As the food industry continues to grow, more and more businesses are starting to invest in automation. This is good news for food manufacturers, as automation can help them save money, time, and energy.

Food manufacturers face a number of challenges that can slow down their operations. For example, manufacturing requires precise timing and coordination between multiple steps in the process, which is difficult to achieve with manual labor. Automation can help food manufacturers to overcome these challenges.

There are a number of benefits that can be achieved through investment in automation for food manufacturers. Here are five of the most important:

If you are looking to improve your business productivity, investing in automation may be the solution that you are looking for. In today's guide, we'll thoroughly cover the importance and benefits of automation for food industry. Let's take a look at the table of content ahead:

- Meaning of Automation in the Food Industry

- Importance of Automation in the Food Industry

- Top Benefits of Investing in Automation for Food Manufacturers

- Automation in Food Manufacturing: Potential Challenges & Solutions

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Meaning of Automation in the Food Industry

Automation in the food industry refers to the use of machines, robots, and other technologies to automate various processes involved in food production, processing, packaging, and distribution.

The goal of automation is to improve efficiency, reduce costs, and increase productivity while maintaining high levels of quality and safety in the food products.

Examples of automation in the food industry include automated filling and packaging machines, robotic arms for food handling and sorting, computerized control systems for monitoring and regulating temperature, humidity, and other environmental factors in food processing plants, and automated conveyor systems for transporting food products.

Importance of Automation in the Food Industry

Automation in the food industry involves the use of technology to streamline and optimize various processes, from food preparation to packaging and distribution.

There are several reasons why automation is essential in the food industry, including:

Increased Efficiency:

Automation can help reduce the time and labor required for various tasks, resulting in faster and more efficient production processes. For example, automated systems can accurately measure and mix ingredients, resulting in consistent product quality and faster production times.

Improved Food Safety:

Automation can help ensure that food is produced and packaged under strict hygienic conditions, reducing the risk of contamination and foodborne illnesses. Automated systems can also track and trace products from farm to table, enabling rapid identification and recall of any contaminated products.

Cost Savings:

Automation can help reduce labor costs, improve production efficiency, and minimize waste. Automated systems can also optimize inventory management, reducing the need for excess inventory and storage space.

Improved Product Quality:

Automated systems can ensure consistent product quality and reduce errors in the production process, resulting in higher quality products. For example, automated inspection systems can detect defects or contaminants in products, resulting in a higher standard of quality control.

Increased Production Capacity:

Automation can help increase production capacity, allowing companies to meet growing demand without incurring additional labor costs. Automated systems can also operate 24/7, resulting in continuous production and faster product turnaround times.

Overall, automation in the food industry offers numerous benefits, including increased efficiency, improved food safety, cost savings, improved product quality, and increased production capacity. As such, it is an essential tool for food manufacturers seeking to remain competitive in today's rapidly evolving market.

Top Benefits of Investing in Automation for Food Manufacturers

Following, we've discussed some crucial top benefits of investing in automation for food manufacturers. Let's discuss:

Enhances Quality Control

Automation in the food industry can improve quality control in several ways:

- Consistency: Automated systems can provide consistent and precise measurements, resulting in improved quality control. This can help ensure that products meet required standards and specifications, reducing the likelihood of product recalls and improving customer satisfaction.

- Real-time monitoring: Automated systems can monitor the production process in real-time, allowing companies to identify and address any issues that arise quickly. For example, sensors can detect variations in temperature or moisture levels, allowing companies to make adjustments to the production process in real-time.

- Data analysis: Automated systems can collect and analyze data on various aspects of the production process, providing insights into trends and patterns that can help improve quality control. For example, data analysis can identify sources of variability in the production process, allowing companies to take corrective action to improve quality.

- Quality checks: Automated systems can perform quality checks at various stages of the production process, ensuring that products meet required standards and specifications. For example, automated systems can use vision inspection to detect defects in products, such as missing labels or packaging errors.

Automation in the food industry can improve quality control by providing consistent and precise measurements, real-time monitoring, data analysis, and quality checks. This can help ensure that products meet required standards and specifications, reducing the likelihood of product recalls and improving customer satisfaction.

Enhances Targeting Capabilities

Automation in the food industry can improve targeting capabilities in several ways:

- Data collection: Automated systems can collect data on various aspects of the production process, such as inventory levels, sales data, and customer preferences. This data can be used to identify trends and patterns that can help companies target their products and marketing efforts more effectively.

- Personalization: Automated systems can use data on customer preferences to personalize products and marketing efforts. For example, companies can use data on customer preferences to create customized product offerings or targeted marketing campaigns.

- Inventory management: Automated systems can help companies manage inventory more efficiently, reducing the risk of stockouts or overstocks. This can help companies target their products more effectively by ensuring that they have the right products available at the right time.

- Forecasting: Automated systems can use data on past sales and customer preferences to forecast future demand, helping companies target their products more effectively. For example, companies can use forecasting data to adjust their production schedules to meet anticipated demand.

Automation in the food industry can improve targeting capabilities by collecting data, personalizing products and marketing efforts, managing inventory more efficiently, and forecasting future demand. This can help companies target their products more effectively, increasing sales and customer satisfaction.

Gain Better Visibility

Modern consumers are putting more and more pressure on the food industries because they want to know more about where their food originates from and how it got into their shopping basket. So, you must make sure that you have knowledge of the chemicals entering and leaving your supply chain if you want to keep your clients' trust.

A central database created by an integrated system can make it easier and faster to get the data you need. You may be able to acquire visibility into existing and forthcoming legal requirements, assisting you in becoming compliant and market-adaptive, by investing in a system designed exclusively for the food industry.

In order to protect your operations against product recalls, tools like lot tracking or IoT also enable you to quickly identify where impacted products have entered your supply chain and where they are right now. Ultimately, it's preferable if you can answer right away!

Reduce Food Waste

There are many ways to reduce waste in the food processing industry using automated technologies. They can lessen the quantity of products that must be rejected owing to mistakes or flaws by assuring precision and uniformity in the production process.

For instance, the quantity of packages that must be abandoned owing to inaccurate weights will decrease if a packaging machine is set to precisely weigh and package a specified amount of food. As a result, there will be less variation in each package's weight.

Second, it might be beneficial to apply automated techniques to pinpoint and remedy the production process's waste causes. Organizations can, for example, detect and analyze food waste during the production process by using sensors and analytics.

By minimizing overproduction, automated methods can also aid in production optimization. Businesses can avoid producing more food than is necessary, preventing waste, and preserving resources, by monitoring demand and modifying output accordingly.

Ultimately, waste reduction can boost a business's financial performance and lessen its environmental impact.

Enhanced Data Collection and Analysis

Automation in the food industry can enhance data collection and analysis by providing real-time, accurate, and detailed information on various aspects of the production process. Here are some ways automation can improve data collection and analysis:

- Sensor technology: Automated systems can use sensor technology to collect data on various aspects of the production process, such as temperature, humidity, and pressure. This data can be collected in real-time and used to monitor production processes and identify potential issues before they arise.

- Machine learning: Automated systems can use machine learning algorithms to analyze data collected from various sources, such as sensor data, quality control data, and customer feedback. This can help companies identify patterns and trends in the data and make informed decisions based on the insights gained.

- Predictive analytics: Automated systems can use predictive analytics to anticipate changes in demand or identify potential issues before they arise. This can help companies adjust production processes or inventory levels to prevent overproduction and reduce waste.

- Supply chain visibility: Supply chain visibility can be offered by automated systems, allowing organizations to follow items and components from their point of origin to the final consumer. This can assist businesses in identifying possible supply chain problems and resolving them before they have an impact on the quality or safety of their products.

- Real-time monitoring: Automated technologies that monitor production processes in real-time help firms identify issues as they arise and respond appropriately before they get worse. This can improve overall effectiveness and help to stop issues from compromising the quality or safety of the product.

Ultimately, automation in the food industry can enhance data collection and analysis by providing real-time, accurate, and detailed information on various aspects of the production process. This can help companies make informed decisions, identify potential issues before they arise, and improve overall efficiency and quality.

Protect Company’s Reputation and Brand

Automation in the food industry can help companies protect their brand by ensuring consistency in product quality and safety, improving customer satisfaction, and reducing the likelihood of product recalls or other issues that can damage the company's reputation. Here are some ways automation can protect your company's brand:

- Standardization: Automated systems can ensure that products are produced to the same standards every time, reducing the likelihood of variations in quality or safety. This can help build trust with customers and protect the company's reputation.

- Real-time monitoring: Automated systems can monitor production processes in real-time, allowing companies to quickly identify any issues that arise and take corrective action before they escalate. This can help prevent issues from affecting product quality or safety and protect the company's reputation.

- Compliance: Automated systems can help companies comply with regulatory requirements and industry standards, reducing the likelihood of product recalls or other issues that can damage the company's reputation.

Overall, automation in the food industry can help companies protect their brand by ensuring consistency in product quality and safety, improving customer satisfaction, and reducing the likelihood of product recalls or other issues that can damage the company's reputation.

Helps to Keep Your Workforce Safe and Secure

Automation in the food industry can help keep the workforce safe from injury in several ways:

- Reduced manual labor: Automation can eliminate the need for manual labor in certain areas, reducing the risk of injuries associated with repetitive or strenuous tasks. For example, automated systems can handle tasks such as packaging and labeling, reducing the need for workers to perform these tasks manually.

- Ergonomic design: Automated systems are often designed with ergonomics in mind, reducing the risk of injuries caused by awkward postures, repetitive motions, or heavy lifting. For example, conveyor systems can be designed to move products at the correct height for workers to easily handle them, reducing the risk of back injuries.

- Safety features: Automated systems often have built-in safety features, such as sensors and alarms, that can help prevent accidents and injuries. For example, sensors can detect when a worker is in a danger zone and stop the equipment until the area is clear.

- Training and support: Companies that implement automation in the food industry often provide training and support for their employees. This can help workers understand how to safely operate and maintain the equipment, reducing the risk of accidents and injuries.

Ultimately, automation in the food industry can help keep the workforce safe from injury by reducing the need for manual labor, incorporating ergonomic design, implementing safety features, and providing training and support for employees.

End-to-End Traceability

Automation in the food industry can help gain unprecedented levels of end-to-end traceability by providing visibility into the entire supply chain, from raw materials to finished products. This can be achieved through several means:

- Barcode and RFID scanning: Automated systems can use barcode or RFID scanning to track ingredients and products as they move through the supply chain. This can help companies identify the origin of ingredients and track their movement throughout the production process, providing better traceability and transparency.

- Digital record-keeping: Automated systems can maintain digital records of all transactions and activities in the supply chain, providing a comprehensive view of the entire process. This can help companies quickly identify any issues that arise and take corrective action as necessary.

- Blockchain technology: Blockchain technology can be used to create an immutable record of all transactions and activities in the supply chain, providing a tamper-proof and transparent system for tracking products. This can help ensure that products are authentic and traceable, reducing the risk of fraud or counterfeiting.

- Real-time monitoring: Automated systems can monitor the production process in real-time, allowing companies to identify any issues that arise quickly. This can help companies take corrective action to prevent issues from escalating and affecting the quality or safety of the products.

So, automation in the food industry can provide unprecedented levels of end-to-end traceability by using barcode and RFID scanning, digital record-keeping, blockchain technology, and real-time monitoring. This can help companies identify the origin of ingredients, track their movement throughout the supply chain, and quickly identify and address any issues that arise.

Flexibility and Scalability

Automation in the food industry can help companies become more flexible and scalable by increasing their ability to adapt to changes in demand or production requirements. This can be achieved through several means:

- Modular design: Automated systems can be designed in a modular fashion, allowing companies to add or remove modules as needed to adjust production capacity or accommodate changes in product requirements.

- Rapid reconfiguration: Automated systems can be reconfigured quickly and easily to accommodate changes in product requirements or production processes. This can help companies respond to changes in demand or new product opportunities more quickly.

- Remote monitoring and control: Automated systems can be monitored and controlled remotely, allowing companies to adjust production processes or make changes to product specifications from anywhere with an internet connection.

- Predictive analytics: Automated systems can use predictive analytics to anticipate changes in demand or identify potential issues before they arise. This can help companies proactively adjust production processes or inventory levels to meet changing requirements.

- Integration with other systems: Automated systems can be integrated with other systems, such as supply chain management or enterprise resource planning systems, to provide a comprehensive view of the entire production process. This can help companies identify opportunities for optimization or improvement and make more informed decisions.

Overall, automation in the food industry can help companies become more flexible and scalable by using modular design, rapid reconfiguration, remote monitoring and control, predictive analytics, and integration with other systems. This can help companies respond more quickly to changes in demand or production requirements, optimize production processes, and improve overall performance.

Boost Output Rates and Efficiency

Automation in the food industry can increase efficiency and boost output rates in several ways:

- Speed and accuracy: Automated systems can perform tasks faster and more accurately than human workers, resulting in increased efficiency and output rates. For example, automated systems can perform repetitive tasks, such as packaging or sorting, at a much faster rate than human workers.

- Reduced labor costs: Automated systems can reduce labor costs by replacing human workers with machines. This can result in cost savings and increased efficiency, as machines can operate 24/7 without breaks or downtime.

- Reduced waste: Automated systems can help reduce waste by ensuring that products are produced to the exact specifications required. This can help reduce the number of raw materials needed and minimize the amount of waste generated during the production process.

- Continuous operation: Automated systems can operate continuously, without breaks or downtime, resulting in increased output rates. This can help companies meet demand more effectively and reduce lead times.

- Real-time monitoring: Automated systems can monitor the production process in real-time, allowing companies to identify and address any issues that arise quickly. This can help reduce downtime and increase output rates.

Ultimately, automation in the food industry can increase efficiency and boost output rates by increasing speed and accuracy, reducing labor costs, reducing waste, operating continuously, and providing real-time monitoring. This can help companies increase production capacity, reduce costs, and improve overall performance.

Competitive Advantage

Companies are always looking for strategies to outperform their competitors in today's cutthroat business environment. By investing in cutting-edge and effective automated technologies, businesses that manufacture food can differentiate themselves from rivals in the market and produce higher-quality goods with quicker turnaround times. As a result, it's possible that profitability, client satisfaction, and brand loyalty may all rise.

Additionally, businesses that use automation solutions can further establish their reputation as responsible and trustworthy manufacturers as consumers grow more conscious about food safety and quality.

Businesses might also be able to quickly adjust to shifting market demands and trends because to the greater efficiency and flexibility that automated systems offer, further solidifying their place in the sector.

Giving food manufacturing businesses a competitive edge through the use of innovative, efficient automated technologies can ultimately result in greater revenue and long-term success.

Automation in Food Manufacturing: Potential Challenges & Solutions

While automation in food manufacturing offers many benefits, there are also potential challenges that may arise. Here are some common challenges and how to mitigate them:

- Cost: One of the main challenges of implementing automation is the upfront cost of investment. Automation systems can be expensive, and companies may need to make significant investments in technology, equipment, and training. To mitigate this challenge, companies should carefully evaluate the costs and benefits of automation and develop a clear plan for implementation.

- Technical difficulties: Automation systems are complex and may require specialized technical expertise to operate and maintain. Companies may face challenges related to system integration, data management, and software compatibility. To mitigate these challenges, companies should invest in training and development for their staff, partner with vendors and suppliers with expertise in automation, and have a clear plan for maintenance and support.

- Regulatory compliance: Food manufacturing is heavily regulated, and companies must adhere to strict quality and safety standards. Automation can create new compliance challenges related to data management, traceability, and labeling. To mitigate these challenges, companies should ensure that their automation systems are designed to meet regulatory requirements, invest in training and development for their staff, and have clear procedures in place for auditing and reporting.

- Workforce displacement: Automation can lead to job displacement as companies reduce their reliance on manual labor. This can create social and economic challenges, particularly in communities that rely on manufacturing jobs. To mitigate this challenge, companies should develop clear plans for retraining and upskilling their workforce, and work with community stakeholders to identify opportunities for economic development.

- Cybersecurity: Automation systems can be vulnerable to cyber attacks, which can compromise sensitive data and disrupt production processes. To mitigate this challenge, companies should invest in robust cybersecurity measures, such as firewalls, intrusion detection systems, and data encryption. They should also develop clear procedures for incident response and recovery.

In summary, automation in food manufacturing offers many benefits but also presents potential challenges that must be carefully considered and mitigated. Companies can mitigate these challenges by carefully evaluating costs and benefits, investing in training and development, ensuring regulatory compliance, developing plans for workforce displacement, and investing in robust cybersecurity measures.

Wrapping Up

In conclusion, investing in automation for food manufacturers has numerous benefits, ranging from increased efficiency and consistency in quality to improved safety and cost savings.

By automating specific tasks within the food manufacturing process, companies can significantly reduce their production costs while increasing output and improving product quality. Additionally, the use of automation can enhance worker safety, increase productivity, and improve overall customer satisfaction.

Despite the potential challenges that may arise with automation, such as implementation costs and the need for worker retraining, the long-term benefits far outweigh the initial investment. By mitigating these challenges through careful planning and implementation, food manufacturers can take advantage of the many benefits that automation has to offer.

Therefore, we urge food manufacturers to consider automation as a viable investment and take the necessary steps to incorporate it into their operations. By doing so, they can improve their bottom line, boost their brand reputation, and position themselves as leaders in an industry that is constantly evolving.

How Deskera Can Assist You?

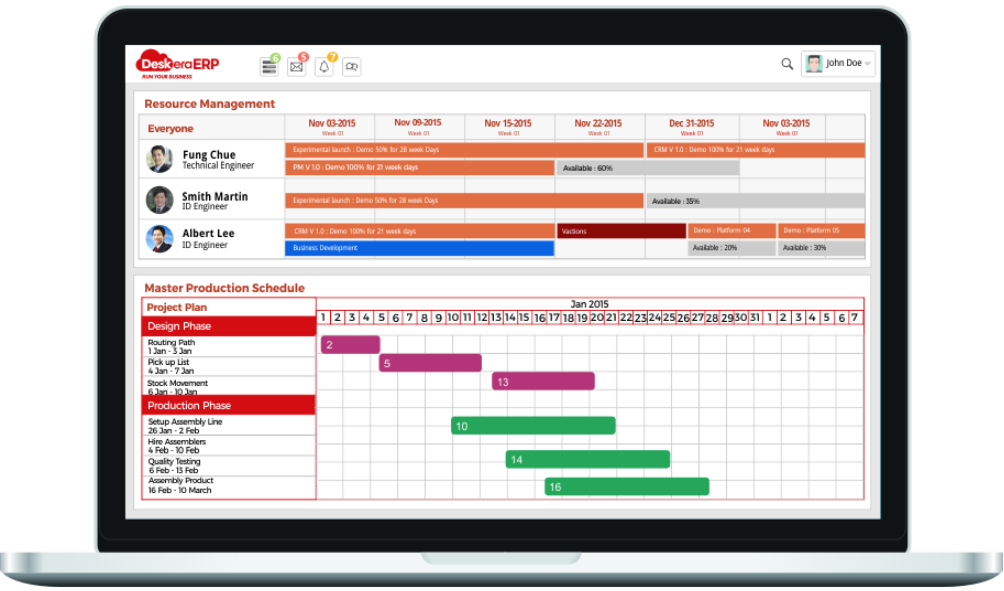

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- The goal of automation is to improve efficiency, reduce costs, and increase productivity while maintaining high levels of quality and safety in the food products.

- Automation can help reduce the time and labor required for various tasks, resulting in faster and more efficient production processes. For example, automated systems can accurately measure and mix ingredients, resulting in consistent product quality and faster production times.

- Automated systems are often designed with ergonomics in mind, reducing the risk of injuries caused by awkward postures, repetitive motions, or heavy lifting. For example, conveyor systems can be designed to move products at the correct height for workers to easily handle them, reducing the risk of back injuries.

- Automated systems can use barcode or RFID scanning to track ingredients and products as they move through the supply chain. This can help companies identify the origin of ingredients and track their movement throughout the production process, providing better traceability and transparency.

- Automated systems can help companies manage inventory more efficiently, reducing the risk of stockouts or overstocks. This can help companies target their products more effectively by ensuring that they have the right products available at the right time.

- Automated systems can be integrated with other systems, such as supply chain management or enterprise resource planning systems, to provide a comprehensive view of the entire production process. This can help companies identify opportunities for optimization or improvement and make more informed decisions.

- Automated systems can use machine learning algorithms to analyze data collected from various sources, such as sensor data, quality control data, and customer feedback. This can help companies identify patterns and trends in the data and make informed decisions based on the insights gained.

Related Articles