In recent years, the automation of many manufacturing processes has led to increased production efficiencies and cost reductions. Some have even speculated that this automation could lead to a future in which less jobs are necessary, as machines take over tasks that have traditionally been handled by human beings.

In this article, we will explore the impact of automation on chemical manufacturing in detail, examining the advantages and challenges of implementing automation technologies, the specific technologies being used, and case studies of successful implementation.

We will also look to the future, exploring the emerging trends and developments that are shaping the future of automation in chemical manufacturing.

Let’s take a look at the table of content ahead:

- What is Automation in Chemical Manufacturing?

- Impact of Automation on the Chemical Industry

- Advantages of Automation in Chemical Manufacturing

- Automation Technologies Used in Chemical Manufacturing

- Case Studies of Successful Implementation of Automation in Chemical Manufacturing

- Challenges and Limitations of Automation in Chemical Manufacturing

- Future of Automation in Chemical Manufacturing

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

What is Automation in Chemical Manufacturing?

Automation in chemical manufacturing refers to the use of technology to automate various processes and tasks involved in the production of chemicals and related products. This can include the use of advanced sensors, control systems, robotics, artificial intelligence, and other technologies to enhance the efficiency and safety of chemical manufacturing processes.

The goal of automation in chemical manufacturing is to reduce human intervention in repetitive or hazardous tasks, while improving the accuracy, quality, and consistency of the final product. Automation can also provide greater flexibility in manufacturing, allowing for faster and more cost-effective production of a wider range of products.

Automated systems can monitor and control various aspects of chemical manufacturing, including the temperature, pressure, and flow rates of materials throughout the production process. They can also collect and analyze data on various parameters, such as product quality, energy consumption, and waste generation, allowing for better decision-making and optimization of processes.

So, the overall use of automation in chemical manufacturing has significant potential to increase efficiency, productivity, and safety, while reducing costs and environmental impact. As technology continues to evolve, we can expect to see further advancements in automation that will continue to transform the chemical manufacturing industry.

Impact of Automation on the Chemical Industry

The impact of automation on the chemical manufacturing industry has been significant in recent years.

With the increasing availability and affordability of advanced technologies such as sensors, control systems, and robotics, many chemical manufacturers have been able to enhance their operations and improve their bottom line.

One of the main benefits of automation in chemical manufacturing is the ability to increase efficiency and productivity. Automated systems can perform tasks more quickly and accurately than humans, allowing for faster and more cost-effective production. This can result in increased output and revenue, as well as reduced labor costs.

Automation also allows for improved quality control and consistency in the production process. By using sensors and control systems to monitor and adjust various parameters, manufacturers can ensure that their products meet the desired specifications every time. This can help to reduce waste, minimize defects, and improve customer satisfaction.

In addition, automation can enhance safety in chemical manufacturing by reducing the need for human intervention in hazardous or risky tasks. Robots and other automated systems can handle dangerous materials or processes, minimizing the risk of accidents or injuries.

However, the impact of automation on the chemical manufacturing industry is not without its challenges. The initial investment and implementation costs of automation technologies can be significant, and there is often a need for skilled workers to operate and maintain these systems. In addition, technical limitations of automation technologies and resistance to change can also pose obstacles to successful implementation.

Despite these challenges, the overall impact of automation on the chemical manufacturing industry has been positive. As technology continues to evolve and improve, we can expect to see further advancements in automation that will help to transform the industry and drive continued growth and innovation.

Advantages of Automation in Chemical Manufacturing

Following, we’ve discussed some crucial advantages of automation in chemical manufacturing. Let’s discuss:

Automation in chemical manufacturing offers several advantages that can significantly improve the efficiency, productivity, and safety of the industry. Here are some of the key advantages of automation in chemical manufacturing:

Increased Efficiency and Productivity:

Automated systems can perform tasks more quickly and accurately than humans, allowing for faster and more cost-effective production. This can result in increased output and revenue, as well as reduced labor costs. By optimizing processes and reducing downtime, automation can also increase overall efficiency and productivity.

Improved Quality Control and Consistency:

Automation technologies can monitor and adjust various parameters, such as temperature, pressure, and flow rates, to ensure that products meet the desired specifications every time. This can help to reduce waste, minimize defects, and improve customer satisfaction.

Reduced Labor Costs and Increased Safety:

By automating repetitive or hazardous tasks, automation can reduce the need for human intervention in dangerous or risky situations. This can help to minimize the risk of accidents or injuries, while also reducing labor costs and increasing worker safety.

Ability to Collect and Analyze Data for Better Decision-Making:

Automation technologies can collect and analyze data on various parameters, such as product quality, energy consumption, and waste generation, allowing for better decision-making and optimization of processes. This can help to identify areas for improvement and drive continuous improvement in the manufacturing process.

Greater Flexibility in Manufacturing:

Automation can provide greater flexibility in manufacturing, allowing for faster and more cost-effective production of a wider range of products.

Furthermore, automated systems can be programmed to adapt to changes in product demand or variations in raw materials, providing manufacturers with greater flexibility in responding to market conditions.

Overall, the benefits of automation in chemical production can considerably increase the sector's effectiveness, productivity, and safety while also lowering costs and having a less detrimental effect on the environment. As technology continues to evolve, we can expect to see further advancements in automation that will continue to transform the chemical manufacturing industry.

Automation Technologies Used in Chemical Manufacturing

Automation technologies used in chemical manufacturing are diverse and constantly evolving as new technologies emerge. Here are some of the main automation technologies used in chemical manufacturing:

Sensors:

Sensors are widely used in chemical manufacturing to monitor various parameters such as temperature, pressure, flow rates, and chemical composition. These sensors provide data that can be used to optimize processes, improve product quality, and increase efficiency.

Control systems:

Control systems are used to automate the control of various parameters in the production process. These systems use feedback from sensors to make real-time adjustments to parameters such as temperature, pressure, and flow rates. This can help to maintain product quality, improve efficiency, and reduce waste.

Robotics:

Robots are used in chemical manufacturing to automate repetitive or hazardous tasks such as handling and transporting materials. This can help to reduce the risk of accidents or injuries, while also improving efficiency and productivity.

Artificial Intelligence (AI):

AI can be used in chemical manufacturing to automate decision-making processes and optimize production. AI systems can analyze data from sensors and other sources to identify patterns and make predictions about the performance of the production process. This can help to improve efficiency, reduce waste, and increase profitability.

Internet of Things (IoT):

IoT refers to the interconnected network of devices and sensors that are used to collect and share data. In chemical manufacturing, IoT devices can be used to monitor and control various aspects of the production process, providing real-time data and allowing for remote control of equipment.

Machine Learning (ML):

ML is a subset of AI that involves training algorithms to learn from data and make predictions or decisions. In chemical manufacturing, ML can be used to optimize processes and improve product quality by analyzing data from sensors and other sources.

So, the use of automation technologies in chemical manufacturing is essential for improving efficiency, productivity, and safety in the industry. As technology continues to evolve, we can expect to see further advancements in automation that will continue to transform the chemical manufacturing industry.

Case Studies of Successful Implementation of Automation in Chemical Manufacturing

There are numerous examples of successful implementation of automation in chemical manufacturing. Here are a few case studies:

Dow Chemical:

Dow Chemical has implemented a variety of automation technologies, including control systems and sensors, to optimize production and improve efficiency. One example is their use of advanced process control (APC) technology to optimize the production of polyethylene. By using APC to adjust various parameters in real-time, Dow was able to increase production rates by 7%, while reducing energy consumption and improving product quality.

BASF:

BASF has implemented a number of automation technologies, including robotics and artificial intelligence, to improve efficiency and safety in their production processes. One example is their use of robots to handle hazardous materials and perform maintenance tasks in their plants. By automating these tasks, BASF was able to improve safety for workers while also reducing downtime and improving efficiency.

DSM:

DSM, a global chemical company, has implemented an advanced process control system to optimize the production of caprolactam, a key intermediate in the production of nylon. By using real-time data to adjust various parameters in the production process, DSM was able to increase production rates by 5%, while also reducing energy consumption and improving product quality.

Solvay:

Solvay, a global chemical company, has implemented a variety of automation technologies, including sensors and control systems, to optimize production and improve efficiency. One example is their use of real-time data analytics to optimize the production of sodium bicarbonate. By using data analytics to identify areas for improvement and make real-time adjustments to the production process, Solvay was able to increase production rates by 10% while reducing energy consumption.

Overall, these case studies demonstrate the benefits of implementing automation technologies in chemical manufacturing, including improved efficiency, productivity, and safety. By using automation to optimize production processes, chemical manufacturers can reduce costs, increase output, and improve product quality, while also reducing environmental impact and improving worker safety.

Challenges and Limitations of Automation in Chemical Manufacturing

While there are many benefits to implementing automation in chemical manufacturing, there are also several challenges and limitations that must be considered. Some of the key challenges and limitations include:

Initial Cost:

One of the biggest challenges of implementing automation in chemical manufacturing is the high initial cost of the technology. Automation systems can be expensive to install and require significant investment in hardware, software, and infrastructure.

Complexity:

Chemical manufacturing processes can be complex, and implementing automation technologies can be a challenging task. The systems must be designed and programmed to handle a wide range of variables and scenarios, and must be able to operate safely and efficiently in a complex environment.

Maintenance and Support:

Automation systems require regular maintenance and support, which can add to the cost of implementing the technology. Additionally, there is a need for specialized expertise to support and maintain these systems, which can be a challenge for some organizations.

Compatibility:

Automation technologies must be compatible with existing equipment and processes in order to be effective. This can be a challenge for organizations that have a mix of older and newer equipment or processes.

Resistance to Change:

Finally, implementing automation technologies can be a cultural and organizational challenge, as it may require significant changes to processes, workflows, and job responsibilities. Resistance to change can be a major barrier to the successful implementation of automation in some organizations.

Overall, while there are many benefits to implementing automation in chemical manufacturing, it is important to carefully consider these challenges and limitations in order to ensure that the technology is implemented effectively and efficiently. By addressing these challenges proactively, organizations can maximize the benefits of automation while minimizing the risks and costs.

Future of Automation in Chemical Manufacturing

The future of automation in chemical manufacturing is expected to be transformative, with continued advances in technology driving new levels of efficiency, productivity, and sustainability. Some of the key trends and developments that are shaping the future of automation in this industry include:

Artificial Intelligence and Machine Learning:

Artificial intelligence (AI) and machine learning (ML) technologies are increasingly being used to optimize chemical manufacturing processes. These technologies can be used to analyze large amounts of data in real-time, identify patterns and anomalies, and make adjustments to production processes to improve efficiency and reduce waste.

Robotics and Autonomous Systems:

Robotics and autonomous systems are also expected to play a greater role in chemical manufacturing in the future. These systems can be used to perform tasks such as mixing, packaging, and transport, reducing the need for manual labor and improving safety and efficiency.

Advanced Sensors and Analytics:

Advanced sensors and analytics are also becoming increasingly important in chemical manufacturing, allowing for real-time monitoring of production processes and the ability to quickly identify and address any issues that arise.

Sustainability and Environmental Stewardship:

As concerns about sustainability and environmental stewardship continue to grow, automation technologies are being used to help reduce waste, conserve resources, and minimize environmental impact. For example, automated control systems can be used to optimize energy usage and reduce emissions.

Modular and Flexible Production:

Finally, the future of automation in chemical manufacturing is expected to be increasingly modular and flexible, with the ability to quickly and easily reconfigure production processes to meet changing demand and market conditions.

Overall, the future of automation in chemical manufacturing is expected to be characterized by ongoing innovation and advancement, with technology driving new levels of efficiency, productivity, and sustainability. By embracing these trends and investing in automation technologies, chemical manufacturers can position themselves for success in a rapidly evolving industry.

Wrapping Up

Automation is transforming the chemical manufacturing industry, providing new levels of efficiency, productivity, and sustainability.

By leveraging advanced technologies such as robotics, AI, and advanced sensors, chemical manufacturers are able to optimize production processes, reduce waste, and improve product quality while also enhancing worker safety and environmental stewardship.

While there are challenges and limitations to implementing automation in chemical manufacturing, including the high initial cost and complexity of the technology, these challenges can be overcome with careful planning and investment in the right expertise and infrastructure.

Looking to the future, the continued development of automation technologies is expected to drive ongoing innovation and transformation in the industry, with new levels of modularity, flexibility, and efficiency.

By embracing these trends and investing in automation, chemical manufacturers can position themselves for success in a rapidly evolving industry, while also contributing to a more sustainable and prosperous future for all.

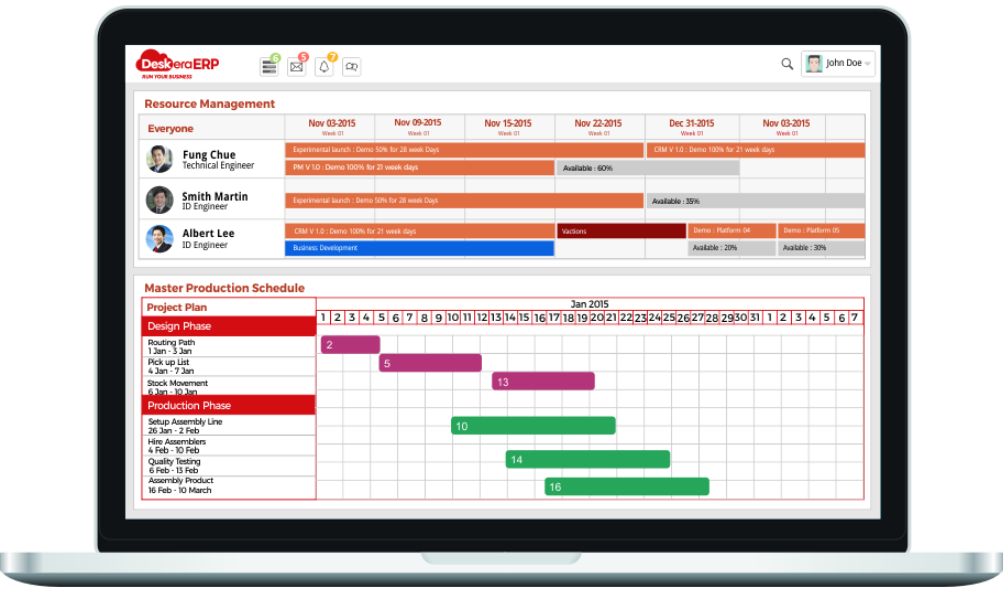

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Automation in chemical manufacturing refers to the use of technology to automate various processes and tasks involved in the production of chemicals and related products. This can include the use of advanced sensors, control systems, robotics, artificial intelligence, and other technologies to enhance the efficiency and safety of chemical manufacturing processes.

- One of the main benefits of automation in chemical manufacturing is the ability to increase efficiency and productivity. Automated systems can perform tasks more quickly and accurately than humans, allowing for faster and more cost-effective production.

- Automation technologies can monitor and adjust various parameters, such as temperature, pressure, and flow rates, to ensure that products meet the desired specifications every time. This can help to reduce waste, minimize defects, and improve customer satisfaction.

- Control systems are used to automate the control of various parameters in the production process. These systems use feedback from sensors to make real-time adjustments to parameters such as temperature, pressure, and flow rates. This can help to maintain product quality, improve efficiency, and reduce waste.

- AI can be used in chemical manufacturing to automate decision-making processes and optimize production. AI systems can analyze data from sensors and other sources to identify patterns and make predictions about the performance of the production process. This can help to improve efficiency, reduce waste, and increase profitability.

- Chemical manufacturing processes can be complex, and implementing automation technologies can be a challenging task. The systems must be designed and programmed to handle a wide range of variables and scenarios, and must be able to operate safely and efficiently in a complex environment.

- As concerns about sustainability and environmental stewardship continue to grow, automation technologies are being used to help reduce waste, conserve resources, and minimize environmental impact.

Related Articles