In today's highly dynamic and globalized supply chain environment, supplier relationships are more than just transactional—they are strategic. Organizations no longer focus solely on cost savings but also on collaboration, compliance, innovation, and long-term value.

This shift in mindset is driving businesses to rethink how they manage their supplier base, leading to a renewed focus on Supplier Lifecycle Management (SLM).

Supplier Lifecycle Management refers to the end-to-end process of managing suppliers from initial identification and onboarding to performance evaluation, risk management, and even offboarding.

With supply chain disruptions and geopolitical uncertainties becoming increasingly common, companies are realizing the critical importance of having structured, transparent, and tech-enabled supplier processes.

In fact, SLM is expected to grow by 5.6% by 2030, with many organizations planning to reinvent their SLM strategies within the next three years to strengthen supplier relationships, reduce operational risks, and extract greater value from partnerships.

Effective SLM is not just about minimizing risks—it's also about unlocking growth opportunities through better collaboration and data-driven decision-making. Businesses that invest in robust SLM frameworks are better equipped to ensure compliance, streamline procurement, manage costs, and foster innovation across their supplier networks. The result? A more resilient, agile, and competitive supply chain.

For companies looking to elevate their supplier management, modern ERP systems like Deskera ERP offer powerful capabilities to streamline every stage of the supplier lifecycle.

From automated onboarding and integrated supplier databases to real-time performance tracking and compliance monitoring, Deskera ERP enables organizations to manage supplier relationships with greater efficiency and insight.

Its intuitive interface and flexible features make it a valuable tool for businesses aiming to transform their supply chain into a strategic advantage.

What is Supplier Lifecycle Management (SLM)?

Supplier Lifecycle Management (SLM), also known as vendor lifecycle management, is a strategic approach that organizations use to manage their relationships with suppliers from initial contact through to final offboarding.

It encompasses all stages of supplier interaction—starting with sourcing and selection, continuing through onboarding and performance evaluation, and ending with offboarding when a supplier is no longer needed. The ultimate goal of SLM is to build collaborative, value-driven partnerships that reduce costs, improve supply chain efficiency, and mitigate operational risks.

SLM takes a holistic view of supplier relationships, integrating processes such as Procure-to-Pay (P2P) and Source-to-Contract (S2C) into one unified lifecycle.

While the P2P cycle focuses on the transactional side of procurement—from requisition to payment—the S2C cycle emphasizes strategic sourcing, supplier evaluation, and contract negotiation. Together, these processes contribute to a well-rounded SLM framework that supports both operational efficiency and long-term strategic value.

The supplier lifecycle begins with identifying and evaluating potential vendors based on key criteria like cost, quality, lead time, compliance, and alignment with organizational values. After successful onboarding, businesses set expectations and integrate suppliers into their systems.

Throughout the partnership, supplier performance is regularly monitored using key performance indicators (KPIs), helping to uncover opportunities for improvement and innovation. Regular communication and collaboration remain central to maintaining strong relationships and ensuring mutual success.

Eventually, some supplier relationships come to a natural close—whether due to changing business needs, project completion, or underperformance. Effective offboarding ensures that this transition happens smoothly while preserving the relationship for potential future engagement.

When managed well, SLM enables companies to improve visibility across their supply base, enhance supplier accountability, and stay agile in a competitive, fast-changing market environment.

What’s the Difference Between SLM and SRM?

Though Supplier Lifecycle Management (SLM) and Supplier Relationship Management (SRM) are interrelated, they focus on different dimensions of supplier engagement.

Below is a comprehensive breakdown of their distinctions across multiple areas.

1. Definition and Core Purpose

- SLM: A structured framework to manage every phase of a supplier’s engagement—from sourcing and onboarding to performance management and offboarding.

- SRM: A strategic discipline focused on nurturing collaborative, long-term partnerships with key suppliers to drive mutual growth and innovation.

2. Scope and Applicability

- SLM: Applies to all suppliers, regardless of their strategic importance.

- SRM: Reserved for key or strategic suppliers who offer high value or critical capabilities.

3. Approach: Process vs. Relationship

- SLM: Process-driven, emphasizing compliance, efficiency, and lifecycle visibility.

- SRM: Relationship-driven, emphasizing trust, joint initiatives, and strategic alignment.

4. Objectives

- SLM: Improve supplier quality, mitigate risk, ensure compliance, and optimize performance across all engagements.

- SRM: Enhance collaboration, foster innovation, and create long-term value with select partners.

5. Lifecycle Coverage

- SLM: Manages the entire supplier journey, from onboarding to offboarding.

- SRM: Focuses on the active relationship stage, particularly during contract execution and collaboration.

6. Metrics and KPIs

- SLM: Tracks operational metrics such as delivery time, quality scores, compliance rates, and cost savings.

- SRM: Focuses on strategic KPIs like innovation contribution, joint project outcomes, and relationship health.

7. Duration of Engagement

- SLM: Typically involves finite timelines, based on the project or contract duration.

- SRM: Built for long-term, ongoing relationships aimed at strategic growth.

8. Ownership and Stakeholders

- SLM: Usually led by procurement teams and involves supply chain, compliance, and finance departments.

- SRM: Involves senior leadership, business unit heads, and innovation teams, alongside procurement.

9. Tools and Technology

- SLM: Relies on ERP systems, supplier portals, contract management, and onboarding tools.

- SRM: Uses collaboration platforms, performance dashboards, strategic planning tools, and communication systems.

10. Risk Focus

- SLM: Centers on operational and contractual risk—like late deliveries or compliance breaches.

- SRM: Addresses strategic risk—such as loss of innovation capability or breakdown in key alliances.

11. Value Creation

- SLM: Focuses on efficiency and operational value.

- SRM: Aims to create shared, strategic value for both the buyer and supplier.

Stages of Supplier Lifecycle Management (SLM)

Supplier Lifecycle Management (SLM) is a structured approach to managing suppliers from initial identification to offboarding. It ensures supplier relationships are efficient, compliant, and strategically aligned with business goals.

Below are the key stages of the supplier lifecycle:

1. Sourcing and Selection

This first stage focuses on identifying, evaluating, and selecting suppliers that align with the business's operational and strategic needs.

- Define criteria such as cost, quality, delivery timelines, compliance, and sustainability practices.

- Evaluate suppliers through demos, samples, interviews, and past performance analysis.

- Select suppliers based on overall fit and long-term potential.

2. Onboarding

Once suppliers are selected, onboarding ensures a smooth integration into your business ecosystem.

- Set up contracts, roles, responsibilities, and communication protocols.

- Share relevant documentation such as compliance requirements, order processes, and payment details.

- Grant access to platforms or portals used for collaboration and information exchange.

3. Performance Management

Ongoing performance evaluation is vital to ensure suppliers are meeting expectations and delivering value.

- Monitor KPIs such as quality, delivery accuracy, and responsiveness.

- Provide regular feedback to suppliers and initiate corrective actions when needed.

- Recognize high-performing suppliers to encourage continuous improvement.

4. Risk Management

Identifying and mitigating supplier-related risks is crucial to maintaining business continuity and minimizing disruptions.

- Conduct financial, operational, and compliance risk assessments.

- Develop contingency plans to handle supplier failures or market volatility.

- Diversify the supplier base where necessary to reduce dependency.

5. Supplier Relationship Management (SRM)

This stage focuses on fostering collaborative relationships with strategic suppliers for mutual benefit.

- Engage in regular communication and joint problem-solving sessions.

- Recognize contributions and promote shared innovation opportunities.

- Strengthen ties to gain preferential access to resources or services.

6. Data and Information Management

Maintaining up-to-date and accurate supplier data helps support operational efficiency and compliance.

- Store and manage contact information, certifications, tax documents, and performance records.

- Ensure data integrity across systems and maintain audit trails.

- Update supplier information as changes occur during the relationship.

7. Offboarding

When a supplier relationship concludes, structured offboarding ensures a clean exit while preserving continuity and compliance.

- Communicate the offboarding timeline and requirements clearly.

- Finalize payments, close out documentation, and retrieve assets or data.

- Conduct exit reviews to capture insights and improve future processes.

Why Supplier Lifecycle Management Matters

Effective Supplier Lifecycle Management (SLM) plays a vital role in ensuring that supplier relationships are strategic, productive, and aligned with overall business objectives. A well-structured SLM framework not only supports operational efficiency but also strengthens resilience and competitive advantage.

Here's why it matters:

Enhancing Supply Chain Efficiency

SLM enables organizations to streamline every stage of supplier engagement—from selection and onboarding to performance monitoring and offboarding.

By establishing standardized processes and leveraging automation where possible, businesses can minimize delays, reduce manual effort, and improve coordination across departments.

This leads to faster procurement cycles, fewer disruptions, and greater transparency throughout the supply chain.

Reducing Risks and Ensuring Compliance

Suppliers often pose financial, operational, and reputational risks. Through proactive risk management and due diligence at each stage of the supplier lifecycle, companies can identify vulnerabilities early and implement mitigation strategies.

SLM also supports compliance with industry standards, legal regulations, and sustainability requirements by enforcing controls, conducting audits, and ensuring timely documentation.

Improving Supplier Performance

Continuous performance evaluation is at the heart of successful SLM. By setting clear expectations and tracking key performance indicators (KPIs), businesses can assess supplier reliability, product quality, and service levels.

This data-driven approach not only helps identify underperforming suppliers but also promotes accountability and drives improvements over time, ensuring alignment with business goals.

Fostering Innovation and Collaboration

Strong supplier relationships built through structured lifecycle management foster trust, open communication, and collaboration.

This creates opportunities for co-innovation, such as developing new products, exploring emerging markets, or improving existing processes.

By working closely with strategic suppliers, companies can tap into their expertise and resources, unlocking long-term value and competitive advantage.

Key Challenges in Managing the Supplier Lifecycle

Implementing a robust Supplier Lifecycle Management (SLM) strategy is not without its challenges. As supplier networks grow in complexity, organizations must proactively address several operational and strategic hurdles.

Below are some of the most pressing challenges businesses face when managing the supplier lifecycle—and how they can overcome them:

1. Supplier Risk Assessment and Mitigation

Evaluating and managing supplier-related risks—such as financial instability, geopolitical disruption, or ethical non-compliance—can be a daunting task. This is especially true when suppliers lack transparency in their operations or sourcing practices.

Without a structured risk framework, companies may overlook critical vulnerabilities. An effective approach includes regularly assessing vendor financial health, contract adherence, delivery reliability, and dependency levels to reduce exposure and increase supply chain resilience.

2. Measuring and Improving Supplier Performance

Monitoring supplier performance across a diverse network requires consistent tracking and interpretation of metrics like lead time, defect rates, and service responsiveness.

The challenge lies in capturing meaningful data in real-time and translating it into actionable insights. Without standardized performance indicators and regular reviews, businesses risk tolerating subpar service or missing out on optimization opportunities.

3. Ensuring Data Quality and Consistency

Supplier data must be accurate, complete, and up to date to support sound decision-making. However, data quality issues such as duplicate records, outdated contact details, or inconsistent reporting formats often undermine efforts to manage suppliers effectively.

Establishing a robust data governance framework—complete with validation rules and regular audits—is essential to maintain confidence in supplier information across departments.

4. Technology Integration and Interoperability

Integrating SLM tools with existing business systems such as procurement, inventory, and finance platforms is often a major technical hurdle. Siloed systems lead to fragmented data, redundant processes, and user inefficiencies.

To overcome this, companies increasingly adopt integrated ERP platforms that centralize supplier data, streamline workflows, and provide end-to-end visibility into supplier performance and relationships.

5. Change Management and Internal Alignment

Rolling out SLM processes often requires organizational change, which may meet resistance from stakeholders used to traditional methods. Misalignment between procurement, finance, and operations teams can also hinder the adoption of new systems.

Clear communication, role-based training, and leadership support are crucial for encouraging cross-functional collaboration and embedding SLM practices into daily operations.

6. Regulatory Compliance and Ethical Standards

As supply chains become global, adhering to evolving regulatory requirements—including labor laws, environmental policies, and industry certifications—becomes more complicated.

Managing supplier compliance across different jurisdictions and ensuring that vendors meet ethical sourcing standards demands ongoing vigilance, supplier education, and sometimes third-party audits.

7. Scalability of SLM Programs

As a company grows, so does the complexity of its supplier base. A manual or fragmented approach to managing supplier lifecycles may not scale effectively.

Businesses must ensure their SLM strategies and tools are flexible enough to handle increased volumes, new geographies, and evolving business requirements without compromising efficiency or transparency.

Benefits of a Well-Structured Supplier Lifecycle Management (SLM) Process

A well-structured Supplier Lifecycle Management (SLM) strategy is more than just a procurement tool—it is a vital component of a company’s overall operational excellence. When implemented effectively, SLM enhances collaboration, optimizes costs, reduces risks, and contributes to long-term business sustainability.

Below are the key benefits of a strong SLM process:

1. Improved Operational Efficiency

By centralizing supplier data and eliminating redundant or manual tasks, SLM streamlines procurement workflows and administrative processes. Automation of tasks such as onboarding, contract management, and performance tracking reduces manual errors and accelerates decision-making across departments.

2. Optimized Cost Management

SLM enables businesses to track spending patterns, compare supplier quotes, and negotiate better contracts. Through data-driven insights, companies can identify cost-saving opportunities—such as bulk discounts or supplier consolidation—while improving ROI on goods and services.

3. Strengthened Risk Management

By embedding proactive risk identification and mitigation into every stage of the supplier lifecycle, SLM reduces the likelihood of disruptions. Businesses can monitor factors like on-time delivery, quality issues, and compliance breaches, and create contingency plans that minimize financial and reputational risks.

4. Enhanced Supplier Selection and Onboarding

SLM ensures a systematic evaluation of potential suppliers based on strategic criteria, including product quality, sustainability practices, and compliance track records. This structured approach reduces onboarding time and helps companies align supplier capabilities with long-term business goals.

5. Stronger Supplier Relationships and Collaboration

A robust SLM strategy promotes open communication, shared objectives, and collaborative problem-solving. These partnerships are especially valuable in dynamic markets, allowing companies to work closely with vendors to co-develop new products or pivot quickly to meet shifting customer needs.

6. Continuous Supplier Performance Improvement

Ongoing monitoring through key performance indicators (KPIs) enables companies to assess and refine supplier performance over time. With real-time data and feedback loops, underperforming vendors can be coached toward improvement, while high performers are recognized and rewarded.

7. Enhanced Supply Chain Resilience

SLM encourages the development of a diversified supplier network and robust business continuity plans. By maintaining alternate sources and evaluating supplier health regularly, companies can respond quickly to geopolitical instability, supply shortages, or sudden demand shifts.

8. Increased Visibility and Transparency

Modern SLM systems offer dashboards and analytics that provide a 360-degree view of the supplier ecosystem. This transparency empowers procurement, compliance, and finance teams to make informed decisions quickly, identify emerging risks, and track supplier progress against strategic KPIs.

9. Improved Compliance and Regulatory Adherence

Through integrated compliance checks, documentation workflows, and audit trails, SLM helps businesses stay aligned with local and global regulations—such as labor laws, environmental standards, and anti-bribery rules. This is especially critical in highly regulated industries like pharmaceuticals, aerospace, or food and beverage.

10. Sustainability and ESG Alignment

Many modern SLM strategies include environmental, social, and governance (ESG) criteria as part of supplier evaluations. Companies can prioritize ethical sourcing, reduce carbon footprints, and support diverse supplier initiatives, ultimately contributing to their broader sustainability objectives.

11. Better Forecasting and Planning

SLM systems collect valuable supplier data over time, which can be used for forecasting demand, planning future orders, and budgeting more accurately. These insights improve procurement planning, reduce stockouts or overstocking, and align supply chain goals with business growth.

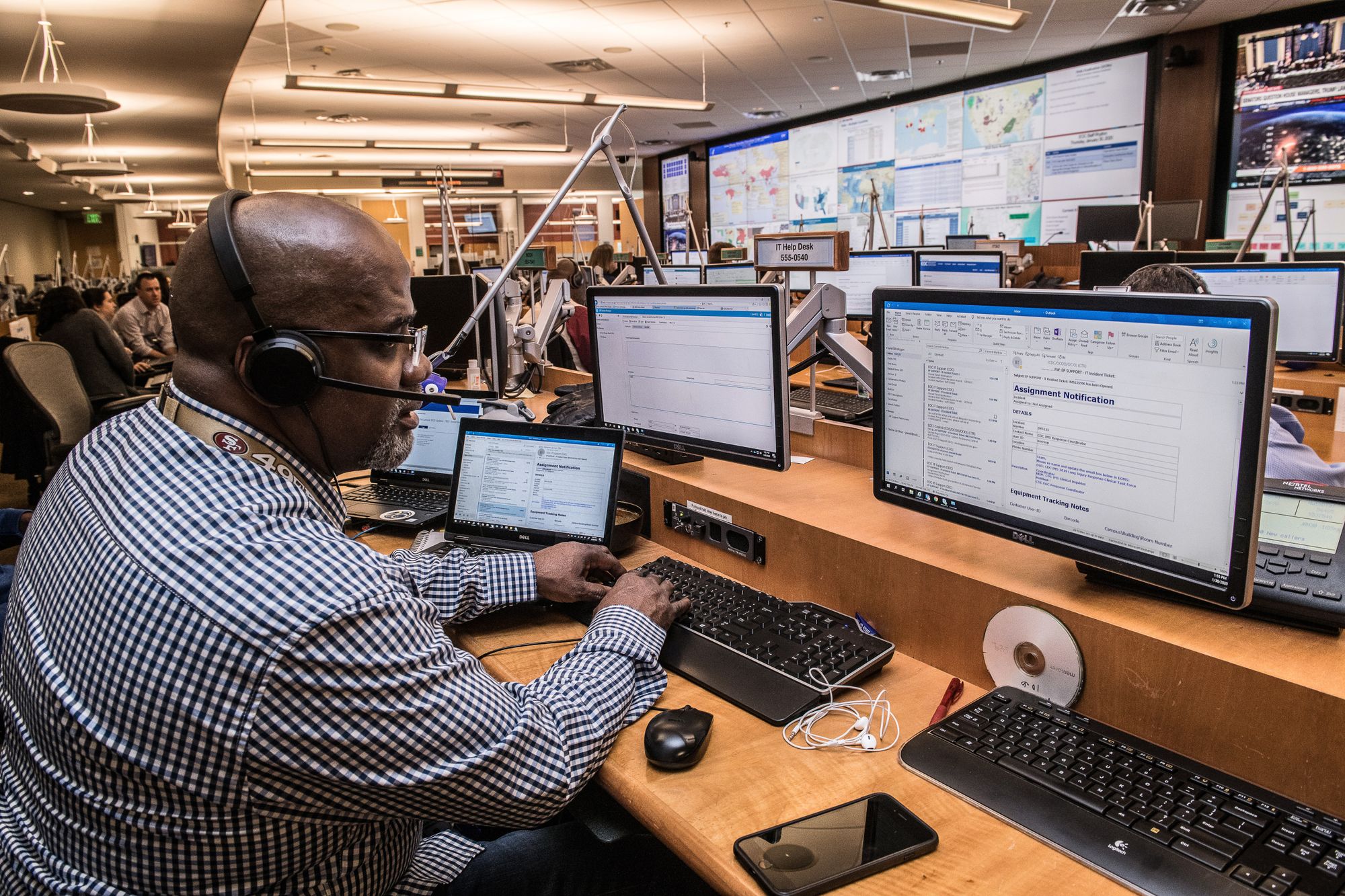

Technology’s Role in Supplier Lifecycle Management (SLM)

Modern Supplier Lifecycle Management (SLM) is powered by advanced technologies that streamline supplier interactions, enhance data accuracy, and empower organizations to make more informed decisions.

By digitizing and automating key aspects of the supplier journey—from onboarding to performance tracking—businesses can boost efficiency, agility, and strategic alignment across their supply chains.

Below are the core technological components reshaping SLM:

1. Supplier Portals and Automated Onboarding Tools

Digital supplier portals serve as centralized platforms where vendors can securely submit documents, update their profiles, track payments, and communicate with procurement teams.

Automated onboarding tools speed up the enrollment process by guiding suppliers through compliance checks, documentation uploads, and electronic contract signing. This reduces manual paperwork, shortens onboarding timelines, and ensures consistency across supplier entries.

Example: A company using an onboarding automation tool can reduce supplier setup time from weeks to days while maintaining strict adherence to internal policies and regulatory requirements.

2. Integration with ERP and Procurement Systems

Seamless integration between SLM tools and existing Enterprise Resource Planning (ERP) or procurement platforms ensures real-time data exchange across departments.

This interoperability eliminates silos, improves visibility into supplier performance and purchasing history, and allows for more cohesive decision-making. Integrated systems also enable automated updates to inventory levels, purchase orders, and compliance documents based on supplier activities.

Benefit: Procurement, finance, and supply chain teams work with consistent, up-to-date data, eliminating duplication and reducing the risk of costly errors.

3. AI and Analytics in Supplier Evaluation

Artificial Intelligence (AI) and advanced analytics bring a new level of intelligence to supplier evaluation and performance management.

These technologies can analyze vast volumes of supplier data—such as delivery timelines, quality scores, responsiveness, and financial health—to generate real-time performance dashboards and risk alerts.

Predictive analytics can even forecast future supplier performance or disruptions based on historical trends.

Use Case: AI-driven scoring models can help prioritize high-risk suppliers for audits or identify underperforming vendors before they affect production schedules.

4. Role of Cloud-Based Platforms

Cloud-based SLM platforms provide scalability, accessibility, and agility—key attributes for managing complex global supply chains.

These platforms enable remote teams and suppliers to access real-time data, communicate efficiently, and collaborate on projects regardless of location.

Cloud solutions also ensure that businesses benefit from automatic updates, enhanced security, and easier deployment of new features.

Advantage: Businesses can quickly scale their SLM operations without significant upfront infrastructure investments, adapting to new market demands or supplier needs with minimal disruption.

Best Practices for Effective Supplier Lifecycle Management (SLM)

Creating a robust and sustainable Supplier Lifecycle Management (SLM) strategy requires more than simply managing transactions—it involves building a strategic framework that aligns with business goals, fosters long-term supplier relationships, and mitigates risk.

The following best practices can help businesses optimize their SLM processes and extract maximum value from their supplier partnerships:

1. Architect a Strategic Supplier Ecosystem

Start by identifying the core capabilities your business needs to deliver value to customers. Use these insights to evaluate current and potential suppliers, ensuring alignment with long-term business goals.

Develop a performance tracking framework that monitors progress toward shared objectives, such as innovation, quality, sustainability, and cost efficiency.

Tip: Regularly revisit your supplier ecosystem to ensure it evolves alongside market shifts, new technologies, and changes in customer expectations.

2. Segment Suppliers by Value and Risk

Organize your supplier base by categorizing vendors according to their strategic importance, spend volume, delivery frequency, and potential risk exposure.

This allows procurement teams to focus resources and attention where they matter most—on high-value or high-risk suppliers.

Example: Mission-critical suppliers may require quarterly business reviews and dedicated account managers, while low-risk vendors can be managed through automated procurement workflows.

3. Define and Measure Clear Supplier KPIs

Establish objective and relevant key performance indicators (KPIs) to assess both supplier performance and internal procurement efficiency. Common KPIs include:

- On-time delivery rates

- Order accuracy

- Lead times

- Quality defect rates

- Cost savings or value-added services

Make sure to align KPIs with your broader business goals and regularly update them as conditions change.

4. Conduct Comprehensive Supplier Assessments

Regular supplier assessments—using audits, surveys, feedback loops, and performance scorecards—offer a complete view of a vendor’s capabilities and potential risk areas.

Include both quantitative and qualitative data to evaluate not just performance but also cultural fit, innovation potential, and responsiveness.

Benefit: A well-rounded assessment can reveal early signs of underperformance or misalignment, allowing proactive intervention.

5. Cultivate Mutually Beneficial Partnerships

Transition from a transactional to a collaborative supplier relationship model. Open communication, shared goals, and joint problem-solving encourage innovation and enable both parties to respond to market demands more effectively.

Example: Retailers and suppliers can co-develop products or coordinate demand forecasting to reduce stockouts and boost mutual profitability.

6. Implement Dynamic Supplier Performance Management Systems

Deploy tools that can dynamically track and analyze supplier performance in real time. These systems allow businesses to provide actionable feedback, identify performance trends, and maintain continuous alignment with strategic priorities.

Integration Idea: Connect SLM systems with your ERP, CRM, and inventory platforms to automate updates and improve supply chain responsiveness.

7. Proactively Identify and Mitigate Risks

Establish a regular cadence for risk assessments, stress testing, and contingency planning. Use real-time monitoring tools to track supplier financial health, geopolitical risks, regulatory changes, and operational stability.

Real-world example: A pharmaceutical company tracking raw material suppliers in volatile regions might shift sourcing strategies to mitigate disruption risks.

8. Optimize Processes Through Automation

Adopt automation tools to reduce manual effort and improve consistency in areas such as supplier onboarding, contract generation, compliance documentation, and order processing.

Automation not only boosts operational efficiency but also reduces the risk of human error and accelerates turnaround times.

9. Leverage Data Analytics for Strategic Insights

Advanced analytics and AI tools can identify patterns, flag anomalies, and predict supplier risks or opportunities long before they’re visible through traditional means.

Use these tools to inform strategic decisions like vendor consolidation, order allocation, or contract renegotiation.

Insight: Analytics-driven supplier scoring models can help identify which vendors are driving value—and which may be causing silent inefficiencies.

10. Foster a Culture of Continuous Improvement

Promote ongoing learning, innovation, and feedback within your organization and supplier network. Train staff in SLM best practices and encourage them to share insights and propose improvements.

Regular engagement sessions with suppliers can also uncover joint initiatives that improve operations on both sides.

Practice: Set quarterly supplier development goals or host collaborative improvement workshops with strategic partners.

11. Ensure Regulatory and Sustainability Compliance

Incorporate compliance monitoring into your SLM workflows to ensure that suppliers are meeting legal, ethical, and environmental standards.

This is particularly vital in industries such as food, healthcare, and electronics, where violations can result in steep fines and reputational damage.

Sustainability Angle: Evaluate suppliers based on ESG (Environmental, Social, Governance) criteria to build a supply chain that supports long-term business sustainability.

A mature and forward-thinking SLM strategy is built on a foundation of strategic alignment, transparency, continuous evaluation, and the smart use of technology.

By following these best practices, organizations can drive stronger supplier performance, reduce risks, and unlock long-term value from their procurement operations.

What to Look for in an SLM Software

The key features that you should look for in an SLM software are:

1. End-to-End Supplier Lifecycle Coverage

Look for software that supports the complete supplier journey—from onboarding and qualification to performance management and offboarding. This ensures consistency, transparency, and efficiency across all supplier touchpoints.

Must-have features:

- Supplier onboarding workflows

- Approval and qualification tracking

- Centralized supplier database

- Offboarding and risk-based disengagement processes

2. Integration Capabilities

The SLM solution should integrate seamlessly with your existing systems—such as ERP, procurement, finance, and inventory platforms—to ensure a unified and synchronized data ecosystem.

Look for integrations with:

- ERP (e.g., Deskera ERP)

- Procurement systems (e.g., Deskera MRP)

- Contract lifecycle management tools

- Financial systems and compliance software

3. Supplier Self-Service Portals

Empower suppliers with self-service capabilities to manage their profiles, submit documents, respond to RFPs, and view performance reports. This reduces administrative load and improves supplier engagement.

Features to look for:

- Supplier registration and document upload

- Real-time profile updates

- Performance dashboards and communication tools

4. Automation and Workflow Customization

Automate repetitive tasks such as supplier approvals, risk assessments, and performance reviews. Ensure the platform allows you to tailor workflows to your company’s specific compliance and procurement policies.

Useful automations:

- Alerts for expiring certifications

- Risk escalation workflows

- Approval routing based on supplier category

5. Advanced Analytics and Reporting

Robust SLM tools offer dashboards, KPIs, and real-time analytics that track supplier performance, compliance metrics, and risk scores. This data enables smarter decision-making and continuous improvement.

Look for:

- Customizable reports and dashboards

- Predictive analytics and risk scoring

- Spend analysis by supplier category or region

6. Risk Management and Compliance Monitoring

Ensure the software includes tools to monitor supplier compliance with legal, financial, and environmental standards. Bonus points for real-time risk scoring and alerts.

Key capabilities:

- Automated risk assessments

- Regulatory compliance tracking (e.g., ESG, ISO, GDPR)

- Supplier financial health monitoring

7. Collaboration and Communication Tools

Built-in messaging, shared dashboards, and document collaboration can streamline supplier communication and reduce email silos.

Collaboration tools may include:

- Internal chat with suppliers

- Document co-authoring and version control

- Notifications and alerts for pending tasks

8. Scalability and User-Friendly Interface

Choose a platform that can grow with your business—supporting multi-site, multi-region operations with ease. A modern, intuitive interface improves user adoption across procurement and supplier teams.

Scalability checklist:

- Multi-language, multi-currency support

- Role-based access control

- Mobile accessibility or app support

9. Contract Management Integration

Many suppliers are tied to long-term agreements. The SLM software should allow seamless integration with contract management tools or include built-in CLM features.

Desired capabilities:

- Contract version tracking

- Renewal alerts

- Contract-performance linking

10. Audit Trails and Data Security

Protect sensitive supplier and company data with strong security protocols and maintain audit trails for compliance and accountability.

Look for:

- Full audit logs of changes and approvals

- Role-based permissions

- Encryption and compliance with global data protection standards (e.g., GDPR, SOC 2)

Bonus: AI-Powered Supplier Insights

Some modern SLM platforms come equipped with AI and machine learning capabilities to forecast supplier risks, recommend alternative vendors, and optimize sourcing decisions.

How Deskera ERP Helps You Streamline Supplier Lifecycle Management

Deskera ERP is a powerful cloud-based platform designed to simplify and optimize business operations—including supplier lifecycle management (SLM). Whether you're a small business or a growing enterprise, Deskera’s integrated modules for procurement, inventory, accounting, and reporting make it a valuable tool for managing your suppliers efficiently and strategically.

Here’s how Deskera ERP can help:

Centralized Supplier Information Management

Deskera provides a unified platform to store and manage all supplier-related data—contacts, contracts, certifications, and performance history—enabling better visibility, faster access, and data-driven decisions.

Automated Procurement Workflows

From issuing purchase orders (POs) to tracking approvals and receiving goods, Deskera automates the entire procurement cycle. This reduces manual errors, shortens approval times, and ensures timely deliveries.

Real-Time Supplier Performance Insights

With built-in reporting and analytics, Deskera allows you to monitor supplier metrics such as delivery times, PO accuracy, and costs. These insights help you identify high-performing vendors and areas that need improvement.

Seamless Integration with Inventory and Accounting

Deskera connects procurement with inventory and accounting modules. This integration ensures that every supplier transaction is instantly reflected in your inventory levels and financial statements—helping maintain accuracy and efficiency across the board.

Cloud-Based and Mobile-Friendly

Access supplier data and approve purchase requests from anywhere with Deskera’s mobile-friendly interface. This is especially helpful for remote teams or businesses managing multiple sites.

AI-Driven Assistance with David

Deskera’s AI assistant, David, helps automate repetitive tasks, recommends next steps, and even flags anomalies in supplier data or transactions—making your supplier management smarter and faster.

Key Takeaways

- Supplier Lifecycle Management (SLM) is a strategic approach to managing supplier relationships from onboarding through evaluation, performance monitoring, and contract termination—ensuring maximum value and compliance throughout the supplier engagement.

- Each phase of the supplier lifecycle—qualification, onboarding, performance management, collaboration, and offboarding—requires structured processes to ensure consistency, mitigate risk, and maintain supplier alignment with business objectives.

- A well-structured SLM process improves operational efficiency, optimizes costs, reduces supplier-related risks, strengthens supplier performance, and fosters long-term strategic partnerships.

- Technology—such as AI-powered analytics, cloud-based platforms, ERP integrations, and supplier portals—plays a crucial role in automating workflows, enhancing visibility, and improving supplier evaluations in real time.

- Implementing best practices such as segmenting suppliers, defining success metrics, fostering collaborative partnerships, leveraging automation, and promoting continuous improvement ensures a high-performing, resilient supplier network.

- When choosing SLM software, prioritize features like centralized data management, automated workflows, supplier risk tracking, performance analytics, integration with ERP systems, and scalable cloud access to support long-term growth.

- Deskera ERP simplifies supplier lifecycle management by offering integrated procurement, accounting, inventory, and analytics tools—backed by automation and AI—to streamline operations, reduce manual tasks, and boost supplier collaboration.

Related Articles