Did you know that 14 billion pencils are made around the world each year? Most people don't know about the journey each pencil takes before it ends up in your hand.

Think about it: The wood might come from trees in Oregon. The "lead" (which is actually graphite) could be from Sri Lanka. The metal part might have bits from Africa. The rapeseed oil used in the eraser might have come from Indonesia.

All these materials have to come together to make a pencil, and these materials are collectively called inventory. For pencils, there are three main types of inventory:

- Raw Materials: The basic ingredients like wood and graphite.

- Work-in-Progress: Partly finished pencils, like ones without erasers.

- Finished Goods: Complete pencils ready to be sold.

In this blog, we'll explore these inventory types and how they form the foundation of our manufacturing processes.

Types of Inventory?

When it comes to categorizing inventory, there are primarily four types of inventory that businesses commonly deal with:

Raw Materials Inventory

Raw materials inventory consists of the basic components used in production. It's the building blocks of your products. For a furniture maker, raw materials might include lumber, screws, and fabric. A bakery's raw materials would be flour, sugar, and eggs.

Work-in-Progress (WIP) Inventory

WIP inventory represents items in the production pipeline. These are products that have started their journey but aren't ready for sale. In a car factory, a vehicle frame with attached wheels but no engine would be WIP inventory.

Finished Goods Inventory

These are completed products ready for customer purchase. For a toy company, this would be packaged action figures ready to ship. Retailers mainly deal with finished goods.

Maintenance, Repair, and Operating (MRO) Inventory

MRO items keep operations running smoothly. They're not part of the final product but are vital for business functions. This includes tools, machine parts, cleaning supplies, and office materials.

In addition to these four types of inventory, some businesses may also consider a more granular classification, leading to seven types of inventory:

Safety Stock Inventory

This is the buffer stock that guards against unexpected demand spikes or supply chain hiccups. A grocery store might keep extra milk as safety stock in case of a sudden heatwave. It prevents stockouts but ties up capital.

Decoupling Inventory

Decoupling inventory separates different production stages, allowing for flexibility. In a bottling plant, it might be a stock of empty bottles between the bottle-making and filling processes. This prevents a slowdown in one area from immediately affecting another.

Anticipation Inventory

This inventory is built up for expected future demand. A swimwear company might increase stock before summer, or a retailer might stock up before Black Friday sales.

What is Inventory Management

Inventory management helps businesses balance their stock levels. Too little inventory means lost sales and production stops. Too much ties up money, increases storage costs, and risks product obsolescence.

Effective inventory control requires tools and methods. Some businesses use simple things like Excel or even just write things down on paper. Others go for dedicated programs made just for tracking inventory, commonly known as inventory management systems.

Here's a list of the most commonly used types of inventory systems:

- Periodic Inventory System

- Perpetual Inventory System

- Just-in-Time (JIT) Inventory

- ABC Inventory Management

- First-In, First-Out (FIFO)

- Last-In, First-Out (LIFO)

Types of Inventory Management

Different businesses use various methods to keep track of their stock. Each method has its own strengths.

Businesses combine these approaches with their inventory management software to streamline stock control and prevent shortages or overstock.

Here are some common ways to manage inventory:

- Perpetual Inventory Management - A grocery store using this method would know exactly how many cartons of milk are left after each sale. This helps businesses make quick decisions about when to reorder products.

- Periodic Inventory Management - A small bookstore might use this method, counting books at the end of each month. While not as current as perpetual tracking, it works well for stores with steady stock levels.

- Just-in-Time (JIT) Inventory Management - A car factory using Just-in-Time (JIT) might receive seats just hours before they're installed in vehicles. This method saves storage space and reduces waste but requires careful coordination with suppliers.

- ABC Analysis - A hardware store might put expensive power tools in group A, common hand tools in B, and small items like screws in C. This helps businesses focus more attention on their most valuable items.

- Economic Order Quantity (EOQ) - A T-shirt company might use EOQ to decide how many shirts to order, balancing bulk discounts with storage costs.

Inventory Management with Deskera MRP

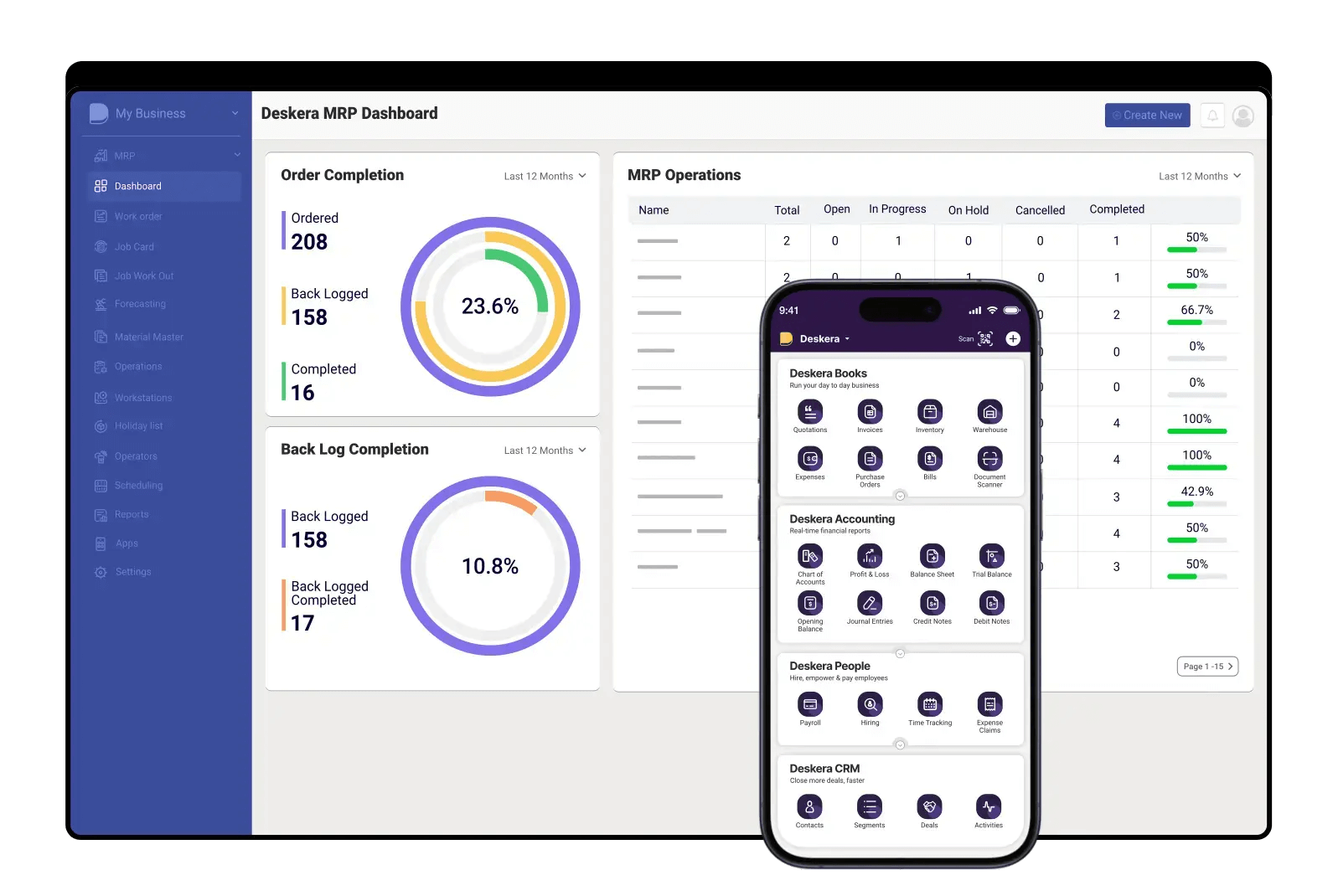

Managing inventory effectively can be a complex and time-consuming task, especially for growing businesses. Deskera MRP offers a comprehensive solution for streamlining inventory management processes.

With Deskera MRP, you can:

- Track inventory levels in real-time across multiple locations

- Set up automated reorder points and purchase orders

- Generate detailed inventory reports and analytics

- Integrate with other business systems for seamless data flow

- Optimize inventory levels based on demand forecasting and historical data

Deskera MRP eliminates manual errors and guesswork, enabling you to make data-driven decisions and improve your bottom line.

Schedule a call with us today, and experience the difference for yourself.

Key Takeaways

To summarize our blog on types of inventory, here are the key takeaways:

- Inventory is a critical asset for businesses, and understanding the different types of inventory is essential for effective management.

- The 4 main types of inventory are raw materials, work-in-progress, finished goods, and MRO inventory.

- A more granular classification may include 7 types of inventory, adding safety stock, decoupling inventory, and anticipation inventory.

- Effective inventory management techniques include perpetual inventory management, periodic inventory management, JIT, ABC analysis, and EOQ.

Related Articles