A report by the National Association of Purchasing Management found that companies with effective supplier management practices can reduce supplier-related issues by up to 70%. Supplier management can make or break a successful supply chain. It's the glue that holds everything together and ensures everyone is on the same page.

Supplier management is a crucial component of a successful supply chain. It involves overseeing and coordinating the activities of suppliers to ensure that they deliver high-quality goods and services at a reasonable cost and on time. This helps to minimize risk, increase efficiency, and improve the overall performance of the supply chain.

Effective supplier management requires a well-defined process that includes selection, evaluation, and ongoing monitoring of suppliers. The process should also include regular communication and collaboration with suppliers to resolve issues and improve performance over time.

In this article, we will delve into the importance of supplier management and the key components of successful supplier management in the supply chain.

Here's what we shall cover in this post:

- What is Supplier Management in Supply Chain?

- Supplier Management Market

- What is the Role of a Supplier in the Supply Chain?

- Importance of Supplier Management in Supply Chain

- Key Performance Indicators for Supplier Management

- Future of Supplier Management in Supply Chain

- How Deskera Can Assist You?

- Conclusion

- Key Takeaways

What is Supplier Management in Supply Chain?

Supplier management is a critical aspect of the supply chain that focuses on overseeing and optimizing relationships between a company and its suppliers.

It is the process of selecting, monitoring, and evaluating suppliers to ensure they meet the organization's quality, cost, delivery, and performance needs.

Key Components of Supplier Management

- Supplier Selection:

Supplier selection is the first step in supplier management and is critical to the success of the supply chain. This process involves evaluating potential suppliers based on criteria such as quality, cost, delivery, and capacity, to select the best fit for the organization.

Companies should consider factors such as sustainability, ethics, and the supplier's reputation when selecting to ensure that their suppliers align with their values and goals.

- Contract Management:

Contract management is the process of establishing and maintaining a contract with a supplier. This process involves negotiating the terms and conditions of the agreement, establishing performance expectations, and monitoring the supplier's performance over time.

A well-structured contract helps to ensure that the expectations and responsibilities of both parties are clearly understood, reducing the risk of disputes and increasing the likelihood of a successful relationship.

- Supplier Monitoring:

Supplier monitoring is the ongoing process of tracking and evaluating the supplier's performance against established metrics and expectations. This involves collecting and analyzing data on key performance indicators, such as delivery times, product quality, and cost, to ensure that the supplier is meeting the agreed-upon standards.

Regular supplier monitoring helps identify improvement opportunities and ensure that the supplier is meeting the company's needs.

- Supplier Evaluation:

Supplier evaluation is a periodic review of the supplier's performance, typically performed at the end of a contract or at regular intervals. This process involves assessing the supplier's performance against established metrics and expectations and providing feedback to the supplier.

Supplier evaluations help to identify areas for improvement and to ensure that the supplier continues to meet the company's requirements over time. Companies should use supplier evaluations to inform decisions about whether to renew or terminate contracts or to make changes to the terms and conditions of existing agreements.

- Supplier Development:

Supplier development is the process of working with suppliers to help them improve their capabilities and performance. This can include training, providing resources and support, and working together on projects and initiatives.

Companies that invest in supplier development benefit from improved quality, cost savings, and stronger relationships with their suppliers. Supplier development should be seen as a long-term investment, with a focus on building mutually beneficial relationships that drive performance and growth.

Supplier Management Market Scenario

Companies are placing a greater emphasis on sustainability and are looking for suppliers who share their commitment to environmental and social responsibility. The use of technology, such as supplier management software, has become increasingly popular as companies look to automate and streamline the supplier management process.

With the increasing globalization of supply chains, companies are working with suppliers from all over the world, which can create new challenges in supplier management.

The increasing competition in many industries has led companies to focus on cost reduction, which has resulted in a greater emphasis on supplier management to negotiate better prices and reduce costs.

Impact of the Market on Supplier Management

- Market Dynamics:

The market plays a significant role in supplier management, as market conditions can majorly impact the supply chain. Market dynamics, such as fluctuations in demand, changes in competition, and shifts in technology, can affect the availability of goods and services and the cost and quality of these offerings.

Companies must be able to respond quickly to market changes in order to remain competitive and minimize the risk of supply chain disruptions.

- Competition:

Competition is one of the key drivers of change in the market and has a direct impact on supplier management. As competition increases, suppliers may face pressure to reduce prices, improve quality, or offer new and innovative products and services.

Companies must be able to adapt to these changes in order to remain competitive and maintain strong relationships with their suppliers.

- Technological Advancements:

Technological advancements are having a major impact on the market and are driving changes in supplier management. For example, advances in digital technologies, such as automation and artificial intelligence, are changing the way that goods and services are produced and delivered.

Companies must stay up-to-date with these advancements and be able to incorporate new technologies into their supply chain in order to remain competitive.

- Globalization:

Globalization is also affecting supplier management, as companies increasingly source goods and services from suppliers around the world. The globalization of the market has created new opportunities for companies, but it has also introduced new risks and challenges, such as cultural differences, language barriers, and distance.

Companies must be able to navigate these challenges to build strong relationships with their global suppliers and ensure their supply chain's success.

- Sustainability:

Sustainability is becoming an increasingly important issue in the market and has a significant impact on supplier management. Companies are under pressure to source goods and services from environmentally and socially responsible suppliers.

This is driving changes in supplier selection and contract management as companies seek to work with suppliers that share their values and goals.

What is the Role of a Supplier in the Supply Chain?

Suppliers play a critical role in the supply chain, as they are responsible for providing goods and services to organizations. This section will discuss the role of suppliers in the supply chain and the responsibilities they must fulfill.

Responsibilities of Suppliers in Supply Chain:

- Quality Control:

Suppliers must ensure that their goods and services meet the required quality standards and specifications. This involves following established quality control procedures and conducting regular inspections to ensure that products are of the highest quality.

Organizations rely on suppliers to provide high-quality goods and services, and it is the supplier's responsibility to ensure that their products meet the required standards.

- On-Time Delivery:

Suppliers must deliver goods and services on time to meet the organization's needs and avoid disruptions to the supply chain. This requires careful planning and coordination to ensure that products are delivered as needed and that there are no delays in the supply chain.

Suppliers must also be able to respond quickly to changes in demand and adjust their operations accordingly.

- Cost Management:

Suppliers must work with organizations to reduce costs and negotiate favorable prices for their goods and services. This requires suppliers to proactively identify cost-saving measures and work with organizations to implement these measures.

Cost management is critical to supplier management, as organizations rely on suppliers to provide cost-effective solutions to meet their needs.

- Risk Management:

Suppliers must identify and mitigate any potential risks associated with their operations, such as disruptions in supply, to ensure the stability of the supply chain.

This involves monitoring potential risks and implementing contingency plans to minimize their impact on the supply chain. Suppliers must also be proactive in identifying new risks and developing strategies to mitigate these risks.

- Communication:

Suppliers must communicate effectively with organizations to ensure that they understand their needs and requirements. This requires regular and open communication to ensure that organizations and suppliers are on the same page and that there are no misunderstandings.

Effective communication is key to building a successful relationship between organizations and suppliers.

Importance of Suppliers in Supply Chain

- Critical Component:

Suppliers are a critical component of the supply chain, as they are responsible for providing the goods and services that organizations need to operate. Without suppliers, organizations would not be able to meet their needs and fulfill customer demands.

Suppliers play a crucial role in ensuring that organizations have the resources they need to operate effectively.

- Contributes to Efficiency:

Effective supplier management can help organizations reduce lead times and improve overall supply chain efficiency. Organizations can streamline the supply chain and improve their overall efficiency by working with suppliers to optimize their operations.

This can result in faster delivery times, lower costs, and higher customer satisfaction.

- Enhances Product Quality:

Suppliers play a crucial role in ensuring that the goods and services they provide meet the required quality standards, which can enhance the overall quality of the products and services produced by organizations.

Suppliers help organizations maintain their reputation and build customer trust by providing high-quality goods and services.

- Supports Cost Reduction:

Suppliers can help organizations reduce costs by negotiating favorable prices for their goods and services and implementing cost-saving measures.

Organizations and suppliers can reduce costs and improve the bottom line by working together to identify cost-saving opportunities.

- Mitigates Risks:

By identifying and mitigating any potential risks associated with their operations, suppliers can help organizations maintain the stability of their supply chain. This involves monitoring potential risks and implementing contingency plans to minimize their impact on the supply chain.

Importance of Supplier Management in Supply Chain

Supplier management is a critical component of the supply chain, as it helps organizations ensure that they have access to the goods and services they need to operate.

This section will discuss the importance of supplier management in the supply chain and why it is a crucial aspect of successful supply chain management.

- Improved Quality:

Effective supplier management helps organizations ensure that they receive high-quality goods and services from their suppliers. This involves setting clear quality standards and regularly monitoring supplier performance to ensure these standards are met.

By focusing on supplier quality, organizations can improve the overall quality of their products and services, enhancing their reputation and building customer trust.

- Increased Efficiency:

Supplier management can help organizations reduce lead times and improve overall supply chain efficiency. By working with suppliers to optimize their operations, organizations can streamline the supply chain and reduce the time it takes to receive goods and services.

This can result in faster delivery times, lower costs, and higher customer satisfaction.

- Cost Reduction:

Effective supplier management can help organizations reduce costs by negotiating favorable prices for their goods and services and implementing cost-saving measures. Organizations and suppliers can reduce costs and improve the bottom line by working together to identify cost-saving opportunities.

Additionally, by using supplier performance metrics to monitor supplier performance, organizations can ensure that they are getting the best value for their money.

- Improved Relationships:

Supplier management helps organizations build strong relationships with their suppliers, which can help ensure the supply chain's stability. By maintaining open and regular communication with suppliers, organizations can resolve any issues that may arise and maintain a positive relationship.

Additionally, by working with suppliers to optimize their operations, organizations can help suppliers improve their performance, enhancing the supply chain's overall stability.

- Risk Mitigation:

Effective supplier management can help organizations mitigate supply chain risks, such as disruptions in supply or quality problems. By setting clear performance expectations and regularly monitoring supplier performance, organizations can identify potential risks and take action to mitigate them.

Additionally, by working with suppliers to develop contingency plans, organizations can minimize the impact of any disruptions in the supply chain.

Key Performance Indicators (KPIs) for Supplier Management

Supplier management is an essential part of any supply chain, as it helps organizations ensure that they receive high-quality goods and services from their suppliers.

Organizations can use Key Performance Indicators (KPIs) to measure supplier management's effectiveness. This section will discuss the key KPIs for supplier management and how organizations can use them to measure supplier performance.

On-Time Delivery

On-time delivery is a critical KPI for supplier management, as it measures the reliability of suppliers in delivering goods and services on time. Organizations can track this KPI by monitoring the percentage of orders that are delivered on or before the agreed-upon delivery date.

This KPI is important as it helps organizations ensure they have the resources they need to operate and meet customer demands.

Quality Metrics

Quality metrics are another key KPI for supplier management, as they measure the quality of goods and services. Organizations can track quality metrics such as product defects, returns, and customer satisfaction ratings.

By monitoring quality metrics, organizations can identify any quality problems and take action to resolve them, which can improve customer satisfaction and reduce costs.

Cost Metrics

Cost metrics are important KPIs for supplier management, as they measure the costs associated with goods and services provided by suppliers. Organizations can track cost metrics such as the cost of goods sold, total supplier costs, and the cost of quality problems.

By monitoring cost metrics, organizations can identify opportunities for cost savings and negotiate better prices with suppliers, which can improve the bottom line.

Lead Time

Lead time is the amount of time it takes for an organization to receive goods and services from suppliers. This KPI is important as it helps organizations ensure they have the resources they need to operate and meet customer demands. Organizations can track lead time by monitoring the time suppliers deliver goods and services after an order has been placed.

Compliance Metrics

Compliance metrics are critical KPIs for supplier management, as they measure suppliers' compliance with regulations and standards. Organizations can track compliance metrics such as the number of audits conducted, the number of supplier violations, and the percentage of suppliers compliant with regulations and standards.

By monitoring compliance metrics, organizations can ensure that their suppliers are meeting their obligations and reduce the risk of regulatory penalties.

KPIs are an important tool for measuring the effectiveness of supplier management in the supply chain. By monitoring KPIs such as on-time delivery, quality metrics, cost metrics, lead time, and compliance metrics, organizations can identify opportunities for improvement and ensure that they are receiving high-quality goods and services from their suppliers.

Organizations can improve their supply chain performance and achieve their business goals by focusing on supplier management KPIs.

Future of Supplier Management in Supply Chain

Increased Use of Technology

Supplier management in the future will be heavily influenced by advancements in technology. Automation and the use of AI will streamline the processes involved in supplier management, making it more efficient and effective.

This will include the use of cloud-based systems for data management and real-time analytics for better decision-making. Additionally, the use of blockchain technology will increase transparency and security in supply chain transactions.

Sustainability and Ethical Considerations

As consumers become more conscious of the impact of their purchases on the environment and society, they increasingly demand that suppliers adhere to ethical and sustainable practices.

This trend will drive the need for more comprehensive supplier management practices that consider sustainability and ethical concerns. Companies will need to regularly assess their suppliers' practices to ensure they align with their sustainability and ethics goals.

Collaboration and Partnerships

Collaboration and partnerships will play an increasingly important role in the future of supplier management. Companies will need to work closely with their suppliers to ensure the smooth functioning of the supply chain.

This will require open and transparent communication, shared goals, and mutual trust. Companies that foster strong relationships with their suppliers will be better positioned to respond to changes in the market and anticipate potential problems.

Supply Chain Visibility and Transparency

Visibility and transparency will become increasingly important in the future of supplier management. Companies will need to have real-time visibility into their suppliers' operations to ensure that their supply chain is running smoothly.

This will require the use of advanced technology, such as the Internet of Things (IoT) and blockchain, to track the movement of goods and monitor supplier performance. Companies that invest in supply chain visibility and transparency will be better equipped to respond to disruptions and make informed decisions.

Risk Management

The future of supplier management will emphasize risk management more. Companies will need to assess and mitigate potential risks in their supply chain, such as natural disasters, economic volatility, and political instability.

This will require companies to have contingency plans in place and to develop relationships with multiple suppliers to reduce dependence on any one supplier. Companies that proactively manage risk in their supply chain will be better positioned to weather disruptions and maintain the continuity of their operations.

How Deskera Can Assist You?

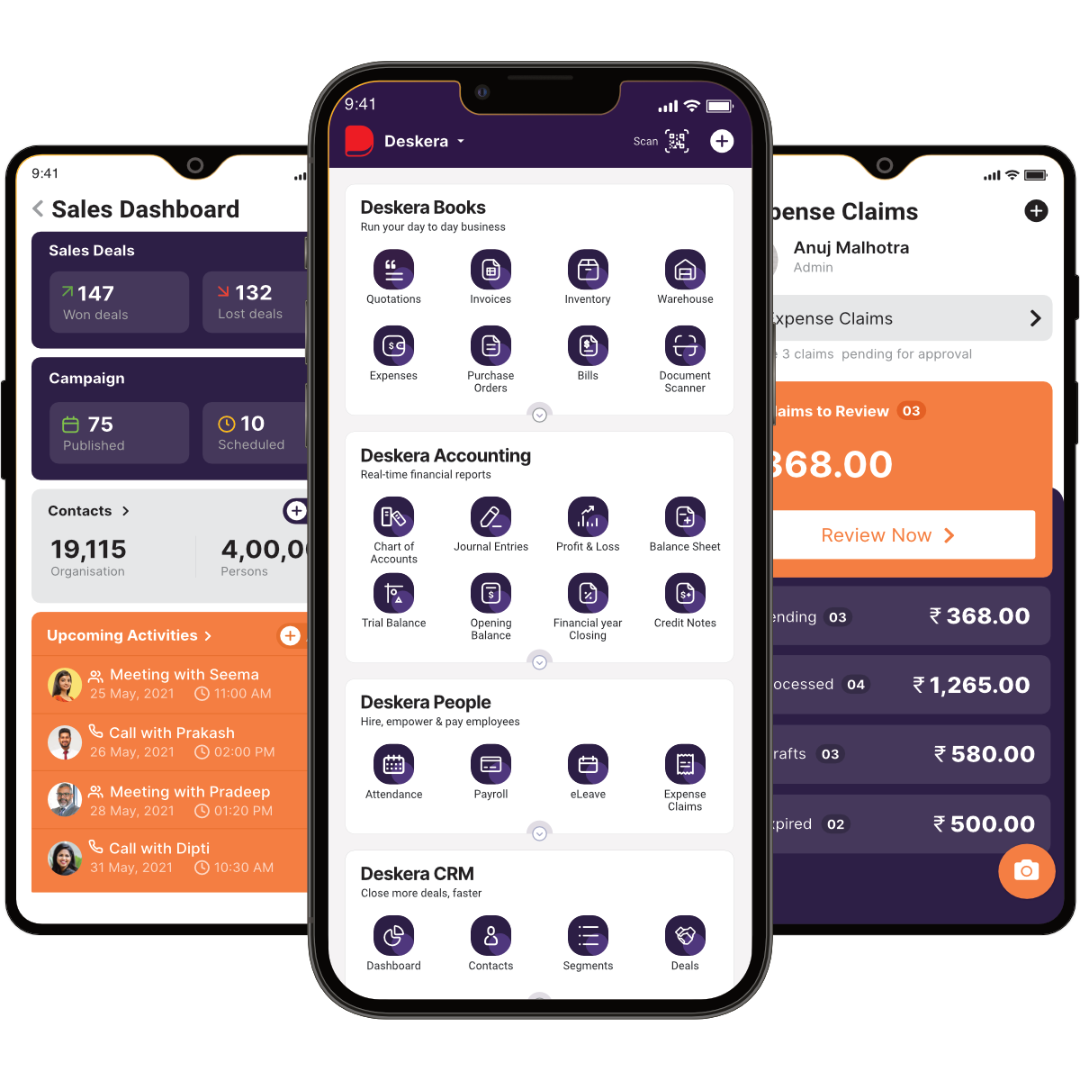

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Conclusion

Supplier management is a crucial component of the supply chain, as it helps organizations ensure that they receive high-quality goods and services from their suppliers. Effective supplier management requires a well-defined process that includes identifying and selecting suppliers, monitoring supplier performance, and managing supplier relationships.

To effectively manage suppliers, organizations need to clearly understand their needs and expectations, as well as the capabilities and limitations of their suppliers. They also need to have strong communication and collaboration with their suppliers and use data analytics and technology to monitor supplier performance and make informed decisions.

In today's rapidly changing business landscape, organizations need to be proactive in managing their suppliers and adapting to changes in the supply chain. This requires continuous improvement and a focus on innovation and sustainability, as well as effective risk management and contingency planning.

Finally, it is important to continually evaluate and improve the supplier management process, as the needs and expectations of the supply chain may change over time. By regularly reviewing and refining the supplier management strategy, organizations can ensure that they remain competitive and continue to deliver value to their customers.

Key Takeaways

- Putting supplier management in the supply chain is essential for organizations to achieve their business goals and succeed in a rapidly changing and highly competitive business environment.

- By putting supplier management in the supply chain, organizations can reduce the risk of supply chain disruptions, improve the quality of their products and services, and achieve their business goals.

- To put supplier management into practice, it is important to clearly understand the suppliers' capabilities and limitations, as well as their roles and responsibilities in the supply chain.

- By investing in supplier management, organizations can ensure that they are receiving high-quality goods and services from their suppliers and are well-positioned for future success.

- Supplier diversity programs can also be a valuable tool in supplier management, as they promote the inclusion of a wide range of suppliers, including those owned by women, minorities, and veteran-owned businesses.

- Regular supplier audits and assessments are necessary to ensure that suppliers meet expectations and follow established protocols and identify areas for improvement.

- The use of technology, such as supplier portals and e-sourcing platforms, can greatly enhance supplier management by streamlining processes and improving communication.

Related Articles