The global pest control market size was valued at $19.73 billion in 2020 and is projected to reach $28.07 billion by 2026, with a CAGR of 6.0% during the forecast period. (Source: MarketsandMarkets)

Also, Integrated Pest Management (IPM) is becoming increasingly popular in the pest control industry, with 87% of pest management professionals reporting that they offer IPM services to their customers.

Pest infestations are a nuisance that can cause significant damage to property and pose a threat to public health. As a result, pest control has become a vital service in our modern society. However, the methods used to control pests have evolved significantly over the years. With so many options available, it can be challenging for pest control manufacturers to determine the best approach.

Each technique has pros and cons, from chemical pesticides to biological controls and physical barriers.

In this article, we will explore the advantages and drawbacks of different pest control manufacturing techniques, helping you make informed decisions about which method is best for your needs.

- What are Pest Control Manufacturing Techniques?

- Why are Different Techniques Needed

- Chemical Pest Control Techniques

- Biological Pest Control Techniques

- Physical Pest Control Techniques

- Integrated Pest Management

- Comparative Analysis of Different Pest Control Manufacturing Techniques

- Limitations of Different Pest Control Manufacturing Techniques

- ERP and MRP Systems for Pest Control Manufacturing

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What are Pest Control Manufacturing Techniques?

Pest control manufacturing techniques refer to the processes used in the production of various pest control products such as insecticides, rodenticides, and other pest management solutions. These techniques aim to produce products that are effective in controlling pests while also being safe for humans, pets, and the environment.

Some of the common pest control manufacturing techniques include:

- Formulation: This involves combining different active ingredients and other additives to create a product with the desired properties. Formulations can be in the form of powders, granules, liquids, or gels.

- Mixing: This involves blending the formulation's ingredients to ensure uniform distribution of the active ingredients.

- Grinding: This is used to reduce the size of solid ingredients, making them easier to mix and dissolve.

- Extrusion: This is a process used to create pellets or beads of the active ingredients, which are then mixed with other ingredients to form the final product.

- Emulsification: This is used to create emulsions, which are a mixture of two immiscible liquids, such as oil and water.

- Encapsulation: This involves coating the active ingredients with a protective shell to prevent them from breaking down too quickly or being washed away.

- Quality Control: This is a critical step in pest control manufacturing that involves testing the products to ensure they meet the required standards for efficacy and safety.

Why are Different Techniques Needed?

Different pest control manufacturing techniques are needed for a variety of reasons, including:

- Different types of pests require different types of control methods: Different pests require different types of pest control products to effectively control them. For example, an insecticide effective against mosquitoes may not work on ants, and a rodenticide effective against mice may not work on rats.

- Different formulations are needed for different applications: Pest control products come in various formulations, such as sprays, baits, dust, and granules, and each formulation is suited for specific applications. For example, a liquid insecticide may be more suitable for treating large outdoor areas, while a bait may more effectively control ants or termites in small indoor spaces.

- Safety considerations: Different pest control manufacturing techniques may be needed to ensure the safety of humans, pets, and the environment. For example, some formulations may be less harmful to non-target organisms or may have less of an impact on the environment than others.

- Regulatory requirements: Different manufacturing techniques may be required to meet regulatory requirements for efficacy, safety, and environmental impact. For example, a product may need to be tested for its efficacy against the target pest, as well as its safety for humans and non-target organisms, before it can be approved for use.

Chemical Pest Control Techniques

Chemical pest control techniques involve the use of synthetic or natural chemicals to control or eliminate pests such as insects, rodents, and other pests. Chemical pesticides can be applied in various forms, including sprays, baits, dust, and fumigants.

Chemical pest control techniques are widely used in agriculture, public health, and residential settings to control pests, and prevent damage to crops and property.

There are several types of chemical pest control techniques, including:

- Insecticides: Insecticides are chemicals used to kill or control insects. They work by interfering with the insect's nervous system or other physiological processes. Examples of insecticides include pyrethroids, organophosphates, and carbamates.

- Rodenticides: Rodenticides are chemicals used to control rodents such as rats and mice. They work by interfering with the rodent's blood clotting system, leading to death from internal bleeding. Examples of rodenticides include anticoagulants and acute toxicants.

- Fumigants: Fumigants are chemicals that are used to control pests in enclosed spaces such as grain storage facilities, mills, and buildings. Fumigants are released as a gas or vapor and penetrate into the treated area, killing pests such as insects, rodents, and fungi. Examples of fumigants include phosphine, methyl bromide, and sulfuryl fluoride.

- Repellents: Repellents are chemicals used to repel or deter pests from specific areas. They work by interfering with the pest's sense of smell, taste, or touch. Examples of repellents include DEET, citronella, and camphor.

While chemical pest control techniques can effectively control pests, they can also negatively impact non-target organisms, such as beneficial insects and other wildlife. They can also contribute to environmental pollution and the development of pesticide resistance in pests. Therefore, it is important to use chemical pesticides judiciously and in accordance with established safety guidelines and regulations.

Biological Pest Control Techniques

Biological pest control techniques involve the use of natural enemies, such as predators, parasites, and pathogens, to control pests. These techniques aim to balance pests and their natural enemies in a given ecosystem, thus reducing or eliminating the need for chemical pesticides. Biological control techniques are widely used in agriculture, forestry, and urban pest management.

There are several types of biological pest control techniques, including:

- Predators: Predators are natural enemies that consume pests. For example, ladybugs and lacewings are predators that feed on aphids and other insect pests.

- Parasitoids: Parasitoids are insects that lay their eggs in or on the bodies of other insects. The developing parasitoid larvae feed on the host insect, eventually killing it. Examples of parasitoids include wasps that parasitize caterpillars and flies that parasitize aphids.

- Pathogens: Pathogens are microorganisms that cause disease in pests. For example, Bacillus thuringiensis (Bt) is a bacterium that produces a toxin that kills certain pests, such as caterpillars and mosquitoes.

- Genetic Control: Genetic control techniques involve the use of genetic engineering to modify pests or their natural enemies. For example, sterile insect technique involves the release of large numbers of sterile male insects, which mate with wild females, reducing the overall population.

Biological pest control techniques have several advantages over chemical pesticides, including lower environmental impact, reduced development of pesticide resistance, and increased sustainability.

However, they also have limitations, such as the difficulty of predicting and controlling natural enemy populations and the potential for unintended effects on non-target organisms. Therefore, using a combination of different pest control techniques, including biological control, to effectively manage pests while minimizing the impact on the environment and non-target organisms is important.

Physical Pest Control Techniques

Physical pest control techniques involve the use of mechanical or physical methods to control pests. These techniques aim to eliminate or prevent pest infestations through physical barriers, traps, and exclusion methods. Physical pest control techniques are widely used in residential, commercial, and industrial settings to control pests without the use of chemical pesticides.

There are several types of physical pest control techniques, including:

- Exclusion: Exclusion involves sealing or blocking entry points to prevent pests from entering buildings or other structures. This can be done by sealing gaps around doors, windows, and other openings, installing screens or mesh barriers, and repairing or replacing damaged building materials.

- Traps: Traps are devices that capture and kill pests. There are several types of traps, including glue, snap, and live traps. Traps can be used to control a variety of pests, including rodents, insects, and other small animals.

- Heat Treatment: Heat treatment involves using high temperatures to eliminate pests. This technique is particularly effective for bed bugs and other insects that are sensitive to heat. Heat treatment involves raising the temperature of a room or building to a level that is lethal to pests.

- Vacuuming: Vacuuming involves using a vacuum cleaner to remove pests and their eggs from carpets, furniture, and other surfaces. This technique is particularly effective for controlling pests such as fleas and bed bugs.

Integrated Pest Management

Integrated Pest Management (IPM) is a holistic approach to pest control that aims to manage pests through a combination of different techniques, including biological, chemical, and physical control methods. IPM is based on pest prevention, monitoring, and management principles and emphasizes using non-chemical control methods before resorting to chemical pesticides.

The key components of IPM include:

- Pest Identification and Monitoring: Accurately identifying the pest species and monitoring their populations to determine if and when control measures are needed.

- Prevention: Implementing measures to prevent pest infestations, such as sanitation, structural repairs, and cultural practices, to create an environment that is less conducive to pests.

- Cultural Control: Modifying cultural practices, such as crop rotation and pruning, to reduce pest populations and their impact on crops.

- Biological Control: Introducing natural enemies, such as predators, parasites, and pathogens, to control pest populations.

- Chemical Control: Using chemical pesticides as a last resort, and only when other methods have failed or are ineffective.

- Evaluation: Regularly evaluate the effectiveness of pest management strategies and make adjustments as needed.

IPM is widely used in agriculture, forestry, and urban pest management and is recognized as a sustainable and environmentally responsible approach to pest control. By integrating multiple control methods and minimizing the use of chemical pesticides, IPM can effectively manage pest populations while minimizing the impact on non-target organisms and the environment.

Comparative Analysis of Different Pest Control Manufacturing Techniques

Different pest control manufacturing techniques have their own unique advantages and limitations. Here is a comparative analysis of some of the most commonly used techniques:

Chemical Control

Chemical control techniques, such as synthetic pesticides, effectively eliminate pest populations. However, they have several drawbacks, including potential harm to non-target organisms, development of pesticide resistance, and potential negative impact on the environment.

Biological Control

Biological control techniques, such as natural enemies and pathogens, have a lower environmental impact and do not contribute to pesticide resistance. However, they are slower-acting and may not provide immediate control of pest populations.

Physical Control

Physical control techniques, such as traps and exclusion methods, effectively reduce pest populations without using chemicals. However, they may require ongoing maintenance and monitoring, and may have limited effectiveness against certain pests.

Integrated Pest Management

IPM combines multiple control methods to effectively manage pests while minimizing environmental and non-target organisms' impact. IPM emphasizes the use of non-chemical control methods and chemical pesticides as a last resort. However, IPM may require more resources and expertise to implement effectively.

Ultimately, the choice of pest control manufacturing technique will depend on factors such as the type of pest, the environment, the severity of the infestation, and the desired level of control. In many cases, a combination of different techniques may be necessary to effectively manage pests while minimizing the impact on the environment and non-target organisms.

Limitations of Different Pest Control Manufacturing Techniques

Each pest control manufacturing technique has its own set of limitations. Here are some of the limitations of commonly used pest control techniques:

Chemical Control

Chemical control, which involves the use of chemical pesticides to control pest populations, has several limitations. Here are some of the main limitations of chemical control as a pest control manufacturing technique:

- Non-Target Impacts: Chemical pesticides can harm non-target organisms, including beneficial insects, wildlife, and humans. This can disrupt ecosystems and have negative impacts on human health.

- Development of Resistance: Repeated use of chemical pesticides can lead to the development of pesticide resistance in pest populations, making the pesticides less effective over time.

- Environmental Pollution: Chemical pesticides can pollute soil, water, and air, causing harm to ecosystems and human health.

- Persistence: Some chemical pesticides can persist in the environment for long periods, potentially causing harm even after being applied.

- Cost: Chemical pesticides can be expensive, especially in large-scale agricultural operations. Additionally, the costs of dealing with the negative impacts of chemical pesticides, such as environmental cleanup and health care, can also be high.

- Regulatory Restrictions: The use of chemical pesticides is subject to regulatory restrictions and may require permits or specialized training. These restrictions can limit the availability of certain pesticides and increase the cost of chemical control.

Biological Control

Biological control, which involves the use of natural enemies or pathogens to control pest populations, has several limitations. Here are some of the main limitations of biological control as a pest control manufacturing technique:

- Slower Acting: Biological control methods can be slower acting than chemical control, as they often require time for natural enemies to establish or pathogens to spread.

- Target Specificity: Biological control methods are typically more targeted to specific pest species and may not be effective against all types of pests.

- Limited Availability: Some natural enemies or pathogens may not be available in certain regions or may be difficult to cultivate or transport.

- Environmental Factors: The effectiveness of biological control methods can be influenced by environmental factors such as temperature and humidity.

Physical Control

Physical control is a method of pest control that involves the use of physical barriers, traps, or other devices to prevent pests from entering or causing damage to a particular area. While this method can be effective in certain situations, it also has several limitations that may make it less effective in others. Here are some of the limitations of physical control as a pest control manufacturing technique:

- Limited effectiveness: Physical control methods are often only effective against certain types of pests and may not be able to eliminate an entire pest population. For example, while a barrier may prevent some pests from entering a particular area, it may not be effective against pests that can fly or burrow.

- Labor-intensive: Physical control methods can be labor-intensive and require regular monitoring and maintenance to be effective. For example, traps may need to be checked and cleaned regularly to prevent them from becoming ineffective.

- Costly: Physical control methods can also be costly, particularly if they require expensive materials or equipment. For example, installing a physical barrier around a large area can be prohibitively expensive.

- Environmental impact: Some physical control methods, such as the use of pesticides, can have negative environmental impacts. For example, pesticides may harm non-target species or contaminate soil and water.

- Safety concerns: Some physical control methods can also pose safety risks to humans or pets. For example, traps may accidentally injure or kill non-target species or pets.

Integrated Pest Management

Integrated Pest Management (IPM) is a holistic approach to pest control that combines a variety of pest management techniques to minimize the use of pesticides and maximize the effectiveness of pest control measures. While IPM can be an effective method of pest control, it also has several limitations that may make it less effective in certain situations. Here are some of the limitations of IPM as a pest control manufacturing technique:

- Time-consuming: IPM requires ongoing monitoring and assessment of pest populations, as well as the implementation of various pest management techniques. This can be time-consuming and require significant resources.

- Complex: IPM can be complex, requiring a deep understanding of pest biology and behavior and a wide range of pest management techniques. This can make it difficult to implement for some organizations or individuals.

- Costly: Implementing an IPM program can be costly, particularly if it requires extensive training or the use of specialized equipment. Additionally, the ongoing monitoring and assessment required by IPM can add to the program's overall cost.

- Lack of standardized protocols: IPM programs can vary widely in their approach, and there is no standardized protocol for implementing IPM. This can make it difficult to compare different IPM programs' effectiveness or establish best practices.

- Limited effectiveness against some pests: While IPM can be effective against many types of pests, there are some pests for which it may not be effective. For example, certain invasive species may be difficult to control using IPM techniques.

Cultural Control

Cultural control is a method of pest control that involves manipulating the environment or cultural practices to reduce pest populations or damage. While cultural control can be an effective method of pest management in some situations, it also has several limitations that may make it less effective in others. Here are some of the limitations of cultural control as a pest control manufacturing technique:

- Limited effectiveness: Cultural control may be ineffective against some pest species or in certain environmental conditions. For example, certain pests may be able to adapt to cultural control methods over time, rendering them less effective.

- Long-term approach: Cultural control is often a long-term approach to pest management, requiring changes to cultural practices or the environment that may take time to implement and see results. This may not be suitable for situations where quick action is necessary to prevent damage or control pest populations.

- High labor requirements: Cultural control methods can be labor-intensive, requiring significant effort to implement and maintain. For example, cultural practices such as crop rotation or sanitation practices may require additional time and effort from farmers or other individuals.

- Limited scope: Cultural control methods may only be effective in certain situations or against certain pests. For example, cultural practices that are effective against insect pests may not be effective against rodents or other types of pests.

- Dependence on cultural practices: Cultural control methods may depend on specific cultural practices or environmental conditions, which may not be suitable or feasible for all situations. For example, certain crops may not be able to be rotated due to climate or soil conditions.

ERP and MRP Systems for Pest Control Manufacturing

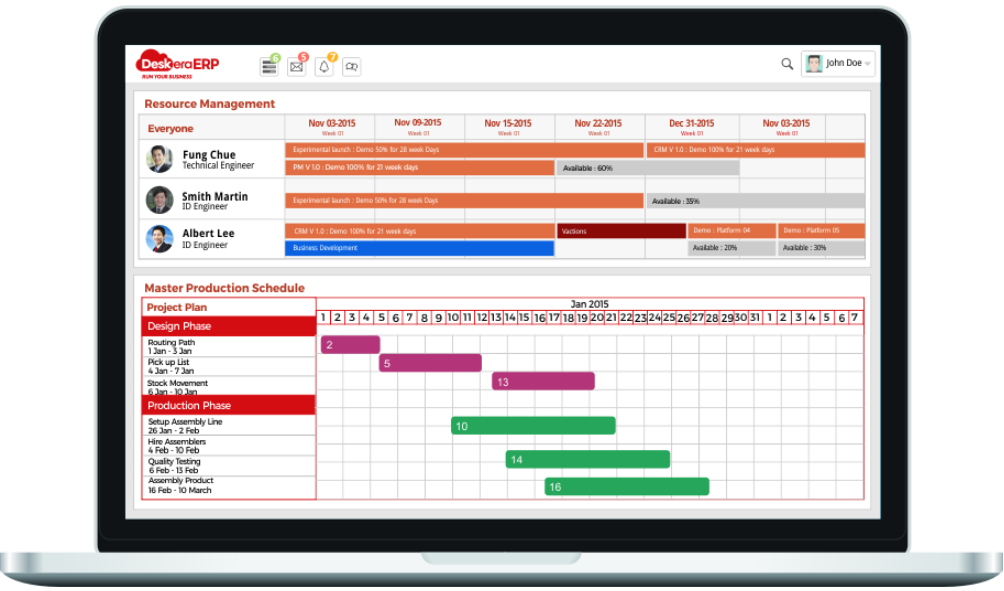

ERP (Enterprise Resource Planning) and MRP (Materials Requirement Planning) systems are commonly used in manufacturing industries to manage production processes, inventory, and supply chain operations. These systems can also be useful in pest control manufacturing to improve efficiency, reduce costs, and enhance overall operations.

ERP systems can provide a centralized platform for managing various aspects of pest control manufacturing, such as scheduling, inventory management, and customer orders. This can help to streamline processes and reduce manual labor, improving overall efficiency and productivity. For example, an ERP system could be used to manage the scheduling and routing of pest control technicians, track inventory levels of pesticides and equipment, and automate invoicing and billing processes.

MRP systems are designed to help manufacturers plan and manage their inventory levels based on forecasted demand and production schedules. In pest control manufacturing, an MRP system could be used to ensure that adequate supplies of pesticides and equipment are available when needed. This can help to prevent stockouts and reduce the risk of delays or disruptions in pest control operations.

By integrating ERP and MRP systems, pest control manufacturers can gain greater visibility and control over their operations, improve inventory management and production planning accuracy, reduce costs, and enhance customer service. These systems can also provide valuable data and insights to help companies make better decisions and continuously improve their operations.

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- There are different types of pest control manufacturing techniques, including physical control, chemical control, biological control, cultural control, and integrated pest management.

- Physical control methods can be effective but have limitations, such as being labor-intensive and requiring frequent maintenance.

- Chemical control methods can be effective but may have negative environmental impacts and can lead to pesticide resistance.

- Biological control methods can be environmentally friendly but may not be effective against all pest species.

- Cultural control methods can be a long-term approach to pest management but may require significant effort and may only be effective in certain situations.

- Integrated pest management combines various pest management techniques to minimize the use of pesticides and maximize effectiveness, but it can be complex and time-consuming to implement.

- It is important to carefully evaluate the effectiveness and limitations of each pest control manufacturing technique when developing a pest management strategy.

- Using a combination of different techniques may be the most effective approach to pest control, depending on the specific situation and pest species.

Related Articles