When it comes to running a business, disruptions in the supply chain can be a real curse. Supply chain disruptions can have a huge impact on a business, from delays in shipping to complete stoppages of production.

A disruption in the supply chain can have serious consequences for businesses, ranging from financial losses to customer dissatisfaction. It is important for businesses to have a clear understanding of what a supply chain disruption is, and how it can affect their operations. Hence, we have this article ready for you, let's get started!

This article covers the following:

- What is Supply Chain Disruption?

- Causes of Disruptions in Supply Chain

- Impact of Supply Chain Disruptions

- Strategies to Mitigate Supply Chain Disruptions

- Examples of Supply Chain Disruptions

- Benefits of Resilient Supply Chains

- Best Practices for Supply Chain Resilience

- Technology Solutions for Supply Chain Resilience

- Supply Chain Risk Management

- The Future of Supply Chain Resilience

What is Supply Chain Disruption?

Supply chain disruption is a term used to describe any event or situation that affects the normal flow of goods or services. This can include anything from a natural disaster, to a labor strike, to a pandemic.

Disruptions can cause delays, shortages, and other problems in the supply chain, leading to increased costs and decreased customer satisfaction. Companies must be prepared to respond to these events and mitigate their impact on their supply chain.

This includes having a detailed plan in place to identify and address the risks associated with supply chain disruption. Additionally, companies should invest in technology and processes to ensure their supply chain remains resilient in the face of unexpected events. With careful planning and the right technology, companies can reduce the risks associated with supply chain disruption and maintain their competitive edge.

What Causes Supply Chain Disruptions?

Supply chains are complicated and interconnected systems, and disruptions to them can cause serious problems. Disruptions can range from minor glitches to major catastrophes that can cost businesses millions of dollars. Understanding the causes of supply chain disruptions can help businesses take steps to minimize the impact of such events.

Natural Disasters

Natural disasters like hurricanes, earthquakes, and floods can have a devastating impact on supply chains. These events can reduce the availability of raw materials, slow down transportation, and disrupt communication networks.

Political Instability

Political instability in certain parts of the world can lead to supply chain disruptions. Trade sanctions and tariffs, as well as civil unrest, can all have an impact on the ability of businesses to get the materials they need to fulfill orders.

Economic Shifts

Economic shifts can also lead to supply chain disruptions. A recession or economic downturn can lead to reduced demand and cause businesses to scale back their operations. This can lead to supply chain disruptions as suppliers may not be able to meet the reduced demand.

Technology Failures

Technology is an integral part of many supply chains. If there is a technology failure, it can cause significant disruptions. This can range from a computer system crash to a security breach that compromises sensitive information.

Human Error

Human error is another common cause of supply chain disruptions. This can include an employee making a mistake in an order or data entry or a supplier making an error in their shipment.

By understanding the causes of supply chain disruptions, businesses can take steps to minimize their impact. This can include investing in redundancies and backup systems, developing plans for dealing with crises, and diversifying supply chains. By taking proactive steps, businesses can protect themselves from the negative impacts of supply chain disruptions.

What is the Impact of Supply Chain Disruptions?

The modern global economy is highly interconnected and reliant on the smooth functioning of supply chains. Unfortunately, disruptions in supply chains are becoming increasingly commonplace, and their impact is far-reaching and costly.

Disruptions can take a variety of forms, such as natural disasters, political instability, and customer demand changes. Regardless of the cause, supply chain disruptions can have a significant impact on businesses, their customers, and the economy as a whole.

The direct impact of supply chain disruptions is felt most heavily in terms of lost sales and profits. When supply chains are disrupted, businesses can’t deliver their products or services to customers in a timely manner.

This often results in lost sales, missed opportunities, and a decrease in customer satisfaction. In addition, supply chain disruptions can lead to increased production costs, additional storage costs, and higher shipping costs.

All of these can have a significant impact on the bottom line. The indirect impact of supply chain disruptions can be even more costly. When supply chains are disrupted, businesses often have to scramble to make alternative arrangements for the delivery of their products and services.

This can lead to delays in production, a decrease in quality, and a decrease in customer satisfaction. Furthermore, supply chain disruptions can damage a company’s reputation and jeopardize customer loyalty.

Finally, supply chain disruptions can have an impact on the economy as a whole. When businesses are unable to deliver their products and services on time, it can lead to a decrease in consumer spending.

This decrease can lead to an overall decrease in economic activity. In conclusion, supply chain disruptions can have a significant impact on businesses, their customers, and the economy as a whole.

Businesses must be prepared to respond quickly and effectively to any supply chain disruptions they may face. It’s also important to understand the potential economic impacts of such disruptions, so that businesses can develop strategies to minimize their impact.

What are Some of the Strategies to Mitigate Supply Chain Disruptions?

Supply chain disruptions can have a huge impact on businesses and their customers. From small delays to major crises, supply chain disruptions can cause problems that can have long-term effects on operations and customer satisfaction.

As a result, it’s important for businesses to have strategies in place to mitigate the potential harm that supply chain disruptions can cause. Here are some strategies businesses can use to reduce the effects of supply chain disruptions:

Implement a Risk Management Plan

Developing a risk management plan can help businesses identify potential issues and prepare responses for when disruptions occur. This can help businesses react quickly and minimize the effects of any disruption.

Diversify Your Suppliers

Having multiple suppliers can help businesses reduce the risks of supply chain disruptions. When one supplier is affected by a disruption, other suppliers can step in to fill the gap.

Manage Inventory Levels

Having an adequate amount of inventory can help businesses mitigate the effects of supply chain disruptions. Having too much inventory can lead to excess costs and lead times, but having too little can cause problems if there are disruptions.

Utilize Just-in-Time Delivery

Just-in-time delivery can help businesses reduce the risks associated with supply chain disruptions. By having inventory delivered when it’s needed, businesses can reduce the chances of being left with excess inventory or being unable to fill customer orders.

Leverage Technology

Technology can be used to help businesses monitor their supply chain and anticipate potential disruptions. By using predictive analytics and artificial intelligence, businesses can better prepare for disruptions and respond when they occur.

By following these strategies, businesses can better prepare for and manage supply chain disruptions. By having a plan in place, businesses can reduce the likelihood of being affected by a supply chain disruption and minimize the potential impact of the disruption.

What are Some Examples of Supply Chain Disruptions?

Here are some of the examples of supply chain disruptions that you must be aware of as business owners:

Natural disasters

Floods, earthquakes, and other natural disasters can disrupt the entire supply chain process. For example, in 2017, Hurricane Harvey caused several chemical plants to shut down, leading to a shortage of raw materials for many companies.

Political instability

Political unrest, civil war, and other geopolitical events can disrupt supply chains. For example, during the Arab Spring, several countries experienced supply chain disruptions due to protests, strikes, and other unrest.

Trade wars

Trade wars can cause tariffs and other restrictions that can disrupt global supply chains. For example, the US-China trade war has caused significant disruption in the supply chains of companies that rely on Chinese goods and services.

Cyberattacks

Cyberattacks can disrupt supply chains by disrupting access to key systems and information. For example, in 2017, the WannaCry ransomware attack caused major disruptions in many countries’ supply chains.

Labor shortages

Labor shortages can cause delays in the production and delivery of goods, leading to supply chain disruptions. For example, many companies experienced disruptions in their supply chains due to the lack of skilled labor in certain areas.

Technology failures

Technology failures can disrupt the supply chain process. For example, in 2018, a software bug caused a major disruption in Amazon’s supply chain, leading to delays in orders.

Transportation issues

Delays in transportation can disrupt the supply chain process. For example, in 2017, a trucker strike in France caused major disruptions in the supply chain for many companies.

Supplier Issues

Suppliers can cause disruptions in the supply chain process. For example, if a supplier fails to deliver goods on time or fails to meet quality standards, the entire supply chain can be disrupted.

What are the Benefits of Resilient Supply Chains?

The world has been rocked by a series of disruptions to supply chains over the past several years, ranging from natural disasters and pandemics to extreme weather events and political unrest.

In a world of increasingly interconnected global economies, disruptions have far-reaching implications for businesses and consumers alike. For businesses, supply chain disruptions can cause significant financial losses due to delayed or canceled orders and production, as well as lost sales and market share.

Furthermore, disruptions can damage a company’s reputation, as customers and other stakeholders may become unhappy with their experience. Fortunately, businesses can take steps to become more resilient to supply chain disruptions.

By investing in a resilient supply chain, businesses can protect themselves and their customers from the financial and reputational costs of supply chain disruptions. The benefits of a resilient supply chain are numerous.

For one, businesses can reduce the risk of costly disruptions by diversifying their sourcing and production across multiple countries, regions, and suppliers. This diversification can help ensure that if one location is affected by a disruption, the business can still fulfill orders.

Furthermore, businesses can also take steps to reduce the lead times between orders and delivery. By reducing lead times, businesses can reduce the impact of disruptions, as they will have more time to identify and respond to them.

Another benefit is that a resilient supply chain can help businesses gain greater visibility into their supply chains. By having more visibility into their supply chains, businesses can better identify potential risks and take steps to mitigate them.

Finally, businesses can also use a resilient supply chain to build stronger relationships with their customers and other stakeholders. By having a better understanding of their supply chains, businesses can be more transparent and accountable to customers, thus strengthening their relationships.

Overall, investing in a resilient supply chain can help protect businesses from the financial and reputational costs of supply chain disruptions. By diversifying sourcing, reducing lead times, and gaining greater visibility into the supply chain, businesses can become more resilient to disruptions and build stronger relationships with customers and other stakeholders.

What are the Best Practices for Resilient Supply Chains?

In a world of constantly evolving supply chains, disruptions can create a significant impact on a company’s bottom line. Whether it’s a natural disaster, a cyber-attack, a labor strike, or even a pandemic, the ability to quickly and efficiently respond to supply chain disruptions is essential for the long-term success of any business. In this blog, we’ll explore the best practices for supply chain resilience and discuss what companies can do to prepare for and respond to supply chain disruptions.

Develop a Risk-Awareness Strategy

The first step to creating a resilient supply chain is to understand the risks associated with it. Companies should develop a risk-awareness strategy to identify potential risks and assess the probability of their occurrence. This strategy should also cover potential responses to disruptions and the potential impact of each.

Establish a Risk-Mitigation Plan

Once the risks have been identified, companies should establish a risk-mitigation plan to minimize their impact. This plan should include strategies such as diversifying suppliers and building redundancies into the supply chain to ensure continuity in the event of a disruption.

Implement a Proactive Monitoring System

It’s important to have a proactive monitoring system in place to detect potential supply chain disruptions and alert the appropriate personnel. This system should include real-time data analysis so that potential issues can be identified and addressed before they become major problems.

Maintain Open Communication

Open communication between all stakeholders is essential for responding quickly and efficiently to supply chain disruptions. Companies should establish clear channels of communication and ensure that the appropriate personnel is aware of any changes or issues that arise.

Invest in Technology Investing in technology can help companies to mitigate supply chain disruptions and ensure that operations remain efficient. Companies should look for solutions such as supply chain visibility software, predictive analytics, and automated systems to help them prepare for and respond to supply chain disruptions.

By following these best practices, companies can minimize the impact of supply chain disruptions and ensure that their operations are resilient and efficient. With the right preparation and response strategies in place, companies can ensure that supply chain disruptions don’t disrupt their bottom line.

Technology Solutions for Supply Chain Resilliance

The global supply chain, which is the backbone of modern commerce, is increasingly vulnerable to disruption. Natural disasters, global pandemics, political unrest, and other unforeseen events can cause major supply chain disruptions, leading to losses in profits, customer satisfaction, and more.

To mitigate the risk of disruption, it is essential for companies to invest in technology solutions that can help them maintain supply chain resilience. To start, companies should focus on strengthening their end-to-end supply chain visibility.

Visibility is key to understanding the locations and statuses of goods, as well as the potential risks associated with them. Doing so can help companies anticipate potential disruptions and take preventive measures to mitigate their effects.

To ensure accurate visibility, companies should invest in systems that can provide real-time data, such as GPS tracking and RFID tags. In addition, companies should focus on improving their supply chain agility.

Agility is the ability to quickly and efficiently respond to changes in demand, supply, and market conditions. Companies should invest in systems that can help them quickly and accurately monitor their supply chain for any changes, such as predictive analytics and automated decision-making systems.

These systems can provide companies with the information they need to make informed decisions and quickly implement changes to their supply chain. Finally, companies should focus on improving their supply chain resiliency. Resiliency refers to the ability to quickly recover from disruptions and return to normal operations.

To achieve this, companies should invest in systems that can reduce the impact of disruptions, such as alternative sourcing solutions, third-party logistics, and automated supply chain optimization tools. These systems can help companies minimize the damage caused by disruption and quickly restore their supply chain.

By investing in technology solutions that can improve supply chain visibility, agility, and resiliency, companies can ensure that their supply chain remains resilient and adaptive to any changes. Doing so can help them reduce the risk of disruption and maintain the efficiency and profitability of their operations.

Supply Chain Risk Management

Supply chain risk management is a critical component of any business. As technology advances and global supply chains become more complex, the potential for disruptions and risks increases.

Companies must be prepared to mitigate and manage risks in order to remain profitable and competitive. Risks can arise from a variety of sources, including natural disasters, political instability, cyber threats, and product recalls. Companies must identify potential risks before they occur and develop strategies to reduce their impact.

This requires an understanding of the external environment, the company’s internal processes, and its partner networks. A key element of supply chain risk management is the development of a risk management plan.

This plan should identify potential risks and outline strategies to mitigate them. Companies should also consider how they can take advantage of opportunities that arise from these risks.

For example, companies can use the uncertainty of global markets to their advantage by diversifying their supply chains. When it comes to supply chain disruptions, companies should be proactive in their approach.

This includes planning for potential risks and setting up contingency plans in case of disruptions. Companies should also consider the use of technologies such as blockchain and predictive analytics to better monitor their supply chains.

Finally, companies should ensure that their supply chain partners are able to respond quickly to disruptions. This includes having adequate resources and personnel in place to handle any disruptions.

Companies should also consider the use of third-party providers, who can help manage and monitor supply chains. Supply chain risk management is a complex process, but it is essential for businesses to remain competitive in today’s global economy.

Companies must identify potential risks and develop strategies to mitigate them. They must also be proactive in their approach, which includes setting up contingency plans and investing in technologies to better monitor their supply chains. By doing so, companies can ensure that their supply chains remain resilient, even in the face of disruptions.

What is the Future of Supply Chain Resilience?

In today’s world, disruptions to the global supply chain are becoming increasingly common. From natural disasters to political unrest to pandemics, the supply chain is being pushed to its limits. As a result, supply chain resilience is becoming an increasingly important topic.

It is no longer enough to simply plan for the unexpected; supply chain professionals must become proactive and adaptive in their efforts to ensure the flow of goods and services remains unharmed. So what does supply chain resilience look like in the future?

To begin, supply chain professionals must take a holistic approach to supply chain management. This means looking at the entire supply chain ecosystem and understanding how disruptions can occur at any point along the chain.

Secondly, supply chain professionals must develop a risk management plan that takes into account the potential impacts of disruptions and how they can be mitigated.

For example, companies may consider investing in innovative technologies such as blockchain and predictive analytics to better monitor and manage the supply chain in real time.

Finally, supply chain resilience must be seen as part of a larger corporate strategy. Companies must recognize that supply chain disruptions can have a significant impact on their operations, brand, and profits.

As such, supply chain resilience must be seen as an essential part of a company’s long-term success. This means adopting a proactive approach to supply chain management and investing in the right technologies and processes to ensure the supply chain can withstand any potential disruption.

By taking a proactive approach to supply chain management and investing in the right technologies and processes, companies can ensure that their supply chain remains resilient in the face of any potential disruption. In doing so, companies can not only protect themselves against disruptions but also position themselves for long-term success.

How Can Deskera Assist You?

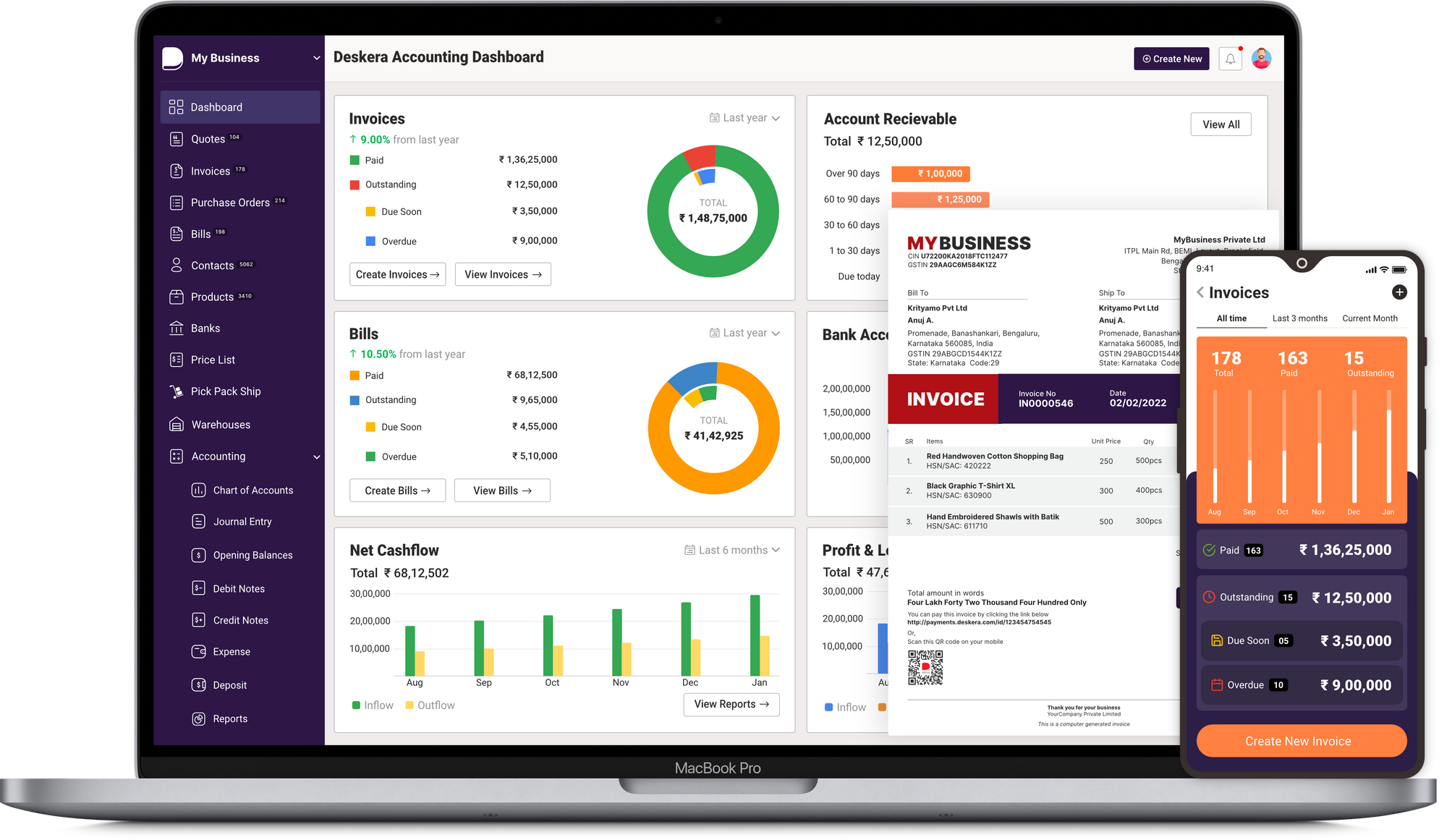

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities, such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Related Articles: