In 2021, the output of garment manufacturing in the United States was $16.5 billion. These figures depict a 23.8% increase from 2009.

If there is one industry that is less likely to face a pause, it is the apparel industry. This is to say that if you are looking to make it in the manufacturing sector, garments could be a lucrative answer. Yet, there are certain tips and steps you will need to follow.

Moreover, garment production is a detailed process. It will be easier to sustain the industry if production is up to standard. You will need to ensure a systematic preproduction phase of material preparation. Backed up with automated systems, you can ensure great outcomes for your garment manufacturing business!

We have gathered all the critical points that a garment manufacturer must know. Let’s get started.

Garment Manufacturing Industry: An Overview

We know for a fact how the garment industry boosts the global economy. And rightly so. It is difficult to find a person who would not have a fascination for apparel.

With over 90,000 workers in the US, the garment manufacturing sector offers ample employment opportunities. The sector exhibits an estimated global market size of over $800 billion.

Various kinds of apparel are worn by men and women worldwide. Some most commonly worn outfits include shirts, dresses, coats, pants, and so on. The garment goes through a rigorous process before it takes the shape of a proper outfit.

Let’s see the steps involved.

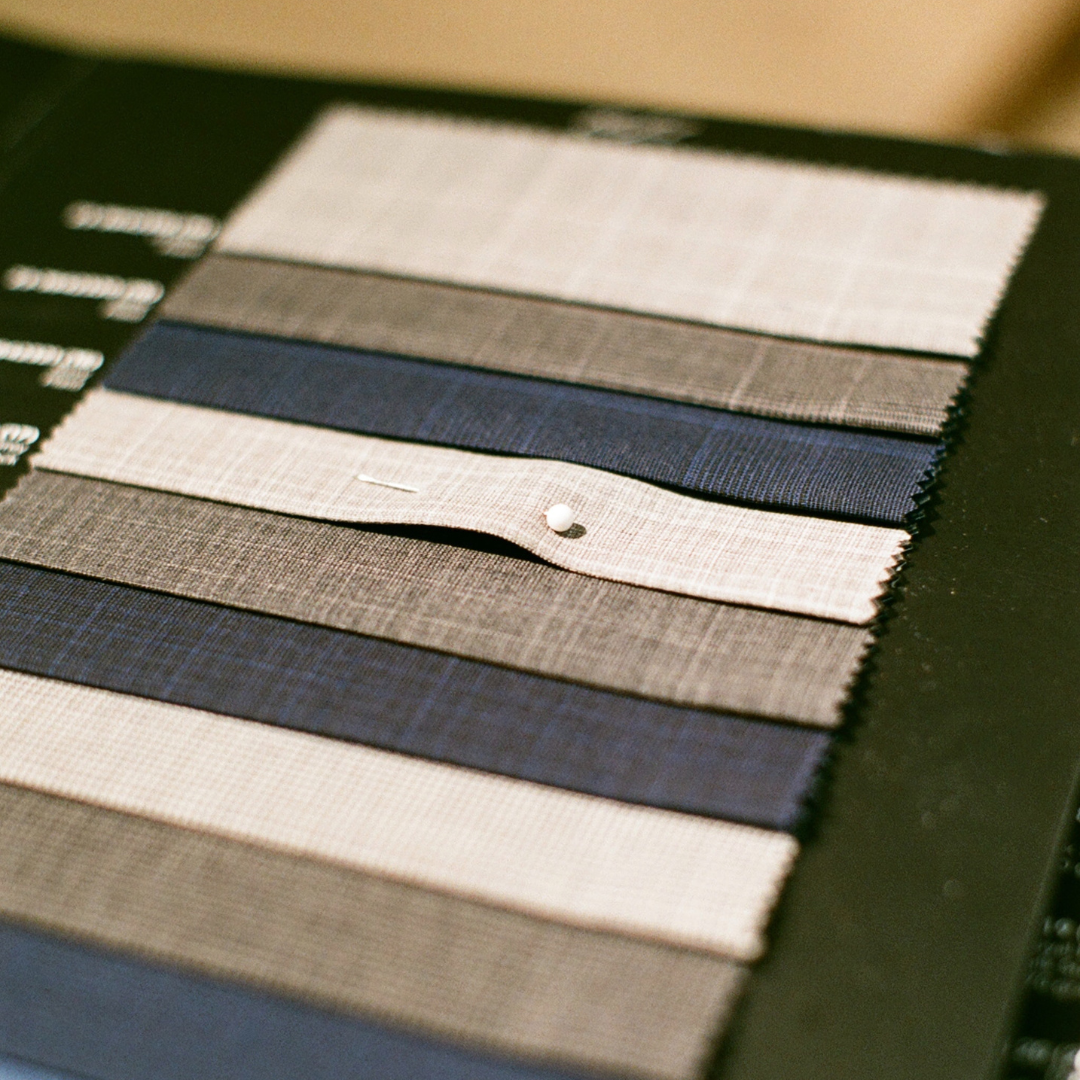

Fabric Selection

The most important aspect before garment production is fabric selection. There could be different attributes of the finished product. Therefore, selecting the right fabric for a proper finished product is vital. Some of the most common fabrics that the garment sector utilizes include the following:

- Cotton

- Wool

- Polyester

- Denim

Fabric Cutting

Once the fabric selection is complete, it goes through cutting. The size and shape must be perfectly configured before the cutting of the fabric begins.

The cutting is done through large machines. These machines are well-adept to handle large sizes of garments.

Sewing

Once the fabric has been cut, it moves on to the next process. The cut fabric is assembled before moving on. Frequently used techniques for sewing, the garment is as follows:

- French seams

- Flat-felled seams

Adornment of Fabric

Fundamentally, this stage is about decorating or embellishing the garment. Embroidery and applique are some common adornments added to a piece of fabric. These could be changed to suit the requirements.

Finally, the garment is ready. The concerned staff examines the quality of the final product. The team assesses various parameters and ensures that it fits the end user. The approval of quality ensures it is ready to be worn or used by customers. Eventually, the packages of the ready fabric are shipped.

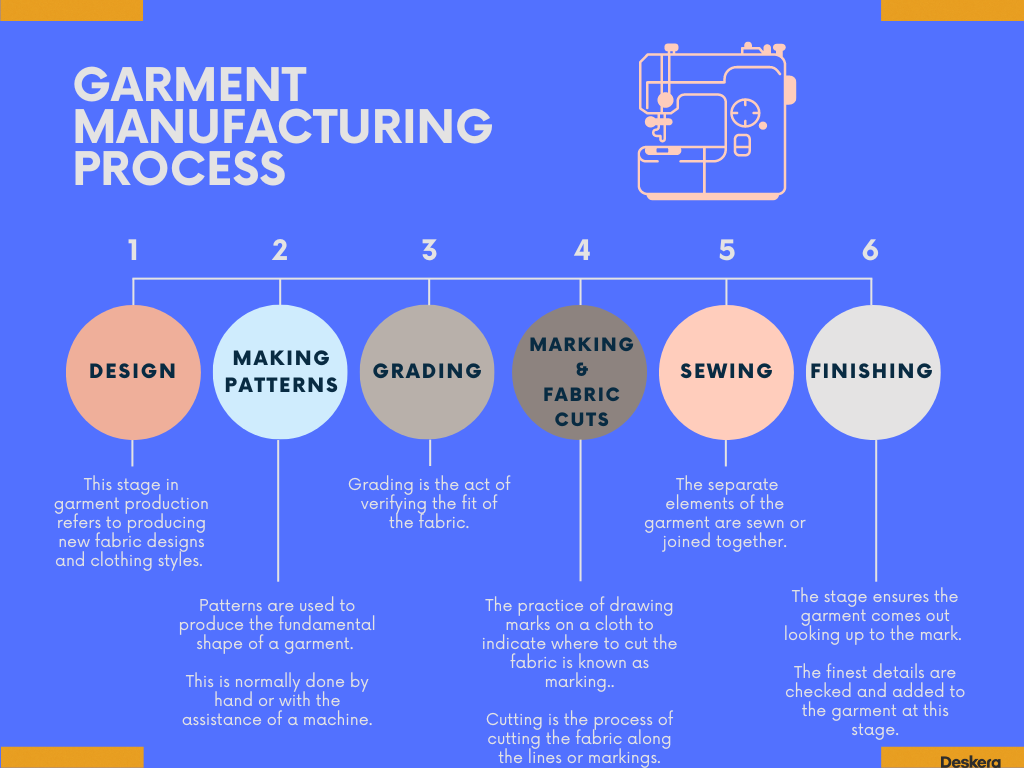

What is Garment Manufacturing Process?

Garment production is a well-organized process that includes various steps. These are laying, marking, cutting, stitching, checking, finishing, pressing, and packaging. This is the process of transforming raw materials into final goods.

Design and Creation

This stage in garment production refers to producing new fabric designs and clothing styles. Additionally, it entails refining existing clothes. The objective of this activity is to create goods that are both fashionable and functional.

When you set out to design and develop, you must conduct extensive research on current fashion trends. It is always wise to know the trends and the latest demand in the market beforehand. There are various ways in which you can accomplish your research. Here they are:

- Participating or attending trade exhibitions

- Taking clues from Fashion magazines

- Speaking with trendsetters

All these methods will let you know what has been trending. Once you have determined what is popular, you may begin sketching your own designs.

From here, the process moves on to creating prototypes. This happens once you have some sketches. A preproduction sample takes the process further to determine how the clothing will appear and feel on individuals. They will also assist you in determining whether there are any manufacturing issues. If there are any concerns, you must address these before beginning mass production.

When your prototypes are ready, the next step is to select the appropriate fabrics for your clothes. There are numerous textiles available, and you must choose the ones that work best for your items. You should also consider the fabric's care instructions.

After you have chosen your fabrics, the following step is to start making your outfits. This procedure can be carried out in-house or by a clothes manufacturer. If you outsource, you must pick a reputable company with garment production experience.

Making Patterns

A pattern must be developed once the design part is complete. This is accomplished by transferring the design to paper or fabric. After this, you cut out the component sections that comprise the outfit.

The pattern maker is essential for manufacturing, just like any other garment production process. Patterns are used to produce the fundamental shape of a garment. This is normally done by hand or with the assistance of a machine.

When the pattern is finished, it is used to cut fabric and assemble the garment. Patterns can be created using various methods. The most popular of which is to employ a paper or cardboard template.

The outline of the desired garment is then traced into the fabric using this template. When the tracing is accomplished, the cloth is cut along the traced lines. It is then sewn together to produce the finished garment by the pattern maker.

Companies often deploy techniques such as computer-aided design (CAD) programs. It is another frequent approach for designing patterns.

Computer-aided design is a method of creating digital 2D drawings and 3D models of real-world objects. The digital process is carried out before the objects are made. The model thus created enables us to understand the real features of the objects.

With 3D CAD, you can easily review, simulate, and alter designs. This paves the way for unique and differentiated goods to reach the market quickly. This tool enables the user to make a virtual model of the garment they wish to design. A CAD application has the advantage of being able to generate numerous garments at once. Additionally, it can make modifications to the pattern before it is cut into the cloth.

Regardless of how they are created, patterns are an important aspect of the garment production process. They are used to guarantee that each garment is the correct size and shape and that all pieces fit perfectly together.

These tools simplify the process of manufacturing garments that look well and fit well.

Grading

The process of pattern creation is soon followed by grading. After the pattern is cut, the garment goes through a procedure known as grading. Grading is the process of producing different sizes of a garment from a basic size.

As the name suggests, grading is the act of verifying the fit of the fabric. There are a variety of sizes created. The grading process ensures the fit's effectiveness in various sizes. This is accomplished by producing multiple variations of the pattern in various sizes.

Grading is classified into two types.

- Horizontal

- Vertical

Often, companies tend to use horizontal grading more than vertical grading. This is so because it is easier to make tiny width modifications than lengths. We can consider a simple example of a shirt. It is simple to add or subtract a few inches from the width of the pattern pieces. It can be easily modified to make a larger or smaller shirt.

Vertical grading is used to create different lengths from a base length. On the other hand, horizontal grading is used to create different widths from a basic width. Vertical grading is less preferred as it can be more challenging. It is more difficult to add or subtract a few inches from the length of the pattern pieces.

Importance of Grading

Grading is mainly done by computer these days. However, designers and pattern makers should still understand the fundamentals of how it works. Grading is an important aspect of garment production because it enables producers to produce a wide range of sizes from a small number of pattern pieces.

This increases the efficiency of clothing mass production and helps to keep manufacturing prices low.

Marking and Fabric Cuts

The marking and cutting processes are two of the most critical procedures in the garment manufacturing process. The practice of drawing marks on a cloth to indicate where to cut the fabric is known as marking. Cutting is the process of cutting the fabric along the lines or markings. There are several methods for marking fabric for cutting.

The manufacturing team can either use chalk or any other marking instrument for the purpose.

Alternatively, they may also use a permanent marker for marking fabric. Permanent markers are useful because they do not wipe off or fade over time. Unlike the markings done by chalk, markings done by a marker remain visible. Typically, this is done on larger pieces of fabric, such as bolts of fabric.

When the fabric has been marked, it is time to cut it. This can be accomplished using a rotary cutter, scissors, or a knife. Companies use sharp instruments to avoid fraying or ripping the cloth when cutting fabric.

Marking and fabric cutting are two critical processes in the garment production process. The careful marking and cutting of the cloth ensure that the outfits are well-made and appear professional.

Sewing

Once the marking and cuts are done, the fabric proceeds to the sewing stage. In this step, the separate elements of the garment are sewn or joined together. A sewing machine laced with needles and the right thread combination is used for sewing.

The sewing process is in charge of sewing all the fabric components that make up a garment. Therefore, it is rightly one of the most crucial processes in garment production. It is impossible to give a proper usable shape to a garment without sewing.

The sewing process includes joining or chaining one or more sewing threads with the textile fabric. There are various interlacing points in the textile fabric. The joint produced is described by the manner, position, and a number of joining or interlacing points.

Sewing is the art of connecting or securing objects with stitches formed with a needle and thread. This term describes the technique used in factories to mass-produce a wide range of clothing.

The fundamental sewing parameters that are determined before the process include the following:

- Stitches

- Seams

- The stitching technique used

Sewing can be accomplished by either hands or machines.

Hand stitching is more labor-intensive and slower. Yet, it can produce incredibly delicate and detailed stitches. Machine stitching is more efficient and quicker. However, the results of machine sewing may not be as perfect as those of hand sewing.

There are numerous sorts of stitches that can be used in sewing. The type of stitch chosen will be determined by the fabric being sewn. Furthermore, the function of the stitch and the sewer's preference also play a role.

Stitches that are commonly used include the following:

- Straight

- Buttonholes

- Zigzag

These stitches are most commonly employed for seams, hems, and other construction elements.

Straight Stitches

If a garment is going to be subjected to a lot of wear and tear, using a stitch that will endure repeated use is good. Straight stitches have the virtue of being exceedingly strong and lasting. Furthermore, straight stitches are simple to cut and sew. This makes them perfect for mass customization.

Zigzag Stitches

Zigzag stitches are one of the most fundamental and vital types used in garment production. They are made by sewing a straight line of zigzag-shaped stitches. These stitches can be used to accomplish the following:

- Finish the raw edges

- Stitch together two pieces of cloth

- Add an aesthetic element to the fabric

There are several techniques to make zigzag stitches on a sewing machine. The most frequent approach is to use a zigzag foot. This is a specialized attachment in a sewing machine. It aids in the movement of the fabric under the needle in a zigzag pattern. Some machines also include built-in zigzag stitch capabilities. The sophisticated sewing machines provide this stitch by pressing a button.

Using the correct needle size and thread weight when zigzag stitching stitches is critical. A too-small needle might cause stitches to break. Then again, a too-heavy thread can add bulk. Stitch width and length should also be modified to fit the project. On the other hand, broader stitches are better for ornamental purposes. Then there are smaller threads that have more useability.

With a little practice, zigzag stitches are quite simple to learn. Gradually, they may open up a new world of possibilities for your sewing projects. As you gain expertise, you can add exceptional levels of stitches to beautify the fabric.

Buttonholes

A buttonhole is a small hole formed in cloth that allows a button to be passed through it. It also facilitates attaching the button. It is also known as a button loop or eyelet. These can be manually or machine-stitched.

- Buttonholes that are hand-sewn are more durable than machine-sewn ones. They are preferred despite being tedious and more difficult to make.

- They are most commonly used on items that will not be washed frequently. Some example of these type of clothing is suits and coats.

- Machine-sewn buttonholes are quicker and easier than hand-sewn ones. They find application in a wide range of clothes, too. An example could be casual wear and children’s clothing.

- Buttonholes come in a variety of forms, sizes, and finishes.

- The round buttonhole is the most prevalent, but oval and keyhole styles are also popular.

- The buttonhole should be somewhat larger than the button. This facilitates the button to flow comfortably through it.

- Buttonholes are made before the garment is put together. Once the buttonholes are in place, the buttons may be stitched on to match.

- Buttonholes are typically positioned at key areas, such as the center front or cuff, to make fastening and unfastening the garment easier.

Tips for Easy Buttonholes

Creating flawless buttonholes can be difficult, but here are a few pointers:

- Use a sharp needle and good-quality thread to prevent skipped stitches.

- The stabilizer should be placed beneath the cloth. This prevents it from stretching or distorting while you stitch.

- Making a tidy and even buttonhole. Before stitching on your outfit, practice on a scrap piece of fabric to get the hang of it.

- Sewing is important in garment manufacturing because it binds the fabric together.

Garments would end up looking dull if the apt sewing process is not implemented. As a result, it is critical to select the appropriate stitch for the fabric.

Finishing

This is the final step and involves embellishments. The stage ensures the garment comes out looking up to the mark. The finest details are checked and added to the garment at this stage.

The finishing stage includes adding accessories that may include the following:

- Snaps

- Zippers

- Buttons

By adding these embellishments, the step ensures the garment has the desired appearance. Finishing also ascertains that the functionality of the fabric is intact. In other words, this stage is all about making the outfit look great.

Here are some steps you can take to establish finer finishing of the garment:

- Washing

- Bleaching

- Dyeing

- Printing

- Coating

This stage marks the conclusion of the garment manufacturing process. From here, the fabric is transferred to the warehouse of the factory. Thereafter, the fabric packages are sent to individual shops and outlets.

Types of Garment Manufacturing Process

The garment manufacturing process has been evolving for centuries. With time, we have been introduced to different types of garment manufacturing processes. Some require high-tech equipment, while others rely solely on humans. The only thing both production techniques have in common is that clothing is always stitched together by hand.

In this section, we shall look at the various types of garment manufacturing processes.

Individual or Make-Through System

This manufacturing approach is typically employed in small-scale firms with modest production volumes. A single tailor handles all phases of garment manufacture in the make-through production system. The tailor is in charge of creating the pattern, cutting the fabric, stitching it, and completing it.

The make-through system is today's oldest and most widely used form of garment production. However, there is only one person who oversees the entire process. The method comes across as inefficient due to a lack of process alignment. It may impede production. This is one of the system's most serious flaws.

However, because a single tailor is in charge of the entire process, the make-through approach aids in the production of identical results.

Another downside of the make-through technology is its high manufacturing costs. The laborers must be highly skilled, which raises the cost. However, unlike in other systems, tailors are not required to be qualified to operate heavy machines. The make-through system is how most businesses get started. The technology also works well in conjunction with other garment manufacturing technologies.

Progressive Bundle System (PBS)

This is a more streamlined traditional production system than the make-through approach. The progressive bundle system likewise largely relies on personnel to drive activities. The name of the system perfectly describes how it operates.

Tailors are lined up and assigned a certain assignment. Each tailor is handed a package of clothing on which to perform their work. The bundle is then wrapped up and sent on to the next operator.

In this method, the tailor only has one responsibility. This paves the way for an accelerated pace of production. This way, there is no time wasted putting materials away or retrieving a tool. However, a considerable amount of time is lost in assembling and passing the bundles.

Therefore, the progressive bundle system may appear time-consuming. Yet, it is one of the most cost-effective solutions to boost manufacturing volume.

The progressive bundle system also permits tailors to be moderately skilled. As they have only one role, it is sufficient if they excel at it. To function properly, the system must be well-oiled. As a result, a problem with even one tailor impacts the entire production line.

Section Production System

The progressive bundle system is a variant of the section production system. Instead of being in a line, the tailors are split into groups here. This is a solution to the line-balancing problem that could occur in a progressive bundling system.

One-Piece Flow System

This is another variant of the progressive bundling system. It is a single item rather than a bundle of clothing traveling through the production line. Everything else remains the same.

Also, in this case, there is one charge assigned per worker. With nominal responsibilities, tailors need not have a high level of competency.

Unit Production System

The unit manufacturing system is a more upscale version of the progressive bundle system. The garment is moved from one station to the next using a computerized manufacturing line. This eliminates the lags that occur in the PBS. The unit production system allows for continuous workflow, which leads to greater productivity.

There are fewer opportunities for an assembly line to break down. This is because only a single garment is shipped rather than a bundle. As a result, a problem with a single tailor will not affect the entire line.

The unit manufacturing approach is ideal for enterprises that generate large quantities of merchandise. The first installation costs a lot of money. However, the enhanced manufacturing capabilities allow you to swiftly recoup the expense.

This technique makes it simple to maintain clothing quality. The system keeps track of each piece of clothing. If any rework is required, the employees can simply identify the problematic item and make the necessary adjustments. The technology is particularly useful because it allows for easy extension. You can easily add extra workspaces and tweak them.

Tailors do not need to be highly skilled to operate this production technique. This is because the assembly process is automated. However, you may require a maintenance person on duty because the entire line is affected if a machine fails.

Modular Production System

To complete a garment, this garment production system relies on the teamwork of a department. The team can establish its own pace and pick who will play which role. A single tailor or team member is in charge of multiple duties. This necessitates the deployment of skilled employees to make this production system function.

There is a sequential workflow which proves to be efficient. It makes workers more efficient and allows crafting more clothes in less time. We must also note that this is entirely man-powered and the crew works together. This fact ensures a better chance of restoring worsening situations.

Yet, this approach may provide some difficulties. The performance is measured based on the team’s output. As a result, the entire team will be held accountable for your achievement. There may be no individual recognition of work. However, major issues can be ruled out because the work involves expert workers.

3 Ways to Reduce Lead Time in Garment Manufacturing Business

You can employ one of the following ways to reduce lead time in garment manufacturing:

- Streamline all business operations

- Excellent supply chain management

- Negotiating shorter lead times with the suppliers

In the manufacturing industry, lead time refers to developing and delivering a product to customers. Lead time is estimated by adding the time taken by the following elements:

- number of days required to obtain materials

- make things

- deliver final products

Streamline All Business Operations

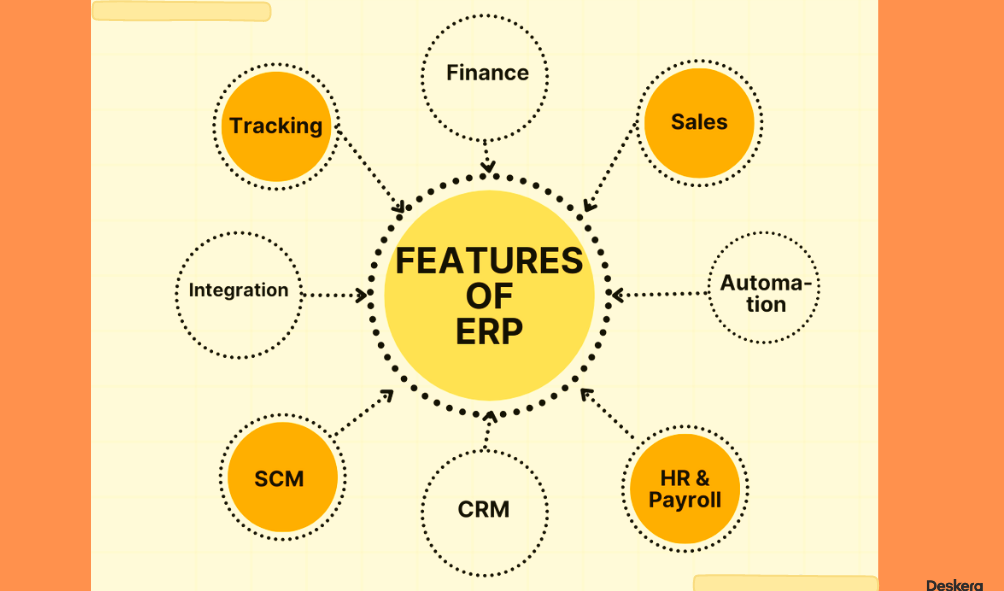

The advanced ERP and MRP systems make streamlining easily achievable. These systems offer automation and integration of various business functionalities. This way, you can have real-time updates from all departments.

Read our Complete Guide on MRP Here

Here are the prominent benefits of Enterprise Resource Planning systems:

- Integration

- Finance and Accounting

- Sales

- CRM

- HR

- SCM

Integration

Having all business modules under one roof is certainly an advantage. You can view and use the data from all your units effectively. Handling sales, accounting, CRM, and so on will become a cakewalk with an ERP system.

Finance and Accounting

From helping you manage your balance sheets and general ledger, ERP can prove beneficial. Accounts receivables, payables, and managing accurate financial statements are all possible with ERP.

Sales

ERP enables the easy creation of invoices with invoice templates. With the sales module of ERP, you can gauge your goals better. Creating sales orders and checking receipts of payments are all a breeze.

SCM

The supply chain is an integral component of a manufacturing company. Get all your supply chain aspects aligned with the supply chain management module of ERP.

CRM

Customer relationship management can be a hassling process. However, with ERP, all the related aspects are simplified. You can maximize your profit and attract better opportunities with the CRM module of ERP.

HR

Employee management can be easy with ERP. From managing employee benefits to their attendance and leave are all taken care of. The Human Resource module of ERP helps connect all the aspects of HRM.

Besides these, you may adopt lean manufacturing principles. Also, you may utilize just-in-time or JIT production methods.

Excellent Supply Chain Management

Maintaining a healthy supply chain is important to a business. You can lower your lead times with great supply chain management. For this, you must maintain adequate inventory levels.

Negotiating Lead Times with Suppliers

In the garment manufacturing industry, lead time is critical. You can also try to bargain with your suppliers for reduced lead times. This will be easy to accomplish if you have an excellent relationship with them. Alternatively, you may prepare to pay a premium for speedier delivery.

You may help to shorten the overall lead time for your clothing by optimizing your manufacturing operations. This will aid in increasing your efficacy and diligence.

4 Benefits of ERP for the Garment Manufacturing Industry

You may increase productivity and profitability by using software to automate manufacturing operations. Your garment manufacturing business can benefit from the software in a variety of ways, including the following:

Conclusion

The textile and clothing industries operate in a highly competitive environment. To succeed, you must always be prepared to perform at the greatest levels. Whatever the approach, you must grasp the underlying goal.

“How do you aim to attain it and what results are expected”, are a few questions you can begin with. Also, calculate how you shall fare in a competitive context. Today, we have a variety of quality management systems. They all work with the goal of making the company stronger. Each system has its own set of policies and procedures.

When studying several systems, implementers find themselves in a quandary because all are good. So, you may often lack clarity on this. In such a case, analyze your targets and goals. Know what you really require for your business. Highlight the major issues surrounding your manufacturing process. Understand the challenges you would like to overcome at the earliest.

These are questions to be asked to oneself. A genuine and honest response will qualify your business for success. Once you have your requirements in place, combine them with advanced technology. Supplementing your manufacturing business with an ERP and MRP system can do the trick. The results of these could be pleasantly surprising for you!

How can Deskera Help You?

As a manufacturer, you must keep track of your inventory stock. The state of your inventory directly impacts production planning, human and machine utilization, and demand forecasts.

Deskera ERP and MRP solutions can assist you in the following areas:

- Create production schedules

- Make Bill of Materials

- Make detailed reports

- Create your own dashboard

Deskera ERP is a comprehensive solution for managing suppliers, real-time tracking of supply chain activity, and streamlining a range of other organizational functions.

Deskera Books helps you manage your accounts and finances more effectively. It helps to maintain good accounting standards by automating billing, invoicing, and payment processing.

Deskera CRM is a powerful tool that may help you arrange your sales and close deals rapidly. It enables you to perform critical tasks such as lead generation via email and gives you a full view of your sales funnel.

Deskera People is a straightforward tool for centralizing human resource management duties. ERP technology speeds up payroll processing and helps you with other tasks like calculating overtime, benefits, bonuses, training programs, and much more.

Key Takeaways

- With over 90,000 workers in the US, the garment manufacturing sector offers ample employment opportunities. The sector exhibits an estimated global market size of over $800 billion.

- Fabric passes through different stages. These are fabric selection, cutting, sewing, and adorning the fabric.

- Garment manufacturing process includes six steps. These are designing, pattern making, grading, markings and fabric cuts, sewing, and finishing.

- Design and creation involve the objective of this activity is to create goods that are both fashionable and functional.

- A pattern must be developed once the design part is complete. This is accomplished by transferring the design to paper or fabric. After this, you cut out the component sections that comprise the outfit.

- After the pattern is cut, the garment goes through a procedure known as grading. Grading is the process of producing different sizes of a garment from a basic size.

- The practice of drawing marks on a cloth to indicate where to cut the fabric is known as marking. Cutting is the process of cutting the fabric along the lines or markings.

- A sewing machine laced with needles and the right thread combination is used for sewing.

- Stitches, seams, and stitching technique are the fundamental sewing parameters.

- Finishing is the final step and involves embellishments. Buttons and zippers are some accessories that can be added at this stage.

- There are six commonly-used garment manufacturing processes.

- Make-through system, progressive bundle system, section production system, one-piece flow system, unit production system, and modular production system are the types of manufacturing systems.

- Streamlining business operations, excellent supply chain management, and negotiating shorter lead times with suppliers are some ways to reduce lead times.

- Production planning, quality control, marketing & sales, and inventory management are some of the ways in which ERP system can help garment manufacturing companies.

Related Articles