In our daily lives, we come across several goods that are mass-produced on machines from raw materials. Every day, factories all across the world produce commodities, consumer goods, durable goods, and an endless array of other things.

When talking about the manufacturing process, heavy metals and machinery are typically the first things that come to mind. There were times, though, when it only applied to certain segments. Given how much has changed, you can discover several types of manufacturing process that could even surprise you. Since the industrial revolution, the industry has become much more diverse.

In today’s guide, we'll examine each of the six types of manufacturing processes. Let's first understand the manufacturing process before delving into the various types of manufacturing processes.

First, let’s take a look at the table of content:

- What is Manufacturing Process?

- Different Types of Manufacturing Processes?

- Manufacturing Process Types Structured by Scale

- Various Manufacturing Methods According to the Nature of the Product

- Manufacturing Process Types according to Role of the Process

- Manufacturing Process Types by Automation Level

- How Deskera Can Assist You?

Let’s Start!

What is Manufacturing Process?

A manufacturing process is defined as a series of steps involving machinery, devices, and labor to convert raw material into finished goods.

Moreover, a manufacturing process also has to have set norms, such as tolerances, quality measurements, and performance metrics.

It assists in maintaining coordination across all parts of production, including labor, machine operation, material flow, and more. Moreover, this coordination is required to maintain efficiency and consistency.

Every business has thoroughly considered and chosen a manufacturing process that is suited for their product and kind of production, regardless of the size of the business or the intricacy of its product line.

Furthermore, the method utilized may frequently depend on the type of product being produced. Some businesses may simply require a simple system while others may require complex mixing or blending activities.

However, it's quite uncommon to see a variety of production techniques being used in diverse industries or even combining into a single manufacturing company.

Each business employs a unique set of procedures and methods to produce the final goods. When a business chooses the best manufacturing method, factors including:

- Market demand for products,

- Technique,

- Consumer demand,

- State of components, raw materials, and chemicals,

- Resources on hand,

- State of factory, and

- Turnaround time, and more

These production methods each have advantages and disadvantages of their own. However, manufacturers carefully examine the aforementioned factors to determine which approach is ideal for your business.

Different Types of Manufacturing Processes?

Following we have discussed different types of manufacturing process. Let’s learn:

1. Repetitive Manufacturing

As the name suggests, repetitive manufacturing uses the repeated production technique to generate the same product on an assembly line. The same or substantially similar products will be produced quickly and in big quantities continuously. Repetitive manufacturing is one of the oldest techniques, which is still in use.

These are some of the manufacturing sectors that use this kind of production process:

- Automotive

- Electronics

- Semiconductor

- Durable consumer goods

These sectors rely on mass production, and they make great candidates for repeated manufacturing since there is a steady and predictable demand from consumers for the finished product. The assembly line will largely not alter over time while producing a single product.

A time- and resource-based method is used to create master plans. Repetitive manufacturing is frequently utilized in large-volume, sales-order-focused industries like the automobile or for make-to-stock production. Robots and other automated high-volume manufacturing tools are used in these facilities to boost throughout while lowering manufacturing costs.

In the end, everything comes down to reliably creating items at a certain rate. This committed process works nonstop all around the year to meet consumer demand. The operating speed of the iterative manufacturing process can be altered by the manufacturer.

The automotive sector employs this strategy most frequently. The fact that it lowers the cost of creating items or components is one of its main advantages. Additonally, scheduling is also made easier, and performance visibility can be regularly checked.

2. Job Shop Manufacturing

The job shop manufacturing method focuses more on one-off manufacturing jobs and uses fewer assembly lines than the other manufacturing methods. Other than that, the production process at the workshop uses very little automation. Each employee has the opportunity to make improvements to the final product as it passes through their station, before it moves on to another, and finally when it is completed.

In order to replenish stock after it wears out, job shop manufacturers usually produce customized goods in lesser quantities.

The capacity to create customized goods, simplicity of change adaption, effective resource use, and the option to give particular processes precedence are some of the key benefits of using this approach. Companies that sell customized products like eyeglasses or ready-made frames use job shop manufacturing.

This manufacturing technique is ideal for bespoke manufacturing because of its propensity to produce highly specialized items in low volumes and at a slower rate.

Think about a shop that makes custom cabinets. Employees will be adding to the cabinet when it is brought to them at their designated workstations. The tasks of sawing the wood, applying resin, cleaning the varnish, and assembling the pieces can all be assigned to different people.

Keep in mind that workshop production is not limited to low-tech products. This technique is also employed in the advanced production of rockets and fighter jets in the aerospace and defense industries. To ensure a high-quality build, these products are created by professional workers who prioritize quality control while using cutting-edge manufacturing techniques.

3. Discrete Manufacturing

Discrete production is the counterpart of repetitive manufacturing. Although it also uses manufacturing lines, this strategy frequently results in completed goods that are very different from one another.

Discrete manufacturing uses production or assembly lines with different setups and changeover periods, just like repetitive manufacturing processes do. In this kind of manufacturing process, parts, components, and sub-assemblies are used to create finished goods.

The finished products are typically combinations of various parts, and they are offered for sale in separate chunks. For instance, this technology is used to make handcrafted furniture, smartphones, and even airplanes.

When moving between various product models, the assembly line architecture typically needs to be altered. This is known as a changeover in manufacturing plants because it necessitates setup costs in terms of materials, time, and labor.

Customers anticipate mass customization in the computer industry, for instance, in addition to the firm's continued rapid technological improvement. To produce and assemble orders for the newest electrical components utilized in the development of newer laptops and PCs, the assembly line will need to be modified.

4. Continuous Process Manufacturing

Process manufacturing, often called continuous manufacturing, makes it easier to produce comparable items repeatedly. This also entails continuous manufacturing, similar to repeated manufacturing.

Long-term manufacturing cost reductions, quicker production cycles, fewer potential for error, high-quality output, and process efficiency are a few of the main advantages of employing this technology. Businesses in the glass, chemical, and pharmaceutical sectors use this continuous, uninterrupted manufacturing method.

Continuous production, which runs around-the-clock, is similar to repeated manufacturing.

The difference between continuous production and other manufacturing processes is that raw materials are often in the form of gases, liquids, powders, or slurries in continuous production.

However, granule materials may be the final product in sectors like mining. Product designs are identical unless the disciplines utilised to create a final product or a production system are more diverse.

Industries involved in traditional industrial manufacturing that frequently use continuous processes include:

- Pharmaceutics

- Industrial and chemical gases

- Fertilizers

- Steel, iron, and alloys furnace

- Power plants

- Oil refinement

- Paper

5. Batch Process Manufacturing

A company engages in batch production when it produces items in sets or batches in response to consumer demands. A list of goods that is compiled by the manufacturing company and updated in response to market developments is available for customers to order from.

Businesses that manufacture products for other industries commonly use batch manufacturing, especially if they rely on a limited number of important clients to meet their revenue goals. They might even manufacture some products in advance of times of high demand, but they typically wait to begin production until the client gives the go-ahead.

Batch manufacturing may be useful for businesses that produce a range of goods with the same fundamental machinery. They can adjust their specifications to fulfil a specific requirement without changing their operations or equipment.

The industries of food, medicine, and clothing are just a few that might use this strategy. For instance, a garment factory can use the same equipment to produce a range of apparel products and sell them to several client companies.

To meet a higher demand from clients, batch processing is used, much as discrete and workshop methods. Every order is handled as a batch, and after production is complete, the equipment is cleaned and readied ready for the next batch.

Several key benefits of using the batch manufacturing method include higher cost effectiveness when producing a full batch of goods at once, greater flexibility, reduced waste, efficient resource utilization, and lower operational costs.

However, this method has certain extra disadvantages as well, which shouldn't be overlooked.

For instance, the need for careful quality checks, higher storage costs, and the potential for a batch of errors to result in higher expenses and lost time. This approach is used to create pharmaceuticals, electrical goods, apparel, fast food, and flatpack furniture,

6. 3D Printing

Since its introduction in the 1980s, 3D printing has provided producers with a means of producing things utilizing a variety of composites and materials without the usual need of physical labor or automation.

This production method has increased by 875% over the last five years since the 1980s. Despite being in its early stages, 3D printing shows promise as a potential industrial method in the future.

Many in the industry now recognize 3D printing as the sixth production technique. A range of composites and materials, such as polymers and metals are used in 3D printing. It works opposed to physical labor or automation to make objects. Products made from 3D printing have already been sold in a variety of industries, from apparel to food.

A few of the significant expenditures related to 3D printing are high-capacity printers, which can range in price from $50,000 to $500,000,000 per, and time spent on the product's design or development.

According to the Federation of American Scientists, the cost of 3D printing technology has dropped by about 80% in recent years. Despite the fact that it may still appear excessively expensive at this time, you won't have to wait long for prices to drop much lower.

Another benefit is that it enables organizations to produce and test products before investing into them. This may result in cost, resource, and waste savings. Currently, this increasing production technique is used to create the following products:

- Prosthetic limbs

- Shoes

- Firearms

- Dental and medical technology

- Musical instruments

- Buildings

Manufacturing Process Types Structured by Scale

Following we have discussed manufacturing process types by scale. Let’s learn:

Job Shop Manufacturing

A job-shop production strategy can be identified by:

- Producing things in small numbers or as one-offs (one to two dozen per month).

- A wide range of products.

- Utilizing universal tools for cutting, measuring, and other tasks.

- According to the concept of technologically related operations, workplaces are grouped.

- Absence of task assignment to specific persons.

- High personnel qualifications that consider the range of duties performed.

- Inadequate technological improvement in the manufacturing procedure of the goods.

- The fact that the final product or its large pieces are what planning, controlling, and accounting are focused on (subassemblies).

- The final three characteristics result in a low preparatory cost for the production of new items.

This type of unique production method is typically used in pilot plants that create complex items and specialist systems.

Mass Production

The mass production method has the following features:

- In this production, products are created in massive quantities. It can go upto6-10 thousand pieces per month.

- Usage of distinctive and specialized machinery, apparatus, and technology.

- The placement of workstations reflects how a technical process is developing.

- Specialized jobs only carry out one operation.

- The technological procedure is thoroughly developed.

- Preparing to produce new goods is the process' most expensive step (in comparison with other types of production).

- Planning, rationing, and accounting have as their targets the operations and the details.

- Employees may be less educated.

This type of manufacturing method is typically used to make consumer goods.

Batch (or serial) Manufacturing

The characteristics of a serial production process are as follows:

- Manufacturing carried out in batches and cycled periodically. Every month, there are a few hundred small-cut pieces as well as 2,500–5,000 large-scale pieces.

- Workplaces are grouped based on organizational and technical principles using a variety of basic and specialized tools, attachments, finishing, and measuring equipment.

- Restricted choice of products produced.

- A workspace is reserved for a select few unique actions.

- Average in terms of employee qualifications.

- Detailed technological process development.

- The targets of planning, rationing, and accounting are the units and particulars of the product.

- Costs associated with starting up the manufacture of new items are relatively significant when compared to one type of manufacturing.

Facilities that produce high-end goods and specialized systems that quickly outgrow their original plans frequently use this type of production process.

Various Manufacturing Methods According to the Nature of the Product

Manufacturing processes can be categorized based on the number of goods manufactured in a single production run. The following four production techniques create diverse quantities of goods:

Discrete Manufacturing

As previously discussed, any method that creates single products is referred to as discrete manufacturing. Even though two goods are nearly identical at the end of the same production process, they can still be identified from one another.

Goods or products made by discrete manufacturing are unique and distinguishable from those on the production line before and after them.

After leaving the production line, these goods are offered for sale to customers and businesses as ready-to-use products.

Most discrete manufacturing involves:

a) Mass production oriented with standard pricing

Make-to-Stock Manufacturing

‘Make-to-Stock (MTS) Manufacturing,’ also referred to as ‘Mass production’, is a manufacturing production strategy where a production facility creates products based on anticipated future sales and past consumer behavior.

The finished products are included in the stock or inventory of the business. The stock may be used by the company's distribution division to fulfil customer orders or to transport it to retail locations.

Further, this approach can be successful for companies that manufacture in-demand goods that consumers might buy in huge quantities.

Additionally, it's cost-effective and enables high-output factories to manufacture surplus goods, which could be helpful in periods with lower production.

Consumer goods are frequently produced by companies that rely on make-to-stock manufacturing. It includes personal care items, garments, cars, toys, and food.

Moreover, the manufacturing directors and company executives forecast the potential degree of consumer demand for a certain product using analytics and consumer data from preceding months. They used their projections to set manufacturing quotas.

While a company might develop a few distinct product lines, such limited-edition games or automobiles, uniformity is necessary to increase production efficiency.

b) Custom-oriented with custom pricing

- Make-to-Order (MTO) Manufacturing

Make-to-order (MTO) manufacturing, also referred to as mass customization, is a production process that generates products in response to customer orders or demands.

This method can be used by job shops and other specialized manufacturing facilities to design and produce a new product in response to each customer request.

The MTO model uses standardized goods with predetermined Bills of Materials, much like the Make-to-Stock (MTS) Manufacturing model.

Before starting the manufacturing process, they could work with the customer to produce a prototype or use one that they supply.

Make-to-order manufacturing often takes place in facilities with specialized workspaces that allow an artisan to produce the product from beginning to end rather than using assembly lines.

Make-to-order manufacturing enterprises typically generate specialized goods for other businesses rather than consumer goods. They can reuse concepts and prototypes by producing fewer, more expensive things or by placing several orders for a single, customized item.

This kind of production is common in the creation of commercial printing, industrial equipment, and the building and upkeep of boats.

For instance, a company that manufactures specialized machine parts for industrial or chemical plants would manufacture a filter for a biochemical company. These companies commonly use computer modelling and 3D printers' tools to create customized items.

Ultimately, MTO strategy provides items in response to client requirements as opposed to demand forecasts. Lead times are longer than they would be conventional MTS production.

Assembly-to-order (ATO) Manufacturing

The manufacturing technique known as "assemble-to-order manufacturing," also known as "make-to-assemble manufacturing," combines mass production and customization.

Businesses that employ this production technique usually mass-produce the product's component parts before customizing them in response to consumer requirements.

A limited amount of customization options may be offered to customers, such as the ability to add more features, change a piece's color, or print branding on the finished product.

Furthermore, some companies only offer customization choices for specific products. And others only offer it to customers who buy a certain number of products.

For instance, a company that sells eyewear might offer a range of specifications depending on the parts that the company always has on hand. Online customers can select the base material for the frame, change the color, add accessories like logos, and select the lens type. When the customer pays for the item, the eyewear company's staff can assemble and ship it.

The ATO model is regarded as being particularly adaptable and lean. The manufacturer may offer clients shorter lead times than with the MTO model, despite the fact that it travels more slowly.

Configure-to-order (CTO) Manufacturing

According to the Configure to Order manufacturing process, products are created using the parameters that the customer specifies.

When a corporation employs the CTO model, it gives customers a wide variety of options for product attributes, leading to a sizable number of product versions with different feature combinations.

The CTO strategy allows customers more opportunity to select the specifications for their items, much like the MTO and ATO models do. Businesses can offer mass customization using the CTO approach and still fulfil orders quickly.

Note that the CTO standard product's specs don't vary sufficiently to need assigning separate part numbers to each version. It is possible to begin brand-new projects for orders that are getting more complex, and if the variation from the norm is too big, you can switch to the engineer-to-order mode of production.

Engineer-to-Order (ETO) Manufacturing

Engineer to order construction is used to create complex, highly specialized items. With this approach, products that have never been built before are created, indicating a closer, more creative cooperation with the client.

As opposed to other manufacturing techniques, ETO's process flow is far from being seamless. The ETO model also includes the manufacturing process, which typically results in a longer lead time for order fulfilment than with any other production mode. The entire design process, including testing and implementing changes, specific material procurement procedures, etc., are also included in the ETO model.

In order to give customers goods that are customized to match their specific needs, businesses using the ETO model must retain higher process flexibility than those using the MTO, ATO, or CTO models. Fully customized solutions require additional flexibility in terms of production processes and material sources.

Process Manufacturing

Process manufacturing creates things in large quantities using raw materials such as granules, gases, powders, liquids, grains, emulsions, and grains.

Manufacturing procedures are used to create a variety of products, such as petroleum, concrete, cereals, and beverages.

The capacity to disassemble and break things back down to their individual components while keeping the ability to distinguish distinct pieces of a product from one another is another quality that distinguishes discrete manufacturing from process manufacturing.

Due to the fact that the ingredients blend and cannot be separated, this is not possible in process manufacture.

Process production is split into two categories:

- Process RPT / Batch manufacturing – Process Repeated Manufacturing

- Process Continuous Flow manufacturing – Continuous production

Manufacturing Process Types according to Role of the Process

Depending on their role in the entire process of manufacturing finished items, production processes can be distinguished in the following types. Let’s learn:

Basic Manufacturing Processes

Basic processes serve to provide raw materials the properties of finished items, converting them into finished goods.

In this instance, a partial production process is connected to either the performance of any stage of raw material processing or the fabrication of a finished good's component.

Serving Processes

Serving processes are designed for technical and energy resources, material provision, storage prior to further processing (storage), control (control operations), movement (transport processes), and other purposes.

Auxiliary Manufacturing Processes

The environment for the core manufacturing process to function normally is created by auxiliary operations (making tools for the needs of their production, repairing technological equipment, etc.).

Managerial Processes

The formulation and execution of decisions, the control over and coordination of production progress, the oversight of the precision with which programs are implemented, the analysis and recording of work completed—these are just a few examples of managerial processes that are frequently intertwined with production process development.

Manufacturing Process Types by Automation Level

Following we have discussed manufacturing process types by the amount of automation. Let’s learn:

1. Manual Process

In manual manufacturing processes, automation is not involved at any stage. During this process, facility workers use particular equipment and skills to manufacture each product.

In simple words, manual manufacturing does not require mechanisms, machines, or power tools.

Few companies still carry out all manufacturing by hand. For instance, A small farm that collects honey from beehives kept on the property and puts it in jars is an example of fully manual production.

2. Machine-Manual Process

In order to produce goods, skilled workers use manual power tools during machine-manual processes. These can include equipment like power saws, drills, blowtorches, or other tools that call for training and safety measures.

Worker participation is essential for machine-manual processes, which are completed with the aid of tools and mechanisms.

Job shops typically employ hand machining to create specialized items for their clients. For instance, when creating custom furniture out of reclaimed wood, a carpenter can utilize hand machining to cut, shape, and sand pieces.

3. Machine Processes

Machine processes are performed on machine tools, machines, and mechanisms with a minimum of worker interaction.

4. Semi-automated Processes

A worker controls an automated machine that produces the good in semi-automatic or partially automatic production. Further, the production manager may check the quality of final goods or monitor the machine's speed.

Although, this type of manufacturing process is common in the creation of consumer goods and technological products, where automated robots are able to complete tasks more precisely than humans.

5. Fully automated Processes

In completely automated production, equipment follows computer programs to create things. Automated operational control takes place out in fully automated or complex processes in addition to automated manufacturing.

Some facilities use robotic manufacturing technology, which improves the manufacturing process using the concepts of artificial intelligence and machine learning.

This kind of approach may be used in chemical factories where equipment can handle hazardous materials properly.

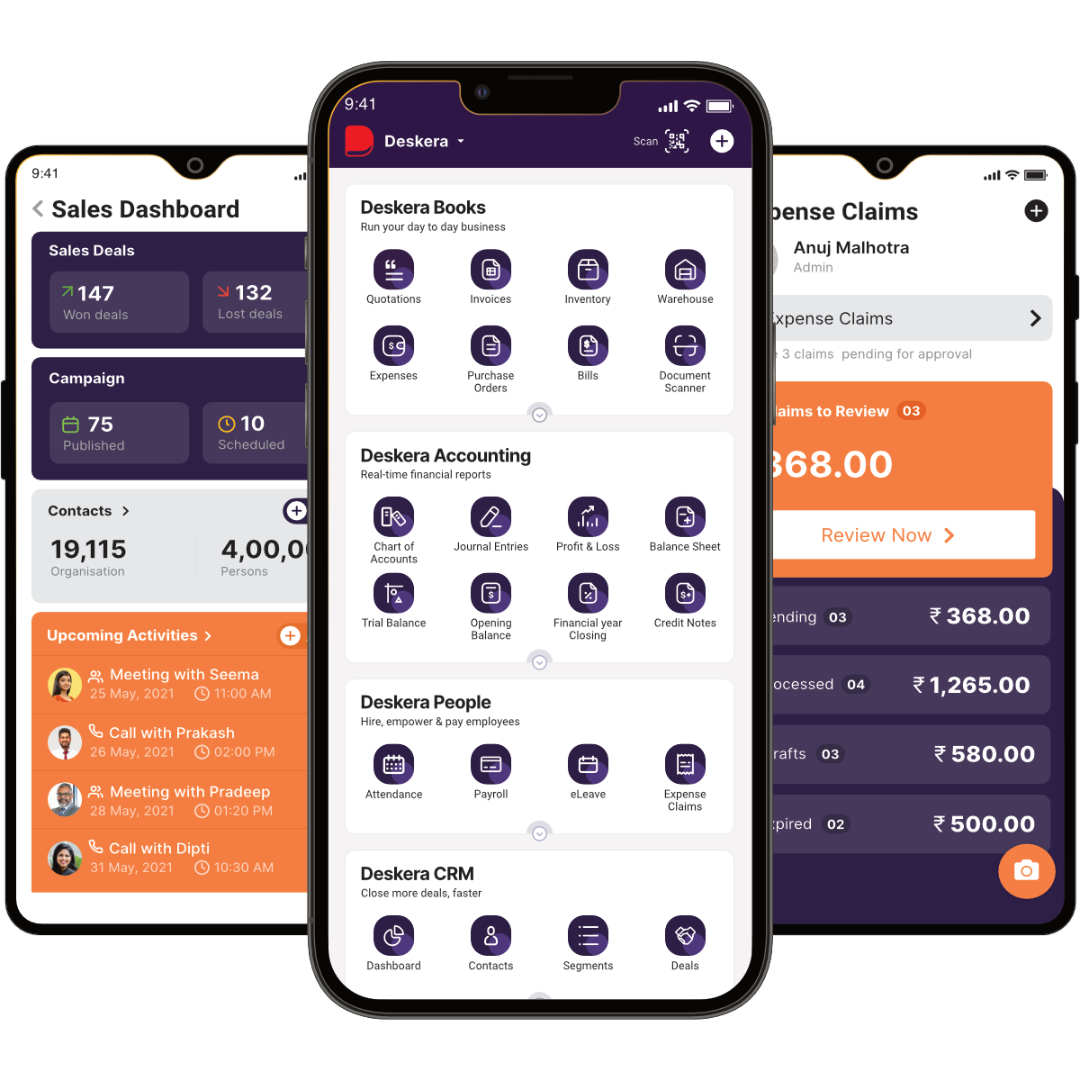

How Deskera Can Assist You?

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real time, as well as streamline a variety of other corporate operations.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more.

This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Key Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- A manufacturing process is defined as a series of steps involving machinery, devices, and labor to convert raw material into finished goods.

- Process manufacturing, often called continuous manufacturing, makes it easier to produce comparable items repeatedly. This also entails continuous manufacturing, similar to repeated manufacturing.

- Batch manufacturing may be useful for businesses that produce a range of goods with the same fundamental machinery. They can adjust their specifications to fulfil a specific requirement without changing their operations or equipment.

- ‘Make-to-Stock Manufacturing,’ also referred to as ‘Mass production’, is a manufacturing production strategy where a production facility creates products based on anticipated future sales and past consumer behavior.

- The manufacturing technique known as "assemble-to-order manufacturing," also known as "make-to-assemble manufacturing," combines mass production and customization.

- In manual manufacturing processes, automation is not involved at any stage. During this process, facility workers use particular equipment and skills to manufacture each product.

Related Articles