Inventory control is a critical aspect of the manufacturing industry, as it directly impacts a company's profitability, customer satisfaction, and overall operational efficiency. To ensure success in this highly competitive landscape, manufacturing executives must have a firm grasp of key metrics that allow them to effectively manage and optimize their inventory levels.

Monitoring the right inventory control metrics provides valuable insights into various aspects of the supply chain, including demand forecasting, production planning, order fulfillment, and cash flow management. By tracking these metrics, manufacturing executives can make data-driven decisions, identify areas for improvement, and implement strategies to streamline their inventory management processes.

In this article, we will delve into the top inventory control metrics that every manufacturing executive should monitor. These metrics serve as key performance indicators (KPIs) and act as a compass to steer businesses toward operational excellence. Let’s take a look at the table of content below:

- Meaning of Inventory Control Metrics in Manufacturing

- Importance of Effective Inventory Control in the Manufacturing

- Significance of Monitoring Key Inventory Control Metrics

- Top Inventory Control Metrics Every Manufacturing Executive Should Monitor

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Meaning of Inventory Control Metrics in Manufacturing

Inventory control metrics in manufacturing refer to the key performance indicators (KPIs) used to measure and assess the effectiveness of inventory management processes and strategies.

These metrics provide valuable insights into the efficiency, accuracy, and financial impact of inventory control practices within a manufacturing organization.

By monitoring and analyzing these metrics, manufacturing executives can make data-driven decisions to optimize inventory levels, reduce costs, improve operational efficiency, and enhance customer satisfaction.

Furthermore, these metrics help in evaluating the overall health of the inventory management system and identifying areas for improvement.

Importance of Effective Inventory Control in the Manufacturing

Effective inventory control is crucial for the success of manufacturing companies for several reasons:

Cost Optimization: Inventory represents a significant portion of a manufacturing company's investment. Effective inventory control helps minimize carrying costs, such as warehousing, storage, insurance, and obsolescence expenses. By avoiding excess inventory or stock-outs, companies can optimize their capital allocation and reduce unnecessary expenses.

Improved Customer Service: Maintaining optimal inventory levels ensures timely order fulfillment and reduces the risk of stock-outs. This leads to improved customer satisfaction, increased customer loyalty, and a competitive advantage in the market. Satisfied customers are more likely to become repeat customers and refer the company to others.

Enhanced Operational Efficiency: Efficient inventory control enables streamlined production and supply chain processes. It ensures that materials and components are available when needed, reducing downtime and production delays. This results in smoother operations, improved productivity, and better utilization of resources.

Demand Planning and Forecasting: Effective inventory control requires accurate demand planning and forecasting. By analyzing historical data and market trends, manufacturers can make informed decisions about production quantities, procurement schedules, and lead times. This reduces the risk of overstocking or understocking, minimizing inventory holding costs and optimizing production schedules.

Risk Management: Inventory control helps manage risks associated with supply chain disruptions, market fluctuations, and unexpected events. By maintaining buffer stocks or safety stock levels, manufacturers can mitigate the impact of unforeseen events such as delays in material delivery or sudden changes in customer demand.

Efficient Cash Flow Management: Excessive inventory ties up valuable working capital and limits cash flow. Effective inventory control helps optimize inventory levels, reducing the amount of capital tied up in inventory. This enables manufacturers to allocate their financial resources more efficiently and invest in other areas of the business, such as research and development or marketing initiatives.

Improved Decision-Making: Monitoring inventory control metrics provides manufacturers with valuable data for decision-making. By analyzing metrics such as inventory turnover, stock-out rates, and lead times, executives can identify inefficiencies, bottlenecks, and areas for improvement. This data-driven approach allows for proactive decision-making and the implementation of strategies to optimize inventory management processes.

In summary, effective inventory control in the manufacturing industry is essential for optimizing costs, improving customer service, enhancing operational efficiency, managing risks, and making informed decisions. By implementing robust inventory control practices and monitoring key metrics, manufacturers can achieve better financial performance, competitive advantage, and long-term sustainability in a dynamic market environment.

Significance of Monitoring Key Inventory Control Metrics

Monitoring key inventory control metrics is significant for several reasons:

Performance Evaluation: Inventory control metrics provide a means to evaluate the performance and effectiveness of inventory management strategies and processes. By tracking these metrics over time, manufacturing executives can assess whether their inventory control efforts are meeting objectives and identify areas for improvement.

Data-Driven Decision-Making: Monitoring inventory control metrics provides valuable data and insights that enable data-driven decision-making. Executives can analyze the metrics to identify patterns, trends, and anomalies in inventory levels, turnover, stock-outs, and other factors. This helps them make informed decisions about production planning, procurement, demand forecasting, and inventory optimization.

Early Problem Detection: Tracking inventory control metrics allows for the early detection of potential issues or inefficiencies in inventory management. For example, a sudden increase in stock-out rates may indicate a problem with demand forecasting or procurement processes. By monitoring metrics regularly, executives can identify such issues promptly and take corrective actions before they escalate into larger problems.

Continuous Improvement: Key inventory control metrics serve as benchmarks for continuous improvement initiatives. By setting targets and comparing actual performance against those targets, executives can identify gaps and implement strategies to bridge them. Continuous monitoring of metrics enables a proactive approach to process optimization, inventory reduction, and cost savings.

Performance Comparison: Monitoring inventory control metrics allows for benchmarking and performance comparison against industry standards or competitors. This provides insights into how well the company is performing relative to its peers and helps identify areas where it may be lagging or excelling. Such comparisons can spur innovation, inspire best practices adoption, and drive the company towards industry-leading performance.

Resource Allocation: Effective monitoring of inventory control metrics aids in efficient resource allocation. By understanding the demand patterns, turnover rates, and lead times, executives can allocate resources optimally across different inventory categories, production lines, or warehouses. This prevents over-investment or under-investment in specific areas and ensures a balanced allocation of resources.

Alignment with Organizational Goals: Monitoring key inventory control metrics ensures that inventory management is aligned with the broader organizational goals. By focusing on metrics that directly impact customer satisfaction, cost reduction, or operational efficiency, executives can ensure that inventory control efforts are supporting the overall strategic objectives of the company.

In conclusion, monitoring key inventory control metrics is crucial for evaluating performance, making data-driven decisions, detecting problems early, driving continuous improvement, comparing performance, optimizing resource allocation, and aligning inventory management with organizational goals. By regularly tracking these metrics, manufacturing executives can achieve efficient inventory control, reduce costs, enhance customer satisfaction, and improve overall business performance.

Top Inventory Control Metrics Every Manufacturing Executive Should Monitor

Following, we’ve thoroughly discussed important inventory control metrics that every manufacturer executive must track and monitor. Let’s learn:

I. Inventory Turnover & its Relevance

Inventory turnover is a key metric used to measure the efficiency of inventory management within a manufacturing organization. It indicates how quickly a company sells and replaces its inventory over a given period. The higher the inventory turnover, the more efficiently the company is managing its inventory.

Relevance of Inventory Turnover:

Efficiency: Inventory turnover is a measure of how effectively a company is utilizing its inventory. A high turnover ratio suggests that inventory is being sold quickly, minimizing the amount of capital tied up in unsold goods. On the other hand, a low turnover ratio indicates potential issues such as overstocking, slow-moving inventory, or poor demand forecasting.

Cash Flow: Efficient inventory turnover improves cash flow by reducing the amount of capital invested in inventory. When inventory is sold quickly, the company generates revenue and can reinvest it in other areas of the business. This frees up cash flow for operational expenses, growth initiatives, or investment in new products.

Cost Reduction: High inventory turnover helps minimize holding costs associated with inventory, such as storage, insurance, and obsolescence. By reducing the time goods sit in inventory, the company can save on these expenses, leading to improved profitability.

Calculation of Inventory Turnover Ratio:

The inventory turnover ratio is calculated by dividing the cost of goods sold (COGS) by the average inventory level during a specific period. The formula is as follows:

Interpreting the Results:

High Turnover Ratio: A high inventory turnover ratio (typically above the industry average) indicates efficient inventory management. It suggests that goods are sold quickly, minimizing inventory carrying costs and improving cash flow. However, an extremely high turnover ratio may also indicate inventory shortages or stock-outs, which can impact customer satisfaction.

Low Turnover Ratio: A low inventory turnover ratio (below the industry average) may indicate issues such as overstocking, slow-moving inventory, or poor demand forecasting. It suggests that goods are sitting in inventory for extended periods, tying up capital and increasing holding costs.

Benefits of Monitoring and Improving Inventory Turnover:

Optimal Inventory Levels: By monitoring inventory turnover, manufacturing executives can determine the ideal inventory levels for their specific industry, market conditions, and customer demand. This helps avoid excess inventory, stock-outs, and associated costs.

Improved Cash Flow: Increasing inventory turnover frees up capital that can be reinvested in other areas of the business or used for growth initiatives. It improves cash flow, enhances financial stability, and provides resources for strategic decision-making.

Cost Reduction: Efficient inventory turnover reduces holding costs, including storage, insurance, and obsolescence expenses. By minimizing the time inventory sits idle, companies can reduce these costs, leading to improved profitability.

Demand Forecasting: Monitoring inventory turnover helps identify trends and patterns in customer demand. This data can be used to refine demand forecasting and procurement strategies, ensuring that inventory levels align with actual demand, minimizing shortages, and reducing excess stock.

Customer Satisfaction: Maintaining an optimal inventory turnover ratio helps ensure products are readily available to customers, minimizing stock-outs and improving overall customer satisfaction. Satisfied customers are more likely to remain loyal and recommend the company to others.

In conclusion, monitoring and improving inventory turnover is essential for efficient inventory management. It helps optimize inventory levels, improve cash flow, reduce costs, refine demand forecasting, and enhance customer satisfaction. By consistently monitoring and evaluating this metric, manufacturing executives can make informed decisions to enhance the overall efficiency and profitability of their inventory management processes.

II. Stock-Out Rate and its Impact

Stock-out rate refers to the percentage of times a product or item is unavailable when demanded by customers. It measures the frequency at which a company experiences stock-outs.

Stock-outs can have a significant impact on customer satisfaction and sales:

Customer Satisfaction: Stock-outs frustrate customers who are unable to purchase the desired product, leading to dissatisfaction and potential loss of loyalty. Customers may turn to competitors to fulfill their needs, resulting in negative word-of-mouth and a damaged brand reputation.

Sales and Revenue: Stock-outs directly impact sales and revenue generation. When customers cannot find a desired item, they are likely to postpone their purchase or seek alternative options. This leads to missed sales opportunities, decreased revenue, and potentially lower market share.

Measuring Stock-Out Rate:

To measure the stock-out rate, follow these steps:

Define the time period: Determine the specific period for which you want to measure the stock-out rate (e.g., weekly, monthly, quarterly).

Count stock-out instances: Track the number of times during the defined period when a product is out of stock and cannot be fulfilled to customer demand.

Calculate stock-out rate: Divide the number of stock-out instances by the total demand for the corresponding period and multiply by 100 to get the stock-out rate as a percentage.

Importance of Tracking Stock-Out Rate:

Tracking the stock-out rate is important for the following reasons:

Inventory Optimization: By monitoring the stock-out rate, manufacturers can identify products or SKUs that frequently experience stock-outs. This helps optimize inventory levels by adjusting procurement, production, and replenishment strategies to meet customer demand more effectively.

Customer Satisfaction and Retention: Tracking stock-out rate allows manufacturers to understand which items are most critical to customers and ensure their availability. By minimizing stock-outs, companies can improve customer satisfaction, retain loyal customers, and build long-term relationships.

Demand Forecasting Improvement: Stock-out rate data provides insights into demand patterns and trends. Analyzing this metric helps refine demand forecasting models and better align inventory levels with customer requirements, reducing the likelihood of stock-outs.

Strategies to Minimize Stock Outs and Improve Customer Service:

To minimize stock-outs and enhance customer service, consider the following strategies:

Accurate Demand Forecasting: Implement robust demand forecasting techniques to predict customer demand more accurately. This involves analyzing historical data, market trends, customer behavior, and external factors to anticipate demand fluctuations and adjust inventory levels accordingly.

Inventory Replenishment Policies: Establish efficient inventory replenishment policies, such as setting reorder points and implementing just-in-time (JIT) or vendor-managed inventory (VMI) systems. These strategies help ensure timely replenishment of stock, minimizing the risk of stock-outs.

Safety Stock and Buffer Inventory: Maintain safety stock or buffer inventory levels for critical items with uncertain demand or longer lead times. This acts as a contingency measure, ensuring availability during unexpected spikes in demand or supply disruptions.

Supply Chain Collaboration: Collaborate closely with suppliers, distributors, and other partners in the supply chain to improve communication, visibility, and coordination. This helps in addressing potential supply constraints, reducing lead times, and minimizing the chances of stock-outs.

Real-Time Inventory Monitoring: Implement inventory management systems that provide real-time visibility into inventory levels. This enables proactive monitoring and timely replenishment, reducing the risk of stock-outs and ensuring accurate order fulfillment.

Effective Communication Channels: Establish effective communication channels with customers to keep them informed about stock availability, lead times, and any potential delays. This transparency helps manage customer expectations and minimizes dissatisfaction due to stock-outs.

In conclusion, tracking the stock-out rate is vital to identify and address inventory availability issues that impact customer satisfaction and sales. By implementing strategies to minimize stock-outs, such as accurate demand forecasting, optimized inventory replenishment, and supply chain collaboration, manufacturers can improve customer service, increase sales, and maintain a competitive edge in the market.

III. Cycle Time and its Significance

Cycle time refers to the total time required to complete one cycle of a specific operation or process in manufacturing. It represents the duration from the start to the finish of a task, such as manufacturing a product, processing an order, or completing a production cycle. Furthermore, cycle time is significant in manufacturing operations for several reasons:

Operational Efficiency: Cycle time provides a measure of the efficiency and effectiveness of manufacturing processes. A shorter cycle time indicates that tasks or operations are being performed more quickly, improving overall operational efficiency and throughput.

Productivity: By reducing cycle time, manufacturers can produce more output within a given timeframe. This leads to increased productivity and output capacity, enabling the company to meet higher customer demands and potentially gain a competitive advantage.

Lead Time Reduction: Cycle time directly affects the lead time of a product or order. By minimizing the time taken to complete each cycle, manufacturers can reduce overall lead times, improving customer satisfaction and responsiveness.

Cost Optimization: Shorter cycle times often result in lower costs associated with labor, energy, equipment utilization, and inventory holding. By optimizing cycle time, manufacturers can achieve cost savings and improved profitability.

Measurement of Cycle Time:

To measure cycle time, follow these steps:

Define the specific task or operation: Determine the process or task for which you want to measure the cycle time. For example, it could be the time required to manufacture a specific product or process a customer order.

Start and end time recording: Record the time when the task or operation begins and when it is completed. Ensure that all relevant components of the cycle are considered, such as setup time, processing time, and any additional steps involved.

Calculate cycle time: Subtract the start time from the end time to determine the duration of the cycle. This provides the cycle time for that specific operation or task.

Importance of Optimizing Cycle Time:

Following, we've discussed the importance of optimizing cycle time.Let's learn:

Improved Productivity: By optimizing cycle time, manufacturers can increase productivity by completing more cycles within a given time period. This allows for higher output levels and better utilization of resources, leading to improved overall efficiency.

Reduced Lead Times: Shorter cycle times directly translate to reduced lead times for products or orders. This enables manufacturers to respond more quickly to customer demands, enhance customer satisfaction, and remain competitive in fast-paced markets.

Flexibility and Responsiveness: Optimizing cycle time enhances the agility and responsiveness of manufacturing operations. With shorter cycles, manufacturers can quickly adapt to changing customer needs, market dynamics, and emerging trends.

Cost Reduction: A shorter cycle time reduces the time and resources required to produce each unit or complete each cycle. This can result in cost savings related to labor, energy consumption, equipment usage, and inventory holding costs. It improves cost efficiency and contributes to higher profitability.

Continuous Improvement: Focusing on optimizing cycle time promotes a culture of continuous improvement within the manufacturing organization. By constantly evaluating and finding ways to reduce cycle time, companies can identify inefficiencies, eliminate bottlenecks, and streamline processes.

Quality Control: Shorter cycle times can also improve quality control efforts. With faster cycles, manufacturers have the opportunity to detect and correct errors or defects more promptly, ensuring higher product quality and minimizing the likelihood of rework or customer returns.

In conclusion, cycle time is a crucial metric in manufacturing operations that measures the time required to complete a specific task or operation. By optimizing cycle time, manufacturers can enhance productivity, reduce lead times, improve cost efficiency, and foster a culture of continuous improvement. This results in improved customer satisfaction, increased competitiveness, and better overall performance in the market.

IV. Carrying Costs

Carrying costs, also known as holding costs, are the expenses incurred by a company to hold and maintain inventory over a specific period. These costs have a significant impact on inventory management and overall profitability. Carrying costs include various expenses associated with inventory storage, handling, obsolescence, and financing.

Impact on Inventory Management:

Carrying costs directly affect inventory management in the following ways:

Cost Implications: Carrying costs contribute to the total cost of inventory ownership. They can significantly impact a company's bottom line and profitability. By understanding and managing these costs effectively, companies can optimize their inventory levels and improve financial performance.

Inventory Optimization: By considering carrying costs, companies can determine the optimal level of inventory to hold. Balancing the costs of carrying inventory with customer demand and operational requirements allows for efficient inventory management and cost control.

Inventory Turnover: Carrying costs can impact inventory turnover, which is the frequency at which inventory is sold and replaced. High carrying costs can lead to longer holding times, lower turnover rates, and increased financial risk associated with excess inventory.

Components of Carrying Costs:

Carrying costs consist of several components, including:

Storage Costs: These costs include expenses related to renting or owning warehouse space, utilities, maintenance, security, and insurance. Storage costs are influenced by factors such as the size of the inventory, storage conditions required, and the location of the warehouse.

Handling Costs: These costs encompass expenses associated with moving, sorting, organizing, and managing inventory within the warehouse. This includes labor costs, equipment maintenance, packaging materials, and any other resources required for inventory handling.

Obsolescence Costs: Obsolescence costs arise from inventory that becomes outdated, expired, or no longer in demand. This includes losses due to product spoilage, technological advancements, shifts in customer preferences, or changes in regulations. Obsolescence costs can be significant, especially for industries with rapidly changing products or short product lifecycles.

Financing Costs: Financing costs are the expenses incurred to finance inventory. This includes interest payments on loans or lines of credit used to purchase or carry inventory. The longer inventory is held, the more financing costs accrue, impacting the overall cost of inventory ownership.

Calculation and Tracking of Carrying Costs:

To calculate and track carrying costs, follow these steps:

Determine Cost Components: Identify and quantify the different components of carrying costs specific to your organization, such as storage, handling, obsolescence, and financing costs.

Assign Cost Rates: Assign cost rates to each component. For example, storage costs can be calculated as a monthly or annual rate per square foot of warehouse space. Handling costs can be calculated based on labor hours or cost per unit moved. Obsolescence costs can be estimated based on historical data or industry benchmarks. Financing costs can be calculated based on the interest rate and the average value of inventory carried.

Calculate Total Carrying Costs: Multiply the quantities or values of inventory held by the corresponding cost rates for each component. Sum up the costs for all components to obtain the total carrying costs.

Track and Analyze: Regularly track and analyze carrying costs over time. Compare carrying costs across different inventory categories, locations, or time periods. Identify trends, areas of high cost, and opportunities for cost reduction.

Importance of Cost Reduction:

Cost reduction in carrying costs is essential for several reasons:

Improved Profitability: Reducing carrying costs directly improves the company's profitability. By minimizing expenses associated with storage, handling, obsolescence, and financing, companies can enhance their financial performance and bottom line.

Efficient Capital Allocation: Lower carrying costs free up capital that can be allocated to other areas of the business, such as research and development, marketing, or expansion initiatives. This enables better utilization of financial resources and enhances growth opportunities.

Inventory Optimization: Cost reduction efforts help optimize inventory levels. By reducing carrying costs, companies can maintain optimal inventory quantities, avoid excess stock, and minimize the risk of obsolescence.

Competitive Advantage: Lower carrying costs enable companies to offer more competitive pricing, improve customer service, or invest in product innovation. This strengthens their market position and differentiation from competitors.

Cash Flow Improvement: Cost reduction in carrying costs can positively impact cash flow. With lower costs, companies can generate higher cash inflows and achieve a healthier cash flow position, allowing for better financial stability and flexibility.

In conclusion, carrying costs play a crucial role in inventory management and overall profitability. By understanding the components of carrying costs, accurately calculating them, and tracking them over time, companies can identify areas for cost reduction, optimize inventory levels, and improve their financial performance. Reducing carrying costs enhances capital allocation, competitiveness, and cash flow, leading to more efficient and profitable operations.

V. Order Fill Rate

Order fill rate is a metric that measures the percentage of customer orders that are fulfilled completely and on time. It reflects the efficiency and accuracy of order fulfillment processes within a company. A high order fill rate indicates that a company is effectively meeting customer demand and delivering products as promised. It is an essential measure of customer service and satisfaction.

Importance of Order Fill Rate:

Order fill rate is important for several reasons:

Customer Satisfaction: A high order fill rate ensures that customers receive their desired products in full and on time. This contributes to positive customer experiences, builds trust, and enhances overall customer satisfaction.

Repeat Business and Loyalty: When customers consistently receive their orders without delays or shortages, they are more likely to become repeat customers and develop loyalty towards the brand. A high order fill rate strengthens customer relationships and encourages future purchases.

Competitive Advantage: In today's competitive market, order fill rate can serve as a competitive differentiator. Companies with a reputation for reliable order fulfillment are more likely to attract and retain customers compared to those with lower fill rates.

Inventory Optimization: Monitoring order fill rate helps companies optimize their inventory levels. By analyzing the rate at which orders are fulfilled, companies can adjust their inventory management strategies, such as stock replenishment and demand forecasting, to meet customer demands more accurately and avoid shortages

Calculation and Interpretation of Order Fill Rate:

To calculate the order fill rate, follow these steps:

Define the time period: Determine the specific time period for which you want to measure the order fill rate, such as daily, weekly, or monthly.

Count fulfilled orders: Track the number of customer orders that are fulfilled completely and on time during the defined period.

Count total orders: Calculate the total number of customer orders received during the same period, including both fulfilled and unfulfilled orders.

Calculate order fill rate: Divide the number of fulfilled orders by the total number of orders and multiply by 100 to obtain the order fill rate as a percentage.

Interpretation of order fill rate results:

High Order Fill Rate: A high order fill rate, ideally close to 100%, indicates that the majority of customer orders are being fulfilled completely and on time. Furthermore, this suggests efficient order fulfillment processes and high customer satisfaction levels.

Low Order Fill Rate: A low order fill rate indicates that a significant number of customer orders are not being fulfilled as expected. This can be attributed to stock shortages, inaccurate demand forecasting, inadequate inventory management, or operational inefficiencies. A low fill rate signifies potential customer dissatisfaction and the need for improvement.

Strategies to Improve Order Fill Rate and Enhance Customer Satisfaction:

To improve order fill rate and enhance customer satisfaction, consider the following strategies:

Accurate Demand Forecasting: Implement robust demand forecasting techniques to anticipate customer demand accurately. This involves analyzing historical data, market trends, and customer behavior to forecast demand patterns more effectively.

Optimize Inventory Management: Ensure optimal inventory levels by aligning them with demand forecasts. This includes setting appropriate reorder points, safety stock levels, and implementing inventory replenishment strategies to minimize stockouts and ensure product availability.

Enhance Supply Chain Collaboration: Collaborate closely with suppliers and other partners in the supply chain to improve communication and coordination. This helps in addressing potential supply constraints, reducing lead times, and minimizing order fulfillment delays.

Streamline Order Processing: Streamline and automate order processing procedures to reduce manual errors and improve efficiency. This includes implementing order management systems, barcode scanning technologies, and order tracking mechanisms to enhance accuracy and visibility throughout the fulfillment process.

Efficient Warehouse Operations: Optimize warehouse operations to improve order picking, packing, and shipping processes. Furthermore, implementing efficient storage systems, optimizing layout design, and utilizing appropriate picking strategies can help expedite order fulfillment and minimize errors.

Continuous Improvement: Adopt a culture of continuous improvement by regularly reviewing and analyzing order fill rate data. Identify areas for improvement, such as bottlenecks, process inefficiencies, or system limitations, and implement corrective measures to enhance order fulfillment efficiency.

By implementing these strategies, companies can improve their order fill rate, meet customer expectations, and enhance overall customer satisfaction. A high order-fill rate leads to repeat business, customer loyalty, and a competitive advantage in the market.

VI. Lead Time

Lead time refers to the duration between the initiation of a process, such as placing an order, and the completion of that process, such as the delivery of the ordered goods or services.

In supply chain management, lead time plays a crucial role in planning and managing the flow of materials, products, and information throughout the supply chain. It encompasses various stages, including order processing, production, transportation, and delivery. Lead time is a key metric that impacts customer satisfaction, inventory management, and overall operational efficiency.

Significance of Lead Time in Supply Chain Management:

Lead time is significant in supply chain management for several reasons:

Customer Satisfaction: Lead time directly affects customer satisfaction. Longer lead times can result in delayed deliveries, leading to customer dissatisfaction. By managing and reducing lead times, companies can improve customer service and meet customer expectations for timely delivery.

Inventory Management: Lead time influences inventory management decisions. Longer lead times require companies to carry higher inventory levels to meet customer demand during the lead time period. By reducing lead time, companies can optimize inventory levels, reduce carrying costs, and minimize the risk of stockouts or excess inventory.

Responsiveness: Shorter lead times enable companies to be more responsive to customer demands and market changes. Companies with shorter lead times can quickly adapt to fluctuations in demand, introduce new products faster, and respond to emerging market trends, giving them a competitive advantage.

Operational Efficiency: Managing lead time is crucial for achieving operational efficiency. By reducing lead time, companies can streamline processes, eliminate bottlenecks, and improve the overall flow of materials and information. This leads to increased productivity, reduced costs, and improved resource utilization.

Measurement and Analysis of Lead Time:

To measure and analyze lead time, consider the following steps:

Define the Start and End Points: Identify the specific process or operation for which you want to measure the lead time. Determine the starting point (e.g., order placement) and the ending point (e.g., product delivery).

Collect Data: Gather data on the time taken at each stage of the process, including order processing, production, transportation, and delivery. Track the time spent at each stage and record the total time taken.

Calculate Lead Time: Sum up the time taken at each stage to obtain the total lead time. This provides an understanding of the overall time required for the process to be completed.

Analyze the Results: Analyze the lead time data to identify potential bottlenecks or areas for improvement. Look for stages or processes with longer durations, delays, or inconsistencies. This analysis helps pinpoint specific areas where lead time can be reduced.

Importance of Reducing Lead Time and Techniques to Achieve It:

Reducing lead time offers several benefits and can be achieved through various techniques:

Improved Customer Service: Reduced lead time enhances customer satisfaction by ensuring timely deliveries and meeting customer expectations. Techniques such as process optimization, efficient transportation planning, and effective communication with suppliers can help reduce lead time and improve customer service.

Increased Agility: Shorter lead times enable companies to respond quickly to market changes, customer demands, and unforeseen events. Techniques like lean manufacturing, flexible production systems, and real-time information sharing within the supply chain facilitate agility and reduce lead time.

Lower Inventory Levels: By reducing lead time, companies can operate with lower inventory levels. This reduces holding costs, minimizes the risk of obsolescence, and allows for better inventory turnover. Techniques such as just-in-time (JIT) manufacturing, vendor-managed inventory (VMI), and efficient supply chain coordination can help achieve lower lead times and optimized inventory levels.

Streamlined Processes: Analyzing lead time can uncover bottlenecks or inefficiencies in processes. Techniques like value stream mapping, process reengineering, and automation can be employed to streamline processes, eliminate non-value-added activities, and reduce lead time.

Collaborative Relationships: Building strong relationships with suppliers, manufacturers, and logistics partners is crucial for reducing lead time. Techniques such as vendor collaboration shared forecasting and planning, and information sharing can facilitate better coordination and reduce lead time throughout the supply chain.

In conclusion, lead time is a vital metric in supply chain management that impacts customer satisfaction, inventory management, and operational efficiency. Measuring and analyzing lead time helps identify bottlenecks and areas for improvement. By reducing lead time, companies can enhance customer service, improve responsiveness, achieve operational efficiency, and optimize inventory levels. Implementing techniques like process optimization, lean manufacturing, collaborative relationships, and streamlined communication can help companies effectively reduce lead time and gain a competitive edge.

VII. Dead Stock

Dead stock refers to inventory items that have become obsolete, outdated, or unsellable and are unlikely to be sold in the future. These are products that have low or no demand, have surpassed their expiration dates, or are damaged beyond repair. Deadstock ties up working capital and occupies valuable storage space, resulting in financial losses and reduced profitability for a company.

Impact on Working Capital and Profitability:

Deadstock negatively affects working capital and profitability in the following ways:

Tied-Up Capital: Deadstock represents tied-up capital that could have been utilized elsewhere in the business. Funds invested in dead stock cannot be used for more productive purposes, such as investing in new products, marketing campaigns, or operational improvements. This can lead to reduced cash flow and hinder business growth.

Holding Costs: Dead stock incurs additional holding costs, including storage fees, insurance, and maintenance expenses. These costs further erode profitability and decrease the overall return on investment.

Opportunity Cost: Dead stock represents missed opportunities. Instead of holding unsellable inventory, the company could have invested in more profitable products or services that are in demand. Dead stock prevents the company from capitalizing on new market trends and customer preferences.

Reduced Margins: Dead stock affects overall profitability by reducing profit margins. As companies struggle to sell obsolete inventory, they may be forced to offer significant discounts or engage in clearance sales, resulting in lower selling prices and diminished profit margins.

Identifying and Classifying Dead Stock:

To identify and classify dead stock, consider the following steps:

Sales Analysis: Analyze historical sales data to identify products that have consistently low or no sales over an extended period. Look for items with minimal or declining demand and identify those that are not likely to be sold in the future.

Expiration Dates: Review inventory for items with expired shelf lives, such as perishable goods, cosmetics, or pharmaceuticals. These items may become unsellable and should be classified as dead stock.

Damaged or Defective Products: Identify inventory items that are damaged, defective, or no longer meet quality standards. These items are unlikely to be sold and should be categorized as dead stock.

Technological Obsolescence: Consider products that have become technologically outdated due to advancements in the market. Items that are no longer in demand or have been replaced by newer models should be classified as dead stock.

Strategies to Minimize Dead Stock and Optimize Inventory Levels:

To minimize dead stock and optimize inventory levels, consider the following strategies:

Accurate Demand Forecasting: Implement robust demand forecasting techniques to accurately predict customer demand. By understanding market trends, seasonality, and customer preferences, companies can avoid overstocking and reduce the risk of dead stock.

Regular Inventory Audits: Conduct regular inventory audits to identify slow-moving or obsolete items. This helps to proactively identify dead stock and take appropriate actions, such as offering promotions, liquidating inventory, or discontinuing products.

Effective Inventory Management Systems: Implement advanced inventory management systems that provide real-time visibility into inventory levels, sales data, and demand patterns. Such systems enable better inventory control, timely decision-making, and proactive measures to prevent dead stock situations.

Supplier Collaboration: Collaborate closely with suppliers to optimize inventory levels and manage the supply chain effectively. Build strong relationships with suppliers to improve communication, facilitate timely deliveries, and avoid overstocking situations.

Promotions and Discounts: Consider implementing targeted promotions, discounts, or bundle offers to sell slow-moving inventory and prevent items from becoming dead stock. This helps generate sales and clear out excess inventory.

Donation or Recycling: Explore options for donation or recycling of dead stock items. Donating obsolete products to charitable organizations or recycling materials can provide tax benefits and reduce the financial impact of dead stock.

Continuous Monitoring and Analysis: Continuously monitor inventory performance, sales data, and market trends. Regularly review and analyze inventory reports to identify slow-moving items and take proactive measures to prevent dead stock situations.

By implementing these strategies, companies can minimize dead stock, optimize inventory levels, and improve profitability. Effective inventory management, accurate demand forecasting, supplier collaboration, and proactive decision-making are key to avoiding dead stock and maximizing the financial performance of the business.

VIII. Forecast Accuracy

Accurate demand forecasting plays a critical role in effective inventory management. It helps businesses anticipate customer demand, optimize inventory levels, reduce costs, and enhance customer satisfaction. By accurately predicting future demand, companies can align their production, procurement, and distribution processes to meet customer needs while minimizing inventory holding costs and avoiding stockouts or excess inventory.

Importance of Accurate Demand Forecasting in Inventory Management:

Optimal Inventory Levels: Accurate demand forecasting enables businesses to maintain optimal inventory levels. By understanding future demand patterns, companies can avoid overstocking or understocking situations, reducing carrying costs and minimizing the risk of stockouts.

Cost Reduction: Accurate forecasts help businesses optimize their procurement and production processes, avoiding excessive ordering or overproduction. This leads to cost reduction in areas such as storage, handling, and obsolescence.

Improved Customer Service: Accurate forecasting ensures that businesses have the right products available when customers demand them. This leads to improved customer satisfaction, increased customer loyalty, and a competitive advantage in the market.

Efficient Resource Allocation: Accurate demand forecasts enable businesses to allocate resources effectively. They can plan production schedules, allocate manpower and equipment, and optimize supply chain operations based on anticipated demand, improving overall operational efficiency.

Measuring Forecast Accuracy and Interpreting Results:

Forecast accuracy is measured by comparing the predicted demand with the actual demand. The following methods are commonly used to measure forecast accuracy:

Mean Absolute Percentage Error (MAPE): MAPE measures the average percentage difference between the forecasted values and the actual values. It provides a relative measure of forecast accuracy, enabling comparison across different products or time periods.

Mean Absolute Deviation (MAD): MAD calculates the average absolute difference between the forecasted values and the actual values. It provides a measure of the average forecast error, irrespective of direction.

Tracking Signal: Tracking signal measures the cumulative deviation of forecast errors over time. It helps identify systematic biases in forecasts, such as consistently overestimating or underestimating demand.

Interpreting the results of forecast accuracy measures:

Lower MAPE and MAD values indicate higher forecast accuracy.

A tracking signal close to zero indicates a well-balanced forecast.

Large positive or negative tracking signals suggest a persistent bias in forecasts.

Techniques to Improve Forecast Accuracy and Reduce Forecast Errors:

Historical Data Analysis: Analyze historical sales data and market trends to identify patterns, seasonality, and demand fluctuations. Use statistical techniques, such as moving averages or exponential smoothing, to identify trends and incorporate them into forecasting models.

Collaborative Forecasting: Collaborate with key stakeholders, such as sales teams, marketing, and suppliers, to gather valuable insights and inputs for demand forecasting. Incorporate their expertise and market knowledge into the forecasting process to improve accuracy.

Market Intelligence: Gather external market intelligence, such as industry reports, competitor analysis, and customer surveys, to understand market dynamics and factors influencing demand. Incorporate this information into forecasting models to enhance accuracy.

Data Integration and Automation: Integrate data from various sources, such as sales data, POS systems, customer feedback, and market data, to get a comprehensive view of demand drivers. Automate data collection and analysis processes to reduce human errors and improve efficiency.

Demand Sensing: Implement demand sensing techniques that leverage real-time data, such as point-of-sale data, social media sentiment analysis, and website analytics, to capture demand signals quickly and adjust forecasts accordingly.

Scenario Planning: Conduct scenario planning by considering different what-if scenarios and assessing their impact on demand. This helps anticipate and account for uncertainties, such as seasonality, market fluctuations, or unforeseen events, to improve forecast accuracy.

Continuous Evaluation and Improvement: Continuously evaluate forecast accuracy and analyze forecast errors. Identify the root causes of errors and take corrective actions, such as adjusting forecasting methods, improving data quality, or refining demand planning processes.

By implementing these techniques, businesses can improve forecast accuracy, reduce forecast errors, and enhance overall inventory management. Accurate demand forecasting leads to optimized inventory levels, cost reduction, improved customer service, and efficient resource allocation, ultimately driving business success.

Wrapping Up

In conclusion, accurate demand forecasting is crucial for effective inventory management in any business. It enables companies to optimize inventory levels, reduce costs, improve customer satisfaction, and allocate resources efficiently. By accurately predicting future demand, businesses can align their production, procurement, and distribution processes, leading to improved operational efficiency and increased profitability.

Accurate demand forecasting helps businesses maintain optimal inventory levels, avoiding the risks of overstocking or understocking. This not only reduces carrying costs but also minimizes the likelihood of stockouts, ensuring that products are available when customers demand them. Additionally, accurate forecasts facilitate cost reduction by optimizing procurement and production processes, avoiding excessive ordering or overproduction, and minimizing expenses related to storage, handling, and obsolescence.

Another key benefit of accurate demand forecasting is improved customer service. By accurately predicting demand, businesses can ensure that the right products are available to meet customer needs, leading to higher customer satisfaction, increased loyalty, and a competitive advantage in the market.

Furthermore, accurate demand forecasting enables efficient resource allocation. Businesses can plan production schedules, allocate manpower and equipment, and optimize supply chain operations based on anticipated demand. This leads to improved operational efficiency, better utilization of resources, and ultimately, enhanced profitability.

To achieve accurate demand forecasting, businesses can employ various techniques such as historical data analysis, collaborative forecasting, market intelligence, data integration and automation, demand sensing, scenario planning, and continuous evaluation and improvement. By incorporating these strategies, companies can improve forecast accuracy, reduce forecast errors, and make informed decisions based on reliable predictions of customer demand.

In summary, accurate demand forecasting is essential for effective inventory management. It enables businesses to optimize inventory levels, reduce costs, enhance customer satisfaction, and allocate resources efficiently. By implementing robust forecasting techniques and continuously improving forecast accuracy, companies can gain a competitive edge, improve operational efficiency, and drive long-term success in their respective industries.

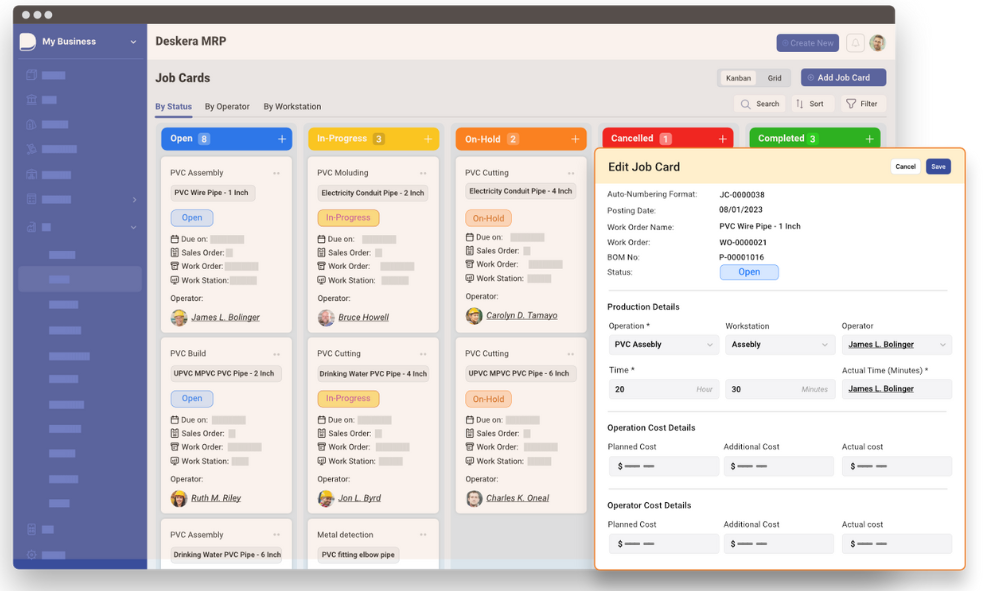

How Deskera Can Assist You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's key features of demand forecasting with Deskera include as follows:

- Establish Demand Forecasting Process

- Automate Data Collection

- Monitor Market Trends

- Analyze Historical Data

- Estimate Future Demand

- Adjust Production Levels

- Manage Supply Chain...and much more!

- Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

- Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

- Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

- Deskera People is a straightforward tool for centralizing your human resource management functions.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Inventory control metrics in manufacturing refer to the key performance indicators (KPIs) used to measure and assess the effectiveness of inventory management processes and strategies.

- Efficient inventory control enables streamlined production and supply chain processes. It ensures that materials and components are available when needed, reducing downtime and production delays. This results in smoother operations, improved productivity, and better utilization of resources.

- Monitoring inventory control metrics provides valuable data and insights that enable data-driven decision making. Executives can analyze the metrics to identify patterns, trends, and anomalies in inventory levels, turnover, stock-outs, and other factors.

- Inventory turnover is a key metric used to measure the efficiency of inventory management within a manufacturing organization. It indicates how quickly a company sells and replaces its inventory over a given period. The higher the inventory turnover, the more efficiently the company is managing its inventory.

- Stock-outs frustrate customers who are unable to purchase the desired product, leading to dissatisfaction and potential loss of loyalty. Customers may turn to competitors to fulfill their needs, resulting in negative word-of-mouth and a damaged brand reputation.

- Collaborate closely with suppliers, distributors, and other partners in the supply chain to improve communication, visibility, and coordination. This helps in addressing potential supply constraints, reducing lead times, and minimizing the chances of stock-outs.

- Cycle time refers to the total time required to complete one cycle of a specific operation or process in manufacturing. It represents the duration from the start to the finish of a task, such as manufacturing a product, processing an order, or completing a production cycle.

Related Articles