Insecticides is a form of pest control that is used to protect plants, animals, and humans from unwanted pests and insects. These chemicals are designed to kill insects, but they can also be used to repel or disrupt them. Insecticides can be used to control insects that damage crops, spread disease, and pollute the environment.

This article covers the following:

- The Benefits of Insecticides in Pest Control Manufacturing

- The Different Types of Insecticides Used in Pest Control Manufacturing

- The Proper Application of Insecticides in Pest Control Manufacturing

- The Potential Risks of Using Insecticides in Pest Control Manufacturing

- Manufacturing Regulations Governing the Use of Insecticides in Pest Control Manufacturing

- The Future of Insecticides in Pest Control Manufacturing

The Benefits of Insecticides in Pest Control Manufacturing

Pests are a major problem in many areas of the world and can cause significant damage to crops and property. Insecticides are one of the most commonly used methods of pest control, and they can provide a number of benefits to those involved in pest control manufacturing. Here are some of the advantages of using insecticides in pest control manufacturing.

Cost-Effectiveness

Insecticides are relatively inexpensive, making them a cost-effective solution for pest control. They are also easy to use, meaning that they can be applied quickly and efficiently, reducing labor costs.

Fast Results

Insecticides work quickly, meaning that they can provide immediate results. This is particularly beneficial in areas where pests are an ongoing problem, as it allows for rapid and effective pest control.

Long-Term Results

Insecticides are designed to be effective for long periods of time, meaning that they can provide long-term pest control. This is especially beneficial in areas where pests are likely to return, as it allows for continued protection from pests.

Safety

Insecticides are designed to be safe for people, animals, and the environment. They are also odorless and invisible, meaning that they can be used in many different locations without causing any disruption.

Versatility

Insecticides can be used to target a variety of different pests, making them a versatile tool for pest control. This is particularly beneficial for those involved in pest control manufacturing, as it allows for the use of a single product to target a variety of pests.

Insecticides are a powerful tool for pest control, and they offer a number of benefits to those involved in pest control manufacturing. They are cost-effective, provide fast results, and offer long-term protection from pests. They are also safe to use and are highly versatile. For these reasons, insecticides are an essential tool for pest control manufacturing.

The Different Types of Insecticides Used in Pest Control Manufacturing

Insecticides are a crucial component of pest control. They can be used to target specific types of pests, or they can be used to control a wide variety of pests. In order to make the most effective use of insecticides, it's important to understand the different types that are available.

There are a variety of insecticides used in pest control manufacturing, each with a different purpose and formulation. Broad-spectrum insecticides are designed to kill a wide variety of pests, such as beetles, fleas, ticks, and moths.

These products are typically used in large-scale operations, such as agricultural fields. On the other hand, selective insecticides are designed to target specific pests.

These are most often used in indoor pest control, as they can be used in situations where pests are present but where broad-spectrum insecticides would be too dangerous.

Exmples of selective insecticides include products designed to kill roaches, ants, flies, and other specific pests. In addition to these two types of insecticides, there are also botanical and microbial insecticides.

Botanical insecticides are made from plants and are sometimes used in organic pest control. These products are typically used in low concentrations and are safer to use around humans, pets, and other animals.

Microbial insecticides use bacteria or fungi to target specific pests. These insecticides work by either killing the pests directly or by disrupting their life cycle. Finally, there are also insect growth regulators, which are chemicals that interfere with the growth and development of pest species.

These chemicals can be used to control pests without killing them and can be beneficial in long-term pest control strategies. No matter which type of insecticide you choose, it's important to follow the instructions on the product label.

Safety should be a top priority when using insecticides, as they can be dangerous if mishandled. With the right product and careful usage, insecticides can be an effective and safe way to protect your home or business from pests.

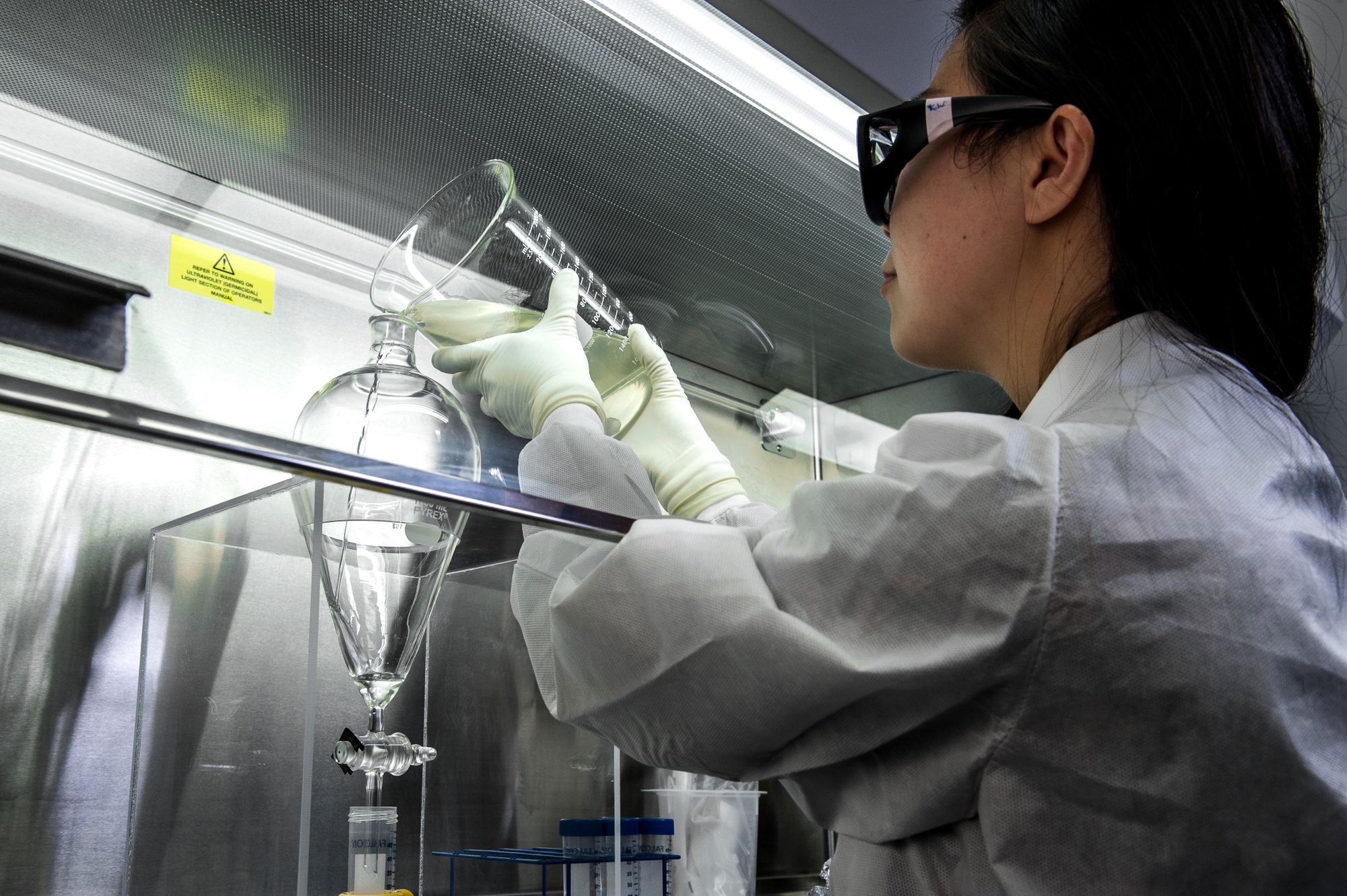

The Proper Application of Insecticides in Pest Control Manufacturing

When it comes to pest control in manufacturing, the proper application of insecticides is essential. Insecticides can be a powerful tool in preventing and controlling insect infestations, but they must be used correctly to be effective.

This blog will discuss the proper application of insecticides in pest control manufacturing, including the types of insecticides available, how to apply them correctly, and safety considerations when using insecticides.

Insecticides are divided into two main types: Contact insecticides, which kill insects on contact, and Systemic insecticides, which are absorbed into the plant or insect and kill it from the inside out.

The most common contact insecticides used in pest control manufacturing are pyrethroids, organophosphates, carbamates, and synthetic pyrethroids. These insecticides are usually applied as a spray or dust and act quickly to kill insects on contact.

Systemic insecticides, such as neonicotinoids, are also used in some cases. These insecticides are absorbed by the plant or insect and can be effective for long-term control.

When applying insecticides in pest control manufacturing, it is important to follow the directions on the product label. Different insecticides have different application rates, and it is important to use the correct rate to ensure that the insecticide is effective.

The product label will also provide instructions on the type of application equipment to use and how to safely apply the insecticide. It is also important to take safety precautions when applying insecticides in pest control manufacturing.

Insecticides can be toxic to humans and animals, so it is important to wear protective clothing, such as gloves and a respirator when handling and applying insecticides. It is also important to keep children and pets away from the area while the insecticide is being applied.

Finally, it is important to properly dispose of any unused insecticides and to follow all local, state, and federal regulations regarding the use of insecticides. In conclusion, the proper application of insecticides in pest control manufacturing is essential for effective pest control.

Different types of insecticides are available, and it is important to follow the product label instructions when applying insecticides. It is also important to take safety precautions when handling and applying insecticides,

The Potential Risks of Using Insecticides in Pest Control Manufacturing

With the rise of pest infestations in homes and workplaces, many people are turning to insecticides in order to effectively combat the problem. While insecticides have the potential to be an effective method of pest control, they can also pose a significant risk to human health and the environment if used inappropriately.

In order to ensure the safe and effective use of insecticides in pest control manufacturing, it’s important to understand the potential risks associated with their use. Insecticides can cause a variety of health issues.

The primary risk associated with insecticides is the potential for poisoning. When used incorrectly, insecticides can cause nausea, vomiting, dizziness, and even death. In addition, long-term exposure to insecticides has been linked to various forms of cancer, birth defects, and reproductive issues.

For this reason, it is essential that any pest control products containing insecticides are used in accordance with the manufacturer’s directions. Insecticides can also have a negative impact on the environment.

Insecticides can contaminate ground and surface water, negatively impacting aquatic ecosystems and the species that inhabit them. Insecticides can also be toxic to birds, mammals, and other beneficial species.

Furthermore, insecticides can damage beneficial insects that are necessary for pollination and other ecosystem services. In order to mitigate these risks, it is important to use insecticides in an appropriate and responsible manner.

When using insecticides, it is important to read and follow all manufacturer’s instructions carefully. It is also important to use the right amount of insecticide for the job, as applying too much could result in unnecessary exposure to toxins.

In addition, pest control companies should strive to use the least toxic insecticides available and use alternative control methods where possible. In conclusion, while insecticides can be an effective method of pest control, they can also pose significant risks to human health and the environment.

For this reason, it is important to use insecticides responsibly, following all manufacturer’s instructions and using alternative methods where possible. By understanding the potential risks associated with insecticides and using them appropriately, pest control manufacturers can ensure that their products are safe and effective.

Regulations Governing the Use of Insecticides in Pest Control Manufacturing

The use of insecticides in pest control manufacturing is a crucial part of controlling the spread of harmful pests and protecting human health. However, the improper use of insecticides can be dangerous and even fatal.

Therefore, it is important to understand the regulations that govern the use of insecticides in pest control manufacturing. The first law that governs the use of insecticides in pest control manufacturing is the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). FIFRA requires that insecticides be registered with the Environmental Protection Agency (EPA) before they can be sold or used in the United States.

This registration process ensures that the insecticide is safe for use and will not harm the environment. In addition to FIFRA, the EPA also has regulations that govern the use of insecticides in pest control manufacturing.

The EPA has established Maximum Residue Limits (MRLs) for many insecticides. These MRLs set the maximum allowable levels for residues of the insecticide in food and feed products.

The MRLs are designed to protect human health and the environment by ensuring that insecticides are used in a safe and responsible manner. The Occupational Safety and Health Administration (OSHA) also has regulations that govern the use of insecticides in pest control manufacturing.

OSHA requires employers to provide workers with appropriate personal protective equipment (PPE) when working with hazardous materials such as insecticides.

This PPE includes protective clothing, respirators, and eyewear. In addition, employers must provide workers with adequate safety training and ensure that all safety protocols are followed.

Finally, states may also have laws and regulations that govern the use of insecticides in pest control manufacturing. These laws and regulations may include restrictions on the use of certain insecticides and requirements for proper storage and disposal of insecticides.

Therefore, it is important to familiarize yourself with your local laws and regulations before using insecticides in pest control manufacturing. In conclusion, the use of insecticides in pest control manufacturing is an important part of controlling the spread of harmful pests and protecting human health.

Therefore, it is important to understand and follow the regulations that govern the use of insecticides in pest control manufacturing. This includes the Federal Insecticide, Fungicide, and Rodenticide Act, the EPA’s Maximum Residue Limits, OSHA’s safety regulations, and any local laws and regulations. By understanding and following these regulations, you can ensure that you are using insecticides in a safe and responsible manner.

The Future of Insecticides in Pest Control Manufacturing

The future of insecticides in pest control manufacturing, is an exciting one. As pest infestations become increasingly difficult to control, manufacturers are developing new, more effective insecticides to combat them.

In recent years, advances in technology have enabled manufacturers to develop insecticides that are more effective, safer to use, and more cost-effective. One of the most significant advances in insecticide development has been the use of synthetic pyrethroids, which are synthetic compounds that have insecticidal properties.

Synthetic pyrethroids are often formulated into liquid, aerosol, or powder products and can be applied in a variety of ways to protect against pests. These products are becoming increasingly popular due to their effectiveness, safety, and cost-effectiveness.

Another important development in pest control manufacturing is the use of biological control agents. Biological control agents are organisms, such as insects and bacteria, that are used to control the population of pests.

These agents can be used to target specific pests, such as mosquitoes, and can be applied directly to the source of the infestation. This method of pest control is becoming increasingly popular due to its effectiveness and safety. In addition to these advances, manufacturers are also exploring other methods of pest control, such as the use of natural predators and traps.

Natural predators, such as birds and bats, are being used to reduce the number of pests in an area, while traps can be used to catch and remove pests from the environment.

These methods are becoming increasingly popular due to their effectiveness and safety. Finally, manufacturers are also exploring the use of integrated pest management, which combines different methods of pest control.

This method utilizes a variety of techniques, such as the use of chemical and biological insecticides, natural predators, and traps, to create a comprehensive approach to pest control.

This approach is becoming increasingly popular due to its effectiveness and safety. The future of insecticides in pest control manufacturing is an exciting one, with a variety of methods and technologies being developed to combat pest infestations.

As technology continues to advance, manufacturers will be able to develop more effective and safer products to protect against pests. In the future, pest control manufacturing will continue to be a vital part of the pest control industry.

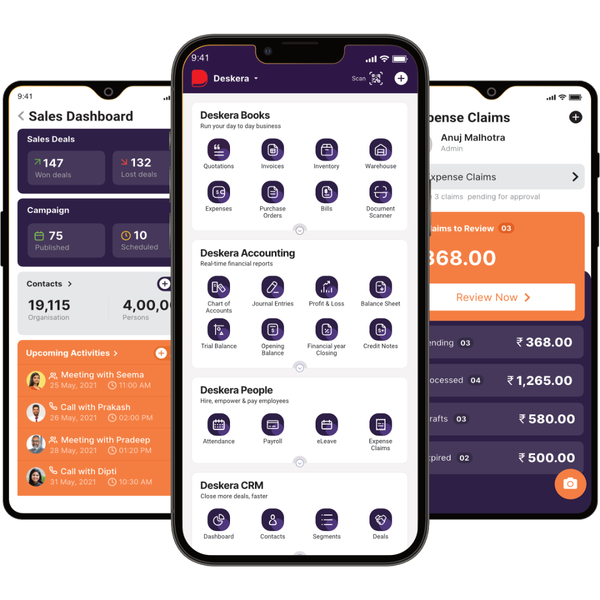

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Insecticides are one of the most commonly used methods of pest control,

- There are a variety of insecticides used in pest control manufacturing, each with a different purpose and formulation.

- When it comes to pest control in manufacturing, the proper application of insecticides is essential.

- The first law that governs the use of insecticides in pest control manufacturing is the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

- Another important development in pest control manufacturing is the use of biological control agents. Biological control agents are organisms, such as insects and bacteria, that are used to control the population of pests.

Related Articles: