Leather is a versatile material that has been used for thousands of years for various purposes, from clothing to furniture to accessories. The manufacturing of leather has evolved significantly over time, from the prehistoric use of animal hides to the mass production techniques of the Industrial Revolution.

Today, leather is still a popular material, but the industry faces new challenges related to environmental sustainability and ethical production practices.

This article will provide an overview of the history and significance of leather manufacturing. Let’s take a look at the table of content:

- Leather and its Importance

- History and Significance of Leather Manufacturing: An Overview

- The History of Leather Manufacturing

- Different Types of Leather

- Environmental Concerns

- Future of Leather Manufacturing

- Wrapping Up

- How Deskera Can Assist You?

Leather and its Importance

Leather is a durable and flexible material made from the skin of animals, primarily cattle, but also goats, sheep, pigs, and others.

The process of converting animal skin into leather involves several stages of treatment, including tanning, dyeing, and finishing, which results in a material that is resistant to wear and tear, water, and fire.

Leather has been used by humans for thousands of years, and it remains a valuable material in many industries today, including fashion, footwear, furniture, and automotive.

One of the key reasons for the importance of leather is its durability. Leather products have a long lifespan compared to many other materials, making them an excellent investment for consumers.

For example, a high-quality leather jacket can last for decades, while a cheaper synthetic alternative may only last a few seasons. This durability also makes leather a sustainable material choice, as it can be repaired and reused rather than discarded after a short period of use.

Leather also has a unique aesthetic appeal that many people find attractive. The natural grain of the animal skin gives leather a texture and character that cannot be replicated by synthetic materials.

Additionally, leather can be dyed in a variety of colors and finished in a range of textures, providing endless design possibilities for fashion designers and other manufacturers.

Beyond its aesthetic and functional qualities, leather also plays an important cultural and historical role. Leather has been used by humans for thousands of years, and it has been a symbol of wealth, status, and prestige in many cultures.

Leather also has historical significance in industries such as transportation, where leather harnesses and reins were used to control horses and oxen, and in warfare, where leather armor was worn for protection.

Overall, leather is an important material with a long and rich history. Its durability, aesthetic appeal, and cultural significance have ensured that it remains a valuable material in many industries today.

History and Significance of Leather Manufacturing: An Overview

The history of leather manufacturing dates back thousands of years, with evidence of leather production found in ancient civilizations such as Egypt, Greece, and Rome.

Early leather manufacturing techniques involved using natural materials such as animal brains, urine, and tree bark to tan and preserve animal hides. These early techniques were relatively crude, and the resulting leather was often stiff and prone to decay.

During the Middle Ages, leather manufacturing became more sophisticated, with the development of techniques such as vegetable tanning and the use of alum as a tanning agent. Leather products such as shoes, belts, and bags became more common during this time, and the industry grew in importance.

The Industrial Revolution marked a turning point in the history of leather manufacturing, with the introduction of mechanized processes and the mass production of leather goods.

Furthermore, tanneries and leather factories sprang up in industrial centers, and leather became an important material for a wide range of products, including clothing, furniture, and transportation.

Today, leather manufacturing is a global industry worth billions of dollars, with production centers in countries such as Italy, China, and the United States. Furthermore, leather remains an important material for a wide range of products, and the industry continues to innovate and evolve, with new technologies and materials being developed to make leather production more sustainable and ethical.

The significance of leather manufacturing lies not only in its economic importance but also in its cultural and historical significance. Leather has been an important material in human society for thousands of years, and it has played a role in everything from fashion and art to transportation and warfare.

Today, leather products remain highly prized and sought-after, and the industry continues to be an important part of many economies around the world.

The History of Leather Manufacturing

The history of leather manufacturing dates back thousands of years, with evidence of early leather production found in prehistoric civilizations.

Over time, leather manufacturing techniques became more sophisticated, with the development of processes such as vegetable tanning and the use of alum as a tanning agent.

During the Middle Ages, leather production became more organized, with the establishment of guilds and trade associations. The Industrial Revolution marked a turning point in the history of leather manufacturing, with the introduction of mass production techniques and the development of new tanning processes such as chrome tanning.

Today, leather manufacturing is a global industry worth billions of dollars, with production centers in countries around the world. The industry continues to evolve, with new technologies and materials being developed to make leather production more sustainable and ethical.

Prehistoric Origins of Leather:

The use of animal hides for clothing and shelter dates back to prehistoric times, with evidence of primitive leather manufacturing techniques found in caves and archaeological sites around the world.

Prehistoric people would have used natural materials such as animal brains and urine to tan and preserve animal hides, creating a crude form of leather.

Early Leather Tanning Techniques:

Over time, leather manufacturing techniques became more sophisticated, with the development of techniques such as vegetable tanning and the use of alum as a tanning agent.

Furthermore, vegetable tanning involves soaking animal hides in a solution of vegetable matter, such as oak bark or chestnut wood, which slowly penetrates the hide and makes it more durable. Alum tanning, which involves the use of aluminum salts, produces a lighter, more flexible leather.

Leather Manufacturing in the Middle Ages:

During the Middle Ages, leather manufacturing became more widespread and organized, with the establishment of guilds and trade associations dedicated to the production of leather goods.

Tanneries and leather workshops were often located near water sources, which were used to power the machinery needed for the production process.

Leather products such as shoes, belts, and bags became more common during this time, and the industry grew in importance.

Industrial Revolution and the Mass Production of Leather:

The Industrial Revolution marked a turning point in the history of leather manufacturing, with the introduction of mechanized processes and the mass production of leather goods.

Tanneries and leather factories sprang up in industrial centers, and leather became an important material for a wide range of products, including clothing, furniture, and transportation.

New techniques such as chrome tanning, which uses chromium salts to produce a soft and supple leather, were developed during this time.

Modern-day Leather Manufacturing Techniques:

Today, leather manufacturing is a highly automated and global industry, with production centers in countries around the world. Modern techniques include computer-aided design and cutting, laser etching, and environmentally friendly processes such as water-based tanning.

Leather products are made for a variety of markets, from high-end fashion and luxury goods to affordable mass-produced items. The industry further continues to innovate and evolve, with new technologies and materials being developed to make leather production more sustainable and ethical.

Different Types of Leather

Leather is a versatile material that can be produced in a variety of types and finishes, each with unique characteristics and uses. Here is a more detailed explanation of some of the most common types of leather:

- Full-grain leather:

Full-grain leather is the highest quality and most durable type of leather. It is made from the top layer of the animal hide, which has not been sanded or buffed to remove any imperfections.

As a result, full-grain leather retains its natural markings, such as scars and blemishes, giving it a unique character. Full-grain leather is strong, durable, and resistant to water and stains. It is often used for high-end leather products such as furniture, handbags, and footwear.

- Top-grain leather:

Top-grain leather is made from the top layer of the animal hide, like full-grain leather, but it is sanded and buffed to remove any imperfections. This results in a smoother, more uniform appearance than full-grain leather.

Furthermore, top-grain leather is slightly less durable than full-grain leather but is still strong and resistant to wear and tear. It is often used for upholstery, clothing, and footwear.

- Corrected-grain leather:

Corrected-grain leather is similar to top-grain leather but has a pattern embossed onto it to give it a more uniform appearance. This type of leather is made by sanding and buffing the surface of the leather to remove any imperfections, such as scars or blemishes. It is then stamped with a pattern to give it a consistent look. Corrected-grain leather is often used for furniture, car interiors, and clothing.

- Split leather:

Split leather is made from the lower layers of the animal hide, which are less durable and of lower quality than the top layer. The top layer is used for full-grain and top-grain leather, while the lower layers are used to create split leather. Split leather is often used for products such as suede clothing, shoes, and handbags.

- Nubuck leather:

Nubuck leather is a type of top-grain leather that has been sanded or buffed on the outside to create a velvet-like texture. This gives it a unique look and feel, but also makes it more susceptible to water and stains. Nubuck leather is often used for shoes, handbags, and furniture.

- Aniline leather:

Aniline leather is a type of leather that has been dyed with aniline dye, which penetrates the leather and gives it a transparent finish. This allows the natural grain and markings of the leather to show through, giving it a natural and authentic appearance. Aniline leather is often used for high-end furniture and clothing.

- Patent leather:

Patent leather is a type of leather that has been treated with a high-gloss finish to give it a shiny, reflective surface. It is often used for shoes, handbags, and accessories.

Each type of leather has its own unique characteristics and uses. The choice of leather type depends on the intended use, desired finish, and budget.

Differences and Uses

Following, we've discussed differences and uses of each type of leather:

Full-grain leather:

Differences: It is the highest quality and most durable type of leather. It has a natural look with visible markings, such as scars and blemishes.

Uses: Full-grain leather is often used for high-end leather products such as furniture, handbags, and footwear.

Top-grain leather:

Differences: It is made from the top layer of the animal hide, like full-grain leather, but it is sanded and buffed to remove any imperfections, giving it a more uniform appearance.

Uses: Top-grain leather is often used for upholstery, clothing, and footwear.

Corrected-grain leather:

Differences: It is similar to top-grain leather but has a pattern embossed onto it to give it a more uniform appearance. This type of leather is made by sanding and buffing the surface of the leather to remove any imperfections, such as scars or blemishes.

Uses: Corrected-grain leather is often used for furniture, car interiors, and clothing.

Split leather:

Differences: It is made from the lower layers of the animal hide, which are less durable and of lower quality than the top layer.

Uses: Split leather is often used for products such as suede clothing, shoes, and handbags.

Nubuck leather:

Differences: It is a type of top-grain leather that has been sanded or buffed on the outside to create a velvet-like texture.

Uses: Nubuck leather is often used for shoes, handbags, and furniture.

Aniline leather:

Differences: It is a type of leather that has been dyed with aniline dye, which penetrates the leather and gives it a transparent finish.

Uses: Aniline leather is often used for high-end furniture and clothing.

Patent leather:

Differences: It is a type of leather that has been treated with a high-gloss finish to give it a shiny, reflective surface.

Uses: Patent leather is often used for shoes, handbags, and accessories.

The choice of leather type depends on the intended use, desired finish, and budget. For example, full-grain leather is preferred for high-end products that require durability and a natural look, while corrected-grain leather is often used for more affordable products that require a uniform appearance.

Split leather and nubuck leather are used for products that require a softer and more tactile finish. Aniline leather is used for high-end furniture and clothing that requires a natural and authentic appearance. Patent leather is used for products that require a shiny, reflective surface.

Environmental Concerns

Leather manufacturing is known to have a negative impact on the environment due to the use of chemicals and water in the tanning process.

Here's an overview of the environmental concerns related to leather manufacturing, regulations to address these concerns, and sustainable leather manufacturing practices.

1. Environmental Concerns:

Following, we've discussed crucial environmental concerns associated with leather manufacturing. Let's check:

- Leather manufacturing involves the use of chemicals, such as chromium, that are toxic and can have harmful effects on the environment and human health.

- The tanning process requires a significant amount of water, and the disposal of wastewater can lead to pollution of nearby water sources.

- The leather industry is also a significant contributor to deforestation and greenhouse gas emissions.

2. Environmental Regulations and Measures:

Following, we've discussed crucial environmental regulations and measures associated with leather manufacturing. Let's check:

- Governments around the world have implemented regulations to reduce the impact of leather manufacturing on the environment. For example, the European Union has set strict regulations on the use of chemicals in leather manufacturing.

- Leather manufacturers have also implemented measures to reduce their environmental impact. For example, some tanneries have switched to using vegetable-based tanning methods that use natural materials and require less water and energy.

- Recycling and upcycling of leather waste are also becoming more common, reducing the amount of leather waste that ends up in landfills.

3. Sustainable Leather Manufacturing:

Following, we've discussed important sustainable leather manufacturing. Let's check:

- Sustainable leather manufacturing involves reducing the environmental impact of leather production by using environmentally friendly materials and methods.

- This can include using natural and biodegradable materials in the tanning process, reducing water and energy consumption, and implementing measures to reduce greenhouse gas emissions.

- Sustainable leather manufacturing also involves using animal hides that are a byproduct of the food industry, rather than raising animals specifically for their hides.

Consequently, leather manufacturing has a significant negative impact on the environment, but there are regulations and measures in place to address these concerns. In addition, sustainable leather manufacturing practices can help to reduce the environmental impact of leather production and ensure that it is more environmentally friendly.

Future of Leather Manufacturing

The future of leather manufacturing looks promising as new technologies and sustainable practices emerge. Here are some trends and advancements to watch for:

Emerging Trends and Technologies:

Following, we've discussed the emerging trends and technologies. Let's check:

- Digitalization and automation in leather manufacturing, such as using artificial intelligence and machine learning to optimize production processes and reduce waste.

- Nanotechnology to create new types of leather materials that are more durable, water-resistant, and environmentally friendly.

- 3D printing technology to create custom leather products, reducing waste and increasing production efficiency.

Advancements in Sustainable And Ethical Leather Production:

Following, we've discussed the advancements in sustainable and ethical leather manufacturing. Let's check:

- The use of eco-friendly and biodegradable materials in leather production, such as mushroom or pineapple leather.

- Implementation of circular economy principles, such as upcycling and recycling leather waste into new products.

- More transparent and ethical supply chains, with increased accountability for animal welfare and labor practices.

New Leather Alternatives:

Following, we've discussed the new leather alternatives. Let's check:

- Leather alternatives, such as plant-based materials, are becoming increasingly popular as consumers seek more sustainable and ethical options.

- Other leather alternatives include synthetic materials, such as polyurethane, that mimic the look and feel of leather without the environmental impact.

- The emergence of new leather alternatives could have a significant impact on the traditional leather industry, as consumers shift towards more sustainable and ethical products.

In conclusion, the future of leather manufacturing looks promising with the emergence of new technologies, sustainable practices, and alternatives. The industry is evolving to meet the growing demand for more environmentally friendly and ethical products. As technology and consumer preferences continue to evolve, the leather industry will need to adapt to remain competitive and sustainable.

Wrapping Up

Leather manufacturing has a rich history that dates back to prehistoric times. Today, the industry is facing environmental concerns related to the use of chemicals and water in the tanning process. However, the future of leather manufacturing looks promising, with advancements in sustainable practices, emerging technologies, and the development of new leather alternatives.

The industry is evolving to meet the growing demand for more environmentally friendly and ethical products. Sustainable leather manufacturing practices, such as using eco-friendly materials and implementing circular economy principles, can help to reduce the environmental impact of leather production.

Additionally, advancements in technology and the development of new leather alternatives will allow the industry to remain competitive and sustainable in the years to come.

As consumers become increasingly aware of the environmental impact of their purchasing decisions, the leather industry will need to continue to adapt to meet the changing demands of consumers.

Overall, the future of leather manufacturing looks bright, with the potential for new innovations and sustainable practices that benefit both the environment and the industry.

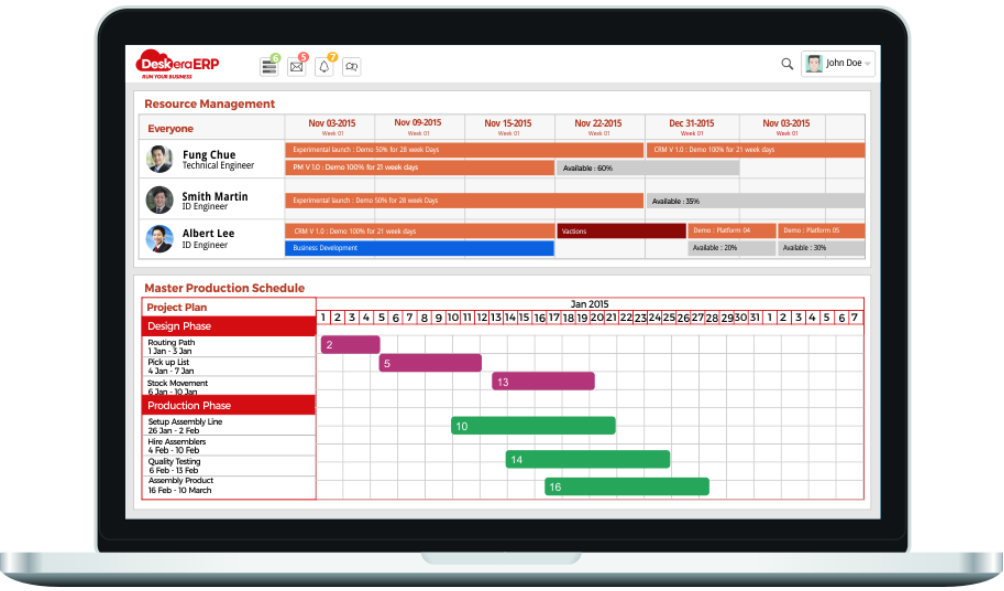

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- During the Middle Ages, leather manufacturing became more sophisticated, with the development of techniques such as vegetable tanning and the use of alum as a tanning agent. Leather products such as shoes, belts, and bags became more common during this time, and the industry grew in importance.

- The significance of leather manufacturing lies not only in its economic importance but also in its cultural and historical significance. Leather has been an important material in human society for thousands of years, and it has played a role in everything from fashion and art to transportation and warfare.

- The use of animal hides for clothing and shelter dates back to prehistoric times, with evidence of primitive leather manufacturing techniques found in caves and archaeological sites around the world.

- Nubuck leather is a type of top-grain leather that has been sanded or buffed on the outside to create a velvet-like texture. This gives it a unique look and feel, but also makes it more susceptible to water and stains. Nubuck leather is often used for shoes, handbags, and furniture.

- Vegetable tanning involves soaking animal hides in a solution of vegetable matter, such as oak bark or chestnut wood, which slowly penetrates the hide and makes it more durable. Alum tanning, which involves the use of aluminum salts, produces a lighter, more flexible leather.

- Tanneries and leather factories sprang up in industrial centers, and leather became an important material for a wide range of products, including clothing, furniture, and transportation.

- Full-grain leather is the highest quality and most durable type of leather. It is made from the top layer of the animal hide, which has not been sanded or buffed to remove any imperfections. As a result, full-grain leather retains its natural markings, such as scars and blemishes, giving it a unique character.

Related Articles