What if your warehouse team could start picking items before the order is even placed? Sounds futuristic? With predictive picking, it’s not only possible—it’s becoming essential. In a world where speed, accuracy, and efficiency define customer satisfaction, predictive picking is transforming how warehouses operate by using data to stay one step ahead.

Predictive picking leverages data analytics, machine learning, and intelligent algorithms to forecast which products are likely to be ordered next. Instead of waiting for an order to arrive, warehouse staff can pre-pick frequently ordered or trending items based on historical data and real-time demand patterns. This proactive approach helps reduce picking time, optimize labor, and significantly accelerate order fulfillment.

As supply chains grow more complex and customer expectations skyrocket, businesses can’t afford to rely solely on traditional picking methods. Predictive picking helps bridge the gap by turning reactive operations into strategic, data-driven workflows. It’s particularly powerful for eCommerce, retail, and high-volume warehouses that need to manage hundreds—or even thousands—of SKUs with precision and speed.

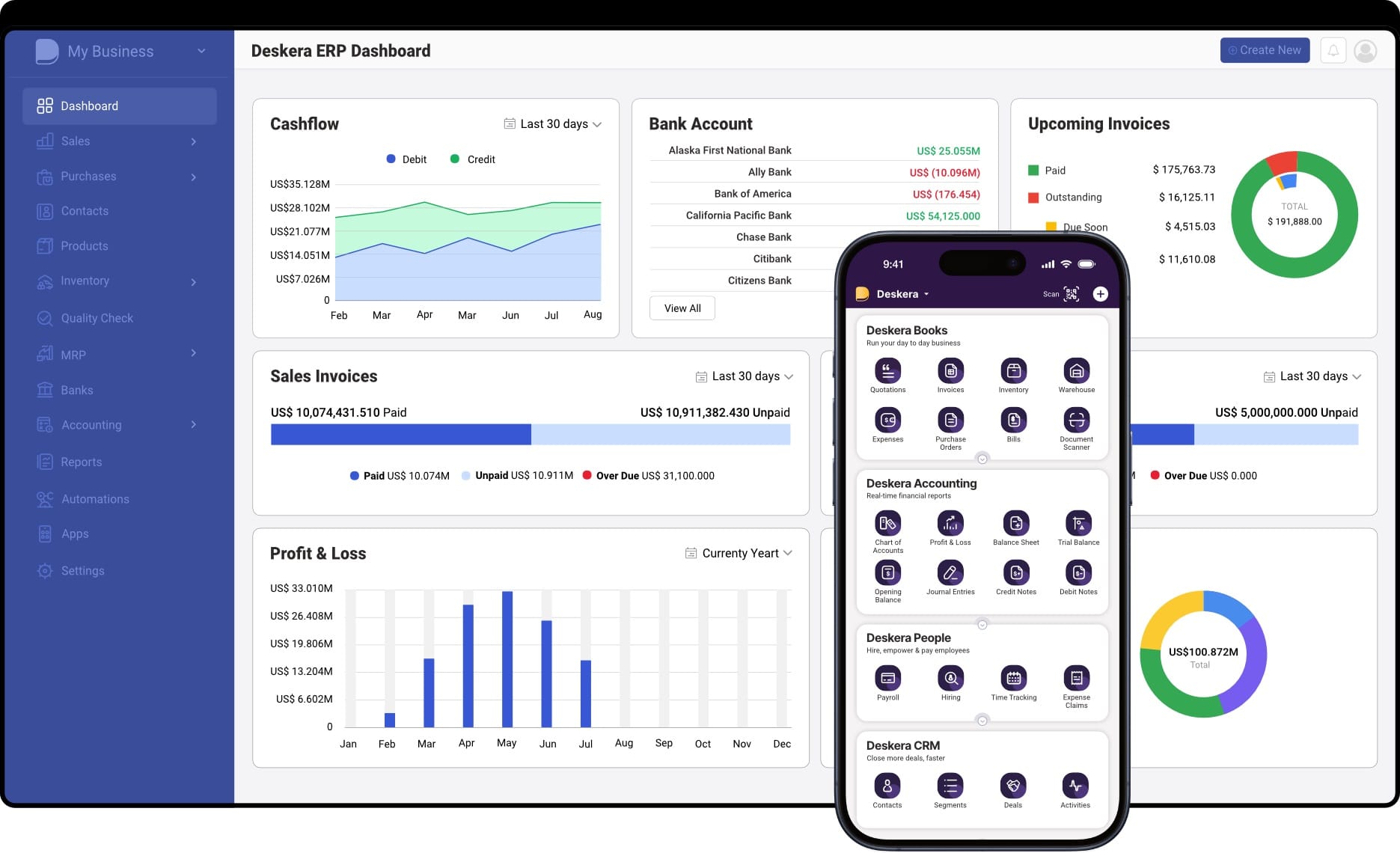

To make the most of predictive picking, you need the right digital infrastructure. Deskera ERP is a cloud-based solution designed to streamline warehouse operations, offering built-in MRP, advanced inventory tracking, and real-time analytics. With features like AI-powered forecasting, mobile accessibility, and smart reporting, Deskera helps businesses adopt predictive strategies while keeping operations agile and data-driven.

What Is Predictive Picking?

Predictive picking is an advanced warehouse management strategy that uses artificial intelligence (AI) and data analytics to forecast future customer orders. By analyzing historical sales data, seasonal trends, and even unstructured information like current product popularity or weather patterns, predictive picking anticipates which items are likely to be ordered next. This enables warehouse staff to pre-pick or position high-demand items closer to packing stations—drastically improving speed and efficiency.

Unlike traditional picking methods, which rely on static processes or manual estimations, predictive picking dynamically adjusts to changing demand patterns. AI algorithms not only suggest what to pick in advance but also help determine the most efficient sequence to pick and pack products already in inventory. For example, during a predicted heatwave, a warehouse might proactively prioritize and reposition fans and cooling appliances for faster delivery.

Predictive picking reduces the risk of stockouts and overstocking, optimizes fulfillment, and minimizes costly picking errors. It also supports smarter inventory placement, such as relocating fast-moving products to shelves closest to dispatch areas. Combined with technologies like RFID scanners and real-time inventory updates, it allows warehouses to function with precision and speed.

Ultimately, predictive picking is part of a broader shift toward data-driven decision-making in supply chain operations. When paired with tools like robotics, route optimization, and smart scheduling, it becomes a powerful lever for operational excellence—helping businesses lower costs, increase accuracy, and deliver better customer experiences.

How Predictive Picking Works

Predictive picking operates at the intersection of data science, machine learning, and warehouse operations. At its core, it uses historical data and AI-powered forecasting to anticipate which products are likely to be ordered next—and prepares warehouse processes accordingly.

The process begins with data collection. This includes structured data like order history, SKU movement rates, seasonal sales trends, and inventory turnover, as well as unstructured data such as social media trends, weather forecasts, and product popularity spikes. AI algorithms analyze this data to generate demand predictions at SKU-level granularity.

Once predictions are made, the warehouse management system (WMS) or ERP software (like Deskera ERP) uses those insights to automate operational decisions. These may include:

- Reorganizing product placement — moving predicted high-demand items closer to picking and packing zones.

- Triggering early picking and packing — for frequently ordered items, so fulfillment can begin even before the order arrives.

- Optimizing picking routes — so that workers follow the most efficient sequence through the warehouse, saving time and reducing fatigue.

In real-time, technologies like RFID scanners, barcode systems, and IoT devices work alongside predictive models to ensure inventory data is updated as items are picked. This closes the loop between forecasting and execution, minimizing errors and enabling quick decision-making on the floor.

For example, if predictive models forecast a surge in sunscreen sales ahead of a sunny weekend, the system may prompt staff to relocate sunscreen near dispatch zones and pre-pack common bundle orders. By doing so, the warehouse reduces response time, prevents delays, and ensures better product availability during peak demand.

Ultimately, predictive picking turns warehousing from a reactive to a proactive operation—cutting down manual guesswork, increasing throughput, and setting the stage for smarter, faster logistics.

Predictive Picking vs. Traditional Picking

Traditional warehouse picking has long been a reactive process—items are picked only after an order is placed, with workers following predefined pick paths or manually interpreting order sheets. While this method works, it often leads to slower fulfillment, higher error rates, and inefficient use of labor and inventory.

In contrast, predictive picking shifts the paradigm by using AI and data analytics to anticipate demand. It enables proactive picking, optimized stock placement, and data-driven decision-making that reduces bottlenecks and enhances warehouse agility.

Here’s a quick comparison to highlight the key differences:

Predictive picking doesn’t just improve warehouse speed—it transforms how the entire operation functions. By implementing systems like Deskera ERP, businesses can easily integrate predictive picking with intelligent inventory control, real-time dashboards, and mobile capabilities for smarter warehouse performance.

Benefits of Predictive Picking

Adopting predictive picking in your warehouse isn’t just about staying ahead of the curve—it’s about transforming your entire fulfillment process.

Here are some of the most impactful benefits:

1. Faster Order Fulfillment

By predicting which items are likely to be ordered next, warehouses can start picking and packing in advance. This proactive approach significantly reduces turnaround time, allowing for quicker shipping and delivery—especially critical in today’s on-demand economy.

2. Improved Picking Accuracy

Predictive systems rely on historical data and real-time insights, which help reduce human errors associated with manual decision-making. When high-demand items are pre-positioned and picked in the most efficient sequence, the chances of picking the wrong item drop dramatically.

3. Optimized Labor Efficiency

Predictive picking minimizes unnecessary walking and backtracking in the warehouse by optimizing pick routes and pre-planning tasks. This leads to better use of labor resources, reducing fatigue, increasing productivity, and helping teams handle more orders with the same workforce.

4. Reduced Stockouts and Overstocking

AI-driven forecasts allow warehouse managers to keep the right amount of inventory on hand. This reduces the likelihood of stockouts—where high-demand products run out—and also prevents overstocking, which ties up capital and storage space.

5. Lower Operational Costs

By streamlining picking workflows, improving accuracy, and optimizing inventory levels, predictive picking helps cut down costs related to excess labor, returns, and inefficient storage. Over time, these savings can significantly boost profit margins.

6. Enhanced Customer Satisfaction

Faster shipping, accurate orders, and consistent product availability lead to a better customer experience. Satisfied customers are more likely to return, leave positive reviews, and recommend your business—fueling long-term growth.

7. Smarter Inventory Placement

With predictive insights, high-velocity SKUs can be automatically moved closer to packing stations or robotic pickers. This strategic placement further boosts efficiency and reduces wear and tear on equipment and personnel.

By integrating predictive picking into a modern ERP system like Deskera ERP, businesses can easily automate these advantages. Deskera’s intelligent forecasting tools, real-time inventory tracking, and mobile accessibility make it easier to adopt predictive strategies and maximize ROI across warehouse operations.

Key Technologies That Enable Predictive Picking

Predictive picking is powered by a combination of cutting-edge technologies that work together to transform raw data into actionable warehouse strategies. Below are the core technologies that make predictive picking possible—and powerful.

1. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are at the heart of predictive picking. These technologies analyze vast datasets—such as order history, buying trends, seasonal demand, and even social media activity—to forecast which products are likely to be ordered next. Over time, these systems continuously learn and improve accuracy, making predictions smarter and more aligned with real-world behavior.

2. Warehouse Management Systems (WMS) and ERP Platforms

Modern WMS and ERP systems like Deskera ERP serve as the control center for predictive picking. These platforms integrate inventory, sales, procurement, and operations data in real time. Deskera, in particular, provides intelligent forecasting, real-time inventory tracking, and mobile dashboards—enabling warehouse teams to make data-driven decisions and automate key processes efficiently.

3. Internet of Things (IoT) Devices

IoT devices—such as smart sensors, RFID tags, and connected scales—provide real-time visibility into stock levels, item movement, and equipment performance. These devices feed crucial data into predictive models, ensuring up-to-date insights that drive better planning and picking strategies.

4. Big Data Analytics

Big data platforms handle the volume, variety, and velocity of data coming from multiple sources—CRM systems, eCommerce platforms, supply chain partners, and more. These analytics tools uncover hidden patterns, allowing predictive systems to identify emerging demand shifts or supply risks quickly and accurately.

5. Mobile and Wearable Technology

Mobile picking devices, voice-picking headsets, and wearable scanners enable real-time communication between predictive systems and warehouse workers. These tools guide employees along optimized pick paths, provide instant updates, and help maintain accurate inventory records.

6. Robotic Process Automation (RPA) and Robotics

In high-volume warehouses, predictive insights are often paired with robotic pickers or automated guided vehicles (AGVs). These machines can respond instantly to forecasted demand, picking and moving products with speed and precision—further amplifying the benefits of predictive picking.

Together, these technologies enable warehouses to transition from static, manual operations to intelligent, data-driven fulfillment centers. When powered by a robust system like Deskera ERP, businesses can seamlessly adopt these innovations and stay competitive in the fast-paced world of modern logistics.

Challenges in Implementing Predictive Picking

While predictive picking offers clear operational advantages, implementing it successfully requires overcoming several practical and technical challenges. Businesses must be prepared to address these obstacles to unlock its full potential.

1. Data Quality and Availability

Predictive models rely heavily on clean, structured, and historical data. Many warehouses, especially those transitioning from manual systems, struggle with fragmented or inaccurate records. Without consistent data on inventory, sales trends, and order patterns, AI algorithms can’t generate reliable forecasts.

2. Integration with Legacy Systems

Many warehouses still operate with outdated WMS or disconnected software systems. Integrating predictive picking technology with existing platforms can be difficult and costly. That’s why modern, cloud-based ERP solutions like Deskera ERP—which are designed for seamless integration—are often critical to success.

3. Change Management and Workforce Training

Shifting from traditional to predictive methods often faces internal resistance. Workers and supervisors accustomed to manual processes may be hesitant to trust algorithm-driven decisions. Organizations must invest in training, user-friendly tools, and clear communication to ensure smooth adoption across teams.

4. High Initial Investment

Implementing AI, IoT, and automation technologies often requires upfront investment in software, hardware, and infrastructure upgrades. For small to mid-sized businesses, this can be a barrier. However, the long-term gains in efficiency and cost savings typically outweigh these initial costs.

5. Real-Time Data Synchronization

Predictive picking requires continuous, real-time updates across systems. If inventory movements aren’t instantly reflected in the central database, it can lead to inaccurate forecasts and picking errors. This necessitates robust connectivity between devices, cloud platforms, and the ERP system.

6. Security and Privacy Concerns

As warehouses collect and store more data from IoT devices and cloud platforms, cybersecurity becomes a critical concern. Businesses must ensure their predictive systems are compliant with data protection regulations and protected against breaches.

Despite these challenges, businesses that plan thoughtfully and use the right tools—like Deskera ERP’s integrated inventory, purchasing, and fulfillment modules—can implement predictive picking with confidence. A phased rollout, starting with high-volume SKUs or pilot zones, often helps mitigate risks and demonstrate ROI early in the process.

How to Get Started with Predictive Picking: A Step-by-Step Implementation Guide

Successfully adopting predictive picking requires a clear roadmap. From assessing your current systems to rolling out AI-powered processes, here are the essential steps to ensure a smooth and effective implementation.

1. Audit Your Current Warehouse Operations

Start by analyzing your existing warehouse processes, from order intake to picking and shipping. Identify inefficiencies, pain points, and gaps in data collection. Understanding your current state will help you set realistic goals for predictive picking and determine what changes are necessary.

2. Centralize and Clean Your Data

Predictive picking thrives on clean, centralized data. Consolidate order history, inventory movement, customer behavior, and supplier lead times into a unified system. Address data silos and inaccuracies, ensuring that the foundation for forecasting is solid and reliable.

3. Choose the Right Technology Platform

Select an ERP or WMS solution that supports AI-driven forecasting and predictive analytics. A modern, cloud-based system like Deskera ERP offers intelligent inventory planning, real-time updates, and mobile accessibility—making it easier to implement predictive picking without the need for heavy customization.

4. Start with a Pilot Program

Implement predictive picking in a small, controlled environment—such as a specific warehouse zone or with high-turnover SKUs. Monitor the outcomes, track KPIs like picking accuracy and fulfillment speed, and gather employee feedback. Use this pilot to refine your process before scaling.

5. Train Your Team

Equip your warehouse staff with training on new tools, devices, and workflows. Help them understand how predictive insights will improve their efficiency and reduce repetitive work. Choose intuitive systems to minimize the learning curve and encourage adoption.

6. Integrate IoT and Automation (Optional)

To maximize results, consider integrating IoT devices like RFID scanners or smart shelves for real-time inventory visibility. For high-volume operations, robotic pickers or conveyor systems can further boost speed and accuracy.

7. Monitor, Adjust, and Scale

Once predictive picking is live, continuously monitor performance metrics such as order fulfillment time, error rates, and inventory turnover. Use these insights to fine-tune algorithms and make process improvements. When confident, scale the system across multiple products, zones, or warehouses.

By following these steps and leveraging a unified platform like Deskera ERP, businesses can ease into predictive picking without disruption—unlocking faster, smarter, and more cost-effective warehouse operations.

Best Practices for Predictive Picking Success

Implementing predictive picking is not just about adopting new tools—it’s about building a strategy that sustains long-term efficiency and accuracy.

Here are some best practices to ensure your predictive picking system delivers consistent results:

1. Maintain High-Quality, Real-Time Data

Accurate predictions depend on reliable data. Regularly audit your data sources, clean outdated entries, and ensure all inventory movements and order details are updated in real time. Integrating RFID, barcode scanners, and IoT devices can help automate this process and reduce manual errors.

2. Prioritize Integration and Compatibility

Your predictive picking system should integrate seamlessly with your ERP, WMS, eCommerce platforms, and supply chain partners. A cloud-based, modular platform like Deskera ERP simplifies this process, allowing all departments to access a single source of truth for smarter decision-making.

3. Focus on High-Impact SKUs First

Not all products require predictive picking from day one. Begin with fast-moving or high-margin SKUs where speed and accuracy make the biggest difference. Once optimized, expand predictive methods to the rest of your inventory gradually.

4. Use AI to Optimize Storage Layouts

Predictive picking works best when paired with dynamic warehouse zoning. Use demand forecasts to reposition top-selling items closer to packing stations and high-traffic areas. This reduces travel time, improves pick rates, and boosts overall productivity.

5. Continuously Monitor and Improve

Predictive models evolve—and so should your approach. Regularly review system performance through key metrics such as order accuracy, picking time, fulfillment rate, and stockout frequency. Use these insights to retrain AI models and adjust workflows where necessary.

6. Encourage Cross-Department Collaboration

Successful predictive picking requires alignment between operations, IT, procurement, and sales. Establish clear communication channels to ensure that demand trends, inventory forecasts, and system updates are shared across teams for maximum efficiency.

7. Stay Agile and Scalable

Predictive picking should grow with your business. Choose flexible systems that can scale across multiple warehouses, support increasing product lines, and adapt to market shifts. Deskera ERP, for example, offers scalable modules and mobile access, making it ideal for evolving warehouse operations.

By following these best practices, companies can avoid common pitfalls and fully realize the value of predictive picking—enhancing speed, reducing costs, and delighting customers with accurate and timely deliveries.

How Deskera ERP Empowers Predictive Picking and Smarter Warehousing

To truly unlock the benefits of predictive picking, businesses need a system that not only supports automation and real-time data but also provides intelligent forecasting and seamless integration.

Deskera ERP is designed to do exactly that—helping modern warehouses operate with precision, speed, and reduced manual effort.

Here’s how Deskera ERP supports predictive picking success:

- Real-time inventory visibility: Track stock levels, movements, and order updates instantly with mobile barcode and RFID scanning, reducing errors and delays.

- AI-powered demand forecasting: Leverage Deskera’s analytics and built-in AI assistant, David, to anticipate demand trends and optimize picking sequences.

- Automated workflows: Streamline repetitive tasks like order creation, stock transfers, and restocking to free up time and reduce dependency on manual processes.

- Smarter storage decisions: Use demand insights to dynamically rearrange your warehouse layout, ensuring high-demand items are always within easy reach.

- Integrated operations: Connect your sales, procurement, and fulfillment processes in one centralized system—minimizing silos and boosting coordination.

- Scalable and mobile-friendly platform: Grow with ease using Deskera’s cloud-based infrastructure, complete with mobile access for on-the-go warehouse management.

By integrating Deskera ERP into your warehouse operations, you can turn predictive picking from a future concept into an everyday advantage—enhancing fulfillment efficiency while cutting costs and complexity.

Key Takeaways

- Predictive picking leverages AI and historical data to anticipate customer orders, helping warehouses optimize picking routes, reduce errors, and improve fulfillment speed.

- It’s a data-driven strategy that uses demand forecasting, real-time inventory insights, and external factors (like seasonality or trends) to determine which items to pick and when.

- The process involves analyzing past order patterns, integrating data from multiple systems, and using AI to guide warehouse staff or automation tools on optimal picking decisions.

- Key advantages include reduced stockouts and overstocking, faster order fulfillment, lower operational costs, improved accuracy, and better customer satisfaction.

- Unlike traditional methods that rely on static lists or manual planning, predictive picking uses real-time data and AI to dynamically adjust priorities and optimize efficiency.

- Getting started requires auditing existing systems, cleaning and centralizing data, selecting the right ERP/WMS platform, running a pilot, training staff, and scaling gradually.

- Maintaining clean data, starting with high-impact SKUs, aligning cross-functional teams, and continuously monitoring performance are essential for sustainable results.

- Deskera ERP empowers predictive picking with real-time inventory tracking, intelligent demand forecasting, mobile tools, and seamless integration across your operations.

Related Articles