Process automation is a great way to gain efficiency and increase productivity. In most cases, manual information tracking can be time-consuming and prone to human error. But with the help of automation tools, a company can streamline processes.

Automation can ensure that all tasks are completed correctly.

Process automation is the process of integrating business functions together. This includes purchasing, sales, and supply chain. With this integration, businesses can track their data more closely. For example, it helps determine whether a product has been sold or when a shipment was made or received.

This post helps us discover all we must know about manufacturing process automation. Let’s see what more we have:

- What is Process Automation in Manufacturing?

- What are the Types of Manufacturing Automation?

- How is Automation used in Production Facilities?

- The Benefits of Automating Manufacturing Processes

- 10 Automation Trends Redefining Manufacturing Today

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What is Process Automation in Manufacturing?

Automation in manufacturing uses manufacturing management software or robotic tools. It is used to perform a factory's tasks when making physical products. These tools are built to meet the needs of businesses. They can lessen overhead and improve efficiency. The devices can allow multiple innovative processes to be integrated into one system.

Automation is the ability to perform repetitive, patterned tasks automatically. This is done by programming a machine or tool with computer code. The machine automatically instructs it to perform a process. Automation in manufacturing can improve efficiency and reduce costs. However, like any other process, this too, has its pros and cons.

Companies are starting to use manufacturing automation. This is a result of years of research and development. It is now often related to electromechanical systems that may be programmed to carry out a variety of tasks.

Not every manufacturer is a good candidate for automation. Yet, most businesses can benefit from the different kinds of automation.

Automation can give you the ability to increase quality and reduce waste. It can also deliver products on time and optimize resource allocation.

What are the Types of Manufacturing Automation?

Automation is the mechanization of processes. It ensures production procedures are followed without human intervention.

On the production floor, a variety of automation techniques are employed. A manufacturing operation will decide what kind of automation to use based on the items being produced. It also dictates the machinery needed and the resources available.

In the case of industrial automation, different processes and pieces of machinery are handled by control systems. This may rely on computers or robots, to finish a task.

It may be used most easily when conducting predictable physical work, collecting data, and analyzing data.

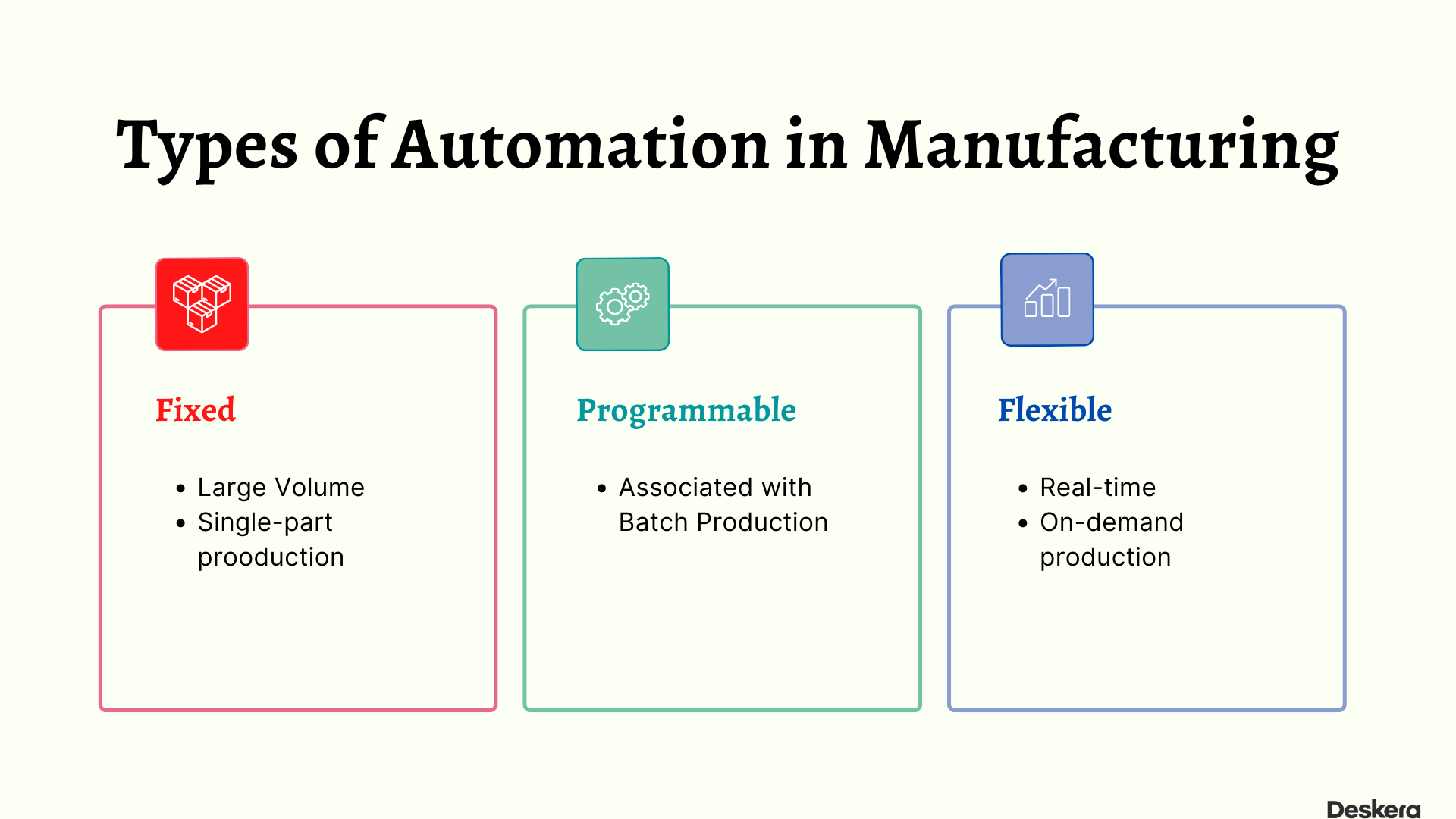

We have the following types of manufacturing automation techniques:

Fixed Automation

This is also known as hard automation. It can be used for producing large quantities and has a high barrier of entry. But it is generally used for parts of the production process that need high levels of reliability.

The main advantage of programmable automation are increased flexibility. The production line runs continuously, and the operators can monitor more items at one time. Changes in demand and small batches can be accommodated by programmable automation.

It can also oversee changes in warehousing or other changes in inventory. In some cases, changes in product design would need to be accommodated as well, but this is rare.

For automation in manufacturing, measure the total cost of changes versus a fixed automation solution. Fixed automation is more expensive, but it is also a more secure solution. Yet, we must know that this may not be an appropriate option for every situation.

Programmable Automation

Programmable automation is related to batch production. It is characterized by producing hundreds to thousands of items. The ability to generate more different parts or products is provided by programmable automation.

To perform changeovers, however, downtime is necessary. The lead times and batch sizes are adjusted to account for this interruption. Costly downtime has prompted an expansion of programmable automation known as flexible automation.

Flexible Automation

Switchovers can be carried out automatically through flexible automation. This may require additional devices to enable automated changeovers. Or restrict equipment to run portions that utilize identical tools.

Flexible automation is often connected to some kind of network that adds value by enabling remote monitoring or control. This is because programs need to be altered. Computer programs are created offline. A designer might upload and execute new programs into ongoing manufacturing from anywhere. It depends on how the gadget is connected, though.

How is Automation used in Production Facilities?

Automation can be used to enhance industrial systems and procedures in several situations. It can take many different forms. The examples include the following:

Order Processing

As a company grows, it could become increasingly difficult to manage a high volume of incoming orders. Businesses can monitor incoming orders and order revisions. They may also want to accomplish price calculations in real time by automating order processing.

The repetitious nature of procurement ties up a lot of precious human resources. Yet, companies can automate procurement by utilizing vendor management systems and supplier portals.

This frees the employees of the cumbersome and repeated tasks. Eventually, allowing the management to reassign staff to more mentally demanding duties.

Production

A common application of automation in the industrial sector is manual production assembly. Businesses deploy a combination of machines, robots, IoT devices, and software to guide workers. They may also collect data and physically complete daily activities. This allows them to optimize the production process on the factory floor.

Additionally, industrial automation software facilitates enhancing operator productivity on the production line. It also aids to gather real-time data. With the help of this information, supervisors may locate the inefficiencies in manufacturing.

The process also lets them take remedial action to promote ongoing progress.

Supply Chain

The supply chain consists of several routine, prone-to-error procedures. It is a crucial process that can affect related processes. An error at any stage can create multiple problems.

These processes could lead to bottlenecks throughout the entire system. However, automation techniques to perform picking, receiving, stocking, and shipping remove errors.

Production routing works well with automated supply chain management. Thus, it helps in improving workflow and productivity.

The Benefits of Automating Manufacturing Processes

Manufacturing automation is evolving from a luxury to a need. Companies increasingly realize the relevance of the process in boosting productivity. Utilizing the advantages it provides will give you a considerable competitive advantage.

Among these advantages are the following:

Reduced Operational Expenses

Even while automation may need a sizable upfront investment, it provides an excellent return. One machine can execute the labor of three to five, and maybe more, people, depending on the workload.

Increased Safety at Work

Some manufacturing processes need employees to operate in hazardous environments. This is because they did not have a practical alternative in the past. Automation allows you to keep workers away from potentially dangerous operations.

Hazardous materials do not need manual handling owing to automation.

A Rise in Productivity

Manual monitoring is tedious and tiresome. Therefore, the factories often employ rotational shifts of workers. Machines can operate continuously without supervision and at the same speed. As a result, your production process will run faster and longer. Also, you can increase production or develop new items without stopping current ones.

Improved Product Quality

In general, machines are more accurate than individuals while performing manufacturing jobs. Additionally, they continuously maintain the same production quality. You will experience greater uniformity and conformity, which will result in a lower fraction defect rate.

Accurate and Reliable Documentation Management

Paper-based document management and manual data collecting are riddled with mistakes. They could contain inconsistencies that may be irreparable. Automated document management systems enable stronger data integrity and security. This is possible owing to their enhanced accuracy.

Better Resource Allocation and Use

Many manufacturing processes still rely heavily on manual labor, even for small, routine jobs. This significantly increases the likelihood of mistakes. Thereby, putting the company at risk for poor quality and non-compliance.

By automating these routine human-based tasks, workers can concentrate on complicated, meaningful work. They can carry out activities that are not well suited for automation. Processes on the shop floor that are more efficiently run due to automated technology might identify weak points. They are also competent in recognizing the possible bottlenecks in the production line.

Additionally, they offer potential fixes for these issues, resulting in better-streamlined manufacturing procedures.

10 Automation Trends Redefining Manufacturing Today

Without question, automation will significantly impact how manufacturing is done in the future. Here are the top 10 factory automation trends that are altering the industry as we know it today. Moreover, they possibly are laying the foundation for the future.

Let’s check them here.

Addictive Manufacturing

Today, manufacturers frequently utilize additive manufacturing. Also referred to as 3D printing, it is used to create parts and products specifically for clients.

In comparison to conventional production techniques, this procedure may use fewer materials. Besides, it generates lesser waste. Additionally, it can be used to make models, prototypes, or individual parts of final goods.

Additive manufacturing is primarily a substantial time and money-saving technology. It is a rapidly expanding trend in the business. This manufacturing trend is expanding rapidly, particularly in the metal fabrication sector. It is also growing among businesses that use metal components in their construction.

New selective laser sintering (SLS) technology for 3D printing metals eliminates tooling expenses. It also drastically reduces product development time. Thus, it enables businesses to produce metal goods in-house and realize significant cost savings.

Furthermore, metal pieces that were previously difficult to create may now be mass-produced at a low cost.

Artificial Intelligence

Information is critical to all businesses. Today, companies have access to more data than ever before. Tools like artificial intelligence and machine learning help them make the most of that data. Thus, these tools have a significant impact on production.

AI is not restricted to robots. Rather, it describes a computer system's capacity to identify patterns. It draws logical inferences that might assist manufacturers in making data-driven decisions.

A manufacturing organization can benefit from AI and machine learning in various ways. This includes the following:

Industry 4.0

Industry 4.0 is a term used to refer to the fourth industrial revolution. It is a concept that focuses on automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of Things (IoT), and cloud computing.

The concept is based on the idea of smart manufacturing. In this, the machines can be connected to networks so that they can exchange data with one another in real time. This data can be used to increase efficiency, reduce costs, and improve quality.

We are aware that Industry 4.0 is a term used to represent the current manufacturing trend toward smart factories. It stands for the fourth industrial revolution.

Industry 4.0 has gained widespread acceptance. It is a result of comprehension of the newest manufacturing technology. This includes IoT, the cloud, powerful computers, robotics, and the human worker. Companies must take advantage of technological developments that have triggered the fourth revolution in manufacturing. This will help them remain relevant and successful in the market.

Enterprise Resource Planning (ERP)

ERP systems assist producers in automating various business processes. It competently achieves this through a single, all-encompassing system. This enables them to monitor the entire manufacturing process and make modifications as necessary.

The use of enterprise resource planning technology in the manufacturing sector has been around for a while. However, it is becoming more popular now that cloud-based SaaS choices are readily available. Furthermore, these are cost-effective for small enterprises.

ERP systems assist manufacturers in automating various operational processes as a single system. This is a common touchpoint. This provides producers with the knowledge they need to monitor the whole manufacturing process. Thus, enabling them to make adjustments and enhancements as necessary.

Industrial Internet of Things (IoT)

Manufacturers can connect to and monitor the many parts of their operations owing to the Internet of Things. This way, they can acquire previously impossible insight. This connectivity enables manufacturers to improve and optimize any aspect of their manufacturing process.

IoT is gaining ground by utilizing intelligent sensors and cloud connectivity enabled by the internet. Businesses are enhancing safety, reducing costs, and optimizing production. They are even developing new products with IoT capabilities.

This network of linked devices is employed primarily in manufacturing and industrial applications. It gathers data that may be used to improve the manufacturing process.

Predictive Maintenance

Predictive maintenance is a technique used to determine the condition of in-service equipment. It helps to predict when maintenance should be performed.

This approach enables maintenance to be scheduled, helping to improve equipment performance. Also, it can reduce maintenance costs and enhance overall productivity. Predictive maintenance uses various techniques such as condition monitoring, vibration analysis, and oil analysis. Also, thermography and others can detect equipment faults. Furthermore, they can predict when they are likely to occur.

Predictive maintenance (PdM) is a strategy that spots irregularities in your operation. It is instrumental in locating potential flaws in equipment and processes. So, you can address them before they break down.

Predictive maintenance ideally enables the frequency of maintenance to be as low as feasible. This fact helps to avoid unforeseen reactive maintenance. Additionally, it avoids the costs associated with performing excessive amounts of preventative maintenance.

Predictive maintenance helps you anticipate maintenance requirements. This further helps in avoiding costs incurred due to abrupt downtime. You can spot patterns that indicate potential issues or breakdowns. This happens by connecting to devices and keeping an eye on the data those devices provide.

Supply Chain Technology

Manufacturing trends suggest businesses are investing in new technologies to enhance every stage of the production process. This includes sourcing, inventory management, assembly, logistics, transportation, and sales.

The development of high mix, low volume (HMLV) manufacturing impacts supply chain operations. Manufacturers must manage the supply chain effectively. This way, they can aim to reduce costs while providing customers with items when and how they want them.

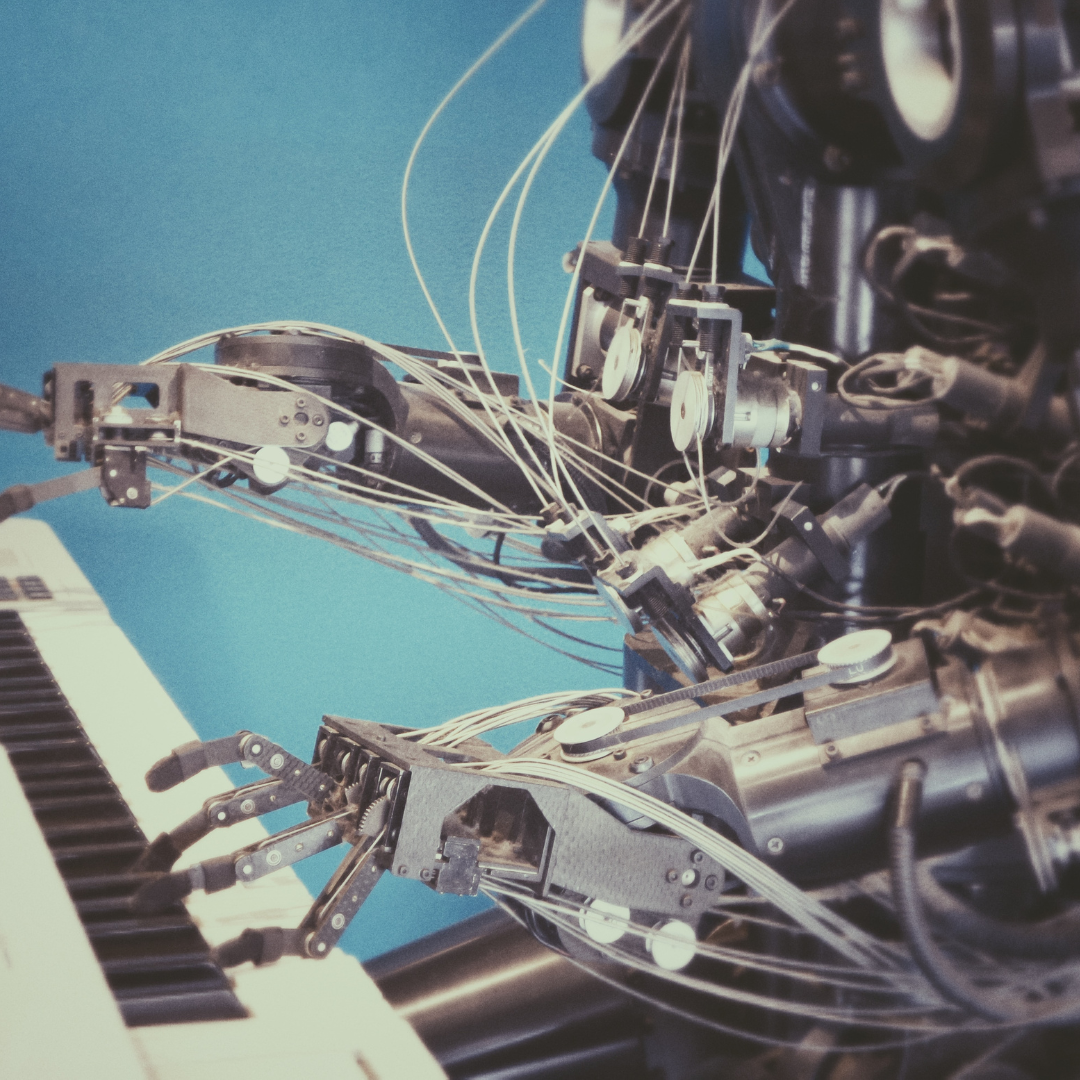

Collaborative Robots or CoBots

Manufacturing trends demonstrate more safety in the workplace owing to robots. By collaborating in factories and warehouses, humans and robots can complete more work quickly and safely. CoBots are robots designed for the human workforce to use as a useful tool that enhances overall workplace productivity.

Automated Picking

With CoBots, picking is one of their most popular applications in the logistics industry. Walking to pick up the product makes up about 50% of the overall process in typical order fulfillment positions. This takes up significant time and resources.

Automated picking is accomplished by using a robot to navigate the warehouse and retrieve the right item. This helps free up workers to perform more skilled work during the fulfillment process.

Efficiency is increasing as a result of these production development and logistical advancements. A human worker could pick up roughly 60 or 70 orders in an hour. In contrast, an automated system could choose up to 300 in the same amount of time.

Mobile Manipulators

Mobility opens up new possibilities for mobile manipulator automation. This revolutionary design combines a manipulator with an AMR (a robotic arm).

In other words, it enables you to automate more operations. You can create higher value from your manufacturing floor. To sum up, the process lets you improve efficiency, reduce costs, and increase scalability.

Conclusion

We understand that manufacturing process automation can seem daunting, but you don’t need to worry. Automation is a tool that makes things work efficiently.

Reduce human error and increase efficiency across your organization with automated manufacturing processes. Lessen the time spent on repetitive tasks by allowing computers to complete them for you. It will free up your time for more strategic work.

Today, we have new technologies and processes for data capture, analysis, and visualization. The automation of a manufacturing process can greatly help improve the quality of your products.

Your business could benefit immensely from manufacturing process automation. It can completely automate your entire production process. Thus, improving the efficiency of your small business.

How can Deskera Help You?

Deskera has some of the best systems that you can use to automate your own business. Deskera ERP and MRP help break your existing businesses' complex processes. This makes them easier to manage and improve for customers.

- Learn how to work with machine learning and automation to streamline your processes, improve productivity, and save time and money.

- Deskera helps you stay competitive by supplying your customers with the tools and training they need to customize the manufacturing process automation that best fits their needs.

- We can help you choose the right options for a variety of industries, including manufacturing.

Deskera Books is an add-on module that helps you handle your cash and accounts. By automating billing, invoicing, and payment processing, high accounting standards are kept up.

Deskera CRM is a powerful instrument that could aid in organizing your sales and hastening contract closure. It gives you a complete view of your sales funnel and integrates with your marketing database. It gives you the ability to communicate effectively with various prospects and understand their needs. Furthermore, it builds strong relationships with them. You can now let your clients know how they can benefit from your product or service.

Deskera People is an easy-to-use solution for organizing tasks related to human resource management. You do not have to manage payroll manually anymore. Manage employees, salaries, and benefits in the same platform. It iss accurate, fast, and reliable.

Key Takeaways

- Process automation is a great way to gain efficiency and increase productivity. In most cases, manual information tracking can be time-consuming and prone to human error.

- Automation in manufacturing uses manufacturing management software or robotic tools. It is used to perform a factory's tasks when making physical products.

- Automation is the ability to perform repetitive, patterned tasks automatically. This is done by programming a machine or tool with computer code that automatically instructs it to perform a process.

- Automation in manufacturing can improve efficiency and reduce costs, but it has many pros and cons.

- Most businesses can benefit from one of the following kinds of automation: Programmable, fixed, or flexible.

- most businesses can benefit from one of the following kinds of automation: Programmable, fixed, or flexible.

- Fixed automation is also known as hard automation. It can be used for producing large quantities and has a high barrier of entry. But it is generally used for parts of the production process that are in need of high levels of reliability.

- Programmable automation is related to batch production. It is characterized by producing hundreds to thousands of items. The ability to generate more different parts or products is provided by programmable automation.

- Flexible automation is often connected to some kind of network that adds value by enabling remote monitoring or control. This is because programs need to be altered.

- Order processing, supply chain, and production are some production facilities where automation is useful.

- Automation helps reduce operational expenses and increases safety at work.

- It facilitates rise in productivity and better resource allocation.

- IoT, ERP, addictive manufacturing, and AI are some of the popular automation trends.

Related Articles