The use of artificial intelligence (AI) in pest control is expected to grow at a CAGR of 38.4% from 2021 to 2026. (Source: MarketsandMarkets) Additionally, as per the Transparency Market Research, the global demand for sustainable pest control solutions is expected to grow at a CAGR of 5.5% from 2021 to 2028.

Are you a manufacturer of pest control chemicals? Do you want to know what lies in the future of the pest control chemical manufacturing industry?

If your answer is yes to these questions, then you are on the right page.

The future of pest control chemical manufacturing is poised for significant change as manufacturers seek to embrace emerging technologies, improve sustainability, and adapt to changing market conditions.

Automation and robotics will play an increasingly important role in manufacturing processes, from production and packaging to distribution and delivery.

Advancements in technologies such as artificial intelligence (AI), collaborative robots (Cobots), augmented reality (AR), autonomous systems, and 3D printing offer potential opportunities for manufacturers to improve their processes, reduce costs, and increase competitiveness.

However, to make the most of the opportunities that lie in this future while being able to mitigate the challenges, it is important to understand all of this in depth.

This article will help you with that by covering the following topics:

- What is the Future of Pest Control Chemical Manufacturing?

- Global Pest Control Chemical Manufacturing Trends and Forecasts

- Innovations in Pest Control Chemical Manufacturing

- Sustainable Pest Control Chemical Manufacturing - Challenges and Opportunities

- Role of Pest Control Chemical Manufacturing in the Global Economy

- Pest Control Chemical Manufacturing Compliance and Regulation Standards

- What are Some Additional Certifications that Pest Control Chemical Manufacturers can Undertake?

- Environmental Impact of Pest Control Chemical Manufacturing

- Advancements in Pest Control Chemical Manufacturing Materials

- Advancements in Pest Control Chemical Manufacturing Methods

- Automation and Robotics in Pest Control Chemical Manufacturing

- Opportunities in Automation and Robotics in Pest Control Chemical Manufacturing

- Challenges in Automation and Robotics in Pest Control Chemical Manufacturing

- Future of Automation and Robotics in Pest Control Chemical Manufacturing

- FAQs related to Pest Control Chemical Manufacturing

- How can Deskera Help You in Pest Control Chemical Manufacturing?

- Key Takeaways

- Related Articles

What is the Future of Pest Control Chemical Manufacturing?

The future of pest control chemical manufacturing is likely to focus on developing products that are more eco-friendly and less harmful to the environment and human health. This trend is driven by increasing awareness and concern over the impact of conventional pesticides on non-target organisms, including beneficial insects, wildlife, and humans.

One approach to achieving this goal is to develop new, natural, or plant-based pesticides that are less toxic than conventional chemical pesticides. For example, researchers are exploring the use of essential oils and other natural compounds as potential alternatives to synthetic chemicals.

Another approach is to improve the efficiency of existing pesticides through new delivery methods and formulations. For instance, microencapsulation technology can improve the targeted delivery of pesticides to pests while minimizing their exposure to non-target organisms.

Furthermore, advances in technology, such as the use of artificial intelligence (AI) and big data analytics, could revolutionize pest control by enabling more precise and targeted application of pesticides. This could reduce the number of pesticides used and minimize their impact on the environment and human health.

Sustainability will continue to be a key concern for pest control chemical manufacturers as consumers and regulators demand products that are safe, environmentally friendly, and ethically produced.

Manufacturers that embrace sustainable practices can expect to see improved customer loyalty, reduced costs, and greater market share. Collaboration and partnerships will also be increasingly important in the pest control chemical manufacturing industry as manufacturers seek to develop innovative solutions and adapt to changing market conditions.

Overall, the future of pest control chemical manufacturing will likely be characterized by a shift towards more sustainable, effective, and safer pest control methods that protect both human health and the environment.

Global Pest Control Chemical Manufacturing Trends and Forecasts

Pest control chemical manufacturing is a significant segment of the chemical industry, which produces various types of chemicals to eliminate or control pests in agriculture, public health, and other applications. The global pest control market size was valued at $20.5 billion in 2019 and is expected to reach $27.5 billion by 2027, growing at a CAGR of 3.7% from 2020 to 2027.

One of the main drivers of the pest control market's growth is the increasing demand for food due to the world's population growth. As more people require food, the demand for pest control chemicals in agriculture will also increase. Moreover, the growing awareness of the health risks associated with pests, such as malaria, dengue, and other insect-borne diseases, is also driving the market's growth.

The pest control chemical manufacturing industry is facing significant challenges in terms of increasing regulations and restrictions on the use of certain chemicals. In recent years, there has been a growing concern about the environmental impact of pesticides and the potential harm they can cause to non-target species, including humans.

Governments around the world have implemented stricter regulations on pesticide use and are promoting the use of safer and more eco-friendly alternatives. This trend is likely to continue, which may impact the growth of traditional pesticide manufacturers.

As a response to these challenges, the industry is increasingly investing in research and development of new, safer, and more effective pest control chemicals. Additionally, there has been a growing interest in integrated pest management (IPM) systems, which combine different pest control methods to reduce reliance on chemical pesticides. IPM systems include practices such as crop rotation, biological control, habitat manipulation, and the use of pheromone traps, among others.

In conclusion, while the global pest control chemical manufacturing market is expected to continue to grow, it will face challenges from increasing regulations and growing demand for safer and more sustainable pest control methods. The industry's response to these challenges, through continuous innovation and the development of new products and technologies, will determine its future growth and success.

Innovations in Pest Control Chemical Manufacturing

There have been several recent innovations in pest control chemical manufacturing driven by the need to develop more sustainable and effective pest control methods. Some of the notable innovations include:

- Plant-based pesticides: Many companies are developing natural or plant-based pesticides that are less toxic and environmentally friendly. For example, Neem-based products have been used for decades as a natural pesticide.

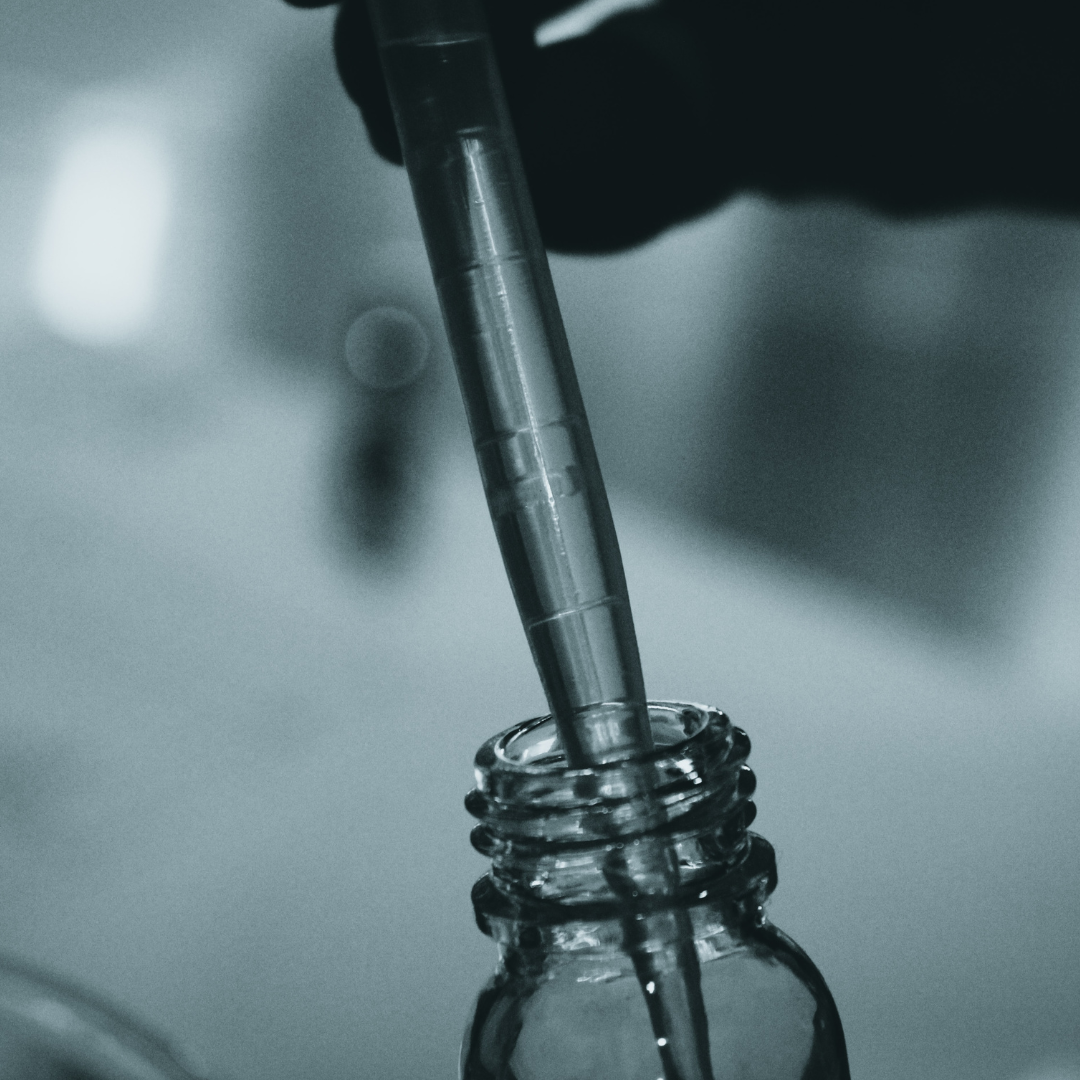

- Microencapsulation technology: This technology improves the targeted delivery of pesticides to pests while minimizing their exposure to non-target organisms. The technology involves encapsulating the active ingredient in a polymer shell, allowing for precise control of release and delivery.

- Integrated pest management (IPM) systems: These systems combine different pest control methods, including chemical, biological, and cultural methods, to achieve more effective and sustainable pest control. This approach reduces reliance on pesticides and promotes the use of non-toxic methods.

- Artificial intelligence (AI) and big data analytics: These technologies are being used to develop more precise and targeted pest control methods. By analyzing data on pest behavior and environmental factors, AI algorithms can optimize pest control strategies and reduce the use of pesticides.

- Biodegradable pesticides: Biodegradable pesticides are designed to break down into harmless substances after use, reducing their impact on the environment. These products are increasingly being developed and used as an alternative to conventional pesticides.

Overall, these innovations in pest control chemical manufacturing are driving the development of safer, more effective, and environmentally sustainable pest control methods.

Sustainable Pest Control Chemical Manufacturing - Challenges and Opportunities

Sustainable pest control chemical manufacturing presents both challenges and opportunities for the industry. Some of the challenges include the following:

- Cost: Developing sustainable pest control products can be more expensive than conventional pesticides. This can make it difficult for companies to invest in research and development and to price their products competitively.

- Regulatory hurdles: The development and approval of new pesticide products can be a lengthy and expensive process. In many countries, there are strict regulations governing the use of pesticides, which can create additional barriers to entry for sustainable pest control products.

- Resistance: Pests can develop resistance to certain pesticides over time. This means that new and innovative products must be developed to combat resistant pests.

Despite these challenges, there are also several opportunities for sustainable pest control chemical manufacturing, including:

- Growing demand for eco-friendly products: Consumers are increasingly aware of the impact of conventional pesticides on the environment and human health. This has led to a growing demand for eco-friendly pest control products.

- Increased funding for research and development: Governments and private investors are recognizing the need for sustainable pest control products and are investing in research and development in this area.

- New technology: Advances in technology, such as AI and big data analytics, are creating new opportunities for developing more precise and targeted pest control methods.

- Integrated pest management (IPM) systems: IPM systems, which combine different pest control methods, are becoming more popular. This approach reduces reliance on pesticides and promotes the use of non-toxic methods.

Overall, sustainable pest control chemical manufacturing presents both challenges and opportunities. However, companies that are able to develop effective and sustainable pest control products are likely to see growing demand for their products in the future.

Role of Pest Control Chemical Manufacturing in the Global Economy

The role of pest control chemical manufacturing in the global economy is significant, as it plays an essential role in protecting crops, livestock, and human health from harmful pests and diseases.

Pest control chemicals are used in agriculture, food processing, healthcare, and other industries to prevent the spread of diseases and protect against pests and insects.

The global market for pest control chemicals is expected to continue to grow in the coming years due to factors such as population growth, urbanization, and increased awareness of the importance of pest control in agriculture and food production.

According to a report by Grand View Research, the global pest control market size was valued at USD 20.2 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 5.5% from 2021 to 2028.

The pest control chemical manufacturing industry is also a major contributor to the global economy in terms of employment and revenue. Many countries have significant pest control chemical manufacturing sectors, and the industry employs thousands of people worldwide.

However, the use of pesticides and other pest control chemicals also has its challenges and concerns. Some chemicals can have negative impacts on the environment and human health if used improperly, and there is a growing demand for safer and more sustainable pest control solutions.

Therefore, the industry is constantly working to develop and implement safer and more sustainable pest control methods to meet these challenges while continuing to support the global economy.

Pest Control Chemical Manufacturing Compliance and Regulation Standards

The pest control chemical manufacturing industry is subject to compliance and regulation standards aimed at ensuring the safety and efficacy of the products and protecting human health and the environment.

Different countries have their own regulations for pest control chemicals, and the manufacturers must comply with the regulations of the country where they are selling or distributing their products.

Some of the key regulatory bodies governing the pest control chemical manufacturing industry include the Environmental Protection Agency (EPA) in the United States, the European Chemicals Agency (ECHA) in the European Union, and the Food and Agriculture Organization (FAO) of the United Nations.

- Environmental Protection Agency (EPA): The EPA is a United States government agency that is responsible for regulating pesticides and other chemicals to ensure they are safe for human health and the environment.

- European Chemicals Agency (ECHA): The ECHA is an agency of the European Union that is responsible for regulating the production and use of chemicals, including pest control chemicals, for ensuring they are safe for human health and the environment.

- Food and Agriculture Organization (FAO): The FAO is a United Nations agency that is responsible for promoting sustainable agriculture and food production, including the regulation of pest control chemicals.

Thus, the regulations typically cover the registration, labeling, storage, transportation, use, and disposal of pest control chemicals. Manufacturers must provide extensive data on the safety and efficacy of their products and undergo rigorous testing before their products can be approved for use.

They are also required to follow strict labeling requirements to ensure that users are aware of the risks associated with the chemicals and how to use them safely.

In addition to regulatory compliance, the pest control chemical manufacturing industry has also been moving towards more sustainable and environmentally-friendly practices.

This includes reducing the use of hazardous chemicals, increasing the use of biodegradable and non-toxic alternatives, and implementing integrated pest management strategies that rely on a combination of pest control methods.

Overall, compliance and regulation standards play a crucial role in ensuring the safe and responsible use of pest control chemicals, protecting both human health and the environment.

What are Some Additional Certifications that Pest Control Chemical Manufacturers can Undertake?

There are several industry-specific certifications and voluntary programs that pest control chemical manufacturers can undertake to demonstrate their commitment to responsible production and environmental stewardship. Some of them include the following:

- ISO 14001 Environmental Management System (EMS) Certification: This certification helps companies establish and implement an effective environmental management system that can help them reduce their environmental impact, improve their operational efficiency, and comply with environmental regulations.

- Green Seal Certification: This certification is a third-party certification program that evaluates and certifies products and services that meet specific environmental standards. Pest control chemical manufacturers can apply for this certification to demonstrate their commitment to sustainability and environmental stewardship.

- EcoLogo Certification: This certification is another third-party certification program that evaluates and certifies products and services that meet specific environmental standards. Pest control chemical manufacturers can apply for this certification to demonstrate their commitment to sustainability and environmental stewardship.

- Responsible Care Certification: This certification program is managed by the American Chemistry Council (ACC) and is designed to help companies improve their environmental, health, safety, and security performance. Pest control chemical manufacturers can apply for this certification to demonstrate their commitment to responsible production and environmental stewardship.

- The Roundtable on Sustainable Palm Oil (RSPO) Certification: This certification program is designed for companies that produce or use palm oil in their products. Pest control chemical manufacturers can apply for this certification to demonstrate their commitment to responsible sourcing and production of palm oil.

- The Global Organic Textile Standard (GOTS) Certification: This certification program is designed for companies that produce organic textiles. Pest control chemical manufacturers can apply for this certification to demonstrate their commitment to producing organic pest control chemicals.

By obtaining these certifications and participating in these voluntary programs, pest control chemical manufacturers can demonstrate their commitment to responsible production and environmental stewardship.

Environmental Impact of Pest Control Chemical Manufacturing

The manufacturing of pest control chemicals can have a significant environmental impact, including:

- Pollution of air, water, and soil: The production of pest control chemicals can result in the release of various pollutants into the environment, such as volatile organic compounds (VOCs), heavy metals, and other toxic substances. These pollutants can contaminate air, water, and soil, leading to serious environmental problems.

- Energy consumption: The manufacturing process of pest control chemicals requires a lot of energy, which often comes from non-renewable sources such as coal and natural gas. This energy consumption contributes to greenhouse gas emissions, which contribute to climate change.

- Waste generation: The manufacturing process of pest control chemicals can generate a significant amount of waste, including hazardous waste. If not properly handled and disposed of, this waste can pose a risk to human health and the environment.

- Impact on biodiversity: Pest control chemicals can have unintended consequences on non-target species, such as birds, mammals, and beneficial insects. This can lead to a decline in biodiversity and disrupt ecosystems.

- Human health impacts: Exposure to pest control chemicals during the manufacturing process can pose health risks to workers and nearby communities.

To reduce the environmental impact of pest control chemical manufacturing, it is important for companies to adopt sustainable production practices, such as using renewable energy sources, minimizing waste generation, and implementing effective pollution control measures.

Additionally, companies can develop and promote safer and more sustainable pest control solutions, such as integrated pest management (IPM) approaches that prioritize non-chemical methods and the use of low-toxicity pesticides.

Advancements in Pest Control Chemical Manufacturing Materials

There have been several advancements in pest control chemical manufacturing materials that have allowed for safer, more effective, and more environmentally friendly pest control solutions. Some of these advancements include:

- Biopesticides: Biopesticides are naturally occurring substances that control pests through non-toxic mechanisms. They are derived from plants, microorganisms, or other natural sources and are often less harmful to non-target organisms and the environment.

- Reduced-risk pesticides: Reduced-risk pesticides are chemical pesticides that have been evaluated and found to have lower risks to human health and the environment than other pesticides. They are often more targeted in their mode of action and have lower toxicity to non-target organisms.

- Microencapsulation: Microencapsulation is a technique that involves enclosing the active ingredient of a pesticide in a protective coating. This allows for a more controlled release of the active ingredient, which can improve the effectiveness of the pesticide while reducing its environmental impact.

- Nanotechnology: Nanotechnology involves the use of tiny particles at the nanoscale level to create new materials and products. In pest control, nanotechnology has been used to create more effective and targeted pesticide formulations, reducing the amount of pesticide required to achieve the desired effect.

- Electronic pest control: Electronic pest control devices use electronic signals to repel or kill pests. These devices are often less harmful to non-target organisms and the environment than chemical pesticides.

- Plant-based extracts: Plant-based extracts, such as neem oil and pyrethrum, have been used for centuries as natural pest control solutions. They are often less harmful to non-target organisms and the environment than chemical pesticides.

These advancements in pest control chemical manufacturing materials have allowed for the development of safer, more effective, and more environmentally friendly pest control solutions. As technology continues to advance, it is likely that we will see even more innovative and sustainable pest control solutions in the future.

Advancements in Pest Control Chemical Manufacturing Methods

There have been several advancements in pest control chemical manufacturing methods that have allowed for safer, more effective, and more environmentally friendly pest control solutions. Some of these advancements include:

- Green Chemistry: Green chemistry involves the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. This approach has been applied to the manufacturing of pest control chemicals to reduce the environmental impact and improve the safety of these products. Green chemistry thus supports sustainability.

- Microbial Fermentation: Microbial fermentation is a method of producing pest control chemicals using microorganisms. This method is often less energy-intensive and less environmentally damaging than traditional chemical synthesis methods.

- Biotechnology: Biotechnology involves the use of living organisms or their components to create new products or processes. This approach has been applied to the production of pest control chemicals to create more effective and targeted pesticides.

- High-Throughput Screening: High-throughput screening is a method of rapidly testing large numbers of chemical compounds to identify those with the desired properties. This approach has been applied to the discovery of new pest control chemicals to identify safer and more effective options.

- Precision Agriculture: Precision agriculture involves using technology to optimize the use of agricultural inputs, including pesticides. This approach can reduce the number of pesticides required and improve the effectiveness of pest control measures.

- Integrated Pest Management (IPM): IPM is a holistic approach to pest management that emphasizes the use of non-chemical methods and the integration of different pest control strategies. This approach can reduce the reliance on chemical pesticides and minimize their environmental impact.

These advancements in pest control chemical manufacturing methods have allowed for the development of safer, more effective, and more environmentally friendly pest control solutions. As technology continues to advance, it is likely that we will see even more innovative and sustainable pest control solutions in the future.

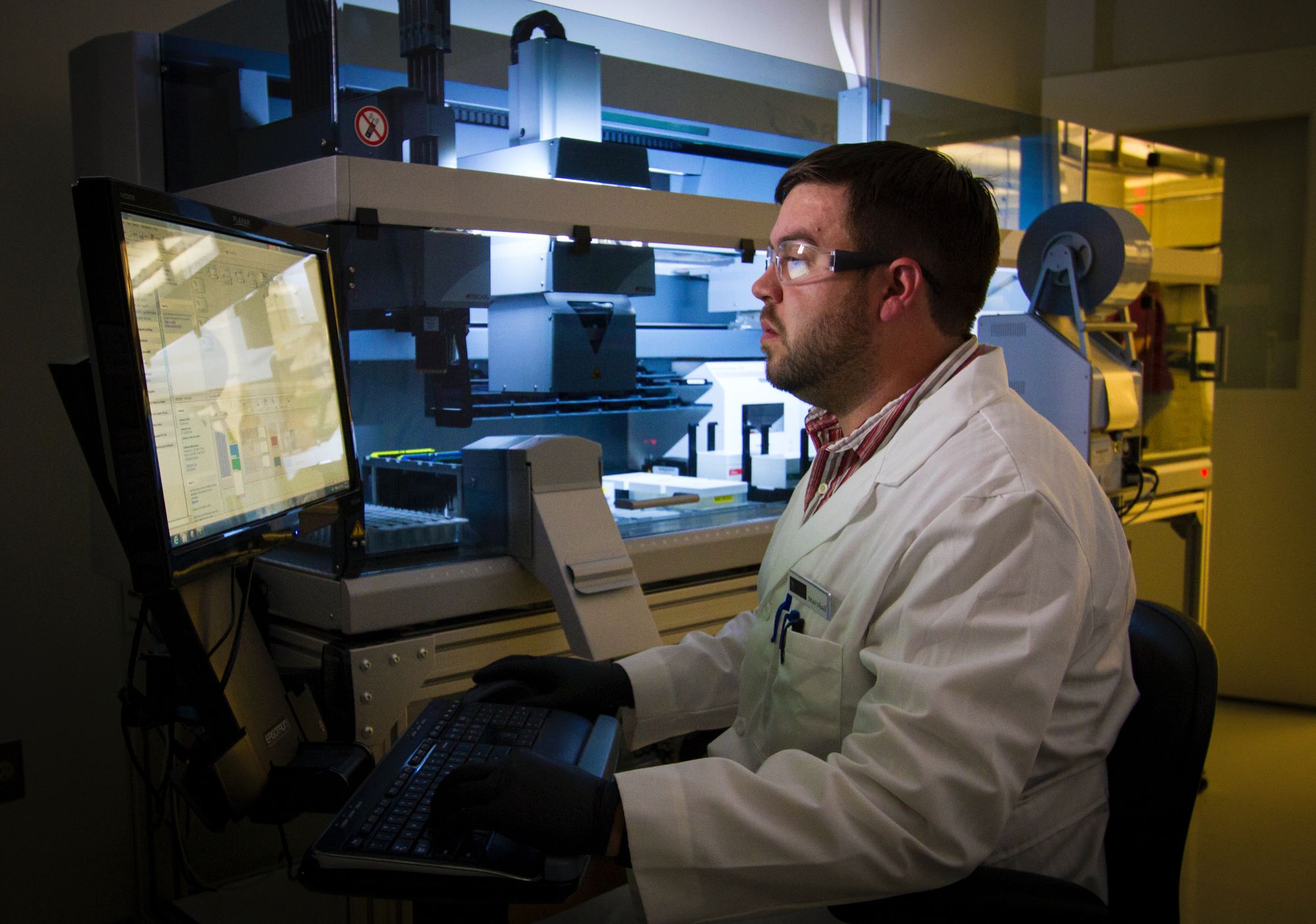

Automation and Robotics in Pest Control Chemical Manufacturing

Automation and robotics are becoming increasingly important in the pest control chemical manufacturing industry. The use of these technologies can increase efficiency, productivity, and safety while reducing costs and the risk of human error. Here are some examples of how automation and robotics are being used in pest control chemical manufacturing:

- Automated Mixing and Dispensing Systems: Mixing and dispensing chemicals is a critical part of pest control chemical manufacturing. Automated mixing and dispensing systems can precisely measure and mix chemicals, reducing the risk of human error and ensuring consistent quality. These systems can also reduce waste and improve efficiency. Thus, there would be no undue pressure on your working capital, and you would be able to improve customer retention.

- Robotic Palletizing and Packaging: Robotic palletizing and packaging systems can automate the process of stacking and packaging bags or containers of finished products. These systems can increase speed and efficiency, reduce the risk of injury to workers, and ensure consistency in the packaging process. This will ensure that there are no additional operating costs and manufacturing costs, which will improve your operational metrics.

- Autonomous Guided Vehicles (AGVs): AGVs are self-driving vehicles that can transport raw materials, finished products, and equipment throughout the manufacturing facility. AGVs can navigate complex environments, avoid obstacles, and reduce the need for manual labor in material handling. It will thus help you save on your operating expenses while maximizing your operating income, leading to an overall improvement in your business metrics.

- Robotics for Inspection and Maintenance: Robots can be used for inspection and maintenance tasks, such as checking equipment for defects, cleaning tanks, and conducting routine maintenance. This can reduce the risk of injury to workers and increase the speed and accuracy of these tasks. It will also help in better management of workplace stress, as well as retention of top talents.

- Drones for Monitoring and Spraying: Drones equipped with cameras and sensors can be used for monitoring crops and detecting pest infestations. They can also be used to spray pesticides on crops, reducing the need for manual labor and improving precision and accuracy.

In conclusion, automation and robotics are transforming the pest control chemical manufacturing industry. These technologies can improve efficiency, increase productivity, and reduce costs and risks associated with manual labor.

This will lead to higher net revenue and net profit ratio for the companies, as well as higher return on investment. Thus, as technology advances, we can expect to see further developments and applications of automation and robotics in this industry.

Opportunities in Automation and Robotics in Pest Control Chemical Manufacturing

The adoption of automation and robotics in the pest control chemical manufacturing industry presents numerous opportunities for manufacturers. Here are some of the opportunities associated with automation and robotics in pest control chemical manufacturing:

- Increased Efficiency and Productivity: Automation and robotics systems can help manufacturers streamline their processes, reduce waste, and increase productivity. By automating repetitive tasks, manufacturers can free up their workers to focus on higher-level tasks and reduce the risk of human error.

- Improved Quality Control: Automation and robotics systems can help manufacturers ensure consistent quality in their products by precisely measuring and mixing chemicals and ensuring accurate packaging and labeling.

- Enhanced Safety: Automation and robotics systems can help improve worker safety by taking on dangerous tasks such as handling hazardous chemicals or lifting heavy objects. This can reduce the risk of injuries and accidents in the workplace.

- Scalability: Automation and robotics systems can be scaled up or down depending on the production needs of the manufacturer. This can help manufacturers adapt to changes in demand or market conditions.

- Data Analytics and Optimization: Automation and robotics systems generate large amounts of data that can be analyzed to identify patterns and optimize manufacturing processes. This can help manufacturers identify areas for improvement, reduce waste, and increase efficiency.

- Customization: Automation and robotics systems can be customized to meet the specific needs of manufacturers. This can help manufacturers produce niche products or respond to specific customer requests.

In conclusion, the adoption of automation and robotics in the pest control chemical manufacturing industry presents numerous opportunities for manufacturers.

By implementing these technologies, manufacturers can improve efficiency, quality, and safety, as well as adapt to changing market conditions and improve their competitiveness.

Challenges in Automation and Robotics in Pest Control Chemical Manufacturing

While automation and robotics offer numerous benefits to the pest control chemical manufacturing industry, there are also some challenges that need to be addressed. Here are some of the challenges associated with automation and robotics in pest control chemical manufacturing:

- High Capital Investment: The initial cost of automation and robotics systems can be significant, which can make it difficult for smaller manufacturers to adopt these technologies. The cost of implementation and maintenance needs to be weighed against the potential benefits of increased productivity and efficiency.

- The Complexity of Integration: Integrating automation and robotics systems into an existing manufacturing process can be challenging, as it requires a significant level of planning, design, and implementation. Integration can also cause disruptions in the production process, which can be costly and time-consuming.

- Lack of Skilled Labor: The implementation and maintenance of automation and robotics systems require specialized skills and knowledge. Finding and training qualified personnel to operate and maintain these systems can be difficult, particularly in regions with a shortage of skilled labor.

- Regulatory Compliance: Automated and robotic systems must comply with various regulations and standards related to safety, environmental impact, and product quality. Compliance can be challenging, as it requires manufacturers to meet multiple regulatory requirements across different jurisdictions.

- Cybersecurity Risks: Automation and robotics systems are vulnerable to cybersecurity threats, such as hacking and data breaches. Manufacturers must implement robust security measures to protect against these threats, which can add complexity and cost to the implementation process.

In conclusion, while automation and robotics offer significant benefits to the pest control chemical manufacturing industry, there are also challenges that need to be addressed. Manufacturers must carefully consider the costs and benefits of adopting these technologies and develop strategies to address the challenges associated with their implementation and maintenance.

Future of Automation and Robotics in Pest Control Chemical Manufacturing

The future of automation and robotics in pest control chemical manufacturing is promising as manufacturers continue to seek ways to increase efficiency, productivity, and safety while reducing costs and the risk of human error. Here are some potential developments we can expect to see in the future:

- Artificial Intelligence (AI): AI technology is becoming increasingly sophisticated and could be used to optimize manufacturing processes, predict maintenance needs, and improve product quality. AI algorithms could also be used to monitor pest populations and predict infestations, improving the efficiency and effectiveness of pest control measures.

- Collaborative Robots (Cobots): Cobots are robots designed to work alongside human workers, providing assistance with tasks such as lifting heavy objects or operating machinery. In pest control chemical manufacturing, cobots could be used to assist with tasks such as mixing chemicals or packaging products, improving efficiency and reducing the risk of injury to workers.

- Augmented Reality (AR): AR technology could be used to provide workers with real-time information and guidance, improving safety and reducing the risk of errors. For example, AR headsets could provide workers with information about chemical compositions or safety protocols, improving their ability to work safely and efficiently.

- Autonomous Systems: Autonomous systems, such as drones or AGVs, could be used to automate tasks such as monitoring crops, detecting pest infestations, and spraying pesticides. These systems could improve efficiency and reduce the need for manual labor while also improving accuracy and reducing the risk of human error.

- 3D Printing: 3D printing technology could be used to manufacture specialized equipment or components, reducing the need for suppliers and improving the speed and efficiency of manufacturing.

In conclusion, the future of automation and robotics in pest control chemical manufacturing is bright, with potential developments such as AI, cobots, AR, autonomous systems, and 3D printing.

Manufacturers that invest in these technologies can expect to see improvements in efficiency, productivity, safety, and quality, as well as greater competitiveness in the marketplace.

FAQs related to Pest Control Chemical Manufacturing

- What role will automation and robotics play in the future of pest control chemical manufacturing?

Automation and robotics will play an increasingly important role in pest control chemical manufacturing as manufacturers seek ways to increase efficiency, productivity, and safety while reducing costs and the risk of human error.

- What emerging technologies offer potential opportunities for pest control chemical manufacturers?

Emerging technologies such as artificial intelligence (AI), collaborative robots (Cobots), augmented reality (AR), autonomous systems, and 3D printing offer potential opportunities for manufacturers to improve their processes, reduce costs, and increase competitiveness.

- How will sustainability be addressed in the future of pest control chemical manufacturing?

Sustainability will continue to be a key concern for pest control chemical manufacturers as consumers and regulators demand products that are safe, environmentally friendly, and ethically produced. Manufacturers that embrace sustainable practices can expect to see improved customer loyalty, reduced costs, and greater market share.

- How can ERP software help pest control chemical manufacturers?

ERP software such as Deskera can help pest control chemical manufacturers streamline their processes, improve efficiency, and manage their operations more effectively, leading to greater competitiveness and profitability in the marketplace.

- What are some of the key challenges facing pest control chemical manufacturers in the future?

Key challenges facing pest control chemical manufacturers in the future include increasing regulatory scrutiny, changing consumer preferences, competition from new entrants, and the need to embrace new technologies and sustainability practices.

- What opportunities exist for pest control chemical manufacturers to collaborate with other stakeholders?

Pest control chemical manufacturers can collaborate with customers, suppliers, regulators, and other stakeholders to develop innovative solutions, improve sustainability, and adapt to changing market conditions.

- How important will compliance and regulatory management be for pest control chemical manufacturers in the future?

Compliance and regulatory management will be increasingly important for pest control chemical manufacturers in the future as regulators impose stricter standards and consumers demand greater transparency and accountability.

- How can pest control chemical manufacturers improve their financial management practices?

Pest control chemical manufacturers can improve their financial management practices by adopting ERP software, implementing sound accounting and billing practices, and leveraging financial forecasting and budgeting tools.

- What steps can pest control chemical manufacturers take to improve product quality and safety?

Pest control chemical manufacturers can improve product quality and safety by implementing robust quality control processes, conducting regular product testing and evaluation, and adhering to industry best practices and standards.

- How can pest control chemical manufacturers stay competitive in a rapidly evolving market?

Pest control chemical manufacturers can stay competitive by embracing new technologies, improving sustainability practices, collaborating with stakeholders, and continually innovating and adapting to changing market conditions.

How can Deskera Help You in Pest Control Chemical Manufacturing?

Deskera is a material requirements planning (MRP) software that can help pest control chemical manufacturers streamline their processes, improve efficiency, and manage their operations more effectively. Here are some ways in which Deskera can help:

- Inventory Management: Deskera can help manufacturers track their inventory levels, monitor stock levels in real time, and optimize their inventory management processes. This can help manufacturers reduce waste and improve efficiency by ensuring that they always have the necessary materials on hand.

- Manufacturing Management: Deskera can help manufacturers manage their manufacturing processes, from production planning and scheduling to quality control and product testing. This can help manufacturers improve efficiency, reduce errors, and ensure consistent quality across their product lines.

- Sales and Customer Management: Deskera can help manufacturers manage their sales processes and customer relationships more effectively, from lead generation and pipeline management to order fulfillment and invoicing. This can help manufacturers improve customer satisfaction, increase sales, and grow their business.

- Financial Management: Deskera can help manufacturers manage their financial operations, from accounting and billing to budgeting and forecasting. This can help manufacturers improve financial visibility, reduce costs, and make more informed decisions about their business.

- Compliance and Regulatory Management: Deskera can help manufacturers ensure compliance with industry regulations and standards, from safety and environmental regulations to quality standards and certifications. This can help manufacturers avoid penalties and reputational damage, as well as improve their competitiveness in the marketplace.

Key Takeaways

Some key takeaways for the future of pest control chemical manufacturing:

- Automation and robotics will play an increasingly important role in pest control chemical manufacturing as manufacturers seek ways to increase efficiency, productivity, and safety while reducing costs and the risk of human error.

- Emerging technologies such as artificial intelligence (AI), collaborative robots (Cobots), augmented reality (AR), autonomous systems, and 3D printing offer potential opportunities for manufacturers to improve their processes, reduce costs, and increase competitiveness.

- Manufacturers that invest in MRP software, such as Deskera, can expect to see improvements in inventory management, manufacturing management, sales and customer management, financial management, and compliance and regulatory management, leading to greater competitiveness and profitability in the marketplace.

- Sustainability will continue to be a key concern for pest control chemical manufacturers as consumers and regulators demand products that are safe, environmentally friendly, and ethically produced. Manufacturers that embrace sustainable practices can expect to see improved customer loyalty, reduced costs, and greater market share.

- Collaboration and partnerships will be increasingly important in the pest control chemical manufacturing industry as manufacturers seek to develop innovative solutions and adapt to changing market conditions. Manufacturers that work closely with customers, suppliers, and other stakeholders can expect to see improved efficiency, increased innovation, and greater success in the marketplace.

Lastly, Deskera MRP can help pest control chemical manufacturers streamline their processes, improve efficiency, and manage their operations more effectively.

By adopting Deskera, manufacturers can expect to see improvements in inventory management, manufacturing management, sales and customer management, financial management, and compliance and regulatory management, leading to greater competitiveness and profitability in the marketplace.

Related Articles