Wood manufacturing is the process of transforming raw wood into usable products. It involves cutting, shaping, and assembling the timber into products such as furniture, flooring, cabinetry, doors, windows, and other decorative pieces.

The process starts with the selection of raw materials such as hardwood, softwood, lumber, or plywood, which are then cut into the desired shapes and sizes. Afterward, the pieces are put together using various techniques such as gluing, nailing, screwing, and bolting.

This article covers the following:

- Types of Wood

- Wood Manufacturing Process

- Joinery Techniques

- Wood Finishes

- Woodworking Tools

- Furniture Design

- Green Building with Wood

- Wood Preservation

- Wood Adhesives

- Pros and Cons of Wood Manufacturing

- Safety in Woodworking

Types of Wood

Wood is one of the most popular materials used in furniture manufacturing, and it comes in many different varieties. Each type of wood has distinct characteristics and benefits, which makes it ideal for creating furniture that fits the aesthetic and functional needs of any home. Here is a closer look at the different types of wood used in furniture manufacturing, and the advantages and disadvantages of each.

Softwoods

Softwoods are the most commonly used type of lumber in furniture manufacturing. These include species such as pine, fir, and cedar. Softwoods are typically less expensive, lighter in weight, and easier to work with than hardwoods. On the downside, they are more prone to warping and are not as strong or durable as other woods.

Hardwoods

Hardwoods are the most popular choice for furniture, as they are strong, durable, and aesthetically pleasing. These include species such as oak, maple, and cherry. Hardwoods are typically much more expensive than softwoods, and they are more difficult to work with. However, they can last a lifetime and are less likely to warp or break than softwoods.

Exotic Hardwoods

Exotic hardwoods are woods from all over the world, such as teak, mahogany, and ebony. These woods are very durable and are often used to create luxurious and high-end furniture. They are usually more expensive than other types of wood, and they can be difficult to work with.

Bamboo

Bamboo is one of the most sustainable materials used in furniture manufacturing, as it is a fast-growing grass that can be harvested in as little as three years. Bamboo is lightweight, strong, and resistant to rot, making it an ideal choice for outdoor furniture. It is typically more expensive than other woods, but it is an environmentally friendly option.

Recycled Woods

Recycled woods are becoming increasingly popular in furniture manufacturing. These are woods that have been reclaimed from old buildings and structures and are given a second life in furniture.

These woods are typically less expensive than other types of wood, and they have a unique character and charm that can’t be replicated with new wood. No matter what type of wood you choose for your furniture, it is important to make sure that it is of high quality and that it is well cared for. Proper maintenance and care will ensure that your furniture looks great for years to come.

Wood Manufacturing Process

Wood manufacturing is an ancient craft that dates back centuries. Woodworking has been used to create everything from furniture and cabinetry to boats and sculptures. Today, it is still a popular craft and many people use it to create beautiful and unique pieces of art.

The process of wood manufacturing involves a few stages. First, the wood is harvested and cut into the desired shape and size. This is usually done by sawing the wood into different pieces of the same size. Once the wood is cut, it is then dried in a kiln to remove any moisture. This helps to prevent the wood from warping or cracking.

After the wood is dried, it is sanded to create a smooth surface. This helps to provide a better finish for the final product. The wood is then treated with a sealant to protect it from the elements. This can include staining, painting, or varnishing.

Once the wood is treated, it is ready to be cut into the desired shape and size. This can be done with a variety of tools, such as saws, routers, and sanders. The pieces are then glued together and fitted to create the desired furniture piece.

Finally, the wood is finished with a coat of sealant or varnish. This provides a protective layer to the wood and helps to preserve it for many years. Wood manufacturing is an ancient craft that is still used today to create beautiful and unique pieces of art.

By understanding the process of wood manufacturing, you can create something truly special for your home or office. With the right tools and techniques, anyone can craft a one-of-a-kind piece of furniture from wood.

Joinery Techniques

Joinery is an important part of furniture manufacturing, as it allows for the connection of different pieces of wood, creating a secure and sturdy structure. Joinery techniques range from the simple, like butt joints, to the complex, like dovetail and mortise and tenon joints, each with its own advantages and disadvantages.

Butt joints are the most basic form of joinery, and are made by simply butting two pieces of wood together and securing them with screws or nails. While this type of joint is not the strongest, it can be used in furniture manufacture if the pieces of wood are of the same thickness and grain direction.

Dovetail joints are one of the strongest joinery techniques, and are made by cutting both pieces of wood at an angle and using a dovetail saw to cut a shaped edge. This joint creates an interlocking connection between the two pieces, and is commonly used in drawers and cabinets.

Mortise and tenon joints are a type of joinery that creates an interlocking connection between two pieces of wood by cutting a mortise into one piece and a tenon on the other.

The tenon is then inserted into the mortise and glued together, creating a strong, secure joint. Rabbet joints are a type of joinery used to connect two pieces of wood together, where one piece has a notch cut into it.

This joint is commonly used to attach a cabinet back to the frame. These are just a few of the joinery techniques used in furniture manufacturing. Each joint has its own advantages and disadvantages, and it’s important to choose the right one for the job. With the right joinery techniques, furniture can be created that is both strong and beautiful.

Wood Finishes

Wood finishes are an important part of the furniture manufacturing process. Not only do they add beauty and style to the furniture, but they also protect the wood from damage and wear over time.

There are many different types of wood finishes available, each with its own unique characteristics and benefits. One of the most popular types of wood finishes is lacquer. Lacquer is a type of varnish that is applied to the wood in liquid form and then cured, which gives the wood a glossy, hard wearing finish.

Lacquer is a great choice for furniture because it provides a long-lasting, durable finish that can withstand daily wear and tear. It is also relatively easy to apply and can be used to create a range of different finishes, such as satin, matte, and gloss. Stains are another popular type of wood finish.

Stains are applied to the wood to give it a specific color or tone. They can be used to create a range of different looks, from a light, natural finish to a deep, rich hue. Stains can also be used to create a range of different textures, such as a distressed look or a smooth, glossy effect.

The last type of wood finish is oil-based. Oil-based wood finishes are applied to the wood in liquid form and then left to dry. Once the oil has dried, it creates a hard, durable finish that will protect the wood from scratches and wear.

Oil-based finishes can be used to create a range of different looks, such as a natural, matte finish or a glossy, sheen look. No matter what type of wood finish you choose, it is important to properly prepare the wood prior to applying the finish.

This includes sanding the wood to remove any imperfections and ensuring that the surface is clean and free of dirt and dust. Once the wood is prepared, it is ready to be applied with a brush, sprayer, or roller.

When it comes to furniture manufacturing, wood finishes play an important role. Not only do they provide protection and enhance the look of the furniture, but they also help to preserve the wood and ensure that it lasts for years to come.

Whether you choose lacquer, stain, or oil-based finish, taking the time to properly prepare the wood and apply the correct wood finish can make all the difference in the end result.

Woodworking Tools

Woodworking is an incredibly rewarding and enjoyable hobby, but it requires the right tools to be successful. With the right tools, you can craft beautiful, durable pieces of furniture with ease.

Whether you’re a beginner or an experienced woodworker, having the right tools and knowing how to use them can make the difference between a successful project and a disaster.

One of the most important tools for woodworking is the saw. There are several different types of saws that can be used in woodworking, including jigsaws, circular saws, bandsaws, and table saws.

Each saw has its own strengths and weaknesses, so it’s important to understand the differences between them and choose the one that best suits your needs. Jigsaws are great for making curved and intricate cuts, while circular saws can make straight cuts and rip through thick pieces of wood quickly and efficiently.

Bandsaws are perfect for making precise and intricate cuts, while table saws are great for making large, straight cuts. Another essential tool for woodworking is the router. Routers can be used to create decorative edges, rout out grooves, and create perfectly round holes.

There are several different types of routers, including plunge routers, fixed base routers, and oscillating routers. Each type has its own unique features and abilities, so it’s important to understand the differences and choose the one that best suits your needs.

In addition to saws and routers, there are several other tools that are essential for woodworking, such as sanders and chisels. Sanders can be used to smooth out rough edges and surfaces, while chisels are perfect for creating intricate and detailed designs.

Both of these tools are essential for creating beautiful and durable furniture. Finally, it’s important to have the right supplies and materials to complete your woodworking project.

Woodworking glue and clamps are essential for assembling furniture, while wood stains and varnishes can be used to give your furniture a beautiful and professional finish. Woodworking is an incredibly rewarding and enjoyable hobby, but it requires the right tools and materials to be successful.

With the right tools and supplies, you can craft beautiful and durable pieces of furniture with ease. Whether you’re a beginner or an experienced woodworker, having the right tools and materials can make the difference between a successful project and a disaster.

Furniture Design

Furniture design in wood manufacturing is an art form that has been practiced for centuries. From the classic lines of a Windsor chair to the sleek curves of a modern coffee table, wood furniture has been a mainstay of living spaces around the world.

With the current trend towards sustainable materials, wood is becoming an increasingly popular choice when it comes to furnishing homes. When it comes to wood furniture design, there are a variety of options.

For those seeking a more traditional look, classic lines, veneers, and inlays can create an elegant and timeless atmosphere. For more modern homes, contemporary designs made of solid woods such as oak and maple can be used to create eye-catching and unique pieces.

No matter the style, strong construction is essential for any furniture design. A well-designed piece of furniture should be able to withstand regular use and wear and tear, and be able to last for many years.

Quality materials and sound craftsmanship are the cornerstones of a good furniture design. When it comes to wood furniture design, there are a few key elements to consider.

The type of wood used plays a big role in the finished look of the piece. Different woods have different properties, such as hardness and grain, that can affect the overall look of the design.

Additionally, the finish used on the wood can also change the appearance of a piece. The design of a piece of furniture should also reflect the purpose it is designed to serve. A well-made chair, for example, should be comfortable, ergonomic, and able to provide support.

A desk should be well-designed to meet the needs of the user. No matter the style or intended purpose, furniture design in wood manufacturing is an art form that takes skill and knowledge to master. With the right materials and construction, a piece of furniture can be a beautiful addition to any home.

Green Building with Wood

Wood is one of the most sustainable and renewable materials used in the furniture manufacturing industry. Not only is it one of the most durable and aesthetically pleasing materials, but it’s also a strong contributor to green building.

Wood has the unique ability to absorb and store carbon dioxide, making it an effective carbon sequestration material. As one of the greenest building materials, wood has the potential to significantly reduce carbon emissions, helping to create a healthier and more sustainable environment.

Green building with wood is becoming more prominent in the furniture manufacturing industry, and manufacturers are striving to use wood responsibly and efficiently. Wood can be sourced from sustainably managed forests as well as recycled and reclaimed sources.

The use of certified lumber ensures that the wood is sourced from forests that are managed in an ethical and environmentally responsible manner. In addition, furniture makers are leveraging advanced technology to reduce the amount of wood used in the manufacturing process, thus reducing their carbon footprint.

Furniture manufacturing companies are also exploring ways to reduce the amount of energy used in the production process. By using energy-efficient woodworking tools and construction techniques, furniture makers can reduce their energy consumption, resulting in lower costs and less environmental impact.

Additionally, furniture manufacturers are utilizing renewable energy sources, such as solar and wind power, to reduce their reliance on traditional energy sources. When it comes to green building with wood, furniture makers must also pay attention to the type of wood they use.

Hardwoods, such as oak and cherry, are naturally denser and more durable, making them an ideal choice for furniture manufacturing. Softwoods, such as pine and cedar, are lighter and more affordable, but they don’t last as long as hardwoods.

By carefully selecting the type of wood used in the manufacturing process, furniture makers can ensure that their products are both durable and eco-friendly. The furniture manufacturing industry is constantly evolving, and green building with wood is becoming an increasingly important part of the process.

By utilizing sustainable wood sources, reducing energy consumption, and carefully selecting the type of wood used, furniture makers can ensure that their products are both aesthetically pleasing and environmentally friendly.

As the demand for sustainable furniture grows, manufacturers must continue to explore ways to reduce their carbon footprint and create a healthier, more sustainable environment.

Wood Preservation

Wood preservation is an important part of wood manufacturing. It involves the use of chemical treatments, various coatings, and other techniques to prolong the life of wood and protect it from the damaging effects of weather, pests, and other environmental factors.

While wood is naturally resistant to decay, it is still vulnerable to environmental elements and can quickly become damaged if not properly protected. The process of wood preservation begins with the selection of the right type of wood.

Different types of wood require different treatments, so it is important to choose the right type for the application. After the type of wood is chosen, the next step is to treat it with a preservative.

This can involve applying a chemical treatment, such as a fungicide or insecticide, or applying a coating to protect the wood from moisture and ultraviolet light. Once the wood is treated, it is then ready for finishing.

This can involve staining or painting the wood to enhance its appearance and make it more resistant to weathering. It is also possible to apply a sealant to protect the wood from moisture or a coating to protect it from UV light.

No matter the type of wood, it is important to properly maintain the wood to ensure it remains in good condition. This includes regularly checking for signs of decay or damage, and taking steps to repair any damage that is discovered.

Proper maintenance is essential to ensure the wood remains in good condition and can be used for many years to come. Wood preservation is an important step in the wood manufacturing process.

It helps to protect the wood from environmental elements, pests, and other factors that can cause it to become damaged over time. Careful selection of the right type of wood, followed by proper chemical treatment and finishing, can help to ensure the wood is properly preserved and remains in good condition for many years to come.

Wood Adhesives

Wood adhesives have become increasingly important in wood manufacturing, as they are used to bond wood together in a variety of applications. Wood adhesives are used in the production of furniture, cabinets, flooring, and many other products.

Wood adhesives are designed to create strong bonds between wood pieces and other components during woodworking. They are available in various forms, such as liquid, paste, and powder.

The type of wood adhesive used in a particular application depends on the type of wood being used, the strength of the bond required, and the environment in which the adhesive will be used.

For instance, liquid wood adhesives are preferred in applications that require quick curing, while paste and powder adhesives are well suited for applications that require a more permanent bond.

Liquid wood adhesives are also easier to apply than paste and powder adhesives. When choosing a wood adhesive, it is important to select one that is compatible with the type of wood being used.

Some adhesives work better with softwoods, while others are better suited for hardwoods. In addition, some wood adhesives are designed to work better with certain finishes, such as lacquer, varnish, or paint.

Wood adhesives are also available in various forms, such as water-based, solvent-based, and hot-melt adhesives. Water-based adhesives are the most commonly used, as they are easy to apply, clean up, and are nonflammable.

Solvent-based adhesives are more durable and create stronger bonds, but they require more time to dry and can be flammable. Hot-melt adhesives are ideal for applications that require a fast setting time, but they are not as strong as other types of adhesives.

When using a wood adhesive, it is important to follow the manufacturer's instructions for proper application. The adhesive should be applied in an even coat, and allowed to dry completely before the pieces are joined together.

In addition, it is important to use the appropriate amount of adhesive for the job, as too little adhesive can result in a weak bond, while too much adhesive can cause the pieces to stick together too firmly.

Adhesives are essential for wood manufacturing, as they allow for strong and lasting bonds between wood pieces. By selecting the right type of wood adhesive, you can ensure that your woodworking projects are successful and long-lasting.

Pros and Cons of Wood Manufacturing

Wood manufacturing is the process of creating products from wood. It involves cutting, shaping, and finishing raw lumber into usable items such as furniture, cabinets, doors, and flooring. Wood manufacturing has been around for centuries and is still used today in a variety of industries. The Pros of Wood Manufacturing

Versatility

Wood is a very versatile material that can be used to create a variety of different products. It can be cut and shaped into whatever shape or size you need for whatever project you’re working on. It’s also strong, durable, and easy to work with.

Natural Beauty

Wood has a natural beauty that can’t be replicated with any other material. Its unique grain pattern and color give it a unique look that can’t be matched. Wood can also be stained or painted to create a variety of different looks.

Eco-Friendly

Wood is a renewable resource that can be sustainably harvested. It’s also biodegradable, so it won’t contribute to landfills like other materials. The Cons of Wood Manufacturing

Expense

Wood is a relatively expensive material compared to other materials, such as plastic or metal. This can make the cost of the project higher.

Handling

Wood can be difficult to handle and can be damaged easily if not handled correctly. It also needs to be stored properly to ensure its integrity.

Environmental Impact

While wood is a renewable resource, its harvesting and manufacturing can have a negative impact on the environment. The use of pesticides, herbicides, and other chemicals can cause pollution and damage to the environment.

Overall, wood manufacturing has many advantages and disadvantages. It’s a versatile and beautiful material that can be used to create a variety of products, but it can also be expensive and difficult to handle.

Its harvesting and manufacturing can also have a negative impact on the environment. If you’re considering using wood for your next project, make sure to weigh the pros and cons before making your decision.

Safety in Woodworking

Safety is an important aspect of any type of work, but it is especially important when it comes to woodworking. Working with wood can be dangerous if proper precautions and safety measures are not taken.

Injuries from woodworking can range from minor scrapes and cuts to serious lacerations and even amputations. To ensure that everyone who works with wood is safe, there are some key safety practices to keep in mind.

Wear Appropriate Clothing

It is important to wear clothing that is appropriate for woodworking. This includes clothing that is loose-fitting and not baggy, as baggy clothing can get caught in machinery.

It is also important to wear closed-toed shoes, long pants, and long sleeves to keep your skin protected from wood chips and dust. Additionally, always wear eye protection and a dust mask when working with wood to protect your eyes and lungs.

Use the Right Tools

Using the right tools is essential for woodworking safety. Make sure you use tools that are appropriate for the job and that are in good condition. Replace any tools that are worn or have loose parts before using them.

Maintain Your Workspace

Keeping your workspace clean and organized is an important safety practice. Make sure that all tools are stored in their proper locations and that there is no clutter on the floor that could cause you to trip. Additionally, keep your work area well-lit so you can see what you are doing.

Follow Instructions

Make sure you read and follow all instructions when using tools and machines. This includes reading the owner’s manual and following any safety guidelines. Pay attention to what you are doing and take your time.

Stay Alert

It is important to stay focused and alert when working with wood. Don’t use tools or machines when you are tired or distracted. Additionally, avoid working with wood in an area that is too noisy or has too many distractions.

These are just a few of the safety practices to keep in mind when working with wood. Following these guidelines will help ensure that everyone who works with wood is safe and injury-free.

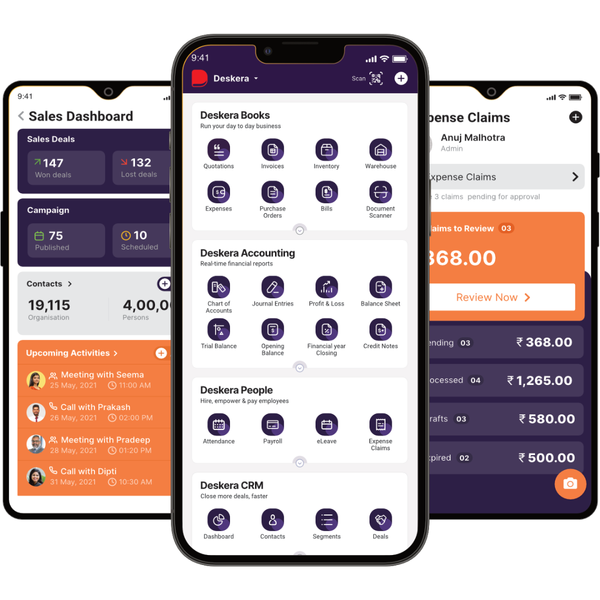

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Sustainable wood is becoming increasingly popular as people become more conscious of the environment and their impact on it.

- Sustainable wood is a great choice for furniture and home décor, as it helps reduce our impact on the environment.

- When it comes to sustainability, wood is one of the most abundant and renewable resources available to us.

- With the increasing concern about global warming and deforestation, it's important to make sure the wood we buy is sourced from sustainable sources.

- Many companies are now labeling their wood with labels that indicate where the wood was sourced and how it was harvested. Look for labels that say FSC-certified, SFI-certified, or PEFC-certified.

Related Articles: