For manufacturing sector, where precision and efficiency are paramount, mastering the intricacies of purchase requisitions can spell the difference between streamlined operations and costly disruptions. As manufacturing executives navigate the ever-evolving landscape, understanding the nuances of purchase requisitions becomes increasingly essential.

Did You Know? According to a recent survey by the Manufacturing Leadership Council, over 60% of manufacturing companies identified procurement inefficiencies as a major roadblock to optimizing their supply chains. This statistic underscores the critical role that purchase requisitions play in the broader spectrum of manufacturing success.

Imagine a scenario where the assembly line grinds to a halt due to a shortage of raw materials, only because the procurement of those materials was delayed by convoluted requisition processes. Such bottlenecks not only dent productivity but also impact the bottom line.

Trivia: The concept of purchase requisitions dates back to the early 20th century, where handwritten notes or memos were used to request materials for production. Fast forward to today, and the digital age has transformed these requisitions into sophisticated electronic workflows, highlighting the evolution of manufacturing processes.

Throughout this guide, we will delve into the intricacies of purchase requisitions in the manufacturing sector. We'll explore their significance, dissect their components, and uncover the art of effective requisition management. From navigating challenges to implementing best practices, we'll equip manufacturing executives with the tools they need to orchestrate a seamless requisition process.

As we journey through real-world case studies and glimpse into the future trends reshaping manufacturing procurement, it becomes evident that purchase requisitions are not just paperwork; they are the linchpin in the intricate machinery of modern manufacturing.

So, let's embark on this exploration of mastering purchase requisitions—a journey that will empower manufacturing leaders to steer their companies toward operational excellence and unrivaled success.

- Importance of Purchase Requisitions in Manufacturing

- Understanding Purchase Requisitions

- Benefits of Effective Purchase Requisition Management

- Challenges in Purchase Requisition Processes

- Steps to Mastering Purchase Requisitions

- Best Practices for Manufacturing Executives

- Future Trends in Purchase Requisitions for Manufacturing

- Continuous Learning and Adaptation in a Changing Business Landscape

- Conclusion

- Key Takeaways

- Related Articles

Importance of Purchase Requisitions in Manufacturing

In the complex tapestry of modern manufacturing, where precision, efficiency, and timely execution are paramount, purchase requisitions emerge as a pivotal thread that holds the entire fabric together. A purchase requisition is far more than just a formal request for materials; it's a strategic cornerstone that ensures seamless workflow orchestration, cost control, and optimal resource allocation.

Navigating the Procurement Puzzle: Manufacturing processes thrive on a delicate balance of input materials, machinery, and skilled labor. Purchase requisitions act as the compass guiding manufacturing executives through the labyrinthine procurement process. By specifying the exact materials, quantities, and delivery timelines, these requisitions serve as the roadmap to acquiring resources with precision.

Budget Adherence and Cost Control: In an era of razor-thin profit margins, effective purchase requisitions act as a financial safeguard. They enable manufacturing executives to align procurement with budgetary constraints, preventing overspending and fostering transparency in spending decisions. According to industry data, companies that prioritize robust requisition processes experience up to 30% lower procurement costs.

Supply Chain Resilience: A well-timed purchase requisition is the linchpin of a resilient supply chain. By accurately forecasting material demands and triggering procurement activities ahead of time, manufacturing executives mitigate the risk of shortages, production delays, and customer dissatisfaction. This not only ensures the continuity of operations but also enhances customer trust.

Enhancing Collaboration: Purchase requisitions bridge the communication gap between various departments. They facilitate clear communication between production, procurement, finance, and inventory management teams, ensuring everyone is on the same page regarding resource requirements. This collaborative approach minimizes misunderstandings, aligns goals, and bolsters interdepartmental cohesion.

In essence, mastering the art of purchase requisitions equips manufacturing executives with a strategic lever to optimize production, control costs, and fortify supply chains. As we journey through this guide, the multifaceted significance of purchase requisitions will become increasingly apparent, emphasizing their pivotal role in the intricate dance of modern manufacturing excellence.

Understanding Purchase Requisitions

Amid the intricate gears and mechanisms that propel manufacturing operations forward, the concept of purchase requisitions stands as a vital cog. To effectively navigate the realm of procurement, manufacturing executives must first grasp the intricacies of purchase requisitions — the cornerstone upon which seamless resource acquisition and streamlined workflows are built.

In this section, we delve into the essence of purchase requisitions, unraveling their definition, significance, and the pivotal role they play in the broader fabric of manufacturing success.

A. Definition and Concept

At its core, a purchase requisition is the ignition spark that sets the wheels of procurement in motion within a manufacturing ecosystem. It encapsulates a formal request initiated by a department or individual within an organization to acquire specific goods or services necessary for operational continuity. This request serves as the initial step in the intricate dance of procurement, triggering a sequence of events that culminate in the arrival of essential materials at the right time and place.

The concept goes beyond a mere list of desired items; it outlines critical details such as item descriptions, quantities, quality standards, delivery schedules, and often budgetary constraints. These requisitions act as both a communication bridge and a strategic directive, fostering alignment between different departments and guiding procurement professionals on the path toward meeting organizational needs.

In essence, a purchase requisition is the compass by which manufacturing endeavors chart their course. It steers the ship toward acquiring the necessary resources, allowing manufacturing executives to strategically allocate materials, optimize production, and uphold the delicate balance between supply and demand. The efficient handling of purchase requisitions lays the foundation for streamlined operations, cost control, and ultimately, manufacturing excellence.

As we venture deeper into the understanding of purchase requisitions, we'll explore their multifaceted role within the broader framework of procurement, uncovering how their thoughtful execution can ripple positively throughout the entire manufacturing spectrum.

B. Role in the Procurement Process

Within the intricate web of procurement, where the timely acquisition of resources is imperative, purchase requisitions emerge as the linchpin that orchestrates the entire process. The role of purchase requisitions extends far beyond being a mere paperwork formality; it's a dynamic catalyst that sets off a chain reaction of actions, approvals, and transactions that ultimately result in the fulfillment of organizational needs.

Triggering the Procurement Engine: The journey begins with the submission of a purchase requisition, which acts as the starting gun for the procurement process. This document encapsulates the specific requirements of materials, equipment, or services, serving as a blueprint for the procurement team's activities.

Streamlining Communication: Purchase requisitions play a pivotal role in interdepartmental communication. They convey the needs of various departments to the procurement team, ensuring that everyone is on the same page regarding resource requirements. This transparency minimizes misunderstandings, streamlines collaboration, and enhances operational efficiency.

Budgetary Alignment: A well-crafted purchase requisition factors in budget constraints and aligns procurement activities with financial planning. By outlining expected costs and adhering to predefined budgets, manufacturing executives gain better control over spending and prevent cost overruns.

Approval Workflow: Purchase requisitions act as gateways that control the flow of procurement activities. Depending on the organization's structure, requisitions often undergo a hierarchical approval process. This ensures that requests are scrutinized for accuracy, necessity, and alignment with strategic objectives before resources are committed.

Synchronization with Suppliers: Once approved, purchase requisitions serve as the foundation for supplier interactions. Procurement professionals leverage these requisitions to initiate requests for quotations, negotiate terms, and place orders. Clear and comprehensive requisitions minimize back-and-forth communication and ensure that suppliers deliver the right materials at the right time.

In essence, purchase requisitions are not just a formality; they're the glue that binds together various stages of the procurement journey. As we navigate through this section, we will unravel the interconnectedness of purchase requisitions with other facets of manufacturing, showcasing their pivotal role in propelling the wheels of industry forward.

C. Key Components of a Purchase Requisition

Like a well-orchestrated symphony, a purchase requisition comprises a harmonious arrangement of essential components that form the basis for efficient procurement. Each element plays a unique role in conveying precise information and guiding the procurement process toward successful fruition.

Item Details: At the heart of every purchase requisition lies a clear and concise description of the requested item. This includes not only the item's name but also vital specifics like model numbers, specifications, and any associated technical details. The more precise this description, the smoother the procurement process.

Quantity: The desired quantity of the item is a critical aspect, ensuring that the procurement team acquires the correct amount to meet operational needs. Whether it's a specific number, measurement, or unit, this component eliminates ambiguity and paves the way for accurate resource allocation.

Delivery Timeline: Timing is of the essence in manufacturing, and specifying the required delivery date in the purchase requisition is paramount. This component helps procurement professionals coordinate with suppliers to ensure that materials arrive precisely when needed, preventing unnecessary delays or stockouts.

Budgetary Information: Every purchase requisition must align with budgetary constraints. Including budget-related details such as estimated cost, cost center, and project code ensures that procurement activities remain within financial parameters, enhancing fiscal responsibility.

Justification: A rationale behind the requisition can provide crucial context. Whether it's for a new project, a maintenance requirement, or a sudden demand surge, this component sheds light on the necessity of the requested item, aiding in informed decision-making during the approval process.

Approvals and Signatures: Depending on the organization's structure, a purchase requisition often requires approval from relevant stakeholders. Including designated spaces for signatures and approval comments ensures a clear audit trail and accountability throughout the procurement process.

Supplier Information: While not always mandatory at the requisition stage, providing preferred suppliers or a list of potential vendors can expedite the subsequent steps in procurement. It offers procurement professionals valuable guidance in sourcing the required items efficiently.

By understanding and meticulously crafting each of these components within a purchase requisition, manufacturing executives ensure that the procurement process is founded on clarity, transparency, and informed decision-making. In the next sections, we'll delve into how these components interact within the broader context of manufacturing operations, highlighting their role in driving organizational success.

Benefits of Effective Purchase Requisition Management

In the intricate dance of manufacturing, where precision and optimization are essential, effective purchase requisition management emerges as a guiding light. Beyond being a procedural necessity, a well-structured purchase requisition process yields a bouquet of advantages that reverberate across the entire organizational landscape.

In this section, we explore how mastering the art of purchase requisitions translates into tangible benefits that bolster cost control, streamline operations, and fortify the foundation of manufacturing excellence.

A. Cost Control and Budget Adherence

Effective purchase requisition management acts as a financial compass for manufacturing enterprises, steering them toward cost control and budget adherence. By providing a structured framework for resource acquisition, purchase requisitions ensure that procurement aligns with predetermined budgets. This alignment prevents overspending, reduces financial waste, and fosters transparency in spending decisions.

The ability to attach budgetary information to requisitions allows decision-makers to evaluate the financial impact of procurement actions in real-time, enabling them to make informed choices that maintain fiscal responsibility. Furthermore, clear budget constraints within requisitions prompt procurement professionals to seek cost-effective solutions, negotiate better deals with suppliers, and explore alternatives that optimize expenditure without compromising quality.

The result is a leaner, more efficient procurement process that safeguards the financial health of the organization while enabling it to allocate resources strategically.

B. Streamlined Procurement Workflow

Streamlining the complex dance of procurement is a primary outcome of effective purchase requisition management. By providing a structured channel for initiating requests, requisitions create a seamless pathway for procurement teams to kickstart the sourcing process. This eliminates ad-hoc requests and redundant communications, minimizing confusion and facilitating consistent procedures.

The inclusion of specific item details, quantities, and delivery timelines in requisitions equips procurement professionals with the information they need to initiate supplier interactions promptly. As a result, the procurement workflow becomes efficient and focused, reducing lead times and the risk of production disruptions due to material shortages.

This streamlined process enhances collaboration between departments, enabling procurement professionals to respond swiftly to changing demands and align resources with production schedules. Overall, efficient purchase requisition management accelerates the entire procurement journey, translating into improved operational agility and reduced time-to-market.

C. Inventory Management and Demand Forecasting

Purchase requisitions serve as valuable data points in the realm of inventory management and demand forecasting. The structured requisition process provides insights into the frequency and quantity of material requests, allowing organizations to fine-tune inventory levels based on actual operational needs. By analyzing historical requisition data, manufacturing enterprises can identify patterns, seasonality, and trends in material consumption.

This information aids in optimizing inventory levels, reducing carrying costs, and preventing overstocking or stockouts. Additionally, purchase requisitions contribute to accurate demand forecasting, as they reflect the real-time requirements of different departments.

This data-driven approach enables manufacturing executives to make informed decisions about production schedules, resource allocation, and procurement strategies. The result is a well-balanced inventory that matches demand, minimizes waste, and enhances the organization's ability to respond to market fluctuations swiftly.

D. Vendor Relationship Improvement

Effective purchase requisition management lays the foundation for nurturing healthy and mutually beneficial relationships with suppliers. By specifying preferred vendors or providing a list of potential suppliers in requisitions, organizations guide procurement professionals toward approved sources, fostering consistency and reliability in sourcing.

This clarity reduces the risk of ad-hoc purchasing from unauthorized vendors, ensuring that suppliers adhere to quality standards and contractual agreements. Furthermore, requisitions that include detailed item descriptions and technical specifications facilitate smoother communication between procurement professionals and suppliers, reducing the likelihood of misunderstandings or misinterpretations.

Over time, consistent and clear requisitions build trust between organizations and suppliers, leading to more favorable terms, negotiated pricing, and improved service levels. These enhanced relationships contribute to a stable supply chain, timely deliveries, and a collaborative environment where both parties work toward mutual success.

In the next section, we delve into the challenges that organizations may encounter in their quest for effective purchase requisition management, uncovering hurdles that hinder optimization and exploring strategies to overcome them.

Challenges in Purchase Requisition Processes

The realm of purchase requisition management is no exception. While these requisitions promise streamlined procurement and efficient operations, they often navigate through a landscape riddled with challenges. In this section, we delve into the obstacles that manufacturing enterprises might face on their journey to effective purchase requisition management.

From communication gaps to approval bottlenecks, we uncover the intricacies of these challenges and offer insights into how organizations can navigate through them to ensure the seamless orchestration of their procurement processes.

A. Lack of Clear Requisition Guidelines

One of the foremost challenges in purchase requisition processes is the absence of clear guidelines for creating and submitting requisitions. Without well-defined instructions, employees might struggle to provide accurate item details, quantities, or delivery timelines, leading to confusion and errors. This can result in delays, incorrect orders, and ultimately disrupt production schedules.

Organizations must establish comprehensive requisition policies that outline formatting standards, mandatory information, and preferred suppliers. By providing employees with a clear roadmap for creating requisitions, organizations can minimize confusion, improve the quality of submitted requests, and ensure that procurement teams receive accurate information to initiate sourcing activities.

B. Communication Gaps Between Departments

One of the foremost challenges in purchase requisition processes is the absence of clear guidelines for creating and submitting requisitions. Without well-defined instructions, employees might struggle to provide accurate item details, quantities, or delivery timelines, leading to confusion and errors. This can result in delays, incorrect orders, and ultimately disrupt production schedules.

Organizations must establish comprehensive requisition policies that outline formatting standards, mandatory information, and preferred suppliers. By providing employees with a clear roadmap for creating requisitions, organizations can minimize confusion, improve the quality of submitted requests, and ensure that procurement teams receive accurate information to initiate sourcing activities.

C. Manual vs. Automated Requisition Systems

The choice between manual and automated requisition systems presents a pivotal challenge. Manual systems, reliant on paper forms or emails, can be prone to errors, delays, and difficulties in tracking requisitions. On the other hand, automated systems offer efficiency, accuracy, and real-time visibility into requisition status. However, transitioning to an automated system requires investment, training, and change management efforts.

Organizations must carefully weigh the benefits and drawbacks of each approach. While manual systems might suffice for smaller organizations with simpler procurement needs, larger enterprises benefit from the scalability, data analytics, and process optimization that automated systems provide.

D. Approval Bottlenecks and Delayed Procurement

The approval process for purchase requisitions can sometimes become a bottleneck, leading to delays in procurement and subsequent operations. If approval workflows are not clearly defined, or if there's a lack of accountability among approvers, requisitions might languish in queues, impeding timely procurement. Organizations should establish well-structured approval hierarchies, designate backup approvers, and implement escalation procedures for urgent requisitions.

Additionally, digital tools can help streamline the approval process by routing requisitions to the right stakeholders, allowing for electronic signatures, and providing real-time visibility into approval status. Timely approvals ensure that procurement activities remain agile, responsive, and aligned with production schedules.

In the subsequent sections, we delve into strategies for overcoming these challenges, offering practical insights for manufacturing enterprises to navigate through the complexities of purchase requisition processes and achieve optimal outcomes.

Steps to Mastering Purchase Requisitions

In the quest for manufacturing excellence, the mastery of purchase requisitions stands as a crucial milestone. Navigating through challenges and seizing opportunities, manufacturing executives can transform their requisition processes into engines of efficiency, cost control, and strategic alignment.

This section serves as a practical guide, outlining a comprehensive roadmap that empowers organizations to not only understand the nuances of purchase requisitions but also implement strategies that elevate their effectiveness. From policy design to training initiatives, automation to monitoring, these steps provide a holistic framework to navigate the intricate terrain of purchase requisitions and steer toward operational excellence.

A. Designing a Comprehensive Requisition Policy

A robust purchase requisition policy serves as the cornerstone of effective procurement management. Crafting a comprehensive policy involves defining requisition formats, mandatory information, approval hierarchies, and preferred suppliers. By establishing clear guidelines, organizations ensure consistency and accuracy in requisition creation.

This policy also aligns requisitions with strategic goals, streamlining resource allocation and budget adherence. A well-designed policy reduces confusion, minimizes errors, and creates a structured framework that guides requisition initiators through the process.

B. Cross-Functional Collaboration and Communication

Effective requisition management thrives on collaboration between departments. Encouraging cross-functional communication ensures that requisitions accurately reflect operational needs. Regular meetings or digital platforms can facilitate dialogue, minimizing misunderstandings and enhancing alignment.

Collaborative input from different departments ensures that requisitions consider various perspectives and comply with production schedules, ultimately optimizing procurement efficiency and reducing delays.

C. Implementing Automated Requisition Systems

Automation revolutionizes requisition management by streamlining processes and eliminating manual bottlenecks. Automated systems facilitate the creation, submission, and tracking of requisitions digitally. They enable real-time visibility, electronic approvals, and simplified communication.

Implementation may require investment, but the benefits in terms of efficiency, accuracy, and data-driven insights far outweigh the initial costs. Automation reduces lead times, enhances compliance, and empowers procurement teams to focus on strategic sourcing.

D. Defining Approval Workflows and Escalations

Efficient approval workflows are pivotal for swift procurement. Organizations should define clear approval paths, designate approvers, and establish escalation protocols for urgent requisitions. This structure prevents bottlenecks, ensures timely decision-making, and keeps procurement activities agile. Escalation mechanisms guarantee that critical requisitions receive attention even in the absence of designated approvers, preventing delays that can disrupt operations.

E. Training and Education for Requisition Initiators

Empowering requisition initiators with training and education fosters requisition accuracy and compliance. Workshops or training sessions can educate employees on requisition policies, preferred vendors, and best practices. When requisition initiators understand the importance of precise details, timely submissions, and adherence to policies, the overall quality of requisitions improves, contributing to a smoother procurement process.

F. Monitoring Key Performance Indicators (KPIs)

Implementing KPIs provides a performance yardstick for requisition management. Metrics like requisition submission times, approval cycle durations, and accuracy rates offer insights into process efficiency. Regularly monitoring KPIs enables organizations to identify bottlenecks, inefficiencies, or areas needing improvement. Data-driven decision-making enhances the effectiveness of requisition processes, driving continuous optimization.

By undertaking these steps, manufacturing enterprises can navigate the complex terrain of purchase requisitions with confidence, fostering an environment of efficiency, accuracy, and strategic alignment. In the following sections, we delve into best practices that manufacturing executives can adopt to lead by example and harness the full potential of purchase requisition mastery.

Best Practices for Manufacturing Executives

In the dynamic landscape of manufacturing, where excellence is a constant pursuit, manufacturing executives stand as guiding beacons for their organizations. As they lead the charge towards operational optimization, mastering the intricacies of purchase requisitions becomes a strategic imperative.

This section serves as a compass, guiding manufacturing leaders through a collection of best practices that empower them to set the tone, align requisition goals with broader business objectives, and foster a culture of continuous improvement. By embracing these practices, manufacturing executives can not only navigate through challenges but also inspire a ripple effect of efficiency and excellence throughout the entire requisition process.

A. Leading by Example: Setting the Tone for Requisition Efficiency

Manufacturing executives play a pivotal role in shaping the organization's culture and practices. By exemplifying efficient requisition management themselves, executives set a powerful example for their teams. When leaders consistently submit accurate and well-prepared requisitions, it communicates the importance of attention to detail and adherence to process.

This behavior cultivates a culture of efficiency, inspiring employees to follow suit. When executives prioritize requisition accuracy and timely submissions, it establishes requisition management as a core organizational value.

B. Aligning Requisition Goals with Overall Business Objectives

Effective requisition management isn't just about acquiring materials; it's about contributing to broader organizational goals. Manufacturing executives should align requisition processes with the company's strategic objectives.

This involves understanding how requisitions impact production schedules, cost control, and customer loyalty and satisfaction. By fostering this alignment, executives ensure that requisitions become an integral part of achieving the company's larger mission.

C. Regularly Reviewing and Optimizing Requisition Processes

Manufacturing environments are dynamic, and requisition processes must evolve accordingly. Regular reviews of requisition processes are essential to identify bottlenecks, inefficiencies, and areas for improvement.

Manufacturing executives should lead or sponsor these reviews to ensure that processes remain efficient, compliant, and aligned with changing business needs. Optimizing requisition workflows leads to reduced lead times, improved accuracy, and enhanced collaboration between departments.

D. Leveraging Technology for Data-Driven Insights

In the digital age, technology offers a treasure trove of insights. Manufacturing executives should leverage data from automated requisition systems to analyze key performance indicators (KPIs). These insights provide a holistic view of the requisition process, enabling data-driven decisions. Executives can identify trends, address issues promptly, and make strategic adjustments based on accurate, real-time information.

E. Encouraging Feedback and Continuous Improvement

Creating an environment that encourages feedback is paramount. Manufacturing executives should actively seek input from employees involved in requisition processes. Their frontline experiences can reveal pain points and suggest innovative solutions. By fostering an open feedback culture, executives ensure that the requisition process remains adaptive and responsive. Continuous improvement becomes a collective effort, leading to refinements that enhance overall operational efficiency.

Through these best practices, manufacturing executives become catalysts for change and efficiency. Their leadership not only shapes the requisition process but also radiates outward, creating a culture where excellence is not just a goal but a way of operating. As we explore real-world case studies and future trends, the impact of these practices becomes even more evident.

Future Trends in Purchase Requisitions for Manufacturing

As technology reshapes industries, manufacturing executives must anticipate and adapt to emerging trends that promise to revolutionize the requisition landscape. This section serves as a window into the horizon, exploring the future trends that will shape how manufacturing organizations approach purchase requisitions.

From AI-driven demand prediction to blockchain-enabled transparency, these trends hold the potential to unlock new levels of efficiency, sustainability, and strategic advantage in the realm of procurement.

A. Integration of AI and Machine Learning for Demand Prediction

The integration of AI and machine learning into purchase requisition processes introduces a new level of sophistication in demand prediction. By analyzing vast volumes of historical data, market trends, external factors like economic indicators, and even social media sentiment, AI algorithms can generate highly accurate demand forecasts.

These forecasts enable manufacturing organizations to anticipate fluctuations in demand with precision, ensuring that they have the right materials available when needed, thus minimizing excess inventory and stockouts. Additionally, AI-powered demand prediction enhances agility in responding to sudden changes in market conditions, allowing manufacturers to adjust procurement strategies in real-time.

This trend not only improves operational efficiency but also contributes to enhanced customer satisfaction through timely and reliable product availability.

B. Blockchain for Transparent and Secure Requisition Tracking

Blockchain technology, famed for its decentralized and tamper-proof nature, has transformative potential in purchase requisition processes. By utilizing blockchain, each step of the requisition journey is recorded in a secure and transparent manner on an unchangeable ledger. This ensures an audit trail that all stakeholders can trust, minimizing the risk of errors, disputes, and fraudulent activities.

The requisition process becomes transparent, enabling real-time tracking of requisition status, approvals, and procurement actions. Blockchain ensures that all participants, from initiators to approvers to suppliers, have access to accurate and consistent information, thus reducing miscommunication and delays.

Furthermore, it enhances accountability and compliance, as every action is traceable and verifiable. Embracing blockchain technology fosters a level of trust and efficiency that can revolutionize the requisition landscape.

C. Sustainable Procurement Practices and Ethical Considerations

The shift towards sustainability is reshaping how organizations approach procurement, including purchase requisitions. This trend encompasses ethical considerations, such as responsible sourcing, fair labor practices, and reduced environmental impact. Manufacturers are increasingly inclined to source materials and products that align with these values.

Requisition processes of the future will factor in sustainability and ethics, requiring requisition initiators to consider the origins, production methods, and social implications of requested items. This trend not only reflects the growing conscientiousness of organizations but also addresses the rising consumer demand for ethical products.

Integrating sustainable procurement practices into requisition processes showcases a commitment to responsible business practices while fostering a positive brand image and meeting evolving market expectations.

As manufacturing enterprises navigate these future trends, they are poised to unlock new avenues of efficiency, transparency, and value-driven procurement. Embracing AI-powered demand prediction, harnessing blockchain's security, and prioritizing sustainability in requisition practices ensure that manufacturers remain competitive, adaptive, and aligned with the changing demands of a dynamic marketplace.

Continuous Learning and Adaptation in a Changing Business Landscape

Manufacturing organizations must recognize that the requisition landscape will continue to evolve, influenced by factors such as technological innovations, supply chain disruptions, and shifting consumer preferences.

To stay ahead in this ever-changing business landscape, manufacturing executives and their teams need to cultivate a mindset of perpetual learning. This involves keeping a pulse on emerging technologies, market trends, and best practices related to requisition management. Regular training programs, workshops, and staying informed about industry developments empower employees to remain updated and adaptable.

Incorporating a culture of continuous learning enables organizations to swiftly embrace new tools and methodologies that enhance requisition processes. For instance, if a new AI-powered procurement system becomes available, a team that values continuous learning will be better prepared to understand, implement, and leverage its capabilities.

Moreover, being open to adaptation means actively seeking feedback from requisition initiators, approvers, and suppliers. By remaining receptive to insights and suggestions, organizations can iterate on their requisition processes, making adjustments that improve efficiency and user experience.

Ultimately, this trend underscores the necessity of viewing requisition management as a dynamic process that requires ongoing education, flexibility, and willingness to evolve. As manufacturing landscapes transform, those who champion continuous learning and adaptation will be at the forefront of driving efficiency, innovation, and success in purchase requisition processes.

Conclusion

Mastering purchase requisitions in the realm of manufacturing is not a mere administrative feat; it's a strategic imperative that can define the trajectory of operational excellence. In this journey through the intricacies of requisition management, we've explored the significance of requisitions as more than just paperwork — they are the linchpin that connects departments, streamlines procurement, and fortifies supply chains.

Challenges such as communication gaps, manual processes, and approval bottlenecks have been unveiled, each presenting an opportunity for organizations to fine-tune their strategies. The steps to mastering requisitions offer a roadmap for success, emphasizing the importance of policy design, cross-functional collaboration, and the integration of technology.

Manufacturing executives, by leading by example and aligning requisition goals with broader business objectives, can set the stage for operational efficiency and innovation. By leveraging technology, embracing feedback, and staying attuned to emerging trends, organizations can ensure that their requisition processes remain agile, efficient, and future-ready.

As we peer into the future, the potential of AI-powered forecasting, blockchain-enabled transparency, and sustainable procurement practices is both exciting and promising. By navigating these trends, manufacturing enterprises can prepare to harness cutting-edge tools to elevate their requisition processes to new heights.

Ultimately, the mastery of purchase requisitions isn't just about improving processes; it's about propelling manufacturing operations to unprecedented levels of excellence. It's about enhancing cost control, driving efficiency, and ensuring that the wheels of production continue to turn seamlessly.

By embracing the insights, strategies, and trends outlined in this guide, manufacturing executives and their organizations can stride confidently toward a future where requisition mastery isn't just a goal — it's a competitive advantage that sets them apart in the dynamic world of manufacturing.

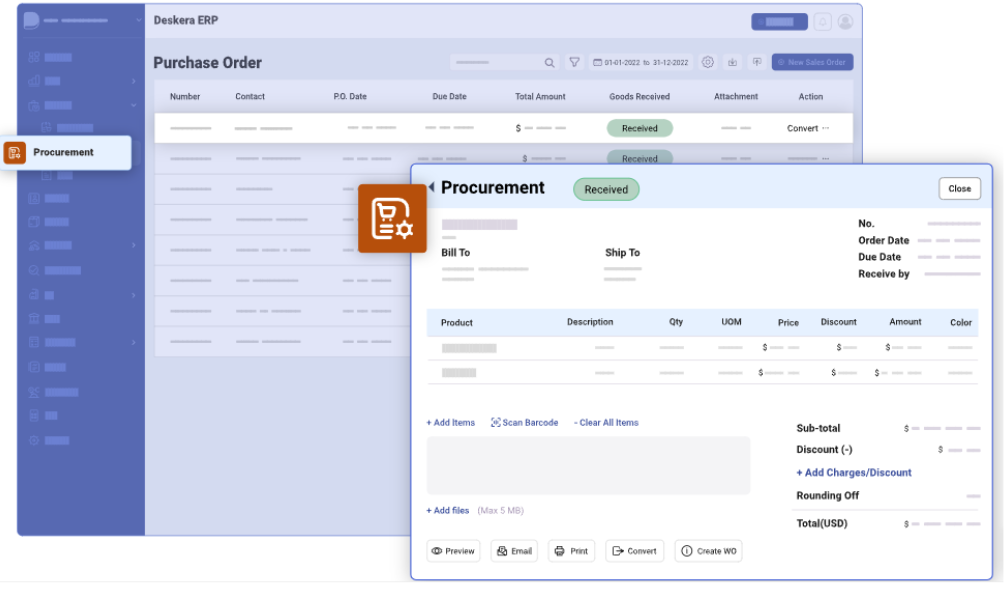

How Can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Here are some ways Deskera ERP's Procurement functionality can assist you:

- Create Requisitions and RFQs

- Generate Vendor Quotations

- Set up Vendor Scorecards

- Manage Preferred Suppliers

- Scan Purchase Invoices

- Create Purchase Orders

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways

- Strategic Significance: Purchase requisitions are not mere paperwork; they are strategic cornerstones that guide procurement, production, and supply chain management.

- Cost Control: Effective requisition management aligns procurement with budget constraints, preventing overspending and fostering financial transparency.

- Streamlined Workflow: Purchase requisitions streamline the procurement process, ensuring accurate material acquisition and minimizing delays.

- Cross-Departmental Communication: Requisitions bridge communication gaps between departments, promoting collaboration and operational cohesion.

- Automation Advantage: Automated requisition systems enhance accuracy, efficiency, and real-time visibility, while reducing manual errors and delays.

- Transparent Approvals: Well-defined approval workflows prevent bottlenecks, ensuring timely procurement and responsive operations.

- Data-Driven Insights: Technology-driven requisition processes offer data-driven insights for informed decision-making and continuous optimization.

- Leadership Influence: Manufacturing executives set the tone for requisition efficiency, aligning processes with business objectives through their actions.

- Future Trends: AI-driven demand prediction, blockchain transparency, and sustainable procurement practices are shaping the requisition landscape.

- Continuous Learning: In a changing business landscape, fostering a culture of continuous learning and adaptation is key to staying agile and innovative.

Mastering purchase requisitions isn't just about improving processes; it's about achieving operational excellence, optimizing costs, and driving strategic alignment. By understanding these takeaways and embracing the insights shared in this guide, manufacturing organizations can pave the way for a future where requisition mastery is a driving force behind their success.

Related Articles