Every business, big or small, has a supply chain that needs careful tending. With Serial Number Tracking of Inventory, the business has been made easy. However, manual tracking of serial numbers can lead to human errors.

Hence, a sophisticated inventory management system will empower you to better meet your customers’ needs error-free. The right system allows you to easily capture data at the receiving dock and track it again when products ship out the door.

In this article, we will not only discuss depth about serial number tracking but how an inventory management system helps you. So, let’s get started!

This article covers the following:

- What is Serial Number Tracking of inventory?

- How does serial number tracking of inventory work?

- What is the difference between serial number tracking and barcodes?

- What is the importance of serial number tracking?

- Five great reasons why you need serial number tracking in your business?

- What are the benefits of serial number tracking of inventory?

- Which industries best benefit from Serial Number Tracking of inventory?

- How can Deskera assist you?

What is Serial Number Tracking of Inventory?

Serial Number Tracking is an inventory tracking system that allows you to track individual units of an item from its initial production stage to its sale. Each unit will possess a unique identification number which will help you find out exactly which unit was sold to whom. Without a serial tracking system in place, it can be difficult to keep an account of your inventory. Let’s see how serial number tracking of inventory work.

How Does Serial Number Tracking of Inventory Work?

A serial number is created by the manufacturer of a product. The goal is to make sure every item’s history is identifiable while it travels through the supply chain and between end users.

If all manufacturers practiced vertical integration (the business practice of controlling all steps in the supply chain, such as distribution and retailing), this would be a relatively straightforward process.

All divisions would use the same systems, and the item’s serial number would be captured at each stage. In reality, most companies don’t pursue vertical integration.

While it can be incredibly valuable, vertical integration is challenging to execute and difficult to reverse. Instead, most companies work with upstream and downstream supply chain partners to derive value from their products.

Consequently, your partners, distributors & wholesaler, warehousing facilities, and retailers need systems to accurately record serial numbers. This ensures that they can manage costly events like a recall while limiting the exposure to their business.

What is the Difference Between Serial Number Tracking and Barcodes?

At first glance, you’d be forgiven for thinking that there’s really no difference between inventory serial numbers and barcodes. After all, aren’t barcodes made up of serial numbers themselves? Well, there’s actually a subtle and slight difference between the two besides the fact that they are made up of numbers.

Firstly, a serial number is a unique identifier. You assign them incrementally or sequentially to an item to uniquely identify them. This means one serial number is linked to one product.

This means that every raw material, semi-finished product, or product has a serial number attached to it. No two products will share the same serial number. Barcodes, in contrast, are applied to an entire line of products in one classification or category.

Say you’re a t-shirt manufacturer. You’re not going to have a unique serial number generated for each t-shirt. You make them in the hundreds and thousands. And there’s no advantage for you to track individual products. So you apply a general barcode to it, for example, a navy blue t-shirt in a large size.

Secondly, a serial number does not have to be numerical only. They may contain letters, symbols, or even a character string. So, alphanumeric serial numbers are nothing new.

On the other hand, barcodes can only be made up of numbers and even a set number of digits. An EAN barcode contains 13 digits only, while UPC barcodes consist of 12 numbers. You want to adhere to barcode standards if you want to trade domestically and internationally.

What is the Importance of Serial Number Tracking?

While some industries are legally required to use serial codes, such as vehicle component manufacturers and medical device manufacturers, those that aren’t should still consider adopting the same practices.

In addition to the benefits of using a serial code system, you’ll be making business easier on you and your employees. With less room for errors, workers can complete orders with confidence and in a shorter amount of time.

Being free from the stress of uncertainty and mistakes will allow for better morale. Serial number tracking makes stocking and shipping less of a hassle and saves time.

Simplifying your processes and consistently tracking items means you’ll always know where to find what you need and confirm it as the right product quickly. So, you can ship more products faster without the risk of sending the wrong product.

Keeping a detailed record of your products with inventory tracking software will create a more straightforward experience for all. With a system that’s easily accessible through a computer or mobile device, you can keep up to date from anywhere.

That detailed record will also provide a complete history that is assuredly accurate. From an individual part to a large group, you’ll have access to the full archive. You can use the data to analyze patterns and forecast future sales, meaning your company can get a step ahead of your competitors and look to the future.

You’ll also be able to adjust your workflow and processes to fit the growth of your business. As you continue to use the tracking software, you will see efficiency trends in different areas of the process.

From there, you can shift scheduling and timing to better suit your workers and how they perform. It’ll also make giving directives to customers easier for your service department.

If a customer needs assistance with their device, they can provide the serial number, allowing you to see exactly what they ordered and provide them with specific details.

Should any refund or recall be necessary, you’ll have the information you need, all the way from the manufacturing process to shipping. In a busy and bustling warehouse, it’s easy to see how anyone could make mistakes. But using serial numbers to keep track of your inventory will provide you and your workers with a more efficient and confident experience.

Five Fantastic Reasons To Have a Serial Number Tracking System

Here are a few reasons why you should have a serial number tracking system in place:

Serial Numbers for Product Recall

Having serial numbers assigned to both products and components can reduce the impact of a product recall dramatically. Imagine you’re a manufacturer with factories all over the world.

Everything is going well until you get three products returned with a faulty widget that causes them to catch fire. You investigate and discover this particular widget is supplied by a half dozen different companies only one of which has shipped you faulty stock.

Without serial number tracking, you would likely need to recall every one of your products at an extraordinary cost. But with a proper serial number tracking system.

Despite all of your products being effectively identical, you use the serial numbers on the returned items to find they came from the same factory. Moreover, the numbers show that all were made in the same production run: you isolate the production runs that used the faulty widget and issue a product recall that affects hundreds rather than thousands of products.

Serial Numbers for Compliance

Sometimes using serial numbers is not a matter of risk mitigation but rather legal compliance. All cars, for instance, are stamped with a Vehicle Identification Number, which contains lot number information showing where and when the vehicle was made as well as a unique segment to the code that identifies the particular car.

Perhaps most famously, every firearm sold must be stamped with a serial number though how well these can be tracked is another issue altogether.

Serial Numbers for After-Sales Service

After-sales service, warranties, and repairs can be dramatically improved if serial number tracking is in place, especially with complex products with multiple components, such as cars or consumer electronics.

This is because some products are sold under the same brand name and model, even though ‘under the hood, the internal components are being constantly refined and improved.

So, for example, a 2020 model of a particular car marque may be built with different window seals, airbags, and stereo ports to the 2019 version but is still marketed as the same vehicle. Conversely, the same parts may be used within multiple makes and models before being phased out.

With products like these, serial number tracking allows you to match the right replacement part to the right product when things go wrong or simply in the course of routine maintenance.

Think of the last time you replaced the toner cartridge on a home printer, for instance, and you’ll appreciate how important serial number tracking is in creating a matrix of matching replacement parts and products.

Serial Numbers for Theft Protection

Another excellent post-sales use for serial number tracking is the protection it can provide your customers in the case of theft. A high-value item that is stolen and then recovered by police can be definitively linked back to its original owner and returned (and the theft proven) if the serial number is provided when the theft is reported.

A digital version of a serial number, a Media Access Code, can also be used to identify items, alerting customer support when a stolen device is turned on and connected to the internet.

Serial Numbers for Inventory Control

Unseen by consumers, serial number tracking can simplify stock management dramatically especially for products with multiple high-value components. With inventory tracked down to the individual component level, time spent rummaging through boxes for specific parts or on the phone to other warehouses becomes a thing of the past while quality management becomes easier.

What are the Benefits of Serial Number Tracking of Inventory?

Here are some benefits of serial number tracking that you must make a note of:

High Visibility and Tighter Groupings

Having every item of inventory visible and correctly grouped pays huge dividends. Serial number tracking makes groupings easier to achieve and more beneficial for forecasting and overall management. Everything from the linking of similar items down to the behavior of certain inventory groups can be achieved.

Knowing the Character of your Inventory

You could say that serial numbering helps you know the character of your inventory, like a name tag, with the most important information underneath. The more you know about your inventory, the better you can plan and make adjustments to get the most out of it.

Complete and Accurate History

Serial numbers allow easy access to the complete history of each individual part or product. This is a great advantage for any business using historical data for forecasting or needing to enact product recalls. Leading inventory management software providers make this a simple and user-friendly task.

Reduced Data Entry and Errors

Serial number tracking is one of the best ways you can cut down on data entry and errors. With each product or item number, every transfer, sale, or order is more accurate and better monitored. Using mobile and barcode technologies optimizes the use of serial numbers and is particularly useful for manufacturing businesses or for those with a large variety of inventory.

Efficient and Streamlined Warehouse Management

There’s usually a lot happening in the warehouse of a business. Even relatively small ones have their problems, so businesses are always looking for new systems to help with the efficiency and effectiveness of operations.

Serial number tracking is one key way that you can reduce errors and increase productivity. The use of serial numbers and mobile technology is by far the best solution to a lot of the issues of running a warehouse. Serial number tracking also allows for the deeper use of lean inventory practices, helping businesses free up capital that’s unnecessarily tied up in stock on hand.

Goods in Process

For manufacturing businesses, serial number tracking is an essential tool. It provides accurate tracking, transporting, and ordering from start to finish of the manufacturing process. It enables the use of techniques like Just-In-Time, which rely on the ability to move or order items required for production at exactly the right time.

After-Sales Processes

Another great advantage is with after-sales processes and actions. If a part is found to be faulty or there is a product return, the necessary data is easily available, accurate, and complete.

Track the Item Through its Lifecycle— from the Design to Build

With serialization, you can comprehensively understand the entire lifecycle of any product in your manufacturing business. It provides details about when a particular product was manufactured and sold, how often it was serviced and maintained, what kind of operating system it runs on, and so on.

You can track your inventory through the design, production, testing, distribution, and maintenance phases. This makes it easier to manage issues around quality control and avoid defective shipping products.

Additionally, suppose defective items do get out. In that case, product recalls are simpler and quicker as you could use the serial numbers to recall specific products instead of executing a blanket recall.

Easier to Repair and Manage Warranties in Case of Any Claims

As there is a serial number assigned to each product, you can know all the product's serial number information. Products such as cell phones, laptops, PCs, or medical devices such as oxygen machines, ECG equipment, scanning devices, and so on, have comprehensive warranties and guarantees attached to them.

The serial number tells you when you’ve sold the product, making any issues related to warranty repairs easy as you can determine the valid warranty period for the customer. This makes the maintenance of your devices much easier as you always have the product history accessible before you carry out any repair activities on the product.

Comply with Government Regulations

Some countries or locations have government laws and regulations mandating serial numbers for tracking products. This is especially true in the case of drug manufacturing or biotech companies. Each medical product must be serialized to ease issues around tracking, recalls, or counterfeiting.

Some examples of government regulations mandating serialization of medical products include:

- The Food and Drug Administration (FDA) mandates manufacturers to track certain devices through the entire distribution chain when and if they receive an order from the FDA to implement a tracking system. These devices could belong to Class I, Class II, or Class III devices.

- The federal Drug Supply Chain Security Act (DSCSA) of 2013 established a system to track and trace prescription drugs with a longer aim to track unit-level traceability throughout the United States supply chain.

- The European Union Medical Device Regulation (EU MDR) set of regulations of May 2021 aims to improve the safety and performance of medical devices throughout their lifecycle. The regulation plans to enhance the coordination of information on medical devices with better transparency and information access in the EU member states.

Preserve Proof of Ownership and Prevent Thefts

Serial numbers being unique, can easily be used to prove ownership of products, especially in the cases of loss or theft. This acts as a form of security for companies using serialization.

For instance, if a laptop is stolen from a retailer, the serial number is scanned every time the laptop moves from one location to another. The serial number has details of the origin attached to it, and this helps in returning the stolen product to the rightful owner or manufacturing company.

Detect Counterfeit Products and Ensure Quality

Serialization prevents other competitors or malicious businesses in the market from swapping and selling inferior products as your products are identified through the unique serial number.

This is critical for medical device companies as it’s a matter of a person’s life, and manufacturers must be able to ensure accountability for each product from their company.

This allows you to ensure the quality of your products and secure delivery of your goods from the point of dispatch until the product reaches the end customer. Your customers will also be happy to use your products, as they know that the product delivered has not been tampered with, is original, and is of the highest quality.

Tracking for Customized Products

Using serial numbers is also great for managing customized or made-to-order products, where not every model is the same. Sending the wrong model could mean losing business or frustrating customers. By using serial number tracking, you can effectively keep track of each individual product and be sure every order will ship to the correct address.

Improved Accuracy

Serial numbers improve tracking flexibility by recording the serial numbers as the product is received but also when a product is shipped. The integrated nature of serial number tracking helps to improve the accuracy of your stock control by removing the need for multiple databases that cause confusion and increase error rates.

Serial numbers also provide a record of expiration and best by dates that let you manage what stock is picked and shipped, reducing the occurrence of waste through perishability or obsolescence by shipping older stock first.

In addition, serial numbers help to maintain a level of service quality by providing the ability to monitor and assess each stage of production or delivery. They can be used to help track any service issues, faults, and product defects, as well as to improve search and reporting functions.

Inventory Control

Serial numbers and the tracking process they provide have significant importance to stock control. They provide companies with the ability to maintain quality control by providing the means that assist in addressing warranty claims or, if necessary, administering a product recall.

In addition, serial numbers help facilitate better stock control through integrated tracking with other business systems and applications. These include the capability of integrating ordering, stock control, and billing software.

Sales in Offline Store

During in-store checkout, the cashier will need to scan the item’s serial number or input it manually into your POS system. You should attract the serial numbers to each item to make the checkout process more convenient.

If your POS system can display the serial number for each item in the shopping cart, it helps the staff see that the system has recorded the serial numbers successfully.

These serial numbers are saved to order history, sales receipts, and customer invoices. Your staff can check one of these documents to reference product information for support. Additionally, when a customer requests a return, the staff should check the item’s serial number and create a credit memo with the recorded number.

Boost Efficiency

For one, you’ll see a higher level of efficiency, as each item is easy to locate and track down. The visible organization allows you to improve workflow processes. No more being held back by difficulties or delays.

Easily Track Items

The documentation will allow you and your suppliers or clients to trace any single item back to the point of its manufacturing. If any product or close group of products has issues, the manufacturer can check to see if a production error is a cause or if it’s on the customer.

Provide Better Customer Service

Your company can handle and investigate warranty claims easily and either issue a trade, return, or refund or send out a full recall, should the problem stem from improper manufacturing or production faults. Also, you can provide your customers with specific details about their model based on the serial code.

Prevent fraud: You’ll be able to ensure that a returned item is the same product you sent simply by checking if the serial number is the same.

Identify popular products: Tracking the serial numbers of sold items can provide you with a list of your most popular sellers this will allow you to make informed restocking decisions when the time comes.

Reduce the risk of error: When working with heavily regulated businesses and products, making a shipping error can be a huge mistake. But, with correctly organized serial numeration, you’ll avoid the risk.

Analyze Sales

Each sale and shipment will provide you with information about your business, top customers, and remaining stock. With an organized system, you can easily view these statistics at any time.

Which Industries Benefit Best from Serial Inventory Tracking?

Some industries are more sensitive to inventory serial number tracking than others. In these industries, being able to distinguish between units based on their histories is essential to quality customer service and retaining business value.

Warehouses that can track serial numbers not just at one stage of their warehouse processes but throughout can carve out a specialist niche and land companies from these industries as customers.

Inventory Serial Number Tracking in the Electronics Industry

Serial numbers play a starring role in the electronics industry. Serial numbers help electronics manufacturers, wholesalers, and retailers track faulty products and identify specific components of a faulty product.

For instance, a defective flat-screen TV may not be the television manufacturer’s fault. In reality, it could be due to a faulty component from its LED screen supplier.

Inventory serial numbers also allow manufacturers to track warranty information. Without proper tracking of serial numbers, businesses would lose money providing free services on products with expired warranties. Conversely, they could jeopardize the customer experience by refusing to provide service for products with a valid warranty.

Inventory Serial Number Tracking in the Automotive Industry

Traceability is a crucial function of the automotive supply chain. It enables all downstream players to trace the origin and sub-assembly of a car’s component parts.

Naturally, serial numbers are an integral part of traceability. In fact, industry players consider it worthwhile to put a serial number on the tens of thousands of possible component parts.

While the automotive industry is known for its vertical integration, that’s not entirely the case when it comes to component parts. Focusing on enhanced methods and technology for inventory serial number tracking for component parts can help your warehouse or 3PL business land a new type of customer.

Inventory Serial Number Tracking in the DNA Testing Industry

The DNA testing market is expected to reach $1.99 billion by 2024, with a compound annual growth rate of 16.4 percent. This represents a massive opportunity for warehouse managers and third-party logistics companies to support this very niche, very detail-oriented market.

Direct-to-consumer DNA testing kits travel through a reverse supply chain. Empty DNA kits travel from the warehouse to consumers. Consumers provide a sample of their DNA and send the used kit back to the company.

As expected, keeping tabs on the samples requires unique identifiers. For instance, when a 23andMe customer orders a kit, it arrives with a unique barcode. A new customer must create an account online and then register that barcode with his or her account.

When their sample is sent to the lab, 23andMe tracks the kit using its unique identifier or serial number. The technicians carry out the testing and enter the results into the secured user profile with the associated number.

Understandably, this requires sophisticated serial number tracking. Losing a sample is costly and embarrassing. And mixing up two samples undermines the entire value proposition of a DNA testing company, which is to provide consumers with scientifically backed information about their heritages and genetics.

Above all, any mistake, whether it’s a mix-up or a loss, negatively impacts the company’s reputation since consumers are trusting it with not only their personal information but their DNA as well.

It’s easy to see how a warehouse that masters the inventory serial number tracking process has a huge competitive advantage in the consumer DNA testing industry. Direct-to-consumer DNA testing companies spend an enormous amount of time and resources on their supply chain management and logistics in an effort to protect their reputations.

The trade-off is they don’t enjoy the cost savings and efficiency of outsourcing to experts in logistics. If a firm can demonstrate its competency not just in logistics but in third-party logistics as well, it can offer unique value to DNA testing companies.

Automate your Serial Number Tracking of Inventory with an Inventory Management System

From the moment you receive an item from your vendor or manufacture it yourself, you can track its progress using serial number tracking via your inventory management system. Either enter the serial number manually in your inventory system or just scan the barcode with a barcode scanner. You can also handpick the items you want to sell from the lot.

FAQs Inventory Management System

What does inventory management software do?

The broadest definition of the term "inventory management software" would have to include ERP and MRP legacy software that records basic data on inventory. Advanced planning and scheduling (APS) helps manage the raw materials and components used in manufacturing, and warehouse management systems (WMSs) have analogous features for warehouse inventory management.

Today, the term "inventory management software" denotes a distinct category of specialized tools for collecting and analyzing inventory-related information for planning purposes.

How does modern inventory management software differ from other supply chain software?

Inventory management software typically includes forecasting and replenishment modules. Forecasting helps you balance target inventories and incoming supplies with expected demand.

Replenishment helps determine the safety stocks that are needed at points along the distribution chain to satisfy orders at a given fill rate. A subset known as inventory optimization software employs complex algorithms to recommend the best locations and quantities for meeting demand across the entire supply chain.

Inventory management software is available standalone or in ERP and supply chain management (SCM) suites.

What is the difference between inventory management and warehouse inventory management?

Warehouse inventory management is the main purpose of a warehouse management system (WMS) as well as some more specialized tools. It controls and optimizes the movement, storage, and tracking of inventory in and around a warehouse.

For example, this software can say when and where to "pick," put away and replenish goods. In contrast, inventory management software usually takes a broader view of inventory planning and optimization across many locations along the supply chain.

What are some of the advantages of using inventory management software?

The quickest return on investment often comes from lower carrying costs.

When tightly integrated with separate demand planning software, inventory management software can improve sales forecasts with accurate, up-to-date information on available inventory.

Users and industry analysts report other benefits:

- Replenishment planning that tells managers when they can expedite or delay orders without negative impacts on customer satisfaction and inventory costs

- The ability to segment safety stock according to key business metrics, such as profitability and customer satisfaction

- Improved inventory visibility for salespeople, which gives them the confidence to promote products without fear of running out of stock

Q: What hurdles will my company face in implementing inventory management software?

Integration, data quality, and training will take the lion's share of your attention. Separately-sold inventory management software must often be integrated into existing ERP and SCM systems, often at great expense and that's just the IT systems.

Typically, separate inventory management and demand planning departments must also come together in collaboration. A formal sales and operations planning (S&OP) process, perhaps with supporting web portals, can facilitate this.

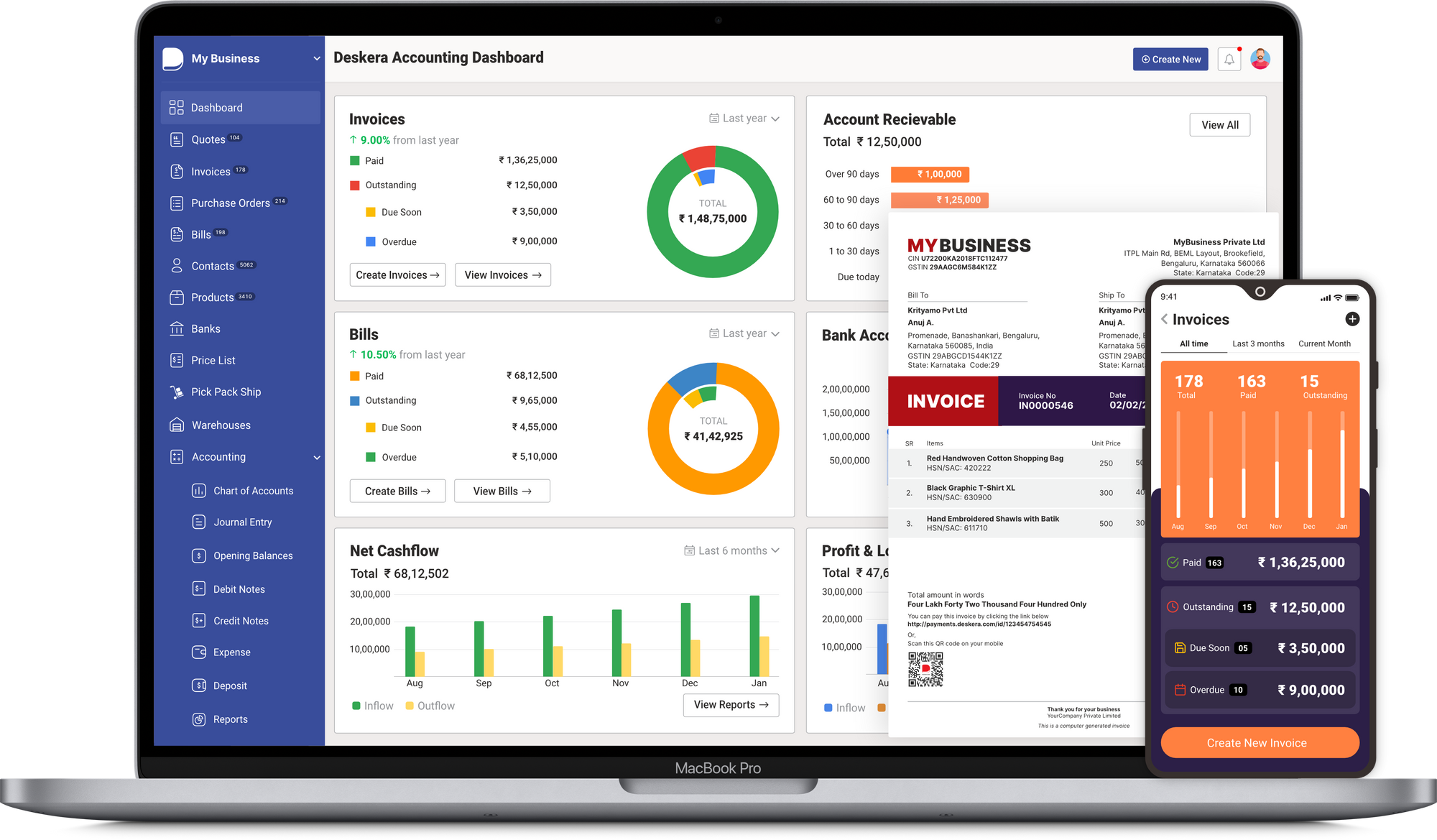

How Can Deskera Assist You?

By now, you’ve understood the significance of serialized tracking of your inventory. However, it’s critical to note that serialization cannot be executed efficiently without the proper technology.

With an inventory management system, you not only simplify this process but make your business efficient. Deskera is one such software that helps you track your serial number efficiently with it's inventory management systems, Deskera Books and CRM.

Key Takeaways

- Serial Number Tracking is an inventory tracking system that allows you to track individual units of an item from its initial stage of production to its sale.

- A serial number is created by the manufacturer of a product.

- Consequently, your partners, distributors & wholesaler, warehousing facilities, and retailers need systems to accurately record serial numbers.

- A serial number is a unique identifier. You assign them incrementally or sequentially to an item to uniquely identify them.

- Serial number tracking makes stocking and shipping less of a hassle and saves time.

Related Articles