Pest control operators face numerous safety and health hazards on a daily basis, from toxic chemicals to physical injuries. Moreover, pest control workers play a critical role in protecting public health by producing pesticides and other products used to control pests.

However, the work environment in pest control manufacturing can expose workers to a range of safety and health hazards, including exposure to hazardous chemicals, physical hazards, and risks of infection.

Therefore, it is essential for employers and workers to take steps to prevent occupational accidents and illnesses by implementing appropriate safety measures and following safe work practices.

This article will discuss various occupational safety and health issues related to pest control manufacturing. We’ll discuss about the hazards workers may be exposed to, control measures, and important safety practices that should be followed to protect workers' health and well-being. Before we get started, let’s take a look at the table of content:

- Protecting Pest Control Manufacturer Workers

- About Pesticide Poisoning

- Toxic Pesticides Chemicals

- Symptoms of Pesticide Poisoning

- Key Strategies that Help to Prevent Pesticides Poisoning in Workplace

- What are the Safe Practices in Using Pesticides?

- Precautionary and Control Measures that Needs to be Implemented

- Some Other Safety and Health Hazards

- Frequently Asked Questions (FAQs) Associated with Occupational Safety and Health for Pest Control Manufacturers

- Wrapping Up

- How Deskera Can Assist You?

Protecting Pest Control Manufacturers Workers

Protecting pest control manufacturing workers is crucial for several reasons, including:

- Health and Safety: Pest control manufacturing workers face a range of potential hazards, including exposure to hazardous chemicals, physical injuries, respiratory hazards, and more. By taking steps to protect workers from these hazards, employers can ensure that workers remain healthy and safe on the job.

- Compliance: Employers have a legal and ethical obligation to provide a safe and healthy workplace for their employees. Failure to protect workers from potential hazards can result in legal and financial consequences, as well as damage to a company's reputation.

- Productivity: When workers feel safe and supported in their work environment, they are more likely to be productive and engaged. On the other hand, when workers are exposed to potential hazards, they may experience stress, anxiety, and reduced productivity.

- Employee Retention: When employers prioritize worker safety and take steps to protect employees from potential hazards, workers are more likely to feel valued and respected. This can lead to higher employee retention rates, as workers are less likely to leave a company that prioritizes their well-being.

Overall, protecting pest control manufacturing workers is essential for promoting a safe and healthy workplace, complying with legal and ethical obligations, boosting productivity, and retaining valuable employees.

About Pesticide Poisoning

Pesticide poisoning occurs when a person is exposed to pesticides in amounts that are harmful to their health. Pesticides are effective chemicals that are used to control pests such as insects, rodents, weeds, and fungi. While pesticides can be effective in controlling pests, they can also pose a significant risk to human health if not used properly.

Pesticide poisoning can occur in a variety of ways, including:

- Inhalation: When pesticides are sprayed or otherwise dispersed into the air, they can be inhaled by workers or others in the area. Inhalation of pesticides can cause respiratory symptoms such as coughing, wheezing, and shortness of breath.

- Skin contact: Pesticides can be absorbed through the skin, especially if workers are not wearing appropriate personal protective equipment (PPE). Skin contact with pesticides can cause symptoms such as itching, redness, and rash.

- Ingestion: Accidental ingestion of pesticides can occur if workers eat or drink in areas where pesticides are being used. Ingestion of pesticides can cause symptoms such as nausea, vomiting, and abdominal pain.

- Injection: Pesticides can be injected into the body through accidental needle sticks or other puncture wounds. Injection of pesticides can cause symptoms such as pain, swelling, and infection.

Toxic Pesticides Chemicals

Pest control manufacturer workers can be exposed to a variety of pesticides that can cause poisoning. Some of the most common types of pesticides that can pose a risk to workers include:

- Organophosphates: These pesticides are commonly used in pest control and can cause acute poisoning symptoms, including nausea, vomiting, headache, dizziness, and difficulty breathing.

- Pyrethroids: These pesticides are also commonly used in pest control and can cause acute poisoning symptoms, including tingling sensations, dizziness, headache, and nausea.

- Carbamates: These pesticides are used to control insects and can cause acute poisoning symptoms, including nausea, vomiting, blurred vision, and difficulty breathing.

- Chlorinated hydrocarbons: These pesticides were once widely used in pest control but have since been banned in many countries. They can cause acute poisoning symptoms, including convulsions, respiratory failure, and death.

- Fumigants: These pesticides are used to control pests in enclosed spaces and can cause acute poisoning symptoms, including nausea, vomiting, headache, and respiratory distress.

It is important for pest control manufacturer workers to take appropriate precautions to prevent exposure to these and other pesticides, including wearing appropriate personal protective equipment (PPE) and following safe handling and disposal procedures. Employers also have a responsibility to provide workers with appropriate training, PPE, and other resources to help prevent pesticide poisoning.

Symptoms of Pesticide Poisoning

The symptoms of pesticide poisoning can vary depending on the type of pesticide, the dose, and the method of exposure. Pesticides can cause a range of acute and chronic health effects, and the symptoms may develop immediately or after a delay.

Following, we've discussed some common symptoms of pesticide poisoning:

- Respiratory symptoms: Pesticides can irritate the lungs and cause coughing, wheezing, shortness of breath, chest tightness, and other respiratory symptoms.

- Skin irritation: Pesticides can cause skin irritation, such as redness, itching, burning, and rash. Some pesticides can be absorbed through the skin and cause systemic effects.

- Eye irritation: Pesticides can cause eye irritation, such as redness, itching, burning, and tearing.

- Headache and dizziness: Pesticides can cause headache, dizziness, and other neurological symptoms, especially if they are inhaled.

- Nausea and vomiting: Pesticides can cause nausea, vomiting, abdominal pain, and diarrhea, especially if they are ingested.

- Muscle weakness and seizures: Some pesticides can cause muscle weakness, tremors, and seizures, especially if they affect the nervous system.

- Cardiovascular effects: Pesticides can affect the heart and circulatory system, causing irregular heartbeat, low blood pressure, and other symptoms.

- Long-term health effects: Chronic exposure to pesticides may result in long-term health effects, such as cancer, neurological damage, reproductive problems, and developmental delays.

It is important to note that some symptoms of pesticide poisoning may be delayed and may not appear until hours or days after exposure. In some cases, chronic exposure to low levels of pesticides may not cause immediate symptoms but can lead to long-term health effects over time.

If you suspect that you or someone else has been exposed to pesticides and is experiencing symptoms of pesticide poisoning, seek medical attention immediately. Early treatment can help prevent serious health effects.

Key Strategies that Help to Prevent Pesticides Poisoning in Workplace

There are several key strategies that can help prevent pesticide poisoning in the workplace. These include:

- Using the least toxic pesticides possible: Choose pesticides that are effective but have the least toxic ingredients. Read labels carefully and follow all process safety precautions.

- Following safe handling and disposal procedures for pesticides: Handle pesticides carefully, and follow all safety guidelines when mixing, applying, and disposing of pesticides. Store pesticides in a secure area, away from food, water, and other sensitive areas.

- Providing appropriate personal protective equipment (PPE) to workers: Provide workers with the necessary PPE, such as gloves, goggles, respirators, and protective clothing, to reduce exposure to pesticides.

- Conducting regular training on safe pesticide handling practices: Provide workers with regular training on safe handling practices, including how to use PPE, how to read and follow pesticide labels, and how to properly mix and apply pesticides.

- Monitoring workers for signs of pesticide exposure: Regularly monitor workers for signs of pesticide exposure, such as respiratory symptoms, skin irritation, or other symptoms. Encourage workers to report any symptoms or concerns.

- Implementing an integrated pest management (IPM) program: Implement an IPM program that uses a combination of strategies to control pests, including non-chemical methods such as sanitation, exclusion, and mechanical control.

By adopting these strategies, employers can reduce the risk of pesticide exposure and poisoning in the workplace. It is important to also provide workers with clear instructions and guidelines for handling and disposing of pesticides, and to regularly review and update safety procedures to ensure they are effective and up to date.

What are the Safe Practices in Using Pesticides?

Using pesticides safely is crucial to minimize the risk of pesticide poisoning and protect the health of workers and the environment.

Safe practices include reading and following the label instructions, wearing appropriate personal protective equipment (PPE), selecting the right pesticide for the job, applying pesticides only as directed, storing and mixing pesticides safely, disposing of pesticides properly, and cleaning up after pesticide use.

By following these safe practices, workers can reduce the risk of pesticide exposure and protect their health and safety.

Risk Assessment

When conducting a risk assessment on the use of pesticides, there are several points to note:

- Identify the hazards: Identify the hazards associated with the use of pesticides, including the potential for exposure through inhalation, skin contact, or ingestion.

- Determine the likelihood of exposure: Consider the likelihood of exposure based on the frequency and duration of pesticide use, the type of pesticide being used, and the methods of application.

- Assess the potential health effects: Evaluate the potential health effects of exposure to the pesticide, including acute effects such as skin irritation or respiratory symptoms, as well as chronic effects such as cancer or neurological damage.

- Identify control measures: Identify appropriate control measures to minimize exposure to pesticides, including engineering controls such as ventilation systems and administrative controls such as training and personal protective equipment.

- Evaluate the effectiveness of control measures: Evaluate the effectiveness of control measures to ensure they are reducing the risk of exposure to pesticides as intended.

- Review and update the assessment regularly: Regularly review and update the risk assessment to ensure it is current and effective, particularly if there are changes in the type or frequency of pesticide use.

- Following the Label Guidelines: It is also important to carefully follow the label instructions on the pesticide container when using approved pesticides, including the application rate, mixing instructions, and safety precautions. The label will provide information on the personal protective equipment (PPE) needed and how to properly dispose of the pesticide. By using approved pesticides according to the label instructions, workers can reduce the risk of pesticide exposure and protect their health and the environment.

- Permitted by Law for Intended Purpose: It is important to use pesticides that are permitted by law for their intended purpose. Using pesticides that are not approved or registered for the intended use can pose serious health and environmental risks. When a pesticide is approved for a specific use, it means that it has been thoroughly evaluated for its safety and effectiveness for that particular purpose. Using pesticides for a different purpose than what it is approved for can lead to unintended consequences, such as increased risk of pesticide poisoning, damage to crops or plants, and contamination of soil and water sources.

By conducting a thorough risk assessment on the use of pesticides, employers can identify potential hazards and implement appropriate control measures to protect the health and safety of workers.

Furthermore, it is important to involve workers in the risk assessment process to ensure that their input is taken into account and to promote buy-in and compliance with safety procedures.

Precautionary and Control Measures that Needs to be Implemented

Precautionary and control measures are important in protecting pest control manufacturers workers from potential hazards associated with the use of pesticides. Here are some key measures that should be taken:

Choosing Pesticides

Selecting the right pesticide for the job is important to ensure effective pest control while minimizing the risk of exposure to workers and the environment. Here are some factors to consider when selecting pesticides:

- Target pest: Identify the pest that needs to be controlled and select a pesticide that is effective against that pest. Different pesticides are designed to control different pests, so it is important to choose the right one for the job.

- Application method: Consider the method of application, such as spray, bait, or trap, and choose a pesticide that is appropriate for that method.

- Toxicity: Consider the toxicity of the pesticide and select the least toxic option that is effective for the job. Pesticides are classified by their toxicity, with categories ranging from "caution" to "danger" or "warning."

- Environmental impact: Consider the environmental impact of the pesticide, including its potential to harm non-target organisms or contaminate soil or water sources. Choose a pesticide that is least likely to cause harm to the environment.

- Regulatory requirements: Check local, state, and federal regulations to ensure the selected pesticide is approved for use and meets all applicable requirements.

- Worker safety: Consider the potential for worker exposure and select a pesticide that can be used safely with appropriate personal protective equipment (PPE) and engineering controls.

By considering these factors, pest control manufacturers can select the most appropriate pesticide for the job while minimizing the risk of exposure to workers and the environment. It is important to follow label instructions and applicable regulations when using pesticides.

Pesticide Storage

Proper storage of pesticides is important to ensure the safety of workers and the environment. Here are some guidelines for storing pesticides:

- Secure location: Store pesticides in a secure location that is inaccessible to unauthorized personnel, such as a locked cabinet or room. This will help prevent accidental exposure or theft.

- Labeling: Pesticides should be labeled with the product name, active ingredient, and any necessary hazard warnings. The label should be legible and in good condition.

- Temperature control: Pesticides should be stored in a cool, dry place away from sources of heat or ignition. Extreme temperatures can degrade the pesticide and make it less effective.

- Separation: Pesticides should be separated from other chemicals and materials, especially food, animal feed, and medical supplies. This will help prevent accidental contamination.

- Spill containment: Have spill containment materials on hand in case of a spill or leak. This can include absorbent materials, spill kits, or a designated spill containment area.

- Regular inspection: Regularly inspect pesticide storage areas to ensure that containers are in good condition, labels are legible, and there are no signs of damage or leaks.

By following these guidelines, pest control manufacturers can ensure that pesticides are stored safely and in compliance with applicable regulations.

Furthermore, proper storage will help protect workers and the environment from the potential hazards associated with pesticide exposure. It is important to dispose of any unused or expired pesticides in accordance with label instructions and applicable regulations.

Transporting Pesticides

Transporting pesticides can be hazardous if not done properly. Here are some guidelines for transporting pesticides safely:

- Use appropriate containers: Pesticides should be transported in appropriate containers that are leak-proof, sturdy, and clearly labeled. Containers should be made of materials that are compatible with the pesticide being transported.

- Secure transportation: Pesticides should be secured during transportation to prevent tipping or shifting. Use straps or restraints to secure containers in place.

- Proper ventilation: Transport pesticides in a well-ventilated vehicle to avoid exposure to fumes. Do not transport pesticides in a vehicle that is used to transport food, medical supplies, or other sensitive materials.

- Avoid extreme temperatures: Pesticides should be transported in a vehicle that is climate-controlled to avoid exposure to extreme temperatures. This will help ensure the effectiveness of the pesticide and prevent degradation.

- Follow regulations: Follow all local, state, and federal regulations regarding the transportation of pesticides. This may include obtaining permits, completing training, or adhering to specific guidelines for the transportation of hazardous materials.

- Emergency response: Have an emergency response plan in place in case of a spill or leak during transportation. This plan should include appropriate PPE, spill containment materials, and procedures for notifying authorities.

By following these guidelines, pest control manufacturers can ensure that pesticides are transported safely and in compliance with applicable regulations.

Moreover, proper transportation will help protect workers, the public, and the environment from the potential hazards associated with pesticide exposure. It is important to dispose of any unused or expired pesticides in accordance with label instructions and applicable regulations.

Diluting and Preparing Pesticides

Diluting and preparing pesticides requires caution and attention to detail to ensure that workers are not exposed to harmful chemicals. Here are some guidelines for diluting and preparing pesticides:

- Follow label instructions: Always follow the label instructions for diluting and preparing pesticides. The label will provide specific instructions on the appropriate dilution ratio, mixing order, and safety precautions.

- Wear appropriate PPE: Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and respirators, when handling and preparing pesticides.

- Prepare in a well-ventilated area: Dilute and prepare pesticides in a well-ventilated area, such as an outdoor location or a ventilated indoor area. This will help prevent exposure to fumes and vapors.

- Use clean equipment: Use clean equipment, such as measuring cups, mixing containers, and sprayers, to prepare and apply pesticides. Contamination from previously used equipment can lead to unexpected reactions or unwanted results.

- Mix slowly and carefully: Mix pesticides slowly and carefully to avoid splashing or spilling. Follow the label instructions for the appropriate mixing order, and do not exceed the recommended dilution ratio.

- Dispose of excess pesticide: Dispose of any excess pesticide according to label instructions and applicable regulations. Do not pour unused pesticides down the drain or dispose of them in the trash.

By following these guidelines, pest control manufacturers can ensure that pesticides are diluted and prepared safely and in compliance with applicable regulations.

Furthermore, proper preparation will help protect workers and the environment from the potential hazards associated with pesticide exposure. It is important to dispose of any unused or expired pesticides in accordance with label instructions and applicable regulations.

Pesticides Application

The application of pesticides is a critical step in pest control, and it requires proper training and attention to detail to ensure worker safety and the effectiveness of the treatment. Here are some guidelines for the safe application of pesticides:

- All individuals aside from the pest control team should leave.

- Remove the food, utensils, crockery, and pets before using the pesticide.

- Turn off the air conditioners and close the ventilation openings.

- Place all available kindling materials outside.

- Use the appropriate safety gear, such as work pants, PVC aprons, gloves, goggles, and respiratory protection.

- Use the pesticide according to the label's instructions and take all necessary safety measures when using it.

- The right nozzle should be used, and the spray pressure should be regulated precisely to avoid "over-spraying" of pesticide.

- Don't liberally apply the insecticide to the area.

- It is not advised to use liquid or powder pesticides outside while there are significant winds present.

After Application of Pesticides

After the application of pesticides, it is important to take certain precautions to ensure worker safety and prevent environmental contamination. Here are some key points to consider:

- Allow sufficient time for the pesticide to dry or settle before entering the treated area. This will help prevent exposure to the pesticide and reduce the risk of transfer to other areas.

- Follow label instructions for re-entry intervals. These are the periods of time that must pass after treatment before workers can safely enter the treated area. Re-entry intervals may vary depending on the type of pesticide and the area being treated.

- Remove and properly dispose of any PPE used during application, including gloves, respirators, and protective clothing. Wash any reusable PPE according to label instructions.

- Clean and decontaminate equipment and surfaces used during application. Use appropriate cleaning agents and methods as recommended by the label.

- Monitor the area for any signs of pesticide residue or unexpected effects, such as damage to plants or adverse health effects in humans or animals.

- Record the date, location, and type of pesticide used for future reference.

Following these recommendations will help pest control companies make sure they are taking the necessary precautions to safeguard employee safety and avoid contaminating the environment after applying pesticides. The chance of unintentional exposure will be decreased, and the possibility of adverse environmental consequences will be minimised, with proper cleanup and decontamination.

Unused Pesticides and Disposal of Pesticides

The disposal of pesticide containers and unused pesticides is a critical step in preventing environmental contamination and ensuring worker safety. Here are some key points to consider:

- Follow label instructions for disposal. The label will provide specific instructions for the disposal of pesticide containers and unused pesticides.

- Use designated disposal sites. Dispose of pesticide containers and unused pesticides at designated disposal sites approved by local or state authorities.

- Do not reuse or repurpose pesticide containers. Pesticide containers should not be reused or repurposed for any other use, as this can result in accidental exposure or contamination.

- Rinse containers before disposal. Rinse empty pesticide containers with water before disposal to ensure that any remaining pesticide is removed.

- Store unused pesticides properly until disposal. Store unused pesticides in their original containers, away from food or feed, and in a secure location to prevent accidental exposure.

- Do not dispose of pesticides in household trash or pour them down drains, sinks, or toilets. This can result in environmental contamination and potential harm to human health and wildlife.

- Pesticide containers should be thoroughly washed with water several times, pierced, or broken before disposal to render them unsuited for usage that could cause accidental poisoning, with the exception of those containing compressed aerosol insecticides.

- To protect the local ecosystem, pesticide waste should be treated in line with the Waste Disposal (Chemical Waste) (General) Regulation of the Environmental Protection Department.

The risk of environmental pollution and worker exposure can be reduced by following these recommendations for pest control producers when it comes to the disposal of pesticide containers and unused pesticides. By disposing of waste properly, pesticide exposure's potential risks to human health and the environment can be reduced.

Personal Protection

Personal protection is an important aspect of pesticide safety in the workplace. Here are some key points to consider:

- Wear appropriate personal protective equipment (PPE) as recommended by the pesticide label. This may include gloves, respirators, protective clothing, and eye and face protection.

- Inspect PPE before use. Make sure that PPE is in good condition and properly fitting. Replace any damaged or worn-out PPE.

- Use PPE consistently and correctly. Wear PPE for the entire duration of pesticide handling and application and follow label instructions for proper use and removal.

- Avoid skin and eye contact with pesticides. If pesticides come in contact with skin or eyes, immediately rinse the affected area with plenty of water.

- Store PPE properly when not in use. Store PPE in a clean and dry location away from direct sunlight or heat sources.

These guidelines will assist pest control companies make sure they are protecting their employees from pesticide exposure. The risk of skin or eye contact with pesticides, which might have negative health effects, will be reduced with the proper use of PPE. In order to avoid unintentional exposure and guarantee worker safety, it is crucial to continually adhere to appropriate measures for personal protection.

Hygiene

Maintaining good hygiene practices is an important aspect of pesticide safety in the workplace. Here are some key points to consider:

- Avoid eating, drinking, or smoking while handling pesticides or in areas where pesticides have been applied. This can reduce the risk of accidental ingestion of pesticides.

- Wash hands and other exposed skin thoroughly with soap and water after handling pesticides or coming into contact with surfaces or objects contaminated with pesticides.

- Remove contaminated clothing and wash it separately from other laundry. This can prevent cross-contamination and reduce the risk of prolonged exposure to pesticides.

- Shower after handling pesticides or after exposure to pesticides. This can help remove any residual pesticides from the skin and reduce the risk of exposure.

- Do not store food or beverages in areas where pesticides are stored or applied. This can reduce the risk of accidental ingestion of pesticides.

- Maintain a clean and well-ventilated work area to prevent the buildup of pesticide residues and fumes.

By following these guidelines, pest control manufacturers can ensure that they are taking appropriate measures to maintain good hygiene practices in the workplace.

Furthermore, proper hygiene practices can help reduce the risk of accidental exposure to pesticides and minimize the potential for adverse health effects. It is important to consistently follow safe practices for hygiene to prevent accidental exposure and ensure worker safety.

First-Aid Plan

Having a first-aid plan in place is important for pesticide safety in the workplace. Here are some key points to consider:

- Make sure that a first-aid kit is easily accessible and well-stocked with items such as bandages, gauze, antiseptic, and gloves.

- Train workers on the appropriate first-aid procedures for pesticide exposure, including how to recognize the signs and symptoms of pesticide poisoning and how to administer first-aid treatment.

- If a worker is exposed to pesticides, immediately move them to a well-ventilated area and remove any contaminated clothing.

- Rinse the affected area with plenty of water, taking care to avoid splashing contaminated water onto other parts of the body.

- If the worker is experiencing severe symptoms, such as difficulty breathing or loss of consciousness, seek medical attention immediately.

- Keep a record of any pesticide exposures and first-aid treatments administered.

The manufacturers of pest management products may make sure they are responding to pesticide exposures appropriately and ensuring worker safety by adhering to these recommendations.

First-aid techniques done correctly can lessen the severity of pesticide poisoning and the likelihood of negative health repercussions. It is crucial to have a clear first aid plan in place and to instruct staff members on what to do in the event of an exposure.

Some Other Safety and Health Hazards

In addition to the risks associated with pesticide exposure, pest control manufacturers may also be exposed to other safety and health hazards in the workplace. These hazards include:

- Physical hazards: Pest control manufacturers may be exposed to physical hazards such as slips, trips, and falls, as well as injuries from handling heavy equipment and machinery.

- Respiratory hazards: Pesticides can release harmful fumes and dust, which can cause respiratory problems if inhaled. Workers may also be exposed to other respiratory hazards such as mold and allergens.

- Skin and eye irritation: Pesticides can cause skin and eye irritation if they come into contact with the skin or eyes. This can be particularly problematic for workers who are not wearing appropriate personal protective equipment.

- Electrical hazards: Pest control manufacturers may work with electrical equipment, which can pose a risk of electrical shock or electrocution if not used properly.

- Ergonomic hazards: Prolonged or repetitive tasks can cause ergonomic hazards such as back pain, joint strain, and carpal tunnel syndrome.

To minimize these hazards, pest control manufacturers should implement appropriate safety and health programs, provide adequate training, and ensure that workers are wearing appropriate personal protective equipment.

It is also important to regularly assess the workplace for potential hazards and take appropriate measures to mitigate them. By addressing these hazards, pest control manufacturers can ensure a safe and healthy workplace for their workers.

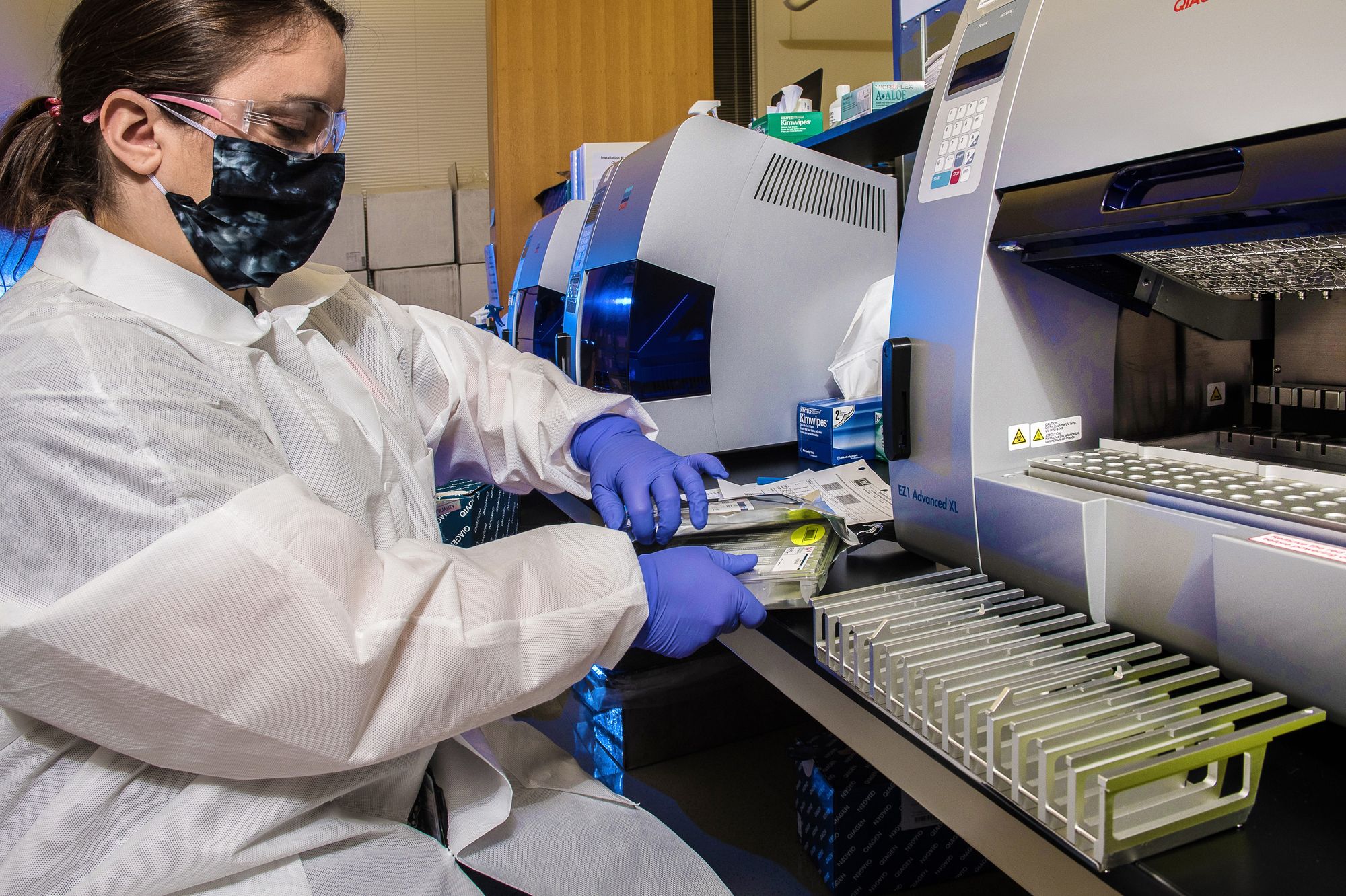

Contraction of Infectious Diseases

Pest control manufacturers may be exposed to infectious diseases while working with pesticides. For example, some pesticides can increase the risk of contracting vector-borne diseases, such as Lyme disease or West Nile virus, if they are exposed to infected pests.

In addition, pesticides may also compromise workers' immune systems, making them more susceptible to infectious diseases. Here are some strategies that can help prevent the contraction of infectious diseases in pest control manufacturing:

Personal protective equipment: Workers should be provided with appropriate personal protective equipment, such as gloves and masks, to reduce the risk of exposure to infectious diseases.

Vaccinations: Employers should encourage or require workers to receive vaccinations against infectious diseases, such as tetanus, hepatitis B, or Lyme disease, depending on the potential risks in their work environment.

Hygiene practices: Workers should be trained on good hygiene practices, such as washing their hands regularly, avoiding touching their faces, and covering their mouths and noses when coughing or sneezing.

Surveillance and monitoring: Employers should establish a system for monitoring workers' health and detecting early signs of infectious diseases. This can help to prevent the spread of disease to other workers or the public.

By implementing these strategies, pest control manufacturers can reduce the risk of infectious disease transmission and create a safer workplace for their workers.

Strategies for Regulating and Preventing

Before starting any anti-rodent work, flea de-infestation should be carried out if at all practicable.

- Spray insect or flea repellent on clothing or exposed skin as needed.

- As far as you can, avoid coming into direct contact with anything that can be infectious, such as contaminated water and insect corpses and faeces.

- Wounds should be covered with sterile, water-resistant dressings.

- Put on long sleeves and personal protection equipment, including plastic gloves, boots, aprons, and protective respirators.

- Follow strict personal hygiene rules.

Pest Attack

A pest attack refers to the presence of unwanted organisms, such as insects, rodents, or weeds, that can cause harm to crops, animals, or human health. Pest control measures aim to prevent or reduce the damage caused by pests.

Here are some common pest control measures:

- Chemical control: The use of pesticides, insecticides, or herbicides is a common method of pest control. This method involves applying chemicals to plants or the soil to kill or repel pests.

- Biological control: This method involves the use of natural predators, such as ladybugs, to control pests. This method is often used in organic farming.

- Physical control: This method involves physically removing or preventing pests from entering the area. For example, installing barriers or traps to prevent rodents from entering a building.

- Cultural control: This method involves changing the cultural practices of farming or gardening to prevent pest attacks. For example, rotating crops to prevent the buildup of pests in the soil.

- Integrated pest management (IPM): IPM is a comprehensive approach to pest control that combines different methods to prevent or manage pest attacks. This method involves monitoring pests, identifying the causes of pest attacks, and implementing a combination of pest control measures to reduce the use of chemicals.

By implementing effective pest control measures, farmers, gardeners, and other stakeholders can prevent pest attacks and reduce the risk of damage to crops, animals, and human health.

Manual Handling Operations

Manual handling operations refer to any activity that involves lifting, carrying, pushing, pulling, or moving objects by hand or bodily force. Manual handling operations can cause injuries such as strains, sprains, and musculoskeletal disorders (MSDs).

Here are some control measures to prevent injuries from manual handling operations:

- Risk assessment: Conducting a risk assessment of manual handling operations can help identify potential hazards and determine appropriate control measures. Employers should assess the weight, size, and shape of objects, as well as the distance and frequency of manual handling operations.

- Training: Providing training and instruction to employees can help prevent injuries from manual handling operations. Workers should be trained in proper lifting techniques, how to use handling aids such as trolleys and lifting equipment, and the importance of taking breaks.

- Handling aids and equipment: Employers should provide handling aids and equipment such as trolleys, pallet trucks, and lifting equipment to reduce the risk of injury. Workers should be trained in how to use these aids and equipment safely.

- Organizational measures: Employers should consider organizational measures such as job rotation, job design, and workload management to reduce the risk of injury from manual handling operations. Employers can also modify the design of the workplace, such as by installing adjustable workstations or reducing the weight of objects.

- Personal protective equipment (PPE): PPE, such as gloves and back belts, can help reduce the risk of injury from manual handling operations. However, PPE should not be used as the only control measure, and should be used in conjunction with other control measures.

By implementing these control measures, employers can reduce the risk of injury from manual handling operations and create a safer workplace for their employees.

Fire and Explosion

Fire and explosion are significant hazards in the workplace and can result in serious injuries or fatalities. Here are some control measures to prevent fires and explosions in the workplace:

- Risk assessment: Conducting a fire risk assessment can help identify potential fire and explosion hazards and determine appropriate control measures. Employers should consider the layout and design of the workplace, the materials used, and the equipment and machinery in use.

- Fire safety training: Employers should provide fire safety training to employees. This should include instruction on how to use fire extinguishers, evacuation procedures, and the importance of good housekeeping.

- Fire detection and alarm systems: Employers should install appropriate fire detection and alarm systems to quickly detect and alert workers to potential fires. These systems should be regularly tested and maintained.

- Fire extinguishers: Employers should provide suitable fire extinguishers and ensure that employees are trained in their use. Different types of extinguishers are appropriate for different types of fires, so it's important to have the right extinguisher for the job.

- Good housekeeping: Keeping the workplace clean and tidy can help prevent fires and explosions. Employers should ensure that materials and waste are stored appropriately and that there are no trip hazards.

- Electrical safety: Faulty electrical equipment can be a major cause of fires and explosions. Employers should ensure that all electrical equipment is regularly tested and maintained, and that employees are trained in the safe use of electrical equipment.

- Chemical safety: Many chemicals can be highly flammable or explosive. Employers should ensure that chemicals are stored safely and that employees are trained in their safe use.

By implementing these control measures, employers can significantly reduce the risk of fires and explosions in the workplace and ensure the safety of their employees.

Frequently Asked Questions (FAQs) Associated with Occupational Safety and Health for Pest Control Manufacturers

Following, we’ve discussed some important frequently asked questions associated with occupational safety and health relating to pest control manufacturer workers. Let’s discuss:

Que 1: What are the main hazards that pest control manufacturers workers are exposed to?

Ans: Pest control manufacturers workers can be exposed to various hazards, including pesticide poisoning, physical hazards, infectious diseases, and fire and explosion risks.

Que 2: How can pesticide poisoning be prevented in the workplace?

Ans: Pesticide poisoning can be prevented by using permitted pesticides, storing and transporting them properly, diluting and preparing them safely, using appropriate personal protective equipment, and practicing good hygiene.

Que 3: What control measures should be taken to prevent physical hazards in the workplace?

Ans: Control measures to prevent physical hazards include conducting risk assessments, implementing engineering controls, providing training, and using personal protective equipment.

Que 4: Can infectious diseases be contracted in the pest control Ans: manufacturing industry?

Ans: Yes, infectious diseases can be contracted in the pest control manufacturing industry, particularly if workers come into contact with animals or animal waste.

Que 5: What should be done with unused pesticides and pesticide containers?

Ans: Unused pesticides and pesticide containers should be disposed of properly, in accordance with regulatory requirements.

Que 6: What should workers do if they are exposed to a hazardous substance or experience an injury in the workplace?

Ans: Workers should immediately report any exposure to hazardous substances or workplace injuries to their supervisor and seek medical attention if necessary.

Que 7: Who is responsible for ensuring occupational safety and health in the pest control manufacturing industry?

Ans: Both employers and workers are responsible for ensuring occupational safety and health in the pest control manufacturing industry. Employers have a legal responsibility to provide a safe and healthy work environment, while workers have a responsibility to follow safe work practices and report any safety concerns to their supervisors.

Wrapping Up

In conclusion, it is vital to prioritize occupational safety and health in the pest control manufacturing industry to protect workers from potential hazards. Pesticide poisoning, physical hazards, infectious diseases, and fire and explosion risks are some of the hazards that can be present in the workplace.

However, by implementing appropriate control measures, such as conducting risk assessments, providing training, using personal protective equipment, and practicing good hygiene and housekeeping, these hazards can be effectively mitigated.

Employers have a responsibility to provide a safe and healthy work environment for their employees. By prioritizing occupational safety and health, not only can employers ensure compliance with regulatory requirements, but they can also improve employee morale and productivity, reduce absenteeism, and prevent costly accidents and injuries.

Workers also have a responsibility to follow safe work practices and report any safety concerns to their supervisors. By working together, employers and workers can create a culture of safety and prevent workplace accidents and injuries in the pest control manufacturing industry.

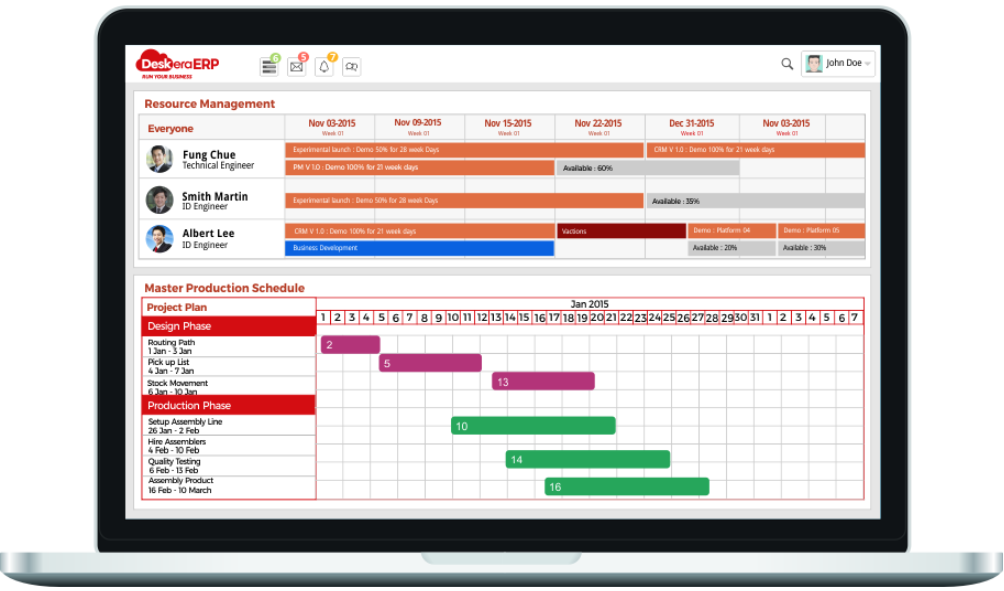

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Pesticide poisoning occurs when a person is exposed to pesticides in amounts that are harmful to their health. Pesticides are chemicals that are used to control pests such as insects, rodents, weeds, and fungi. While pesticides can be effective in controlling pests, they can also pose a significant risk to human health if not used properly.

- The symptoms of pesticide poisoning can vary depending on the type of pesticide, the dose, and the method of exposure. Pesticides can cause a range of acute and chronic health effects, and the symptoms may develop immediately or after a delay.

- Safe practices include reading and following the label instructions, wearing appropriate personal protective equipment (PPE), selecting the right pesticide for the job, applying pesticides only as directed, storing and mixing pesticides safely, disposing of pesticides properly, and cleaning up after pesticide use.

- It is important to use pesticides that are permitted by law for their intended purpose. Using pesticides that are not approved or registered for the intended use can pose serious health and environmental risks. When a pesticide is approved for a specific use, it means that it has been thoroughly evaluated for its safety and effectiveness for that particular purpose.

- Follow label instructions for re-entry intervals. These are the periods of time that must pass after treatment before workers can safely enter the treated area. Re-entry intervals may vary depending on the type of pesticide and the area being treated.

- Integrated pest management (IPM): IPM is a comprehensive approach to pest control that combines different methods to prevent or manage pest attacks. This method involves monitoring pests, identifying the causes of pest attacks, and implementing a combination of pest control measures to reduce the use of chemicals.

Related Articles