In today’s world, food production processes are essential for providing an adequate and safe food supply for the growing global population. The food production process includes a wide range of activities, from farming and harvesting to processing, packaging, and distribution. These processes are essential for meeting the demands of an increasingly sophisticated and diversified food industry.

This article covers the following:

- Understanding the Basics of Food Production

- Understanding Food Safety Regulations

- Utilizing Automated Production Processes

- Developing Processing and Packaging Procedures

- Analyzing Food Production Costs

- Implementing Traceability and Tracking Systems

- Optimizing Food Production Efficiency

- Establishing Food Production Systems

- Monitoring and Controlling Food Production Processes

Understanding the Basics of Food Production

Food production is an essential part of our lives. From growing crops and raising livestock to prepare meals and packaging them for sale, food production is a complex and multifaceted process.

Understanding the basics of food production can provide insight into the industry and help us make more informed decisions when it comes to what we eat. Food production involves a number of steps that are necessary for the safe and efficient production of food.

Growing and harvesting crops, raising livestock, and preparing meals are all part of the process. As food moves from the farm to the table, it goes through a variety of stages. The first step in food production is to grow and harvest crops.

Crops are grown in a variety of ways, from traditional farming and irrigation systems to hydroponic and aeroponic systems. Crops are harvested at the peak of their ripeness and processed for sale.

The next stage in food production is raising livestock. This process involves taking care of animals, providing them with the right nutrients, and ensuring they are healthy and safe. Livestock is then processed for sale in the form of meat, dairy, and eggs. Once the food is harvested and processed, it is ready to be prepared.

This can involve cooking, canning, or freezing the food. Food is then packaged and labeled for sale. Finally, food is transported to its final destination. This can involve shipping food to grocery stores, restaurants, or even directly to consumers.

It’s important to understand the various regulations and safety standards that must be met during the transportation process. Food production is a complex process. It involves a number of different steps and requires careful management to ensure food is safe and of high quality. Understanding the basics of food production can help us make more informed decisions when it comes to the food we eat.

Understanding Food Safety Regulations

Food safety regulations are essential for protecting public health and ensuring the quality of food products. As a result, it’s important for anyone in the food production industry to understand these regulations and how to comply with them.

Food safety regulations are designed to reduce the risk of foodborne illnesses and other health risks that come from consuming contaminated or improperly handled food. These regulations cover a wide range of topics, including proper food handling and storage, sanitation, temperature control, and other processes that can affect the safety of food.

For food producers, understanding food safety regulations means being aware of the rules that must be followed in order to ensure that food is prepared, stored, and served in a safe manner. It also means understanding the various requirements that food production facilities must meet in order to be in compliance with food safety regulations.

This includes having the proper equipment and resources to ensure a safe working environment, as well as ensuring that employees are properly trained and knowledgeable about food safety regulations.

In addition to understanding the rules, food producers should also be aware of the consequences of not following food safety regulations. These can include fines, product recalls, and even criminal charges in some cases.

As a result, it’s important for food producers to be diligent in ensuring that they are following all applicable food safety regulations. By understanding food safety regulations and taking the necessary steps to ensure compliance, food producers can help protect their customers and public health. Additionally, they can help maintain the quality of their products, as well as ensure that their business remains in good standing.

Utilizing Automated Production Processes

In today’s competitive food production industry, successful businesses are looking for ways to increase efficiency and reduce costs. Automated production processes are becoming increasingly popular among food production companies as a way to streamline production and increase profits.

Automation in food production processes is the use of technology to automate manual or labor-intensive processes. Automation can help streamline production by reducing the need for manual labor, increasing the accuracy and consistency of production, and allowing for faster production cycles.

Automated production processes can also help to minimize errors, reduce waste, and increase overall efficiency. Using automated production processes can be beneficial for food production businesses in a variety of ways.

Automated processes can help to reduce the amount of time needed for production, resulting in faster delivery times and improved customer satisfaction. Automated processes can also improve the accuracy of production by ensuring that only the highest quality ingredients are used and that products meet safety and quality standards.

Automated processes can also help to eliminate human error and reduce the possibility of contamination. In addition to reducing labor costs, automation can also help to reduce the cost of materials. Automation can help to reduce inventory and storage costs by eliminating the need to manually order raw materials and store them.

Automation can also reduce energy costs by eliminating the need for manual labor and equipment. Utilizing automated production processes can help food production businesses to increase efficiency, reduce costs, and improve the quality of their products.

Automation can be a great way to reduce labor costs and increase the accuracy of production, resulting in better-quality products and improved customer satisfaction.

Automation can also help to reduce the cost of materials and energy, making production more cost-effective and environmentally friendly. Automated production processes can be a great way for food production companies to stay competitive and increase their profits.

Tips for Streamlining Food Production Processes

Food production is an integral part of running a successful business, as it can help you ensure that your products are of the highest quality and are produced in a timely manner.

However, it can be difficult to know how to streamline your food production processes to ensure that you are producing top-notch products in a cost-effective manner. Here are some tips to help streamline your food production processes:

Implement Automation

Automation can help you streamline your processes and maximize efficiency. This can include automated systems that can accurately track the progress of production and provide real-time updates. Automation can also reduce the need for manual labor, which can help streamline your processes and reduce costs.

Focus on Quality Assurance

Quality assurance should be a top priority in any food production process. Establishing a quality assurance system can help you ensure that your products meet the highest standards and are safe for consumption. Quality assurance processes should include regular testing and inspections, as well as a rigorous documentation process.

Utilize Lean Manufacturing

Lean manufacturing is a process that focuses on identifying and eliminating waste in production processes. By focusing on waste reduction, you can streamline your production process and reduce costs. Lean manufacturing can also help you ensure that your products are of the highest quality.

Implement Standardized Processes

Standardizing your food production processes can help ensure consistency and quality across all of your products. Standardized processes can help reduce errors and ensure that your products are consistently produced in a timely manner.

By implementing these tips, you can streamline your food production processes and ensure that your products are of the highest quality and are produced in a cost-effective manner. With the right processes in place, you can ensure that your products are up to the highest standards and will be enjoyed by your customers.

Developing Processing and Packaging Procedures

As the demand for food production continues to grow, it is important to ensure that the food you produce is safe and of the highest quality. Developing processing and packaging procedures is an important part of food production.

It is also something that should be done with careful consideration and expertise. Processing and packaging procedures are important as they ensure that the food is safe to eat and maintains its quality.

They also help to prevent food spoilage, contamination, and other safety hazards. These procedures should be consistent and well-documented to ensure that the food is safe and of the highest quality.

When developing processing and packaging procedures, it is important to consider the type of food you are producing, its shelf life, and the type of packaging required. You should also consider the temperature, oxygen, and light levels required for proper storage and transportation.

It is also important to have a standard operating procedure for each step of the process. This should include detailed descriptions of each step, as well as safety protocols. It is also important to have a quality control system in place to ensure that the food is of the highest quality and meets all safety standards.

Finally, it is important to ensure that the packaging is appropriate for the food. This means that the packaging should be sturdy and airtight and should be able to protect the food from contamination and spoilage.

Developing processing and packaging procedures can be a complicated process, but it is an essential part of food production. With the right procedures in place, you can help to ensure that your food is safe and of the highest quality.

Analyzing Food Production Costs

When it comes to running a successful business, it’s essential to understand the costs associated with food production. Not only must producers be aware of the cost of their ingredients and materials, but they must also consider the cost of labor, overhead, and other associated costs. To ensure that you make a profit and remain competitive, analyzing and managing your food production costs is paramount.

The first step in analyzing food production costs is to identify all of the costs associated with the production process. This includes things like the cost of ingredients and materials, labor, overhead, shipping, and any other associated costs.

Once you have identified all of the costs, you can begin to evaluate each one. For ingredients and materials, it’s important to compare the cost of different brands and suppliers to see which one offers the best value. Additionally, consider bulk purchasing to reduce costs.

With labor, it’s important to consider the cost of employee salaries, benefits, and other expenses. With overhead, consider the cost of rent, utilities, and other costs. Finally, for shipping, consider the cost of packaging materials, fuel, and other costs.

Once you have identified and evaluated all of the costs associated with food production, you can begin to set benchmarks and create goals for reducing costs. Consider setting goals for reducing the cost of ingredients, labor, overhead, and shipping.

Additionally, consider implementing cost-cutting measures such as automating tasks, streamlining processes, and reducing waste. By implementing cost-cutting measures, regularly analyzing costs, and setting goals for reducing costs, you can ensure that your business remains competitive and profitable.

By taking the time to understand and analyze your food production costs, you’ll have the information you need to make informed decisions and ensure your business’s success.

Establishing Food Production Systems

Establishing a food production system is a major endeavor that requires careful planning and consideration. It involves understanding the needs of the industry, the type of food product desired, the resources and equipment available, and the regulations governing the production of food.

It is important to establish a system that is efficient, cost-effective, and meets the needs of the customer. The first step in establishing a food production system is to understand the needs of the industry.

This includes determining the type of food product desired, the resources and equipment available, and the regulations governing the production of food. It is important to understand the customer’s needs, as well as the current marketplace and trends in the industry.

This information will help to design a production system that meets the customer’s needs and is cost-effective. The next step is to determine the resources and equipment available for the food production system.

This includes both the equipment necessary to produce the desired food product, as well as the personnel necessary to operate the equipment. It is also important to consider the safety and sanitation regulations that must be followed in order to produce a safe and high-quality food product.

Once the resources and equipment have been identified, the production system must be designed. This includes designing the layout of the production area, the production process, and the flow of materials and personnel.

The production process must be designed to be efficient and cost-effective while also meeting the needs of the customer. Finally, the food production system must be regulated. Regulations governing the production of food and safety must be followed in order to produce a safe and high-quality food product.

In addition, there may be local or state regulations that must be followed. It is important to understand these regulations and to comply with them in order to produce a safe and high-quality product.

Establishing a food production system is a major undertaking, but with careful planning and consideration, it is possible to create a system that is efficient, cost-effective and meets the needs of the customer.

It is important to understand the needs of the industry, the resources and equipment available, the regulations governing the production of food, and the customer’s needs in order to create a successful food production system.

Monitoring and Controlling Food Production Processes

Monitoring and controlling food production processes is essential for food safety, quality, and consistency. With the right tools and processes in place, companies can ensure that each batch of food meets its quality standards.

To properly monitor and control food production processes, it's important to understand the various elements involved. Here are a few aspects to consider:

Production Processes

A detailed understanding of the production process is essential. This includes knowing the types of ingredients used, the order of operations, and any potential issues that may arise. Companies should also have a plan in place for dealing with any process-related problems.

Quality Control

Quality control is a must for any food production process. Companies should have a system in place for testing each batch of food to ensure that it meets their quality standards. This includes checking for any contaminants, as well as verifying that the food meets nutritional and safety requirements.

Equipment and Tools

Keeping the equipment used for food production in good working order is essential. Companies should regularly inspect and maintain the equipment to ensure that it meets all applicable safety standards.

Documentation

Accurate and detailed documentation is essential for monitoring and controlling food production processes. Companies should keep records of all ingredients, production processes, and quality control tests. This ensures that any issues can be quickly identified and addressed.

By monitoring and controlling food production processes, companies can ensure that each batch of food meets its quality standards. With the right processes and tools in place, companies can guarantee that their customers receive safe, high-quality food.

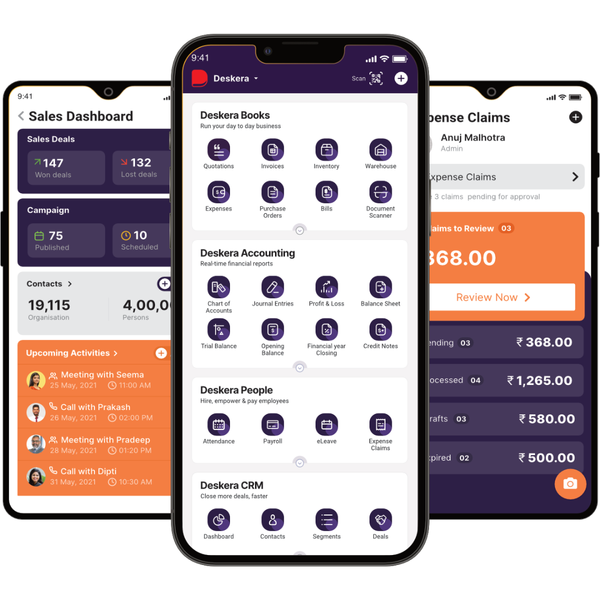

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Understanding the basics of food production can provide insight into the industry and help us make more informed decisions when it comes to what we eat.

- Lean manufacturing is a process that focuses on identifying and eliminating waste in production processes.

- It is important to ensure that the packaging is appropriate for the food.

- Developing processing and packaging procedures can be a complicated process, but it is an essential part of food production. With the right procedures in place, you can help to ensure that your food is safe and of the highest quality.

- Establishing a food production system is a major endeavor that requires careful planning and consideration.

Related Articles: