on the shelves instead of individual clothing items. This reduces the need to handle and manage individual pieces of clothing, leading to a more organized and efficient warehouse.

Increased Order Accuracy:

Kitting can significantly improve order accuracy. Since all the required items for each order are assembled in a kit, the chances of missing or incorrect items in the order are greatly reduced.

This helps to minimize the number of order returns and replacements due to fulfillment errors, saving both time and resources for the business.

Customizable Kits for Customer Preferences:

While kitting typically involves pre-assembling standard kits for commonly ordered items, businesses can also offer customizable kits that allow customers to choose the items they want to include in their orders.

For example, a gift shop can offer customizable gift sets where customers can choose from a selection of items to create their personalized gift kit. This not only enhances customer satisfaction but also allows businesses to cater to individual preferences and increase sales opportunities.

Improved Workforce Productivity:

With kitting, warehouse staff can work more efficiently and productively. Since the picking and packing processes are simplified, staff can focus on other value-added tasks, such as quality control, order processing, and shipping.

This can lead to improved overall warehouse productivity and allows businesses to handle higher order volumes without the need for additional staff.

Streamlined Order Tracking and Reporting:

Kitting can also simplify order tracking and reporting. Since kits are pre-assembled and assigned unique identifiers, businesses can easily track the status of each kit throughout the fulfillment process.

This helps to monitor inventory levels and sales patterns, identify popular kit combinations, and optimize inventory management strategies.

Reduced Shipping Costs:

By kitting items together, businesses can reduce shipping costs. Since multiple items are shipped as a single unit, the shipping cost per item is lower than if each item were shipped individually.

This cost-saving advantage can be particularly significant for businesses that frequently ship bulky or heavy items.

How Kitting Impacts Inventory Accuracy

Inventory accuracy is a critical aspect of efficient inventory management in any business. Accurate inventory records ensure that the right products are available when needed, prevent stockouts and overstock situations, and improve order fulfillment and customer satisfaction.

Kitting, the process of grouping related items as a single unit, can have a significant impact on inventory accuracy.

Reduced Stock Keeping Units (SKUs) and SKU Complexity:

Kitting reduces the number of individual stock-keeping units (SKUs) that need to be managed in the inventory. Instead of tracking each item separately, businesses only need to manage inventory for the kits, which simplifies the inventory management process.

With fewer SKUs to handle, there is a lower risk of data entry errors and discrepancies in inventory records. This reduction in SKU complexity leads to improved inventory accuracy as there are fewer opportunities for mistakes in tracking and counting items.

Enhanced Inventory Visibility:

Kitting provides better visibility into the inventory levels of individual components and finished kits. By tracking the components used in each kit, businesses can easily determine how many kits can be assembled based on the available components.

This enhanced visibility allows for better inventory planning and helps prevent stockouts or overselling of items. As a result, inventory levels are more accurate, and the risk of inventory discrepancies is minimized.

Reduced Cycle Counting Complexity:

Cycle counting is a method used to periodically verify the accuracy of inventory records by counting a small subset of inventory items regularly. Kitting simplifies cycle counting, as staff only need to count the kits rather than individual items.

This simplification of the cycle counting process improves its accuracy and ensures that inventory records are regularly validated.

Real-Time Inventory Updates:

With kitting, inventory updates can be automatically triggered in real time when kits are assembled and disassembled. As kits are picked for orders or components are used to create new kits, the inventory system is updated instantaneously.

Real-time inventory updates ensure that inventory records are always up-to-date, providing accurate information for order processing and stock level monitoring.

Reduced Inventory Shrinkage:

Inventory shrinkage refers to the loss of inventory due to theft, damage, or administrative errors. Kitting can help reduce inventory shrinkage by consolidating items into secure kits.

As individual components are less accessible and require special handling, the risk of theft and damage is minimized. Additionally, the simplicity of kitting reduces the likelihood of administrative errors leading to inventory discrepancies.

Common Challenges in Kitting Implementation

Kitting, the process of grouping related items as a single unit, offers numerous benefits for efficient inventory management and order fulfillment. However, like any business process, kitting implementation comes with its own set of challenges that organizations need to overcome to fully reap its rewards.

- Inventory Management Complexity:

One of the primary challenges in kitting implementation is managing the inventory of individual components and finished kits. Kitting introduces new SKUs, representing the assembled kits, which need to be tracked along with the inventory of individual components.

Solution: To address this challenge, businesses should invest in robust inventory management systems that can handle the complexity of kitting. Advanced inventory software can help automate inventory updates, track component usage, and maintain accurate records of both individual items and assembled kits.

- SKU Proliferation:

Kitting can lead to an increase in the number of SKUs due to various combinations of components used to create different kits. This SKU proliferation can quickly become overwhelming and challenging to manage.

Solution: Implement SKU rationalization strategies to identify and eliminate redundant or low-selling kits. By streamlining the product offerings and focusing on high-demand kits, businesses can reduce the number of SKUs and simplify inventory management.

- Sourcing and Procurement:

Managing the procurement of components used in kitting can be challenging, especially when dealing with multiple suppliers or sourcing from different regions. Ensuring a steady supply of components at the right time and cost can be a significant hurdle.

Solution: Develop strong supplier relationships and establish clear communication channels to address any potential sourcing issues. Consider consolidating suppliers to streamline the procurement process and negotiate favorable terms for component sourcing.

- Quality Control:

Ensuring the quality of individual components and the assembled kits is crucial for delivering a high-quality end product. Defective or incorrect components can lead to costly rework and delays in fulfilling orders.

Solution: Implement robust quality control measures during the kitting process. Conduct regular inspections of components and kits to identify and address any quality issues promptly. Establish clear quality standards and work closely with suppliers to ensure they meet these standards.

- Workforce Training and Skills:

Kitting requires skilled and trained personnel to assemble kits accurately and efficiently. Inadequate training and lack of skills can lead to errors in kit assembly, resulting in inaccurate inventory records and delayed order fulfillment.

Solution: Invest in comprehensive training programs for the workforce involved in kitting. Ensure that employees are well-versed in the kitting process, quality control procedures, and inventory management systems. Regularly evaluate the workforce's performance and provide feedback and additional training as needed.

- Warehouse Space Management:

Kitting can have space implications in the warehouse, especially if finished kits require more space than individual components. Efficient space utilization is essential to avoid overcrowding and ensure smooth operations.

Solution: Optimize the warehouse layout and storage systems to accommodate kitting activities. Use space-saving techniques, such as vertical storage and efficient shelving systems, to maximize warehouse space. Regularly review the warehouse layout to identify areas for improvement.

- Order Variability:

Managing to kit efficiently becomes more challenging when dealing with orders that require multiple configurations of kits or variations in kit contents.

Solution: Develop flexible kitting processes that can accommodate order variability. Utilize modular kitting systems that allow for easy customization of kits based on specific order requirements. Adopt a dynamic approach to kitting to handle different order configurations effectively.

- Lead Time and Lead Time Variability:

Kitting lead time, the time taken to assemble kits after receiving an order can impact order fulfillment timelines. Variability in lead time can result in delayed order processing and customer dissatisfaction.

Solution: Streamline the kitting process to reduce lead time variability. Implement lean manufacturing principles to eliminate waste and inefficiencies in the kitting process. Maintain clear communication with customers regarding lead times and manage their expectations proactively.

- Cost Management:

While kitting can improve inventory management and order fulfillment, it can also incur additional costs, such as labor, storage, and packaging.

Solution: Conduct a thorough cost analysis to understand the expenses associated with kitting. Identify areas where cost optimization is possible, such as negotiating better prices with suppliers, optimizing warehouse space, and streamlining the kitting process to reduce labor costs.

Integrating Kitting With Other Inventory Strategies

Kitting is most effective when integrated with other inventory strategies to create a comprehensive and streamlined approach to managing inventory and meeting customer demands.

Here, we will explore how kitting can be integrated with other inventory strategies to optimize warehouse operations, improve order processing, and enhance overall supply chain efficiency.

Just-in-Time (JIT) Inventory:

Just-in-Time inventory is a strategy where inventory levels are kept minimal, and materials are only ordered or produced when needed. Integrating kitting with JIT can help in the following ways:

- Customization: Kitting allows for easy customization of products, enabling JIT manufacturers to assemble products quickly and efficiently according to specific customer requirements.

- Reduced Setup Time: By having pre-assembled kits of frequently used components, manufacturers can minimize setup time for production runs, thereby reducing lead times.

- Inventory Simplification: JIT often involves handling multiple small orders. Kitting can consolidate these orders into fewer kits, simplifying the inventory management process.

- Demand Forecasting and Planning: Accurate demand forecasting is crucial for both kitting and JIT. Understand the demand patterns for finished products and the components required for assembly. Plan kitting processes based on forecasted demand to ensure that the right components are available in kits as needed.

- Component Grouping: Group components that are frequently used together into kits. This helps reduce the time spent gathering materials and minimizes the risk of errors during assembly. Kits should be designed to match the production process sequence, ensuring that workers can easily access and use the components in the correct order.

- Supplier Collaboration: Collaborate closely with suppliers to ensure timely delivery of components. Suppliers should be aligned with the JIT approach, delivering components just before they are needed in kitting. Maintain open communication channels with suppliers to adjust orders based on changing demand.

Vendor Managed Inventory (VMI):

VMI is a partnership between suppliers and customers, where the supplier manages the customer's inventory levels. Integrating kitting with VMI can lead to the following advantages:

- Enhanced Visibility: Suppliers can use kitting data to monitor the customer's usage patterns, allowing for better demand forecasting and timely replenishment of kits.

- Improved Efficiency: Kitting can streamline the fulfillment process, ensuring that the right components are bundled together for each VMI order, reducing handling time.

- Inventory Accuracy: By outsourcing inventory management to the supplier, customers can rely on the accuracy of kitted inventory levels provided by the supplier.

- Supplier Involvement: Share kitting requirements and schedules with your suppliers, allowing them to prepare and deliver kits to your production facility as needed. Suppliers take an active role in assembling kits and ensuring that components are readily available for use.

- Demand Signals and Triggers: Use demand signals, such as consumption data or production schedules, to trigger the creation of kitted components. These signals can prompt suppliers to prepare and deliver kits in alignment with Just-in-Time (JIT) principles.

- Frequent Replenishment: Utilize frequent and small replenishment orders for kitted components to maintain optimal inventory levels. Suppliers continuously monitor consumption and restock kitted components as required.

Batch and Lot Tracking:

Batch and lot tracking are critical for industries with strict regulatory requirements, such as pharmaceuticals and food. Integrating kitting with batch and lot tracking offers the following benefits:

- Traceability: Kits can be easily traced back to their original batches, enabling efficient recall management in case of product defects or quality issues.

- Compliance: Kitting helps maintain consistency in product assembly, ensuring that the right components from the same batch are used for each kit, and adhering to regulatory requirements.

- Quality Control: Kitting allows for better control over component quality, as batches can be inspected and tested before assembly into kits.

- Batch Information Integration: Integrate batch and lot information into kitting instructions and processes. This ensures that the correct components from the designated batch or lot are included in each kit.

- Recall Readiness: In the event of a product recall, having batch and lot information integrated with kitting allows for precise identification and targeted recall of affected kits.

Cross-Docking:

Cross-docking is a logistics strategy where products are unloaded from incoming shipments and directly loaded onto outbound trucks, reducing the need for storage. Integrating kitting with cross-docking offers the following advantages:

- Order Consolidation: Kitting allows for the consolidation of multiple orders into kits, streamlining the cross-docking process and reducing handling time.

- Faster Fulfillment: Kitted products can be quickly transferred from inbound shipments to outbound trucks, reducing order processing time.

- Space Optimization: Cross-docking reduces the need for long-term storage, and kitting further optimizes warehouse space by consolidating products into kits.

- Incoming Shipments and Unloading: When incoming shipments arrive, components from various suppliers are unloaded and moved to the cross-docking area. Kitted components are identified and sorted based on their destination or assembly requirements.

RFID Technology:

Radio Frequency Identification (RFID) technology enables real-time tracking and monitoring of inventory. Integrating kitting with RFID offers the following benefits:

- Enhanced Visibility: RFID tags on kitted products provide real-time data on their location, status, and movement throughout the supply chain.

- Inventory Accuracy: RFID technology ensures that the right components are used for each kit, reducing the risk of errors and improving inventory accuracy.

- Efficient Replenishment: RFID-enabled kitting allows for automatic replenishment of kits when RFID readers detect low inventory levels.

- RFID Tagging of Components: Attach RFID tags to individual components or sub-components that will be included in kits. Each RFID tag contains a unique identifier that can be used to track and trace the component throughout the supply chain.

- Visibility and Analytics: Leverage RFID data for supply chain analytics and performance monitoring. Gain insights into production efficiency, kitting cycle times, and component usage patterns.

Kanban:

Kanban is a pull-based inventory management system that uses visual cues to trigger replenishment. Integrating kitting with Kanban can lead to the following advantages:

- Visual Management: Kitting enables the use of pre-assembled Kanban cards, making it easy for operators to identify the required components and replenish inventory.

- Reduced Lead Time: Kitted components are readily available, reducing the time required for replenishment in the Kanban system.

- Simplified Handling: Kitted Kanban cards can be easily transferred from one location to another, streamlining the flow of materials.

- Kitting as a Kanban Trigger: Use kitted components as visual Kanban signals to trigger the replenishment of inventory. When a kitted component is consumed in production, it serves as a signal to initiate the production of a new kit.

Tracking and Managing Kit Components

By bundling related items together as kits, businesses can streamline order fulfillment, reduce processing time, and optimize inventory levels. However, to reap the full benefits of kitting, it is crucial to have robust tracking and management systems in place.

Importance of Tracking Kit Components:

- Inventory Accuracy: Tracking kit components is essential to maintain accurate inventory records. Proper tracking helps avoid stockouts, overstocking, and mismanagement of components, which can lead to delays in production and order fulfillment.

- Order Fulfillment Efficiency: By tracking kit components, businesses can ensure that all necessary components are available when assembling kits. This streamlines the order fulfillment process and reduces the risk of errors.

- Cost Control: Efficient tracking and management of kit components enable businesses to identify cost-saving opportunities, such as bulk purchasing of frequently used components or negotiating better prices with suppliers.

- Quality Assurance: Accurate tracking helps maintain the quality of kitted products by ensuring that only approved and inspected components are used in the assembly process.

Challenges in Tracking Kit Components:

- Component Variability: Kits may have multiple variations depending on customer requirements, which can make it challenging to track all the different components accurately.

- Component Lifecycle: Some components may have a shorter shelf life than others, requiring careful monitoring to prevent using expired or outdated components in kits.

- Supplier Coordination: For kits that include components sourced from different suppliers, effective communication and coordination are necessary to ensure timely deliveries and availability.

- SKU Proliferation: Kitting can lead to a significant increase in the number of SKUs (Stock Keeping Units) to track, making it challenging to manage inventory efficiently.

Best Practices for Tracking and Managing Kit Components:

- Robust Inventory Management System: Implementing a reliable inventory management system with features tailored to kitting can streamline tracking and ensure accurate records of kit components.

- Barcode or RFID Technology: Using barcode or RFID tags on kit components can significantly improve tracking accuracy and speed, reducing the risk of errors in assembly.

- Real-Time Monitoring: Adopting real-time monitoring and reporting capabilities allows businesses to have up-to-date visibility into inventory levels and component availability.

- Standardized Assembly Processes: Establishing standardized assembly processes ensures consistency in the use of kit components and minimizes the risk of errors during assembly.

- Component Expiration Alerts: Incorporating alerts for components with limited shelf life helps prevent the use of expired items in kits.

- Supplier Collaboration: Collaborating with suppliers and setting up clear communication channels can ensure timely deliveries and avoid disruptions in the supply of kit components.

- Regular Audits: Conducting regular audits of kit components and inventory levels helps identify discrepancies and maintain accuracy.

- Automated Reordering: Implementing automated reordering systems based on inventory levels and demand forecasts ensures that kit components are replenished on time.

Software Solutions for Tracking Kit Components:

- Inventory Management Software: Advanced inventory management software equipped with kitting functionality allows businesses to track and manage kit components efficiently.

- Enterprise Resource Planning (ERP) Systems: ERP systems provide comprehensive solutions for tracking components, managing inventory, and optimizing supply chain operations.

- Manufacturing Execution Systems (MES): MES software helps monitor the assembly process, ensuring that the correct components are used in kit production.

- RFID and Barcode Systems: Implementing RFID or barcode technology for kit components enables real-time tracking and data capture.

Future Trends in Kitting and Inventory Management

As technology continues to advance and customer demands evolve, the kitting process is expected to undergo significant transformations. Here are the future trends in kitting and inventory management, focusing on the key technologies, practices, and strategies that will shape the industry in the coming years.

Advanced Robotics and Automation

As robotics and automation technologies continue to advance, they are revolutionizing the kitting process in manufacturing facilities and distribution centers. Robots equipped with advanced sensors and artificial intelligence can efficiently pick, assemble, and package kit components with incredible speed and accuracy.

These automated kitting systems eliminate the need for manual labor, reducing errors and increasing productivity. Additionally, collaborative robots (cobots) can work alongside human operators, further enhancing efficiency and safety in the kitting process.

Internet of Things (IoT) Integration

The integration of IoT devices in kitting processes enables real-time tracking and monitoring of kit components and inventory levels. RFID tags, sensors, and smart shelves provide data on component availability, usage, and replenishment needs.

This data can be fed into cloud-based inventory management systems, allowing businesses to optimize their inventory levels and respond quickly to changes in demand. IoT-powered kitting also facilitates predictive maintenance, as sensors can monitor the health of machines and equipment involved in the kitting process, reducing downtime and enhancing overall efficiency.

Artificial Intelligence (AI) for Demand Forecasting

AI-powered demand forecasting algorithms are becoming more sophisticated and accurate, enabling businesses to predict customer demand more precisely. By analyzing historical sales data, market trends, and other relevant factors, AI algorithms can forecast demand for kit components and finished products.

This foresight allows companies to proactively adjust their inventory levels and optimize kitting operations, reducing excess inventory and preventing stockouts.

Augmented Reality (AR) for Kitting

AR technology is transforming the kitting process by providing hands-free, interactive guidance to workers during assembly. AR-enabled smart glasses or mobile devices can overlay digital information onto the physical workspace, guiding operators through the kitting process step-by-step.

This technology improves worker efficiency, reduces errors, and enhances training processes. AR can also facilitate remote collaboration, allowing experts to guide kitting operations from different locations, increasing flexibility and agility in the workforce.

3D Printing for Customized Kits

The advent of 3D printing technology opens up new possibilities for kitting, especially in industries requiring customized components. With 3D printing, businesses can produce unique, on-demand kit components without the need for traditional manufacturing processes or lengthy lead times.

This technology enables rapid prototyping, design iteration, and mass customization, providing a competitive advantage for companies looking to offer tailored solutions to their customers.

Cloud-Based Collaborative Platforms

Cloud-based platforms are becoming increasingly popular for collaborative kitting and inventory management. These platforms allow multiple stakeholders, including suppliers, manufacturers, and distributors, to share real-time data and collaborate on the kitting process.

This transparency enhances supply chain visibility and fosters efficient communication between all parties, leading to smoother operations and better inventory control.

Sustainable Kitting Practices

As sustainability becomes a growing concern for businesses and consumers alike, kitting is expected to evolve with environmentally-friendly practices. Companies will prioritize eco-friendly packaging materials, optimize packaging designs to reduce waste, and consider the environmental impact of kit component sourcing and manufacturing.

Sustainable kitting practices not only align with corporate social responsibility initiatives but also appeal to environmentally-conscious customers.

Blockchain for Supply Chain Transparency

Blockchain technology offers unparalleled transparency and traceability in supply chains, including kitting processes. By recording every transaction and movement of kit components on a distributed ledger, businesses can ensure authenticity, prevent counterfeit components, and trace the origins of each component.

Blockchain-powered supply chains enhance trust among supply chain partners and provide consumers with verifiable information about the products they purchase.

Conclusion

Kitting is a strategic inventory management practice that offers numerous benefits to businesses across various industries. This article has provided a comprehensive overview of what kitting entails, its significance in streamlining operations, and the various ways it can be implemented to enhance efficiency and customer satisfaction.

Kitting involves the process of grouping and packaging related items together as a single unit, creating a new SKU or kit, which simplifies order fulfillment and improves the overall efficiency of inventory handling.

By preassembling kits of frequently ordered items, businesses can reduce order picking time, minimize errors, and enhance overall productivity. This results in faster order processing and improved customer satisfaction.

Kitting reduces inventory holding costs, streamlines replenishment, and helps prevent stockouts by bundling items together in ready-to-ship packages. This allows businesses to operate more efficiently and respond swiftly to customer demands.

By simplifying the packaging and handling of goods, kitting reduces logistics complexity, lowers transportation costs, and enhances overall supply chain efficiency. The preassembly of kits ensures that all necessary items are included in the order, reducing the likelihood of shipping errors and delays.

Inventory management software and barcoding systems play a crucial role in accurately tracking kitted items, maintaining inventory levels, and managing kit configurations. By reducing order processing times and ensuring accurate deliveries, kitting contributes to increased customer satisfaction, repeat business, and positive word-of-mouth referrals.

Furthermore, we explored the potential challenges associated with kitting, such as managing kit variations, tracking inventory accurately, and adapting to changing customer preferences. However, with proper planning, effective inventory management tools, and continuous improvement, these challenges can be addressed successfully.

How Deskera Can Assist You?

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP offers comprehensive inventory management capabilities that empower businesses to efficiently control, track, and optimize their inventory operations. Whether in manufacturing, distribution, retail, or any other industry, Deskera ERP's inventory management features help businesses achieve accurate inventory levels, reduce carrying costs, and enhance supply chain efficiency.

Here's how Deskera ERP can help in inventory management:

- Real-Time Inventory Tracking: Deskera ERP provides real-time visibility into inventory levels across different locations, warehouses, and sales channels. This helps businesses make informed decisions about stock replenishment and allocation.

- Multi-Location Management: For businesses with multiple warehouses or locations, Deskera ERP allows you to track inventory movements, transfers, and stock levels at each location. This ensures accurate inventory management and reduces stockouts or overstocking.

- Stock Reordering: Deskera ERP supports automated stock reordering based on predefined reorder points or minimum stock levels. When inventory reaches a specified threshold, the system can generate purchase orders or replenishment requests.

- Purchase Order Management: The system streamlines purchase order creation, approval, and tracking. It helps in maintaining optimal stock levels by ensuring timely procurement of goods based on demand forecasts.

- Sales Order Integration: Deskera ERP integrates with sales orders, allowing businesses to allocate inventory based on customer orders and prioritize fulfillment based on demand.

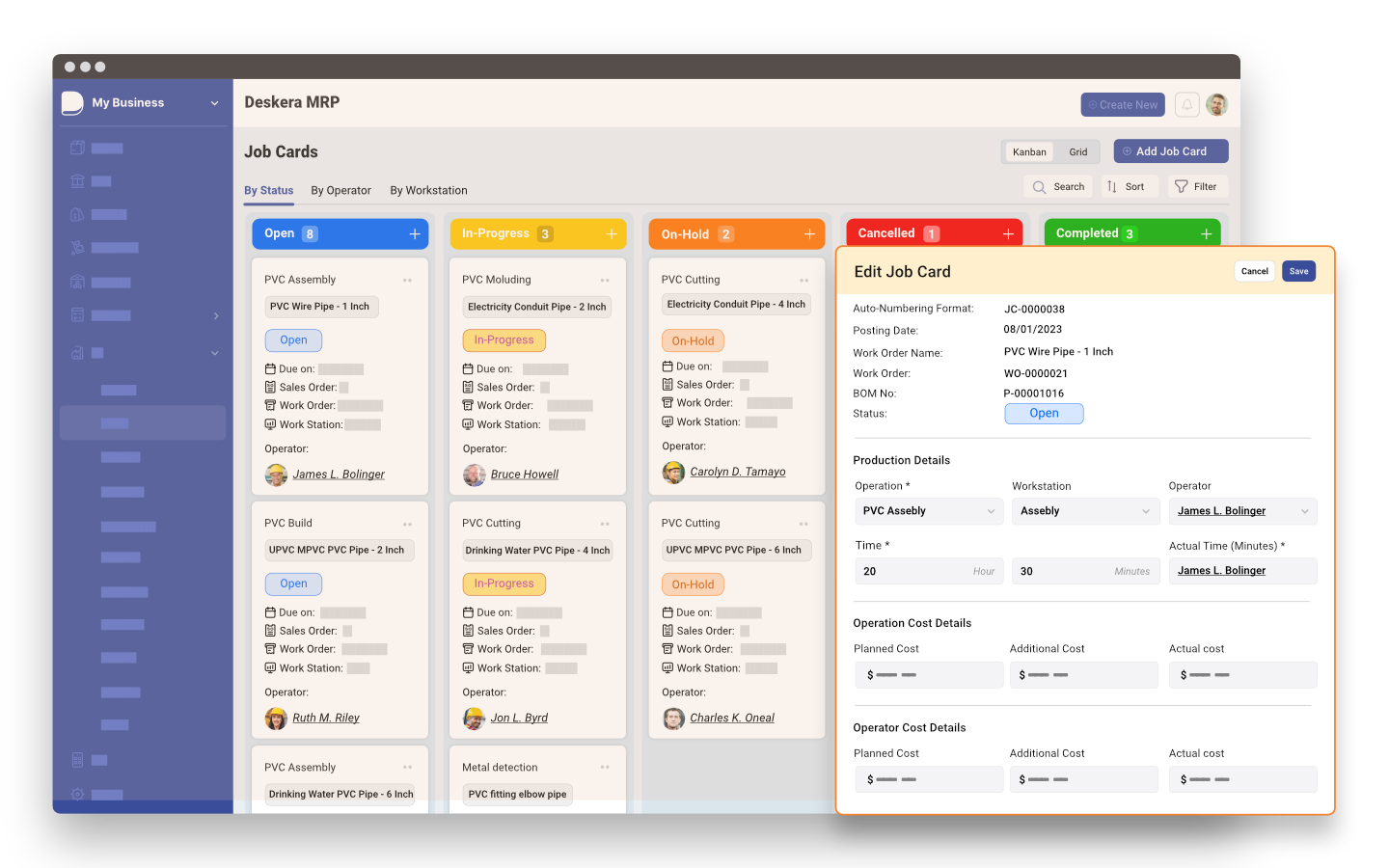

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Key Takeaways

- Kitting in inventory management involves grouping related items as a single unit to simplify order fulfillment and improve efficiency.

- It streamlines warehouse operations, reducing order picking time and minimizing errors in the packing process.

- Kitting enhances overall productivity by preassembling kits of frequently ordered items, leading to faster order processing and improved customer satisfaction.

- There are different types of kitting, such as pre-kitting, post-kitting, and dynamic kitting, each catering to specific business needs and product characteristics.

- By simplifying packaging and handling, kitting improves supply chain management, lowers transportation costs, and enhances overall efficiency.

- Technology, including inventory management software and barcoding systems, plays a crucial role in accurately tracking kitted items and managing inventory levels.

- Kitting can support just-in-time (JIT) manufacturing principles by simplifying component preparation and reducing lead times.

- Analyzing order patterns and customer preferences helps fine-tune kitting strategies for maximum efficiency and cost-effectiveness.

- Kitting practices contribute to sustainability by reducing the need for excessive packaging and shipping materials.

- Optimized inventory levels and reduced carrying costs from kitting practices free up capital for other areas of the business and improve cash flow management.

Related Articles