Recycling has become an increasingly important aspect of many industries, including furniture manufacturing. With concerns about sustainability and environmental impact on the rise, businesses are seeking ways to reduce waste and promote responsible production practices.

Recycling in furniture manufacturing is particularly important as it not only helps reduce waste but also supports the creation of new products from existing materials.

By repurposing materials that might otherwise end up in landfills, furniture manufacturers can reduce their carbon footprint, conserve natural resources, and create a more sustainable future for the industry.

In this article, we will explore the importance of recycling in furniture manufacturing and examine some of the ways in which this practice is being implemented by businesses today. Let's take a look at the table of content below:

- Meaning of Recycling in Furniture Manufacturing

- Importance of Recycling in Furniture Manufacturing

- Environmental Benefits of Recycling in Furniture Manufacturing

- Economic Benefits of Recycling in Furniture Manufacturing

- Social Benefits of Recycling in Furniture Manufacturing

- Challenges of Recycling in Furniture Manufacturing

- Strategies for Effective Recycling in Furniture Manufacturing

- Frequently Asked Questions (FAQs) Associated with Recycling in Furniture Manufacturing

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Meaning of Recycling in Furniture Manufacturing

Recycling in furniture manufacturing refers to the process of taking used or discarded materials and transforming them into new furniture products. This can involve breaking down old furniture and repurposing its components, such as wood, metal, or fabric, into new furniture items.

Furthermore, recycling in furniture manufacturing can also involve using materials that have been recycled or repurposed from other industries. It includes reclaimed wood from old buildings or recycled plastic from discarded products.

The goal of recycling in furniture manufacturing is to reduce waste, conserve natural resources, and minimize the environmental impact of furniture production. By using recycled materials, furniture manufacturers can create sustainable products that are both environmentally friendly and cost-effective.

Importance of Recycling in Furniture Manufacturing

Recycling in furniture manufacturing is important for several reasons:

Environmental Benefits:

Furniture manufacturing can generate a significant amount of waste, and recycling can help reduce the amount of waste that ends up in landfills. By using recycled materials, furniture manufacturers can reduce the need for raw materials and the associated environmental impact of extraction, processing, and transportation.

Cost Savings:

Recycling can help furniture manufacturers reduce their production costs by using recycled materials instead of new ones. This can be especially beneficial for smaller businesses that may not have the resources to purchase new materials at market prices.

Social Responsibility:

Consumers are increasingly aware of environmental issues and are more likely to support companies that prioritize sustainability. By incorporating recycling into their manufacturing processes, furniture companies can demonstrate their commitment to social responsibility and attract environmentally conscious consumers.

Innovation:

Recycling can also inspire creativity and innovation in furniture design. Using recycled materials can challenge designers to think outside of the box and come up with new and innovative ways to create furniture that is both sustainable and aesthetically pleasing.

Ultimately, recycling in furniture manufacturing is essential for reducing waste, conserving natural resources, and promoting sustainability. By incorporating recycling into their production processes, furniture manufacturers can demonstrate their commitment to the environment, reduce their costs, and appeal to environmentally conscious consumers.

Environmental Benefits of Recycling in Furniture Manufacturing

Recycling in furniture manufacturing offers numerous environmental benefits that are critical for mitigating the impact of furniture production on the planet.

As consumer demand for sustainable products continues to increase, furniture manufacturers are increasingly turning to recycling as a way to reduce their environmental footprint and enhance their reputation as socially responsible businesses.

This segment will explore the environmental benefits of recycling in furniture manufacturing, including reducing waste, conserving natural resources, and minimizing the carbon footprint associated with furniture production.

Reduction of Waste in Landfills

Recycling in furniture manufacturing is a crucial strategy for reducing waste in landfills. Furniture is one of the most significant contributors to landfills, with over 9 million tons of furniture waste generated in the US each year. When furniture ends up in landfills, it takes up valuable space and can release harmful chemicals and greenhouse gases into the environment.

By recycling furniture materials, such as wood, metal, and fabric, manufacturers can divert waste from landfills and give old furniture a new lease on life. This not only reduces the volume of waste going to landfills but also reduces the need for new raw materials, which can have a significant environmental impact.

Recycling can also help reduce the amount of energy required to produce new furniture. For example, recycling aluminum requires 95% less energy than producing new aluminum from raw materials. By reducing the energy required for manufacturing, recycling in furniture production can reduce greenhouse gas emissions and mitigate the effects of climate change.

Overall, reducing waste in landfills is a critical environmental benefit of recycling in furniture manufacturing. By diverting furniture waste from landfills and using recycled materials, manufacturers can reduce their environmental impact and contribute to a more sustainable future.

Reduction of Deforestation

Recycling in furniture manufacturing can also help reduce deforestation, which is a significant environmental concern. The furniture industry is one of the largest consumers of wood, with over 2.4 billion cubic meters of wood used globally each year.

Deforestation for the purpose of logging and clearing land for agriculture and other uses has led to the loss of critical habitats, soil erosion, and climate change.

By recycling wood from old furniture and other sources, furniture manufacturers can reduce the demand for new wood and help mitigate deforestation. Using recycled wood can also help preserve the natural habitat of endangered species and reduce soil erosion, which can have a significant impact on local ecosystems.

Moreover, recycling can also help reduce greenhouse gas emissions associated with deforestation. Trees absorb carbon dioxide from the atmosphere and store it in their biomass, making forests a critical carbon sink.

When forests are destroyed, this carbon is released into the atmosphere, contributing to climate change. By reducing the demand for new wood, recycling in furniture manufacturing can help mitigate greenhouse gas emissions and reduce the impact of climate change.

So overall, reducing deforestation is a crucial environmental benefit of recycling in furniture manufacturing. By using recycled wood, furniture manufacturers can reduce their environmental impact, preserve natural habitats, and contribute to a more sustainable future.

Reduction of Greenhouse Gas Emissions

Recycling in furniture manufacturing can help reduce greenhouse gas emissions in several ways.

Firstly, it reduces the need for new raw materials, which require energy for extraction, transportation, and processing. The production of new materials like wood, plastic, and metals often involves significant amounts of energy from fossil fuels, which leads to greenhouse gas emissions.

By using recycled materials, furniture manufacturers can reduce the energy required to produce new materials, resulting in lower greenhouse gas emissions. For example, producing new aluminum from raw materials requires up to 20 times more energy than recycling aluminum, resulting in significant greenhouse gas emissions reduction.

Recycling also reduces the amount of waste going to landfills, which are a significant source of methane, a potent greenhouse gas. When organic materials like wood, fabric, and foam break down in landfills, they release methane, which is 25 times more potent than carbon dioxide in terms of its global warming potential. By diverting these materials from landfills through recycling, furniture manufacturers can help mitigate the impact of methane emissions on climate change.

Furthermore, recycling also reduces the need for incineration, which is another source of greenhouse gas emissions. When furniture waste is burned, it releases carbon dioxide, nitrogen oxides, and other pollutants into the atmosphere. By diverting waste from incineration through recycling, furniture manufacturers can reduce the amount of greenhouse gases emitted into the atmosphere.

In summary, recycling in furniture manufacturing can help reduce greenhouse gas emissions by reducing the energy required to produce new materials, mitigating the impact of methane emissions from landfills, and reducing the need for incineration. By reducing greenhouse gas emissions, furniture manufacturers can contribute to mitigating the impact of climate change and promote a more sustainable future.

Economic Benefits of Recycling in Furniture Manufacturing

Recycling in furniture manufacturing not only offers significant environmental benefits but also economic benefits.

Recycling can reduce costs associated with waste disposal, raw material acquisition, and energy consumption, while also creating new job opportunities and enhancing the reputation of furniture manufacturers.

This segment will explore the economic benefits of recycling in furniture manufacturing, including cost savings, job creation, and improved brand reputation. By embracing recycling, furniture manufacturers can enhance their bottom line while contributing to a more sustainable future.

Cost Savings in Raw Materials

Recycling in furniture manufacturing can lead to significant cost savings in raw materials. By using recycled materials instead of new materials, furniture manufacturers can reduce the amount of money spent on acquiring new resources.

The cost of raw materials can be a significant expense for furniture manufacturers, particularly when prices for new materials are high.

Recycling can help reduce the demand for new materials and stabilize prices, leading to cost savings for manufacturers.

For example, recycled wood can be significantly cheaper than new wood, as it does not require the same amount of processing and transportation.

In addition, the cost of recycled metals can be lower than new metals due to the energy and cost savings associated with recycling.

Furthermore, recycling can help reduce the volatility of raw material prices, which can be affected by factors such as global demand, supply chain disruptions, and natural disasters. By relying on recycled materials, furniture manufacturers can reduce their exposure to these market fluctuations and stabilize their costs.

In addition to cost savings on raw materials, recycling can also reduce the costs associated with waste disposal. By diverting waste from landfills through recycling, furniture manufacturers can reduce the fees associated with waste disposal and potentially earn revenue from the sale of recycled materials.

Overall, the cost savings associated with recycling in furniture manufacturing can enhance a company's financial performance, improving their bottom line and long-term sustainability.

Increased Revenue through the Sale of Recycled Products

Recycling in furniture manufacturing can lead to increased revenue through the sale of recycled products. By recycling waste materials, furniture manufacturers can create new products that are made from recycled materials, such as tables, chairs, and cabinets.

These products can be marketed as eco-friendly, sustainable, and socially responsible, which can appeal to environmentally conscious consumers and businesses.

By offering recycled products, furniture manufacturers can differentiate themselves from competitors and capture a larger share of the growing market for sustainable products.

According to a survey by Nielsen, 73% of global consumers say they would definitely or probably change their consumption habits to reduce their impact on the environment. By providing recycled products, furniture manufacturers can cater to this growing demand and potentially increase their revenue.

Additionally, the sale of recycled materials can generate revenue for furniture manufacturers. Recycling can create a new revenue stream from the sale of materials such as wood, metal, and plastic, which can be sold to other manufacturers or recycling companies. These materials can be used to produce new products, creating a circular economy and reducing waste.

Furthermore, recycling can help reduce the costs associated with waste disposal, which can be a significant expense for furniture manufacturers. By diverting waste from landfills through recycling, manufacturers can reduce the fees associated with waste disposal and potentially earn revenue from the sale of recycled materials.

In summary, recycling in furniture manufacturing can lead to increased revenue through the sale of recycled products, the sale of recycled materials, and cost savings associated with waste disposal. By embracing recycling, furniture manufacturers can capture a share of the growing market for sustainable products, generate new revenue streams, and improve their bottom line.

Job Creation in the Recycling Industry

Recycling in furniture manufacturing can create new job opportunities in the recycling industry. By investing in recycling infrastructure and technology, furniture manufacturers can support job creation and economic development in their communities.

Recycling facilities require workers to sort, process, and transport materials. These workers may include equipment operators, sorters, drivers, and managers. According to the Institute for Local Self-Reliance, recycling creates 10 times more jobs per ton of waste than landfilling. In addition, recycling jobs are often local and cannot be outsourced, contributing to the economic growth and sustainability of communities.

Furthermore, the recycling industry can create jobs in research and development, as new technologies and materials are developed to improve the recycling process. This can include innovations in sorting, processing, and transporting materials, as well as new materials that can be recycled.

By investing in recycling, furniture manufacturers can create new job opportunities and contribute to the economic development of their communities. These jobs can provide stable employment, income, and benefits for workers, helping to improve their quality of life.

In summary, recycling in furniture manufacturing can create new job opportunities in the recycling industry, contributing to economic development and sustainability. By investing in recycling infrastructure and technology, furniture manufacturers can support job creation and enhance the economic competitiveness of their communities.

Social Benefits of Recycling in Furniture Manufacturing

Recycling in furniture manufacturing can also bring social benefits, contributing to a more sustainable and equitable society. In this context, social benefits refer to the positive impact that recycling can have on communities, workers, and consumers. These benefits can include job creation, improved health and safety, and increased access to sustainable products.

Improvement of Community Health

Recycling in furniture manufacturing can lead to the improvement of community health. By reducing the amount of waste that is sent to landfills, recycling can help to prevent pollution and environmental degradation that can have negative impacts on human health.

For example, landfills can release harmful gases such as methane, which can contribute to respiratory problems, headaches, and nausea. Landfills can also contaminate groundwater and surface water, posing a risk to public health. By recycling waste materials, furniture manufacturers can reduce the amount of waste that is sent to landfills, preventing these negative health impacts.

In addition, recycling can reduce the need for the extraction of new resources, which can have negative health impacts on communities located near extraction sites. For example, the extraction of raw materials such as metals and minerals can lead to air and water pollution, which can cause respiratory problems, skin irritation, and other health issues.

Furthermore, recycling can create jobs in the recycling industry, providing stable employment and income for workers. This can have positive impacts on the health and well-being of individuals and their families, as stable employment and income are important factors in maintaining good health.

Overall, recycling in furniture manufacturing can lead to the improvement of community health by reducing the amount of waste sent to landfills, preventing pollution and environmental degradation, and creating new job opportunities.

Education on Sustainable Living

Recycling in furniture manufacturing can also contribute to education on sustainable living. By promoting recycling and the use of recycled materials, furniture manufacturers can help to educate consumers and communities on the importance of sustainable living practices.

For example, furniture manufacturers can include information on the benefits of recycling and the use of recycled materials in their marketing and advertising materials. They can also provide educational resources on their websites and in their showrooms, such as information on the recycling process and the environmental benefits of using recycled materials.

In addition, furniture manufacturers can partner with local schools and community organizations to provide educational programs on recycling and sustainable living practices. This can include tours of recycling facilities, hands-on recycling activities, and information on how to reduce waste and live sustainably.

By promoting education on sustainable living, furniture manufacturers can help to build awareness and understanding of the importance of environmental sustainability. This can lead to behavior changes that support sustainability, such as recycling more and reducing waste, and can ultimately contribute to a more sustainable and equitable society.

In summary, recycling in furniture manufacturing can contribute to education on sustainable living by promoting awareness and understanding of the importance of recycling and the use of recycled materials. By providing educational resources and partnering with local schools and community organizations, furniture manufacturers can help to build a culture of sustainability and contribute to a more sustainable future.

Encouragement of Responsible Consumer Behavior

Recycling in furniture manufacturing can also encourage responsible consumer behavior. By using recycled materials in their products and promoting recycling, furniture manufacturers can encourage consumers to consider the environmental impact of their purchasing decisions.

For example, by using recycled materials in their furniture, manufacturers can demonstrate the viability and durability of recycled materials, and promote the idea that recycled materials can be just as high-quality as virgin materials. This can encourage consumers to seek out products made from recycled materials, and to prioritize sustainability in their purchasing decisions.

In addition, furniture manufacturers can use their marketing and advertising materials to promote responsible consumer behavior, such as by highlighting the environmental benefits of recycling and the use of recycled materials. They can also provide resources to consumers on how to recycle their furniture and other household items, and how to reduce waste and live sustainably.

By promoting responsible consumer behavior, furniture manufacturers can help to shift consumer preferences towards more sustainable products and lifestyles. This can contribute to a more sustainable and equitable society, as well as create new business opportunities for furniture manufacturers who prioritize sustainability.

Ultimately, recycling in furniture manufacturing can encourage responsible consumer behavior by promoting the use of recycled materials, highlighting the environmental benefits of recycling, and providing resources and information to consumers on how to recycle and reduce waste.

Challenges of Recycling in Furniture Manufacturing

Recycling in furniture manufacturing can present several challenges. Some of the key challenges include:

Lack of Infrastructure

One of the biggest challenges facing recycling in furniture manufacturing is the lack of recycling infrastructure. In many regions, the infrastructure for recycling materials is not fully developed or is focused on other materials, such as plastic and paper, leaving furniture manufacturers with limited options for recycling their waste.

This lack of infrastructure can result in several challenges, including:

Limited access to recycling facilities: Furniture manufacturers may have limited access to recycling facilities, which can make it difficult to recycle waste materials. In some cases, manufacturers may need to transport their waste materials over long distances, which can be costly and impact the sustainability of the recycling process.

Limited recycling options: Furniture manufacturers may have limited recycling options, particularly for materials that are difficult to recycle, such as composite materials or mixed materials. This can result in a higher volume of waste that needs to be sent to landfills.

Higher costs: In regions with limited recycling infrastructure, the costs of recycling can be higher, as there may be fewer facilities competing for waste materials. This can impact the profitability of furniture manufacturers who prioritize sustainability.

To address these challenges, furniture manufacturers can work with local and national governments, waste management companies, and other stakeholders to develop and expand recycling infrastructure. This can include building new recycling facilities, investing in research and development to improve recycling technologies, and promoting policies that support recycling and the use of recycled materials.

By working together to build a more robust recycling infrastructure, furniture manufacturers can help to reduce waste, conserve resources, and promote a more sustainable and equitable society.

Limited Availability of Recycled Materials

Another challenge facing recycling in furniture manufacturing is the limited availability of recycled materials. While demand for recycled materials is growing, the supply of high-quality recycled materials can be limited, particularly in regions where recycling infrastructure is less developed.

This limited availability can result in several challenges, including:

Higher costs: Recycled materials can be more expensive than virgin materials, particularly if they need to be transported over long distances or sourced from specialized facilities. This can impact the profitability of furniture manufacturers who prioritize sustainability.

Limited material options: The limited availability of recycled materials can limit the material options available to furniture manufacturers. This can make it difficult to find suitable materials for specific product lines or design specifications.

Lower quality: Recycled materials may not always meet the same quality standards as virgin materials, which can impact the performance and durability of furniture made from recycled materials.

To address these challenges, furniture manufacturers can work to increase the availability of recycled materials by:

Building partnerships with recycling facilities: Furniture manufacturers can build partnerships with local recycling facilities to increase the availability of recycled materials. This can include partnering with facilities to ensure a consistent supply of recycled materials or investing in new recycling infrastructure to increase the availability of specific materials.

Investing in research and development: Furniture manufacturers can invest in research and development to improve the quality and performance of recycled materials. This can include developing new recycling technologies, exploring new material options, and finding ways to improve the durability and performance of recycled materials.

Educating consumers: Furniture manufacturers can also educate consumers on the value and benefits of recycled materials. This can help to increase demand for recycled materials and encourage consumers to seek out sustainable furniture options.

By increasing the availability of recycled materials, furniture manufacturers can reduce waste, conserve resources, and promote a more sustainable and equitable society.

Consumer Behavior

Consumer behavior is another challenge facing recycling in furniture manufacturing. While demand for sustainable and eco-friendly furniture is growing, many consumers still prioritize low prices and convenience over sustainability.

This can result in several challenges, including:

Lower demand for recycled materials: If consumers are not willing to pay more for sustainable furniture, furniture manufacturers may be less likely to invest in recycling and sustainable production practices. This can limit the availability of recycled materials and slow progress towards a more sustainable furniture industry.

Limited consumer awareness: Many consumers may not be aware of the environmental benefits of recycling or the availability of sustainable furniture options. This can limit demand for sustainable furniture and slow progress towards a more sustainable furniture industry.

Confusion over labeling: Consumers may also be confused by labeling and certification systems for sustainable furniture, which can make it difficult to identify and choose sustainable furniture options.

To address these challenges, furniture manufacturers can:

Educate consumers: Furniture manufacturers can educate consumers on the value and benefits of sustainable furniture. This can include marketing campaigns that highlight the environmental benefits of recycling and the availability of sustainable furniture options.

Offer sustainable options at competitive prices: Furniture manufacturers can also offer sustainable furniture options at competitive prices, which can encourage more consumers to choose sustainable options

Work with certification systems: Furniture manufacturers can work with certification systems to develop clear and transparent labeling systems for sustainable furniture. This can make it easier for consumers to identify and choose sustainable furniture options.

By addressing consumer behavior and increasing demand for sustainable furniture options, furniture manufacturers can help to reduce waste, conserve resources, and promote a more sustainable and equitable society.

Strategies for Effective Recycling in Furniture Manufacturing

To overcome the challenges facing recycling in furniture manufacturing, there are several strategies that can be adopted to promote effective recycling and sustainable production practices. These strategies include:

Collaboration between Furniture Manufacturers and Recycling Facilities

Collaboration between furniture manufacturers and recycling facilities is essential for effective recycling in furniture manufacturing. By working together, manufacturers and recycling facilities can increase the availability of recycled materials, reduce waste, and promote a more sustainable and circular economy.

Here are some ways in which furniture manufacturers can collaborate with recycling facilities:

Invest in recycling infrastructure: Furniture manufacturers can work with recycling facilities to invest in recycling infrastructure, such as collection programs, sorting facilities, and processing equipment, to increase the availability of recycled materials.

Design for recyclability: Furniture manufacturers can work with recycling facilities to design products with recyclability in mind, using materials that are easy to disassemble and recycle.

Develop closed-loop systems: Furniture manufacturers can work with recycling facilities to develop closed-loop systems, where products are designed to be recycled and the recycled materials are used to manufacture new products.

Increase transparency: Furniture manufacturers can work with recycling facilities to increase transparency in the recycling process, providing customers with information on the origin and quality of recycled materials used in their products.

Collaborate on research and development: Furniture manufacturers can collaborate with recycling facilities on research and development initiatives, exploring new technologies and techniques for recycling and sustainable production practices.

By collaborating with recycling facilities, furniture manufacturers can promote effective recycling and sustainable production practices, reducing waste, conserving resources, and promoting a more sustainable and equitable society.

Implementation of Recycling Policies

The implementation of recycling policies is critical for promoting effective recycling practices in furniture manufacturing. Recycling policies provide a framework for manufacturers, consumers, and regulators to work together to promote sustainable production and reduce waste. Here are some key elements of effective recycling policies:

Clear goals: Effective recycling policies should have clear goals for reducing waste and promoting sustainable production practices.

Incentives and penalties: Recycling policies can provide incentives for manufacturers and consumers to adopt sustainable practices, such as tax breaks, grants, and rebates. Penalties can also be imposed for non-compliance with recycling regulations.

Infrastructure development: Recycling policies should promote the development of recycling infrastructure, including collection programs, sorting facilities, and processing equipment.

Education and outreach: Recycling policies should promote education and outreach programs to increase public awareness of the benefits of recycling and sustainable production practices.

Collaboration and partnerships: Recycling policies should encourage collaboration and partnerships between manufacturers, consumers, and regulators to promote sustainable production and reduce waste.

By implementing effective recycling policies, furniture manufacturers can promote sustainable production practices, reduce waste, and conserve resources, contributing to a more sustainable and equitable society.

Promotion of Sustainable Consumer Behavior

Promoting sustainable consumer behavior is essential for effective recycling in furniture manufacturing. Consumers play a significant role in driving demand for sustainable products and encouraging manufacturers to adopt sustainable production practices. Here are some strategies for promoting sustainable consumer behavior. Let's learn:

Education and outreach: Education and outreach programs can be used to increase public awareness of the benefits of recycling and sustainable production practices. This can be done through advertising campaigns, social media, and community events.

Product labeling: Product labeling can be used to provide consumers with information on the environmental impact of products, including the materials used, the manufacturing process, and the end-of-life disposal options.

Incentives and rewards: Incentives and rewards can be used to encourage sustainable behavior, such as discounts for recycling, loyalty programs for sustainable products, and rewards for sustainable actions.

Collaborations and partnerships: Collaboration and partnerships between manufacturers, retailers, and consumers can be used to promote sustainable production and consumption practices, such as joint advertising campaigns and product development.

Innovation and technology: Innovation and technology can be used to develop new products and services that promote sustainable behavior, such as smart appliances that conserve energy and recycling apps that help consumers identify recycling options.

By promoting sustainable consumer behavior, furniture manufacturers can increase demand for sustainable products, reduce waste, and promote a more sustainable and equitable society.

Frequently Asked Questions (FAQs) Associated with Recycling in Furniture Manufacturing

Following, we've discussed some frequently asked questions (FAQs) associated with recycling in furniture manufacturing:

Que 1: What types of materials can be recycled in furniture manufacturing?

Ans: Most commonly recycled materials in furniture manufacturing are wood, metal, plastic, glass, and textiles.

Que 2: How can furniture manufacturers ensure that recycled materials are of good quality?

Ans: Furniture manufacturers can work with reputable recycling facilities that follow quality control processes to ensure that recycled materials meet their standards.

Que 3: How can I dispose of furniture that I no longer need?

Ans: Furniture that is in good condition can be donated to charity or sold second-hand. Furniture that is no longer usable can be recycled or disposed of in a landfill.

Que 4: Can recycled materials be used to create high-quality furniture?

Ans: Yes, recycled materials can be used to create high-quality furniture. In fact, many designers are using recycled materials to create innovative and stylish furniture designs.

Que 5: How can I recycle my old furniture?

Ans: There are several options for recycling old furniture, including curbside pickup, drop-off at a recycling facility, or donation to charity. Check with your local recycling programs to see what options are available in your area.

Que 6: Is recycling more expensive than producing new furniture?

Ans: In some cases, recycling can be more expensive than producing new furniture. However, the economic benefits of recycling, such as cost savings in raw materials and increased revenue through the sale of recycled products, can offset these costs over time.

Que 7: How can I as a consumer support sustainable furniture manufacturing?

Ans: As a consumer, you can support sustainable furniture manufacturing by choosing products made from recycled or sustainable materials, supporting companies that have environmentally responsible policies, and disposing of furniture properly through recycling or donation.

Wrapping Up

In conclusion, recycling is a crucial component of furniture manufacturing that cannot be overlooked. By implementing sustainable practices, manufacturers can reduce their environmental impact, conserve natural resources, and ultimately, create a more sustainable future.

Recycling can also help to reduce waste, cut down on energy consumption, and improve the bottom line for businesses. As consumers become more environmentally conscious, demand for sustainable products is likely to grow, making it imperative for furniture manufacturers to prioritize recycling and other eco-friendly practices.

By doing so, they can not only meet consumer expectations but also help to protect the planet for future generations.

How Deskera Can Assist You?

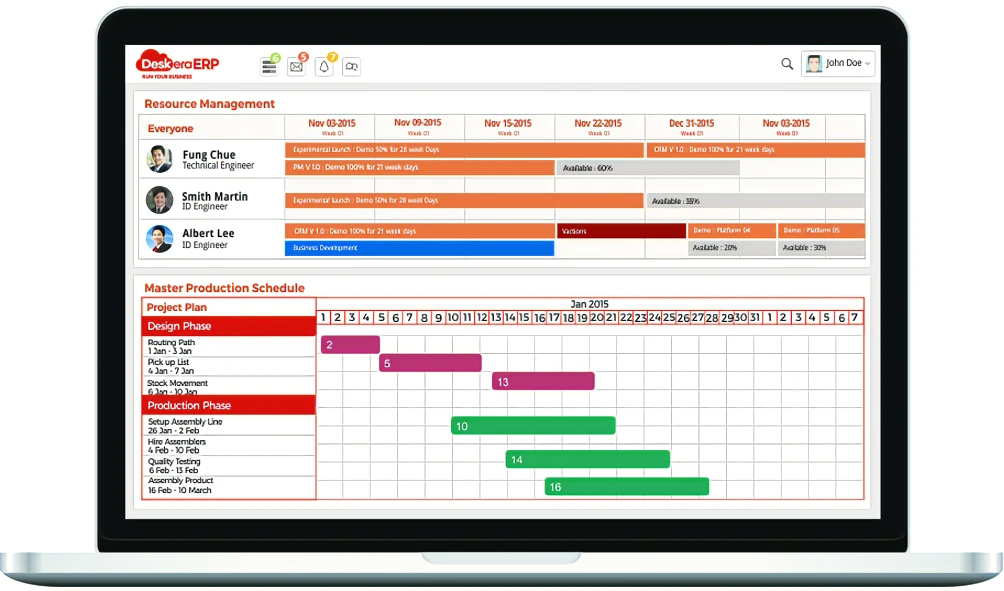

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Recycling in furniture manufacturing can also involve using materials that have been recycled or repurposed from other industries, such as reclaimed wood from old buildings or recycled plastic from discarded products.

- Recycling can help furniture manufacturers reduce their production costs by using recycled materials instead of new ones. This can be especially beneficial for smaller businesses that may not have the resources to purchase new materials at market prices.

- Recycling can help reduce the volatility of raw material prices, which can be affected by factors such as global demand, supply chain disruptions, and natural disasters. By relying on recycled materials, furniture manufacturers can reduce their exposure to these market fluctuations and stabilize their costs.

- Furniture manufacturers can partner with local schools and community organizations to provide educational programs on recycling and sustainable living practices. This can include tours of recycling facilities, hands-on recycling activities, and information on how to reduce waste and live sustainably.

- By promoting responsible consumer behavior, furniture manufacturers can help to shift consumer preferences towards more sustainable products and lifestyles. This can contribute to a more sustainable and equitable society, as well as create new business opportunities for furniture manufacturers who prioritize sustainability.

- Furniture manufacturers can invest in research and development to improve the quality and performance of recycled materials. This can include developing new recycling technologies, exploring new material options, and finding ways to improve the durability and performance of recycled materials.

- Collaboration between furniture manufacturers and recycling facilities is essential for effective recycling in furniture manufacturing. By working together, manufacturers and recycling facilities can increase the availability of recycled materials, reduce waste, and promote a more sustainable and circular economy.

Related Articles