Plastic has become an integral part of our daily lives, from the packaging of products we consume to the materials used in construction, automobiles, and electronics. The global plastic manufacturing industry has witnessed a significant growth in recent years, driven by factors such as the increasing demand for plastic products, technological advancements in plastic manufacturing, and the adoption of sustainable practices.

However, the industry also faces challenges such as environmental concerns related to plastic waste, regulations on plastic usage, and fluctuations in raw material prices. To navigate these challenges and tap into the opportunities presented by the industry, businesses need to keep a pulse on the latest trends and forecasts.

In this article, we will dive into the analysis, trends, and forecasts of the plastic manufacturing industry. We will explore key drivers and challenges impacting the industry, as well as emerging trends such as the adoption of bioplastics and the rise of circular economy models. We will also provide insights into the future of the industry and what businesses can do to stay ahead of the curve.

- Overview of the Plastic Manufacturing Industry

- Industry Analysis

- Market Size and Growth Rate of the Plastic Manufacturing Industry

- Key Players and Market Share

- Emerging Trends and Opportunities

- Challenges and Threats Facing the Industry

- Emerging Manufacturing Technologies

- Emerging Trends in Sustainable Manufacturing and Circular Economy Models

- Market Segmentation

- Future Outlook and Forecasts

- COVID-19 Effect on Plastic Manufacturing

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Overview of the Plastic Manufacturing Industry

The plastic manufacturing industry is a global industry that produces various types of plastics used in a wide range of applications, from packaging and consumer goods to construction and automotive industries. The industry includes a diverse range of companies, from large multinational corporations to small and medium-sized enterprises.

The industry has witnessed significant growth over the past few decades, driven by increasing demand for plastic products, advancements in technology, and low production costs. However, the industry also faces several challenges, including concerns over plastic waste and its impact on the environment, fluctuating raw material prices, and government regulations.

The Asia-Pacific region dominates the global plastic manufacturing market, with China being the largest producer of plastics. The packaging segment is the largest application area for plastics, accounting for more than 40% of the market share, followed by the automotive and construction industries.

To address environmental concerns related to plastic waste, the industry is exploring sustainable practices such as recycling, the use of bioplastics made from renewable resources, and the adoption of circular economy models. Digitalization and Industry 4.0 technologies are also expected to play a significant role in improving efficiency and reducing costs in the industry.

Overall, the plastic manufacturing industry is expected to continue growing, driven by increasing demand from emerging economies and the adoption of sustainable practices. Companies in the industry must stay up-to-date with the latest trends and regulations and adopt sustainable practices to succeed in the long term.

Importance of the Industry to the Global Economy

The plastic manufacturing industry is an essential component of the global economy, with a significant impact on various sectors such as packaging, construction, automotive, healthcare, and electronics, among others. The industry provides various products and services that are integral to modern society, including packaging materials, plastic parts, and components for a range of consumer and industrial goods.

According to industry reports, the global plastic manufacturing industry was valued at over $400 billion in 2020 and is expected to grow at a steady rate in the coming years. The industry employs millions of people worldwide, from manufacturing and production to research and development.

The industry's importance is further underscored by its role in enabling innovation and technological advancements in various sectors. For instance, plastic materials are widely used in healthcare to manufacture medical devices, implants, and drug delivery systems, among other applications. In the automotive industry, plastics are used to improve fuel efficiency, reduce vehicle weight, and enhance safety features.

Moreover, the industry's growth and success have a ripple effect on the global economy, creating new markets and business opportunities for companies involved in the supply chain. For instance, the production of raw materials, equipment, and machinery used in plastic manufacturing provides employment and economic benefits to many countries.

However, the industry also faces challenges, including concerns over plastic waste and its impact on the environment, and the need to adopt more sustainable practices. The industry must embrace sustainable manufacturing practices and develop new materials that reduce dependence on fossil fuels and minimize environmental impact.

Overall, the plastic manufacturing industry plays a critical role in the global economy, providing essential products and services, driving innovation, and creating jobs and business opportunities. The industry must continue to evolve and adopt sustainable practices to ensure long-term success and reduce its environmental impact.

Industry Analysis

The plastic manufacturing industry is a complex and dynamic industry that produces a wide range of plastic products for various applications. An in-depth analysis of the industry can provide insights into its current state, future prospects, challenges, and opportunities. Here is a detailed analysis of the plastic manufacturing industry:

Market Size and Growth

According to industry reports, the global plastic manufacturing market was valued at over $400 billion in 2020 and is expected to grow at a CAGR of 3.9% between 2021 and 2028. The growth is driven by increasing demand for plastic products, particularly in emerging economies, advancements in technology, and low production costs.

Application Areas

The packaging segment is the largest application area for plastics, accounting for over 40% of the market share. The automotive and construction industries are also significant consumers of plastic products, with a growing demand for lightweight and durable materials. Other application areas include healthcare, electronics, and consumer goods.

Geographical Analysis

The Asia-Pacific region dominates the global plastic manufacturing market, with China being the largest producer of plastics. The region's growth is attributed to favorable government policies, low labor costs, and a growing consumer market. Europe and North America are also significant players in the market, with a focus on sustainability and circular economy initiatives.

Market Size and Growth Rate of the Plastic Manufacturing Industry

The plastic manufacturing industry is a significant and growing sector of the global economy. According to market research reports, the global plastic manufacturing market was valued at over $400 billion in 2020 and is expected to grow at a CAGR of 3.9% between 2021 and 2028.

The growth of the plastic manufacturing industry can be attributed to several factors, including increasing demand for plastic products in various sectors such as packaging, automotive, construction, healthcare, and electronics. The growth of emerging economies and urbanization has also contributed to the expansion of the plastic manufacturing market.

Moreover, advancements in technology have led to the development of new and innovative products, materials, and processes, improving the efficiency and cost-effectiveness of plastic manufacturing. The adoption of digitalization and Industry 4.0 technologies has also enabled the industry to improve productivity, reduce waste, and enhance quality control.

The Asia-Pacific region dominates the global plastic manufacturing market, with China being the largest producer of plastics. The region's growth is attributed to favorable government policies, low labor costs, and a growing consumer market. Europe and North America are also significant players in the market, with a focus on sustainability and circular economy initiatives.

Thus, the plastic manufacturing industry is a vital component of the global economy, providing essential products and services and driving innovation. The industry's market size and growth rate are expected to continue to expand in the coming years, driven by increasing demand, technological advancements, and sustainability initiatives. However, the industry must also address environmental concerns related to plastic waste and adopt sustainable practices to ensure long-term success

Key Players and Market Share

The plastic manufacturing industry is highly competitive, with several key players dominating the global market. Here are some of the major players and their market shares in the plastic manufacturing sector:

- Dow Inc. - Dow is a leading producer of plastics, chemicals, and agricultural products, with a market share of around 6%. The company offers a wide range of plastic products, including polyethylene, polypropylene, and polystyrene.

- ExxonMobil Chemical - ExxonMobil is one of the largest integrated petrochemical companies in the world, with a market share of around 5%. The company produces a broad range of plastic products, including polyethylene, polypropylene, and specialty polymers.

- LyondellBasell Industries - LyondellBasell is a global producer of polyolefins, polypropylene compounds, and specialty chemicals, with a market share of around 4%. The company focuses on sustainability and circular economy initiatives, producing bio-based and recycled plastics.

- SABIC - SABIC is a leading producer of petrochemicals and plastics, with a market share of around 3%. The company offers a wide range of plastic products, including polyethylene, polypropylene, and engineering plastics.

- BASF SE - BASF is a global chemical company that produces a wide range of products, including plastics, with a market share of around 2%. The company offers various plastic products, including polyurethanes, engineering plastics, and bioplastics.

- Eastman Chemical Company: Eastman Chemical Company produces specialty plastics and other materials for various applications, including automotive, packaging, and medical.

- Arkema: Arkema is a global producer of specialty plastics and other chemicals, serving various industries, including automotive, construction, and electronics.

- Berry Global, Inc.: Berry Global produces plastic packaging solutions for various industries, including food and beverage, healthcare, and personal care.

- Sealed Air Corporation: Sealed Air produces innovative packaging solutions, including plastic materials, for various industries, including food and beverage, healthcare, and e-commerce.

- DuPont de Nemours, Inc.: DuPont is a leading producer of specialty plastics for various industries, including automotive, electronics, and medical.

Other significant players in the plastic manufacturing sector include Chevron Phillips Chemical, Braskem, Mitsubishi Chemical Holdings, Sumitomo Chemical, and Arkema.

In conclusion, the plastic manufacturing industry is dominated by several key players who are competing to gain a larger market share. These companies are investing in sustainability initiatives, technological advancements, and new product development to stay ahead of the competition.

However, smaller players and startups are also entering the market with innovative solutions and materials, increasing the competition and driving further growth and innovation in the industry.

Geographic Distribution of the Industry

The plastic manufacturing industry has a global presence, with manufacturing facilities located in various regions worldwide. However, the industry's geographic distribution is not evenly distributed and is heavily concentrated in certain regions.

As stated earlier in the post, the Asia-Pacific region has a larger share in the global plastic manufacturing market, accounting for over 45% of the global production capacity. China is the largest producer of plastics in the world, followed by other Asian countries such as India, Japan, South Korea, and Taiwan. The region's growth is attributed to favorable government policies, low labor costs, and a growing consumer market.

North America and Europe are also significant players in the plastic manufacturing industry. The United States is the second-largest producer of plastics globally, with a focus on the automotive and packaging sectors. Europe is known for its advanced technology and sustainability initiatives, with a growing demand for bioplastics and recycled plastics.

The Middle East and Africa (MEA) region is also emerging as a significant player in the plastic manufacturing industry, with countries such as Saudi Arabia, UAE, and Egypt investing heavily in petrochemical and plastics production.

Latin America is another region with significant potential for the plastic manufacturing industry, with Brazil being the largest producer of plastics in the region. The region's growth is attributed to increasing demand for plastic products in various sectors such as packaging, construction, and automotive.

Emerging Trends and Opportunities

The plastic manufacturing sector is continuously evolving, and several emerging trends and opportunities are shaping the industry's future. Here are some of the most significant trends and opportunities in the plastic manufacturing sector:

- Bioplastics - With the increasing focus on sustainability and reducing plastic waste, bioplastics are emerging as a significant trend in the plastic manufacturing sector. Bioplastics are made from renewable resources such as cornstarch, sugarcane, and other plant-based materials, making them a more environmentally friendly alternative to traditional plastics.

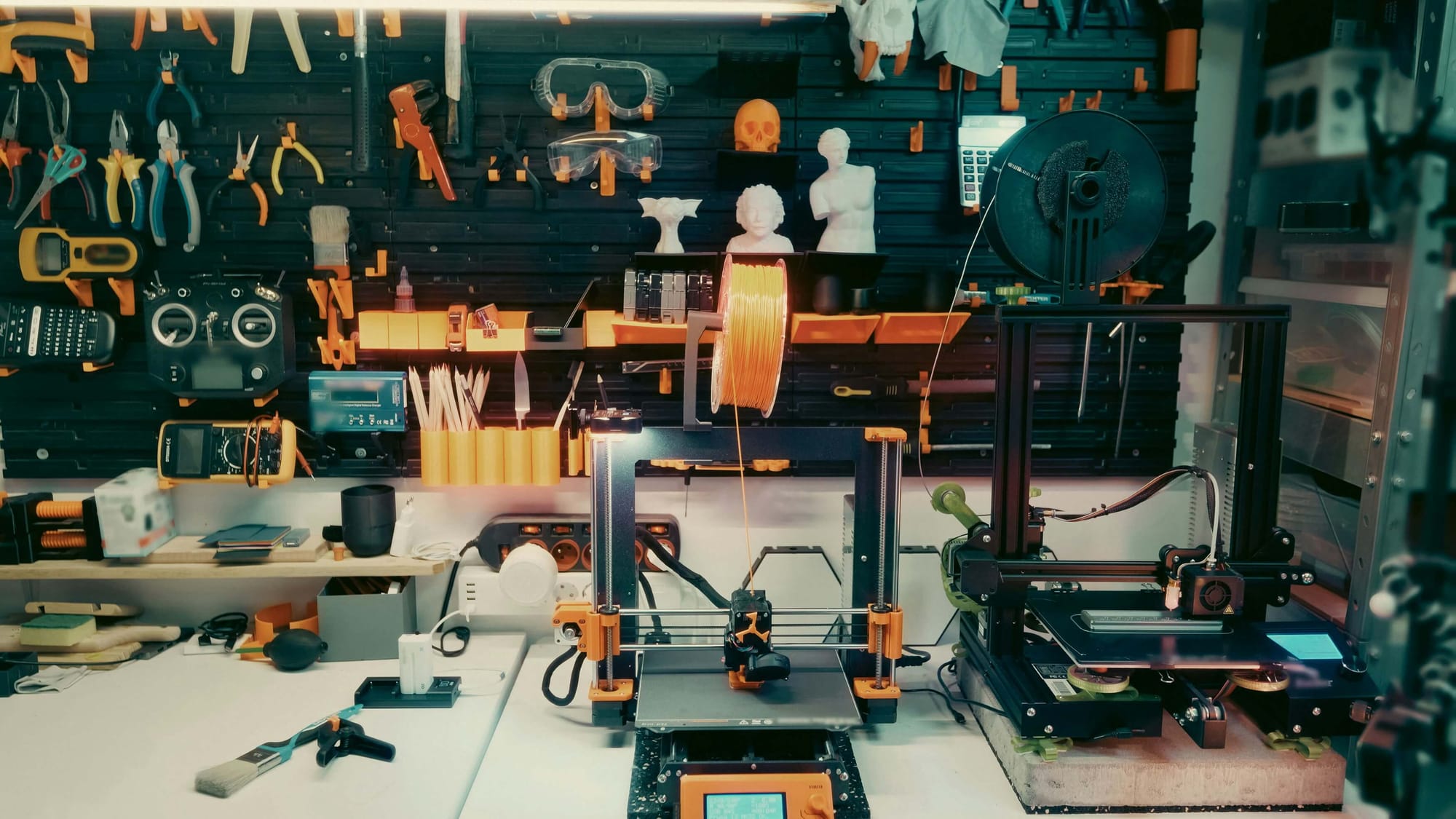

- 3D Printing - The use of 3D printing technology in plastic manufacturing is on the rise, allowing manufacturers to produce complex plastic parts with greater precision and customization. This technology is expected to revolutionize the manufacturing industry and create new opportunities for plastic manufacturers.

- Circular Economy - The circular economy is an emerging concept that aims to minimize waste and promote sustainability by reusing and recycling materials. Plastic manufacturers are increasingly adopting this concept, with many companies investing in recycling facilities and producing more sustainable plastic products.

- Smart Plastics - Smart plastics are materials that can change their physical properties based on external stimuli, such as temperature or light. These materials have various applications in industries such as automotive, packaging, and healthcare.

- Additive Manufacturing - Additive manufacturing is another emerging trend in the plastic manufacturing sector, allowing manufacturers to produce complex plastic parts with less waste and faster production times. This technology is expected to create new opportunities for plastic manufacturers in various industries.

The plastic manufacturing sector is continuously evolving, with several emerging trends and opportunities shaping its future. Bioplastics, 3D printing, circular economy, smart plastics, and additive manufacturing are some of the most significant trends and opportunities in the industry, creating new opportunities for growth and innovation.

Challenges and Threats Facing the Industry

The plastic manufacturing industry faces several challenges and threats, which could impact its growth and sustainability in the long run. Here are some of the significant challenges and threats facing the industry:

Environmental Concerns

One of the most significant challenges facing the plastic manufacturing industry is the growing concern over plastic waste and its impact on the environment. Governments and consumers are increasingly pushing for more sustainable practices and materials, which could lead to a decline in demand for traditional plastics.

Regulatory Pressure

Governments worldwide are implementing stricter regulations and policies aimed at reducing plastic waste, increasing recycling rates, and promoting sustainable materials. These regulations could increase the industry's compliance costs and impact profitability.

Volatility of Raw Material Prices

The plastic manufacturing industry is heavily dependent on the price and availability of raw materials such as crude oil and natural gas. Any fluctuations in these prices can impact the industry's profitability and sustainability.

Technological Disruptions

Emerging technologies such as bioplastics and 3D printing could disrupt the traditional plastic manufacturing industry and create new market players.

Competition from Other Materials

Plastics face stiff competition from other materials such as glass, aluminum, and paper, which offer more sustainable alternatives for packaging and other applications.

Geopolitical Risks

The plastic manufacturing industry's global nature exposes it to geopolitical risks such as trade tensions, political instability, and supply chain disruptions.

Plastic manufacturing industry faces several challenges and threats, ranging from environmental concerns to regulatory pressure and competition from other materials.

Companies in the industry must adapt to changing consumer preferences and emerging technologies to remain competitive and sustainable in the long run.

Manufacturing Processes and Technologies

The plastic manufacturing industry uses a variety of processes and technologies to produce plastic products, each with its own advantages and disadvantages. Here are some of the most common plastic manufacturing processes and technologies:

- Injection Molding - Injection molding is the most widely used plastic manufacturing process, where melted plastic is injected into a mold and allowed to cool and harden into the desired shape.

- Extrusion - Extrusion is a continuous process where plastic is forced through a die to create a long, uniform shape, such as a pipe or a tube.

- Blow Molding - Blow molding is a process where melted plastic is blown into a mold to create a hollow shape, such as a bottle or container.

- Thermoforming - Thermoforming is a process where plastic sheets are heated and formed into the desired shape using a mold.

- Rotational Molding - Rotational molding is a process where plastic powder is heated and rotated inside a mold to create a hollow shape, such as a container or a toy.

- Compression Molding - Compression molding is a process where plastic is placed in a mold and compressed to create the desired shape.

In addition to these processes, plastic manufacturing also involves various technologies, such as 3D printing, which allows manufacturers to produce complex plastic parts with greater precision and customization. Other emerging technologies include smart plastics, which can change their physical properties based on external stimuli, and bioplastics, which are made from renewable resources.

How do Manufacturing processes and technologies work together?

Manufacturing processes and technologies work together in the plastic manufacturing industry to produce high-quality plastic products efficiently and cost-effectively.

For example, a company may use injection molding to produce a large volume of identical plastic parts for a specific product. The injection molding process involves melting plastic pellets and injecting them into a mold to create the desired shape. The mold is then cooled and opened to release the finished part.

To optimize this process, the company may use advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to design and program the mold and machinery for the injection molding process. This allows for greater precision and accuracy in creating the mold and the finished product.

Furthermore, the company may also use automation technologies, such as robotics and sensors, to streamline the manufacturing process and reduce waste and errors. This can lead to increased efficiency and productivity, lower costs, and improved quality control.

Manufacturing processes and technologies work together in the plastic manufacturing industry to optimize production, improve quality control, and reduce costs. Companies must choose the right processes and technologies to suit their specific product needs and manufacturing capabilities to remain competitive and sustainable in the long run.

Emerging Manufacturing Technologies

New and advanced manufacturing technologies are being developed to enhance the efficiency, effectiveness, and sustainability of manufacturing processes. Two of the most prominent emerging manufacturing technologies are 3D printing and nanotechnology.

3D Printing:

- 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from digital designs. The process involves the layer-by-layer deposition of materials, such as plastics, metals, ceramics, and composites, to create complex shapes and structures. It enables the creation of intricate designs that would otherwise be difficult or impossible to produce using traditional manufacturing methods. 3D printing has numerous applications in industries such as aerospace, automotive, healthcare, and consumer goods.

Nanotechnology:

- Nanotechnology involves the engineering and manipulation of materials on a microscopic scale. It deals with materials that are measured in nanometers, which are one billionth of a meter. Nanotechnology has a wide range of applications in manufacturing, including the development of new materials, coatings, and sensors, as well as improvements to existing products. It has potential uses in fields such as electronics, energy, medicine, and environmental protection.

In summary, emerging manufacturing technologies such as 3D printing and nanotechnology are transforming the manufacturing industry, allowing for the creation of new products and materials that were previously impossible or too expensive to produce.

Impact of Technological Innovations on the Industry

Technological innovations have had a significant impact on various industries, transforming the way businesses operate and providing new opportunities for growth and development. Some of the impacts of technological innovations on industries include:

- Increased Efficiency: Technological innovations have improved the efficiency of operations, reducing the time and effort required to complete tasks. For example, automation and robotics have revolutionized manufacturing by streamlining production processes, reducing errors and improving quality control.

- Improved Communication: The development of communication technologies such as email, video conferencing, and instant messaging has made it easier for businesses to communicate and collaborate with customers, suppliers, and partners. This has increased efficiency and reduced the time and cost of communication.

- Increased Flexibility: Technological innovations have made it easier for businesses to adapt to changing market conditions and customer needs. Cloud computing and software-as-a-service (SaaS) have made it easier for businesses to scale up or down as needed and to access new markets and customers.

- Increased Innovation: Technological innovations have created new opportunities for businesses to develop and market new products and services. For example, advances in artificial intelligence and machine learning have led to the development of new applications in fields such as healthcare, finance, and transportation.

- Improved Customer Experience: Technological innovations have made it easier for businesses to understand and meet customer needs. Social media, customer relationship management (CRM) systems, and data analytics have provided businesses with insights into customer behavior and preferences, enabling them to improve the customer experience.

Sustainability and Environmental Impact

Sustainability and environmental impact are important considerations for businesses and industries. Sustainability refers to the ability to meet present needs without compromising the ability of future generations to meet their own needs. Environmental impact refers to the effect of a business or industry on the environment, including air, water, and land pollution, climate change, and biodiversity loss.

Here are some ways in which businesses and industries can address sustainability and environmental impact:

- Reduce Waste: Businesses can reduce waste by implementing recycling programs, using reusable materials, and reducing packaging waste.

- Use Renewable Energy: Using renewable energy such as solar, wind, or hydro power can reduce greenhouse gas emissions and help mitigate climate change.

- Adopt Sustainable Practices: Businesses can adopt sustainable practices such as sustainable sourcing, responsible water usage, and energy-efficient operations.

- Implement Environmental Management Systems (EMS): EMS is a structured approach to managing environmental impacts and reducing waste. It involves identifying environmental risks, setting goals and targets, and monitoring progress.

- Engage Stakeholders: Businesses can engage with stakeholders such as customers, suppliers, and employees to promote sustainability and environmental awareness.

- Pursue Sustainability Certifications: Sustainability certifications such as LEED, B Corp, and ISO 14001 can help businesses demonstrate their commitment to sustainability and environmental impact reduction.

Reducing waste, using renewable energy, adopting sustainable practices, implementing EMS, engaging stakeholders, and pursuing sustainability certifications are some of the ways in which businesses can promote sustainability and reduce their environmental impact.

Environmental Impact of Plastic Manufacturing and Disposal

Plastic manufacturing and disposal have significant environmental impacts. The production of plastic involves the extraction of oil and natural gas, which are non-renewable resources. The manufacturing process also generates greenhouse gas emissions, which contribute to climate change. Once produced, plastic has a long lifespan and is often disposed of improperly, causing further environmental damage.

Here are some of the environmental impacts of plastic manufacturing and disposal:

- Land Pollution: Plastic waste often ends up in landfills, where it takes hundreds of years to degrade. This waste can also litter streets, beaches, and waterways, causing harm to wildlife and ecosystems.

- Water Pollution: Plastic waste that enters waterways can cause harm to marine life. Plastic can entangle and suffocate animals, and marine organisms can mistake plastic for food, causing injury or death.

- Climate Change: Plastic manufacturing and disposal generate greenhouse gas emissions that contribute to climate change. Additionally, plastic waste in landfills can release methane, a potent greenhouse gas that contributes to global warming.

- Resource Depletion: The production of plastic involves the extraction of non-renewable resources such as oil and natural gas. These resources are finite and their depletion can have long-term consequences for the environment.

- Toxic Chemicals: Some plastics contain toxic chemicals such as bisphenol-A (BPA) and phthalates, which can leach into the environment and cause harm to wildlife and human health.

To mitigate these impacts, it is important to reduce plastic use, promote recycling and proper waste disposal, and transition to more sustainable materials.

Emerging Trends in Sustainable Manufacturing and Circular Economy Models

Sustainable manufacturing and circular economy models are becoming increasingly popular as businesses and industries seek to reduce their environmental impact and promote sustainability. Here are some emerging trends in sustainable manufacturing and circular economy models:

- Renewable Energy: Many businesses are transitioning to renewable energy sources such as solar, wind, and hydro power to reduce their greenhouse gas emissions and promote sustainability.

- Closed-Loop Supply Chains: Closed-loop supply chains involve recycling and reusing materials, reducing waste and promoting sustainability. Businesses are exploring ways to implement closed-loop supply chains, such as using recycled materials in their products or developing take-back programs for end-of-life products.

- Product Design for Sustainability: Businesses are designing products with sustainability in mind, such as using sustainable materials, reducing packaging waste, and designing products for disassembly and recycling.

- Digitalization: Digitalization can promote sustainability by reducing the need for physical products and enabling more efficient production and distribution. For example, digital platforms can enable remote work, reducing the need for travel and promoting sustainability.

- Circular Business Models: Circular business models involve designing products for longevity and reuse, rather than disposal. This can involve selling services rather than products, promoting product leasing and take-back programs, and developing closed-loop supply chains.

- Life Cycle Assessment: Life cycle assessment involves analyzing the environmental impact of a product throughout its entire life cycle, from production to disposal. This can help businesses identify areas for improvement and develop more sustainable products and processes.

By adopting these trends, businesses can promote sustainability and reduce their environmental impact.

Industry Initiatives and Government Regulations Aimed At Reducing Plastic Waste and Pollution

Over the years, plastic waste and pollution have become a global concern, and governments, industries, and organizations are taking initiatives to reduce plastic waste and pollution. Here are some industry initiatives and government regulations aimed at reducing plastic waste and pollution:

- Plastic bag bans: Governments in many countries, including Bangladesh, Rwanda, Kenya, and China, have banned the use of single-use plastic bags, encouraging the use of reusable bags instead.

- Extended Producer Responsibility (EPR): EPR programs hold producers responsible for the disposal of their products at the end of their useful life. This initiative aims to ensure that producers design products with sustainability in mind and bear the cost of managing the waste their products generate.

- Plastic packaging reduction: Several companies have pledged to reduce their plastic packaging use, including Coca-Cola, Nestle, and Unilever. They are also exploring alternative packaging options, such as biodegradable materials, to reduce their carbon footprint.

- Deposit return schemes: Many countries have introduced deposit return schemes, where consumers are charged a small fee when purchasing a plastic bottle, which is refunded when the bottle is returned for recycling. This initiative aims to incentivize consumers to recycle and reduce plastic waste.

- Plastic waste recycling: Recycling initiatives are aimed at reducing plastic waste by collecting and recycling plastic waste. Governments and organizations have set up programs to encourage recycling, such as providing recycling bins in public spaces, and establishing recycling centers to collect plastic waste.

- Bans on single-use plastics: Many countries, including Canada, the UK, and the European Union, have banned single-use plastic items such as straws, cutlery, and plates. This initiative aims to reduce plastic waste and pollution by encouraging the use of reusable alternatives.

- Microbead bans: Governments in many countries have banned the use of microbeads in personal care products, such as toothpaste and facial scrubs, which contribute to plastic pollution in oceans and waterways.

These initiatives and regulations aim to reduce plastic waste and pollution by promoting sustainable practices, encouraging recycling, and reducing the use of single-use plastic items.

Market Segmentation

Market segmentation is the process of dividing a large market into smaller, more manageable subgroups or segments based on various factors such as demographics, geographics, psychographics, and behavior.

In the plastic manufacturing industry, market segmentation is crucial to understand the needs, preferences, and behavior of different consumer groups and to develop products and marketing strategies that cater to their specific needs. Here are some common market segments in the plastic manufacturing industry:

- Consumer Goods: This segment includes plastic products that are used for household and personal purposes, such as plastic bottles, containers, toys, and packaging materials. The market can be further segmented based on age, income, and lifestyle.

- Industrial Packaging: This segment includes plastic products used for packaging industrial products, such as drums, pallets, and bulk containers. This segment can be further segmented based on the type of industry, product, and application.

- Building and Construction: This segment includes plastic products used in the construction industry, such as pipes, sheets, and insulation. The market can be segmented based on the type of building, construction materials, and application.

- Automotive: This segment includes plastic products used in the automotive industry, such as dashboards, bumpers, and trim. The market can be segmented based on the type of vehicle, usage, and application.

- Healthcare: This segment includes plastic products used in the healthcare industry, such as medical devices, packaging, and tubing. The market can be segmented based on the type of healthcare facility, patient group, and medical application.

- Agriculture: This segment includes plastic products used in agriculture, such as irrigation systems, mulch films, and greenhouse covers. The market can be segmented based on the type of crop, farming practices, and geography.

Market segmentation in the plastic manufacturing industry is crucial to understand the specific needs and preferences of different consumer groups, develop targeted marketing strategies, and design products that cater to their needs. By understanding market segmentation, plastic manufacturers can tailor their products and marketing efforts to specific segments, leading to greater customer satisfaction and business success.

Breakdown of the Plastic Manufacturing Industry By Product Type, Such as Packaging, Construction, Automotive, and Electronics

The plastic manufacturing industry is a diverse and complex sector that produces a wide range of products for various industries. Here is a breakdown of the plastic manufacturing industry by product type:

- Packaging: The packaging industry is the largest user of plastic materials, accounting for approximately 40% of all plastic usage. Plastic packaging includes products such as bags, bottles, containers, and films, used for food, beverages, personal care products, pharmaceuticals, and more.

- Construction: The construction industry uses plastic materials for various applications, including insulation, piping, roofing, flooring, and wall coverings. Plastic materials are used because they are lightweight, durable, and resistant to moisture and chemicals.

- Automotive: The automotive industry uses plastic materials for various components, including bumpers, dashboards, interior trim, and under-the-hood parts. Plastic components are lightweight, durable, and can be molded into complex shapes.

- Electronics: The electronics industry uses plastic materials for various components, including computer cases, phone cases, and other electronic device housings. Plastic materials are used because they are lightweight, durable, and can be molded into complex shapes.

- Medical: The medical industry uses plastic materials for various applications, including medical devices, syringes, and packaging for pharmaceutical products. Plastic materials are used because they are lightweight, sterilizable, and can be molded into complex shapes.

- Toys: The toy industry uses plastic materials for various products, including action figures, dolls, and games. Plastic materials are used because they are lightweight, durable, and can be molded into complex shapes.

- Sports equipment: The sports equipment industry uses plastic materials for various products, including balls, helmets, and protective gear. Plastic materials are used because they are lightweight, durable, and can be molded into complex shapes.

- Furniture: The furniture industry uses plastic materials for various products, including chairs, tables, and storage containers. Plastic materials are used because they are lightweight, durable, and can be molded into complex shapes.

- Agriculture: The agriculture industry uses plastic materials for various applications, including irrigation tubing, greenhouse coverings, and mulch film. Plastic materials are used because they are lightweight, durable, and resistant to moisture and chemicals.

Overall, the plastic manufacturing industry serves a wide range of industries and applications, and the products produced are critical to many aspects of modern life.

Growth Trends and Opportunities in Each Segment

Here are some growth trends and opportunities in each segment of the plastic manufacturing industry:

- Packaging: The packaging industry is expected to see continued growth due to the increasing demand for convenience and on-the-go products, such as single-serve snacks and beverages. There is also growing demand for sustainable packaging solutions, such as biodegradable and compostable materials.

- Construction: The construction industry is expected to see growth due to increasing urbanization and the need for sustainable building materials. Plastic materials can provide lightweight and energy-efficient solutions, and there is increasing interest in using recycled plastic materials for construction projects.

- Automotive: The automotive industry is expected to see growth due to the increasing demand for electric vehicles, which require lightweight materials to improve fuel efficiency. Plastic materials can also provide design flexibility and cost savings compared to traditional materials.

- Electronics: The electronics industry is expected to see growth due to the increasing demand for consumer electronics and the Internet of Things (IoT). Plastic materials can provide lightweight and durable solutions for electronic devices, as well as design flexibility for innovative product designs.

- Medical: The medical industry is expected to see growth due to the aging population and increasing demand for medical devices and equipment. There is also a growing trend towards using plastic materials for personalized medicine and 3D printing of medical devices.

- Toys: The toy industry is expected to see growth due to the increasing demand for educational and interactive toys. There is also growing interest in sustainable and non-toxic toy materials.

- Sports equipment: The sports equipment industry is expected to see growth due to increasing participation in sports and fitness activities. There is also a trend towards using lightweight and durable materials for sports equipment to improve performance.

- Furniture: The furniture industry is expected to see growth due to increasing demand for furniture in emerging markets and the trend towards compact and multifunctional furniture designs. Plastic materials can provide lightweight and durable solutions for furniture products.

- Agriculture: The agriculture industry is expected to see growth due to increasing demand for food and the need for sustainable agriculture practices. Plastic materials can provide durable and cost-effective solutions for agricultural applications, such as irrigation tubing and mulch film.

Overall, there are many growth opportunities in the plastic manufacturing industry, driven by technological advancements, changing consumer preferences, and global trends towards sustainability and innovation.

Strategies for Competition in the Plastic Manufacturing Sector

The plastic manufacturing industry is highly competitive, and companies employ various strategies to gain a competitive advantage. Here are some common strategies for competition in the industry:

Mergers and Acquisitions

Many companies in the plastic manufacturing industry engage in mergers and acquisitions to expand their product portfolio, gain access to new markets or technologies, and achieve cost efficiencies. For example, in 2020, LyondellBasell completed the acquisition of A. Schulman, a leading producer of high-performance plastic compounds and resins, to expand its portfolio of engineered plastics and gain access to new markets.

Product Differentiation

To stand out from competitors, companies often differentiate their products by offering unique features, such as improved performance, sustainability, or design. For example, some companies offer bio-based plastics made from renewable materials, or recycled plastics made from post-consumer waste. By differentiating their products, companies can attract customers looking for specific solutions or benefits.

Market Expansion

To grow their business, companies often expand into new markets, either by geography or by product segment. For example, a company that specializes in packaging for the food industry may expand into packaging for pharmaceuticals or personal care products. By expanding their market reach, companies can increase their customer base and revenue streams.

Technology Innovation

Technology innovation is a key driver of competition in the plastic manufacturing industry, with companies investing in research and development to create new materials, processes, and products. For example, some companies are developing biodegradable plastics or plastics that can be recycled multiple times without loss of quality. By innovating, companies can stay ahead of competitors and meet changing customer needs.

Sustainability

With growing concern about the environmental impact of plastics, companies that prioritize sustainability can gain a competitive advantage. This includes developing sustainable products, reducing waste and emissions, and adopting circular economy models that promote reuse and recycling of materials. By demonstrating their commitment to sustainability, companies can attract customers who value environmentally responsible practices.

These are just a few examples of the strategies that companies in the plastic manufacturing industry use to compete in the market. Companies often use a combination of these strategies to achieve their business goals and gain a competitive edge.

Future Outlook and Forecasts

The future outlook for the plastic manufacturing industry is complex and uncertain, as the industry faces challenges related to environmental sustainability, regulatory compliance, and changing customer demands. Here are some key trends and forecasts for the industry:

- Growing Demand for Sustainable Materials: As concerns about plastic waste and environmental impact continue to rise, customers are increasingly seeking out sustainable alternatives to traditional plastics. This includes bio-based plastics, recycled plastics, and biodegradable plastics, which are expected to see significant growth in the coming years.

- Advancements in Technology and Materials: The plastic manufacturing industry is expected to see continued advancements in technology and materials, with companies investing in research and development to create new materials and improve existing ones. This includes innovations in biodegradable and recyclable plastics, as well as advancements in manufacturing processes that reduce waste and energy consumption.

- Increased Regulation and Compliance: The plastic manufacturing industry is subject to a range of regulations related to environmental impact, waste reduction, and product safety. As governments around the world enact stricter regulations, companies in the industry will need to invest in compliance measures to avoid fines and penalties.

- Global Economic Growth: The plastic manufacturing industry is closely tied to global economic growth, as demand for plastic products is driven by industries such as packaging, construction, and automotive. As the global economy continues to recover from the COVID-19 pandemic, demand for plastic products is expected to increase, particularly in emerging markets.

- Opportunities for Collaboration and Innovation: The plastic manufacturing industry is ripe for collaboration and innovation, with companies across the value chain working together to address environmental concerns and improve sustainability. This includes collaborations between manufacturers, suppliers, and customers to create closed-loop systems that promote recycling and reuse of materials.

Overall, the plastic manufacturing industry is expected to see continued growth and innovation, but will need to adapt to changing customer demands and environmental concerns in order to remain competitive in the long term.

Implications for Investors, Policymakers, and Other Stakeholders

The plastic manufacturing industry has significant implications for investors, policymakers, and other stakeholders. Here are some key implications for each group:

Investors

Investors in the plastic manufacturing industry should be aware of the increasing demand for sustainable materials and the potential impact of environmental regulations on the industry. Companies that are investing in research and development to create new materials and improve existing ones may be well positioned for future growth. Investors should also consider the potential impact of circular economy models, Industry 4.0 technologies, and additive manufacturing on the industry.

Policymakers

Policymakers have an important role to play in shaping the future of the plastic manufacturing industry. Governments can enact regulations that encourage the use of sustainable materials and promote circular economy models. They can also provide incentives for companies to invest in research and development, and support the adoption of Industry 4.0 technologies. Policymakers should also consider the potential impact of the plastic manufacturing industry on the environment and public health, and work to mitigate any negative effects.

Customers and Consumers

Customers and consumers have a significant impact on the plastic manufacturing industry, as they drive demand for plastic products and materials. Customers can choose to purchase products made from sustainable materials and support companies that prioritize environmental sustainability. Consumers can also reduce their own plastic consumption and recycle materials whenever possible.

Suppliers and Other Stakeholders

Suppliers and other stakeholders in the plastic manufacturing industry can play a role in promoting sustainability and reducing waste. Suppliers can provide sustainable materials and technologies that help to reduce the industry's environmental impact. Other stakeholders, such as NGOs and industry associations, can work to promote sustainable business practices and advocate for policy changes that support sustainability.

Overall, the plastic manufacturing industry is a complex and dynamic sector with significant implications for a range of stakeholders. Investors, policymakers, and other stakeholders should be aware of emerging trends and technologies in the industry, as well as the potential impact of the industry on the environment and public health.

COVID-19 Effect on Plastic Manufacturing

The COVID-19 pandemic has had a significant impact on the plastic manufacturing industry, both in the short and long term. Here are some ways that the pandemic has affected the industry:

- Increased Demand for Plastic Packaging: The pandemic has led to a surge in demand for plastic packaging, particularly for medical and food products. This has led to increased production of plastic packaging products such as bottles, containers, and bags.

- Disruptions to Supply Chains: The pandemic has disrupted global supply chains, making it more difficult for companies to obtain the raw materials and equipment needed for plastic manufacturing. This has led to increased costs and delays in production.

- Shifts in Consumer Behavior: The pandemic has led to shifts in consumer behavior, with more people shopping online and using home delivery services. This has led to increased demand for plastic packaging, as well as a shift away from reusable bags and containers.

- Environmental Concerns: The pandemic has raised concerns about the environmental impact of plastic waste, as the increased use of single-use plastics has led to more plastic waste. This has led to calls for increased recycling and the development of more sustainable materials.

- Acceleration of Industry Trends: The pandemic has accelerated some existing trends in the plastic manufacturing industry, such as the adoption of Industry 4.0 technologies and the use of sustainable materials. This is because companies have had to adapt quickly to changing market conditions and find new ways to reduce costs and increase efficiency.

Overall, the COVID-19 pandemic has had a complex and multifaceted impact on the plastic manufacturing industry. While it has led to increased demand for some plastic products, it has also highlighted the environmental impact of plastic waste and the need for more sustainable business practices. Companies that are able to adapt to these changing conditions and prioritize sustainability are likely to be best positioned for future growth.

Plastic Manufacturing Sector after the Pandemic

The plastic manufacturing sector is likely to undergo several changes and adaptations as a result of the COVID-19 pandemic. Here are some potential trends and developments that could emerge in the post-pandemic era:

- Increased Focus on Sustainability: The pandemic has highlighted the environmental impact of plastic waste and the need for more sustainable business practices. As a result, there may be an increased focus on the development and adoption of sustainable materials, as well as increased efforts to reduce plastic waste through recycling and other means.

- Greater Adoption of Industry 4.0 Technologies: The pandemic has accelerated the adoption of Industry 4.0 technologies such as automation, artificial intelligence, and the Internet of Things. This trend is likely to continue in the post-pandemic era, as companies look for ways to reduce costs, increase efficiency, and improve supply chain resilience.

- Changes to Supply Chain Dynamics: The pandemic has disrupted global supply chains and highlighted the need for greater resilience and flexibility. As a result, there may be changes to supply chain dynamics in the plastic manufacturing sector, with more emphasis on local sourcing, greater collaboration between suppliers and manufacturers, and increased investment in supply chain digitization and automation.

- Increased Demand for Sustainable Packaging: The pandemic has increased awareness of environmental issues and highlighted the importance of sustainable packaging. As a result, there may be increased demand for sustainable packaging solutions such as biodegradable and compostable materials, as well as increased use of reusable and refillable packaging options.

- Greater Emphasis on Worker Safety and Well-being: The pandemic has highlighted the importance of worker safety and well-being, and there may be increased focus on these issues in the plastic manufacturing sector. This could involve greater investment in worker training and education, as well as the adoption of new technologies and practices to reduce the risk of infection and improve working conditions.

Overall, the plastic manufacturing sector is likely to undergo significant changes and adaptations in the post-pandemic era. Companies that are able to adapt to these changes and prioritize sustainability, supply chain resilience, and worker safety are likely to be best positioned for future growth and success.

How can Deskera Help You?

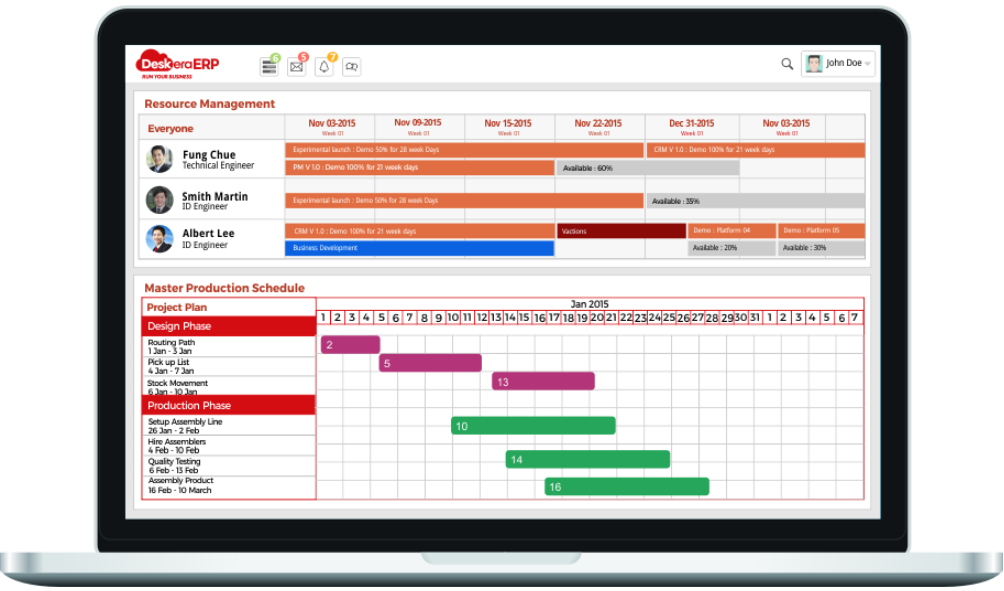

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- The global plastic manufacturing industry is witnessing significant growth, driven by increasing demand for plastic products and technological advancements in manufacturing.

- However, the industry also faces challenges such as environmental concerns related to plastic waste, regulations on plastic usage, and fluctuations in raw material prices.

- Bioplastics, which are made from renewable resources, are gaining traction as a sustainable alternative to traditional plastics.

- The circular economy model, which focuses on reducing waste and maximizing resource efficiency, is gaining popularity in the industry.

- The Asia-Pacific region dominates the global plastic manufacturing market, with China being the largest producer of plastics.

- The packaging segment is the largest application area for plastics, accounting for more than 40% of the market share.

- The automotive and construction industries are also significant consumers of plastic products.

- The COVID-19 pandemic has affected the industry, causing disruptions in the supply chain and shifts in consumer demand.

- The industry is expected to continue growing at a steady pace in the coming years, driven by increasing demand from emerging economies and the adoption of sustainable practices.

- Recycling and circular economy initiatives are expected to gain more prominence in the industry, as companies seek to reduce their environmental footprint and improve sustainability.

- The industry is also exploring new materials and production methods to reduce dependence on fossil fuels and improve product performance.

- Digitalization and Industry 4.0 technologies are expected to play an increasingly important role in the industry, improving efficiency and reducing costs.

- The industry is facing increasing scrutiny from regulators and consumers, which is driving companies to adopt more transparent and sustainable practices.

- Collaboration and partnerships between companies, governments, and other stakeholders are becoming more important in addressing environmental challenges related to plastic waste.

- To succeed in the industry, companies need to stay up-to-date with the latest trends and forecasts, and adopt sustainable practices that align with changing consumer expectations and regulatory requirements

Related Articles