Furniture manufacturing has a rich history dating back to ancient civilizations, where humans used rudimentary tools to create functional and decorative pieces for their homes.

Over the years, furniture design and manufacturing have evolved significantly, with technological advancements and changing societal preferences driving innovation and shaping the industry.

Today, furniture manufacturing is a complex and sophisticated process that involves advanced machinery, sustainable materials, and creative design techniques.

In this article, we will explore the history of furniture manufacturing. Let's take a look at the table of content below:

- Significance of Furniture Manufacturing

- Importance of Understanding the History and Future of Furniture Manufacturing

- History of Furniture Manufacturing: Brief Overview

- Furniture Manufacturing Today

- The Future of Furniture Manufacturing

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Significance of Furniture Manufacturing

Furniture manufacturing is an important industry that plays a significant role in the economy, culture, and society. Furniture manufacturing involves the design, production, and distribution of furniture products, including chairs, tables, sofas, and other household items. Moreover, it has been an essential part of human life for centuries, and its importance extends beyond its practical use.

Furniture manufacturing contributes to the economy by providing jobs and generating revenue through the sale of furniture products. It also supports other industries such as textiles, wood, and metalworking.

Additionally, furniture manufacturing has cultural significance, as furniture designs reflect the trends and styles of a particular period in history. For example, furniture from the Victorian era is known for its ornate and intricate designs, while mid-century modern furniture is characterized by clean lines and simple shapes.

Moreover, furniture is an important part of people's lives as it provides comfort and enhances the aesthetics of a space. Furniture plays a significant role in interior design, and well-designed furniture can transform a living space into a comfortable and welcoming environment. It is also essential for people's health and well-being, as ergonomic furniture can help prevent injuries and promote better posture.

All in all, furniture manufacturing is significant for its economic, cultural, and practical value. It is an industry that has evolved over time, and its impact extends far beyond the production of physical goods.

Importance of Understanding the History and Future of Furniture Manufacturing

Understanding the history and future of furniture manufacturing is essential for several reasons:

- Design inspiration: By studying the history of furniture manufacturing, designers can gain inspiration from past designs and incorporate elements of traditional styles into new and innovative designs.

- Industry trends: Knowledge of the history of furniture manufacturing can help individuals within the industry understand current trends and predict future ones. It allows companies to stay relevant and competitive by adapting to changes in consumer preferences and new technological advancements.

- Environmental impact: Understanding the history of furniture manufacturing can also shed light on the environmental impact of traditional production methods. This knowledge can inspire companies to adopt more sustainable practices and develop eco-friendly furniture.

- Consumer education: Understanding the history of furniture manufacturing allows consumers to make informed decisions about their furniture purchases. By knowing the materials and manufacturing methods used in their furniture, consumers can choose products that align with their values and contribute to a sustainable future.

- Preservation of cultural heritage: The history of furniture manufacturing also has cultural significance, and preserving traditional styles and techniques is important for maintaining cultural heritage.

Eventually, understanding the history and future of furniture manufacturing is crucial for anyone involved in the industry or interested in furniture design and production. It allows individuals to appreciate the craftsmanship and innovation that has shaped the industry while also recognizing the need for sustainable and responsible manufacturing practices in the future.

History of Furniture Manufacturing: Brief Overview

Furniture manufacturing has a long and rich history dating back to ancient civilizations such as Egypt, Greece, and Rome. In these early civilizations, furniture was primarily made from wood, stone, and metal, and was often ornately decorated with intricate carvings and inlays.

During the Middle Ages, furniture manufacturing was mainly done by skilled craftsmen who produced handmade furniture pieces for the wealthy and nobility. The furniture was often made from hardwoods such as oak, and was adorned with elaborate designs and carvings.

In the 18th and 19th centuries, furniture manufacturing saw significant advancements with the rise of the Industrial Revolution. The introduction of new technologies and manufacturing techniques allowed for mass production of furniture, making it more affordable and accessible to the general population.

The development of new materials, such as plywood and plastic, also had a significant impact on furniture manufacturing during the 20th century. These materials allowed for the creation of new and innovative designs that were not possible with traditional materials.

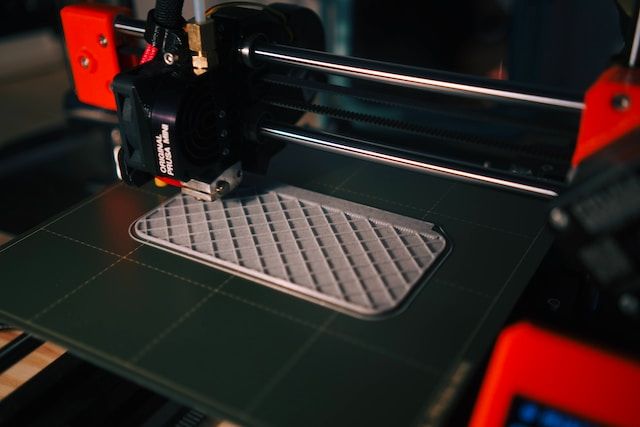

Today, furniture manufacturing continues to evolve with the use of new technologies such as 3D printing and robotics. Sustainability has also become an important aspect of furniture manufacturing, with a growing emphasis on using eco-friendly materials and production methods.

Overall, the history of furniture manufacturing has been marked by innovation, creativity, and the desire to create functional and aesthetically pleasing furniture for people to use and enjoy.

Early Furniture Manufacturing Methods

Early furniture manufacturing methods were primarily handcrafted and involved skilled craftsmen who created one-of-a-kind pieces for wealthy clients.

These craftsmen used traditional tools such as saws, chisels, and planes to shape and carve the wood. Joinery techniques such as mortise and tenon, dovetailing, and tongue and groove were used to join pieces of wood together.

In addition to wood, other materials such as metal, stone, and ivory were also used in furniture manufacturing during this time period. Furniture pieces were often adorned with intricate carvings and inlays, and were decorated with luxurious fabrics and materials.

The production of early furniture was limited to the resources available in the local area, and furniture styles varied depending on the region. For example, in Europe during the Middle Ages, Gothic style furniture was popular, while in Asia, furniture was often characterized by its simplicity and functionality.

Overall, early furniture manufacturing was a highly skilled and labor-intensive process that produced unique and ornate pieces of furniture. While modern manufacturing methods have made furniture production more efficient and affordable, traditional handcrafted furniture remains highly valued and sought after by collectors and enthusiasts.

Advancements in Furniture Manufacturing during the Industrial Revolution

The Industrial Revolution brought significant advancements to furniture manufacturing, transforming it from a craft-based industry to a more industrialized one. New technologies and machines allowed for mass production of furniture, making it more affordable and accessible to a wider population.

One of the key advancements was the development of the steam engine, which allowed for the mechanization of many processes.

The introduction of the circular saw, bandsaw, and planer also made it easier to cut and shape wood. These new machines allowed furniture manufacturers to produce large quantities of furniture quickly and efficiently.

In addition, new materials such as cast iron and steel were used in furniture production, replacing traditional materials like wood and reducing the cost of production. The use of new materials also led to new furniture designs that were not possible with traditional materials.

The introduction of assembly-line production methods further increased efficiency in furniture manufacturing. This allowed for the division of labor, with workers specializing in specific tasks and the production process becoming more streamlined.

Overall, the advancements during the Industrial Revolution had a significant impact on furniture manufacturing, making it more efficient and affordable.

However, it also led to concerns about the quality and durability of furniture as mass-produced pieces were sometimes seen as inferior to handcrafted ones. Nonetheless, the changes brought about by the Industrial Revolution set the stage for further advancements in furniture manufacturing in the following centuries.

The Introduction of Mass Production Techniques and its Impact on Furniture Manufacturing

The introduction of mass production techniques had a significant impact on furniture manufacturing, transforming it from a craft-based industry to a more industrialized one.

Furthermore, mass production techniques made it possible to produce large quantities of furniture quickly and efficiently, making it more affordable and accessible to a wider population.

One of the key mass production techniques was the use of assembly-line production methods. This allowed for the division of labor, with workers specializing in specific tasks, and the production process becoming more streamlined. Assembly-line production methods allowed for faster production times and reduced labor costs.

Another important mass production technique was the use of interchangeable parts. This made it possible to produce identical parts that could be assembled quickly and easily. Interchangeable parts also allowed for easier repair and maintenance of furniture, as parts could be easily replaced if damaged.

The use of new materials such as plywood, plastic, and metal also made it possible to produce new and innovative furniture designs. These materials were often more durable and versatile than traditional materials like wood, allowing for furniture to be designed in new shapes and sizes.

The impact of mass production techniques on furniture manufacturing was significant, as it led to increased efficiency, lower costs, and a wider range of design possibilities.

However, there were also concerns about the quality and durability of furniture produced through mass production techniques. Mass-produced pieces were sometimes seen as inferior to handcrafted ones, and there were concerns about the environmental impact of mass production methods.

Overall, the introduction of mass production techniques revolutionized furniture manufacturing, making it more accessible and affordable for the general population. However, it also raised important questions about quality, sustainability, and the role of traditional craftsmanship in the production of furniture.

The Development of New Materials and Technologies

The development of new materials and technologies has had a significant impact on furniture manufacturing, allowing for new and innovative designs to be created, and improving the efficiency of production methods.

One of the most significant developments in recent years has been the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This has revolutionized the design process, allowing designers to create intricate and complex furniture designs using 3D modeling software. CAM software can also be used to control machines and robots, improving the precision and efficiency of production.

New materials have also had a significant impact on furniture manufacturing. For example, engineered wood products such as plywood and particleboard have replaced solid wood in many furniture designs, as they are more affordable and versatile. Metal and plastic materials have also been used to create new and innovative furniture designs.

In addition, advancements in textile technology have led to the development of new fabrics and materials that are more durable, comfortable, and environmentally friendly. These new materials have been used to create upholstered furniture that is more resistant to wear and tear and easier to clean.

The development of new materials and technologies has led to new design possibilities and more efficient production methods. However, it has also raised important questions about sustainability, as some materials used in furniture production may not be environmentally friendly. As a result, there has been a growing interest in sustainable and eco-friendly furniture manufacturing methods and materials.

Overall, the development of new materials and technologies has had a significant impact on furniture manufacturing, allowing for new and innovative designs to be created, and improving the efficiency of production methods. However, it is important to consider the environmental impact of these developments and to prioritize sustainable and eco-friendly manufacturing practices.

Furniture Manufacturing Today

Following, we've discussed about current manufacturing methods and techniques, impact of technology on furniture manufacturing, and globalization impact on the furniture industry. Let's dive in:

Current Manufacturing Methods and Techniques

Current furniture manufacturing methods and techniques vary depending on the manufacturer and the type of furniture being produced. However, there are some common methods and techniques used in modern furniture manufacturing:

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): As mentioned earlier, CAD and CAM software are used to design and manufacture furniture. These technologies allow for precise measurements and detailed designs that can be quickly and easily modified.

CNC Machines: Computer Numerical Control (CNC) machines are used to cut and shape materials such as wood, metal, and plastic. These machines can be programmed to create precise cuts and shapes, making the manufacturing process more efficient and accurate.

Laser Cutting: Laser cutting technology is often used to cut and engrave materials like wood and metal. This method is more precise than traditional cutting methods and can create intricate designs.

3D Printing: 3D printing technology is used to create prototypes and small production runs of furniture. This method allows for more precise and detailed designs to be created quickly and at a lower cost.

Lean Manufacturing: Lean manufacturing principles are often used in furniture manufacturing to reduce waste and improve efficiency. This involves optimizing the manufacturing process to reduce the amount of time, energy, and materials used.

Sustainable Manufacturing: There is a growing trend towards sustainable furniture manufacturing, which involves using eco-friendly materials, reducing waste, and minimizing the environmental impact of the manufacturing process.

Overall, modern furniture manufacturing methods and techniques are focused on precision, efficiency, and sustainability. The use of new technologies and materials allows for more complex designs and faster production times while reducing waste and environmental impact.

The Impact of Technology on Furniture Manufacturing

Technology has had a significant impact on furniture manufacturing in recent years, transforming the industry and changing the way furniture is designed, manufactured, and sold. Here are some of the ways technology has impacted furniture manufacturing:

- Design: Technology has revolutionized the design process, allowing designers to create more complex and innovative designs using computer-aided design (CAD) software. These designs can be modified quickly and easily, and shared with manufacturers around the world.

- Manufacturing: The use of technology in manufacturing has made the production process faster, more efficient, and more accurate. Machines like CNC routers, laser cutters, and 3D printers can create precise cuts and shapes, reducing waste and improving the quality of the finished product.

- Distribution: Technology has made it easier for manufacturers to sell their products directly to consumers through online platforms, cutting out the need for middlemen like retailers. This has led to lower prices for consumers and increased competition in the marketplace.

- Sustainability: Technology has also had a positive impact on sustainability in furniture manufacturing. Advances in materials and manufacturing processes have made it possible to create furniture that is more eco-friendly and sustainable, reducing waste and minimizing the environmental impact of production.

- Customer Experience: Technology has also improved the customer experience in furniture manufacturing. Online shopping platforms and augmented reality tools allow customers to see and experience furniture in their own homes before making a purchase, improving the accuracy of the decision-making process.

Ultimately, technology has had a transformative impact on furniture manufacturing, making it more efficient, sustainable, and accessible to a wider range of consumers. The use of new materials and technologies has opened up new design possibilities and improved the quality of the finished product, while online platforms and digital tools have made it easier for consumers to purchase furniture and engage with manufacturers.

Globalization and Its Impact on the Industry

Globalization has had a significant impact on the furniture manufacturing industry, transforming the way furniture is designed, manufactured, and sold. Here are some of the ways globalization has impacted the industry:

- Offshoring: Many furniture manufacturers have moved their production facilities to countries where labor is cheaper, such as China and Vietnam. This has led to a decline in furniture manufacturing jobs in developed countries, but has also made furniture more affordable for consumers.

- Increased Competition: With the rise of globalization, furniture manufacturers now face increased competition from manufacturers around the world. This has forced manufacturers to improve the quality of their products and find ways to reduce costs, leading to innovations in design, manufacturing, and distribution.

- Supply Chain: Globalization has led to a more complex supply chain for furniture manufacturers, as they source materials from around the world and distribute products to markets around the globe. This has led to greater efficiency and lower costs, but also presents challenges in terms of logistics, quality control, and sustainability.

- Design: Globalization has also had an impact on furniture design, with designers drawing inspiration from a wider range of cultures and styles. This has led to more diverse and eclectic furniture designs, but has also raised questions about cultural appropriation and authenticity.

- Sustainability: Globalization has had both positive and negative impacts on sustainability in furniture manufacturing. While it has led to greater efficiency and reduced waste in some areas, it has also led to increased transportation and shipping, which can have a negative environmental impact.

Eventually, globalization has transformed the furniture manufacturing industry, creating both opportunities and challenges for manufacturers, designers, and consumers. While it has led to lower prices and greater access to furniture for consumers, it has also raised questions about labor practices, environmental impact, and cultural identity.

Sustainability and the Furniture Manufacturing Industry

Sustainability is becoming an increasingly important issue in the furniture manufacturing industry, as consumers and manufacturers alike recognize the need to reduce waste, conserve resources, and minimize environmental impact. Here are some of the ways sustainability is being addressed in the industry:

- Material Selection: Furniture manufacturers are increasingly selecting materials that are more sustainable and eco-friendly, such as FSC-certified wood, bamboo, and recycled materials. This reduces the environmental impact of production and helps to conserve resources.

- Manufacturing Processes: Manufacturers are also adopting more sustainable manufacturing processes, such as using renewable energy sources, minimizing water and energy usage, and reducing waste. This can lead to significant cost savings and environmental benefits.

- Design: Sustainable design principles are being incorporated into furniture design, with an emphasis on durability, modularity, and recyclability. This ensures that furniture is designed to last longer and can be easily disassembled and recycled at the end of its useful life.

- Circular Economy: The circular economy model is gaining traction in the furniture industry, which involves designing products that can be reused, repaired, or recycled, rather than disposed of. This reduces waste and conserves resources, while also creating new business opportunities for manufacturers and retailers.

- Consumer Education: Consumers are becoming more aware of the environmental impact of their purchasing decisions and are increasingly looking for sustainable options. Manufacturers are responding by providing more information about the sustainability of their products and educating consumers on how to make more sustainable choices.

Overall, sustainability is becoming an increasingly important consideration in the furniture manufacturing industry, as manufacturers and consumers recognize the need to reduce waste, conserve resources, and minimize environmental impact. By adopting sustainable materials, manufacturing processes, and design principles, the industry can reduce its environmental footprint and create more sustainable products for consumers.

The Future of Furniture Manufacturing

Following, we've discussed future of furniture manufacturing. Let's learn:

Predictions for the Future of the Industry

Here are some predictions for the future of the furniture manufacturing industry:

- Sustainability will continue to be a top priority: As consumers become more environmentally conscious, furniture manufacturers will continue to focus on sustainability, with an emphasis on eco-friendly materials, manufacturing processes, and circular economy principles.

- Technological innovation will drive efficiency and customization: Advancements in technology, such as 3D printing and augmented reality, will enable manufacturers to create customized furniture products more efficiently, reducing waste and improving the customer experience.

- Collaboration and transparency will increase: With an increasing focus on sustainability and ethical practices, manufacturers will be more transparent about their supply chains and collaborate with other organizations to promote sustainability initiatives.

- E-commerce will continue to grow: The rise of e-commerce has transformed the furniture industry, with online sales expected to continue to grow. Manufacturers will need to adapt to this trend by optimizing their online presence and providing a seamless online shopping experience.

- Circular business models will become more common: As part of the push for sustainability, furniture manufacturers will increasingly adopt circular business models, such as leasing and rental programs, product take-back schemes, and refurbishment services.

- Diversity and inclusivity in design will increase: As consumers become more diverse and demand greater inclusivity in design, manufacturers will increasingly incorporate diverse perspectives and cultural influences into their products.

Ultimately, the future of the furniture manufacturing industry looks to be focused on sustainability, technological innovation, and a greater emphasis on transparency and collaboration.

As the industry adapts to changing consumer demands and advances in technology, we can expect to see new business models and design trends emerge, all with a greater focus on sustainability and social responsibility.

The Role of Technology in the Future of Furniture Manufacturing

Technology is expected to play a significant role in the future of furniture manufacturing, enabling greater efficiency, customization, and sustainability. Here are some ways in which technology is expected to impact the industry:

- Automation and Robotics: Automation and robotics will continue to improve manufacturing processes, increasing efficiency and reducing costs. This will include automated cutting and shaping of materials, assembly line robots, and even autonomous vehicles for transportation and logistics.

- 3D Printing: 3D printing technology will become more widely adopted in furniture manufacturing, allowing for greater customization and more efficient use of materials. This technology will allow furniture designers to create complex shapes and structures that were previously impossible, while reducing waste and streamlining the manufacturing process.

- Augmented Reality: Augmented reality technology will enable customers to visualize furniture products in their own homes, allowing for greater customization and a more engaging customer experience. This technology will enable customers to see how furniture products will look in their space, allowing them to make more informed purchasing decisions.

- Virtual Reality: Virtual reality technology will enable designers and manufacturers to create and test furniture products in a virtual environment, before physical prototypes are created. This will allow for more efficient product development, reducing the time and cost associated with creating physical prototypes.

- Sustainability Tracking: Technology will enable greater tracking and monitoring of sustainability metrics throughout the manufacturing process. This will allow manufacturers to identify areas where they can improve their sustainability practices, and provide consumers with greater transparency about the environmental impact of the products they are purchasing.

Overall, technology is expected to play a significant role in the future of furniture manufacturing, enabling greater efficiency, customization, and sustainability. As the industry continues to adapt to changing consumer demands and advances in technology, we can expect to see new business models and design trends emerge, all with a greater focus on sustainability and social responsibility.

The Impact of Sustainability on the Future of Furniture Manufacturing

Sustainability is expected to have a significant impact on the future of furniture manufacturing. Here are some ways in which sustainability is expected to impact the industry:

Use of Sustainable Materials: Furniture manufacturers will continue to shift towards using sustainable materials in their products, such as FSC-certified wood, recycled plastic, and other eco-friendly materials. This will reduce the environmental impact of furniture manufacturing and promote responsible forestry practices.

Circular Economy Practices: Furniture manufacturers will increasingly adopt circular economy practices, such as product take-back programs, refurbishment services, and recycling programs. This will enable furniture products to be reused, repaired, or recycled at the end of their life, reducing waste and promoting a more sustainable model of consumption.

Energy and Resource Efficiency: Furniture manufacturers will continue to focus on improving energy and resource efficiency in their manufacturing processes, reducing their carbon footprint and promoting sustainable practices.

Transparency and Traceability: Consumers are becoming increasingly concerned about the environmental impact of the products they buy. Furniture manufacturers will need to be transparent about the materials and processes used in their products and provide traceability through their supply chains to ensure they are meeting sustainability standards.

Collaboration and Innovation: Collaboration between different stakeholders in the furniture industry will become increasingly important in promoting sustainability. Furniture manufacturers, designers, consumers, and policymakers will need to work together to develop innovative solutions that promote sustainability in the industry.

Overall, the impact of sustainability on the future of furniture manufacturing will be significant, with a greater focus on sustainable materials, circular economy practices, energy and resource efficiency, transparency, and collaboration. As the industry continues to evolve, manufacturers that embrace sustainable practices and prioritize environmental responsibility will be better positioned to succeed in the marketplace.

The Influence of Changing Consumer Preferences on the Industry

Changing consumer preferences have a significant influence on the furniture manufacturing industry. As consumers become more environmentally conscious and prioritize sustainability, they are demanding furniture that is eco-friendly and responsibly produced.

Here are some ways in which changing consumer preferences are impacting the industry:

Sustainable Materials: Consumers are increasingly looking for furniture made from sustainable materials, such as FSC-certified wood and recycled materials. Furniture manufacturers are responding to this demand by incorporating eco-friendly materials into their products.

Customization: Consumers are seeking furniture that reflects their personal style and tastes, and are willing to pay more for customized products. Furniture manufacturers are responding to this demand by offering more options for customization, such as choosing fabric, finishes, and other features.

Online Shopping: More consumers are shopping for furniture online, which has led to increased competition and a need for manufacturers to adapt their sales and marketing strategies. Manufacturers are investing in online platforms and digital marketing to reach consumers where they are.

Multi-Functional Furniture: Consumers are increasingly living in smaller spaces, and are seeking furniture that is both functional and space-saving. Furniture manufacturers are responding to this demand by creating multi-functional furniture that can serve multiple purposes.

Social Responsibility: Consumers are increasingly concerned about the social impact of the products they buy. They are seeking furniture that is produced under fair labor conditions and manufactured in an environmentally responsible way. Furniture manufacturers are responding to this demand by adopting sustainable and socially responsible practices throughout their supply chains.

Overall, changing consumer preferences have a significant impact on the furniture manufacturing industry. Manufacturers that are able to adapt to these changing preferences by offering sustainable materials, customization options, online shopping platforms, multi-functional furniture, and socially responsible practices will be better positioned to succeed in the marketplace.

Wrapping Up

The history and future of furniture manufacturing is a story of innovation, technology, and changing consumer preferences. From handcrafted pieces to mass production, the industry has undergone significant changes over the centuries.

Today, furniture manufacturers face new challenges and opportunities, including the need to adopt sustainable practices, respond to changing consumer preferences, and embrace new technologies.

As the industry continues to evolve, manufacturers that prioritize sustainability, customization, and social responsibility will be best positioned to succeed in the marketplace.

The future of furniture manufacturing will be shaped by ongoing developments in technology, as well as a growing focus on sustainability and social responsibility. Advances in 3D printing, automation, and other technologies will enable furniture manufacturers to create products more efficiently and with greater customization options.

At the same time, sustainability will become an increasingly important factor in the industry, with a focus on using sustainable materials, circular economy practices, and energy and resource efficiency.

As the industry moves forward, it will be important for furniture manufacturers to collaborate with designers, policymakers, and consumers to create products that meet the needs and preferences of a changing world. By embracing sustainability, customization, and innovation, manufacturers can create a more resilient and profitable industry that meets the needs of both consumers and the environment

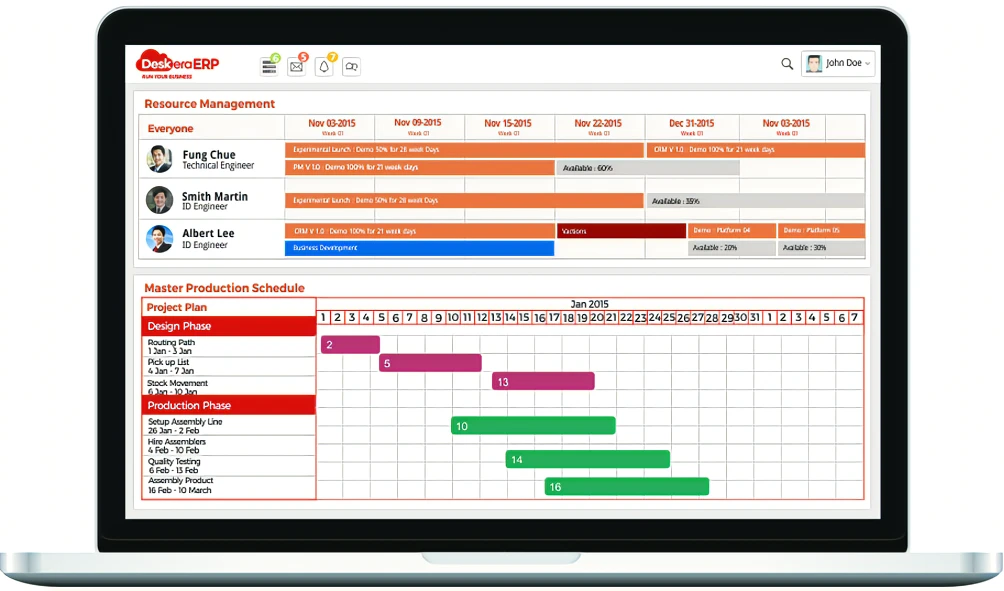

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Knowledge of the history of furniture manufacturing can help individuals within the industry understand current trends and predict future ones. It allows companies to stay relevant and competitive by adapting to changes in consumer preferences and new technological advancements.

- Furniture manufacturing has a long and rich history dating back to ancient civilizations such as Egypt, Greece, and Rome. In these early civilizations, furniture was primarily made from wood, stone, and metal, and was often ornately decorated with intricate carvings and inlays.

- The introduction of mass production techniques had a significant impact on furniture manufacturing, transforming it from a craft-based industry to a more industrialized one.

- Advancements in textile technology have led to the development of new fabrics and materials that are more durable, comfortable, and environmentally friendly. These new materials have been used to create upholstered furniture that is more resistant to wear and tear and easier to clean.

- CAD and CAM software are used to design and manufacture furniture. These technologies allow for precise measurements and detailed designs that can be quickly and easily modified.

- 3D printing technology is used to create prototypes and small production runs of furniture. This method allows for more precise and detailed designs to be created quickly and at a lower cost.

- There is a growing trend towards sustainable furniture manufacturing, which involves using eco-friendly materials, reducing waste, and minimizing the environmental impact of the manufacturing process.

Related Articles