Picture this: You've carefully crafted a delicious recipe, sourced high-quality ingredients, and perfected your manufacturing process. Your product is ready to hit the market and satisfy the taste buds of consumers everywhere.

But, have you given enough thought to your budget? Managing a budget may not be the most glamorous aspect of food manufacturing, but it's a crucial one. Without proper budgeting, your business could quickly spiral into financial chaos, jeopardizing your ability to deliver your product to the market.

The good news is that by managing your food manufacturing budget effectively, you can save money, improve efficiency, and invest in new opportunities.

In this article, we'll explore the key areas you should focus on to make the most of your food manufacturing budget. From assessing your current budget to investing in the right equipment and technology, we'll provide you with practical tips to help you optimize your budget and set your business up for success.

- Assessing Your Current Budget

- Prioritizing Expenditures based on Business Goals and Objectives

- Maximizing Efficiency in Food Manufacturing Operations

- Investing in the Right Equipment and Technology

- How to Increase Profit Margins in Food Manufacturing?

- 5 Tips to Save Money in Food Manufacturing

- How can MRP and ERP systems assist in Saving Cost in Food Manufacturing Industry

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Assessing Your Current Budget

Assessing your current budget is an essential step in managing your food manufacturing budget effectively. It allows you to identify areas where you're overspending and make adjustments to reduce costs. Before you can assess your budget, you need to have a clear understanding of your financial planning. This includes knowing your revenue, expenses, and profit margins.

Once you have a clear picture of your financials, you can start assessing your budget. Begin by examining your expenses and identifying any areas where you can cut costs. This may involve renegotiating supplier contracts, finding more cost-effective ingredients, or reducing labor costs.

Another important aspect of assessing your budget is tracking your spending. This will help you identify any unexpected expenses and ensure that you're staying within your budget. It's also essential to review your budget regularly, preferably on a monthly or quarterly basis, to ensure that you're on track to meet your financial goals.

Assessing your current budget is not just about identifying areas to cut costs. It's also an opportunity to identify areas where you can invest more money to improve your business's performance. For example, investing in marketing or new equipment may increase revenue and improve efficiency in the long run.

Prioritizing Expenditures based on Business Goals and Objectives

Once you've assessed your current budget, the next step in managing your food manufacturing budget effectively is prioritizing expenditures based on your business goals and objectives. Prioritizing your spending will help ensure that you're allocating resources to the areas of your business that will provide the most significant return on investment.

To prioritize expenditures, start by identifying your business's short-term and long-term goals. Short-term goals may include increasing production or reducing costs, while long-term goals may involve expanding your product line or entering new markets.

Once you've identified your goals, categorize your expenses into essential and non-essential categories. Essential expenses are those that are necessary for your business's day-to-day operations, such as ingredients, packaging, and labor.

Non-essential expenses are those that can be reduced or eliminated without significantly impacting your business's operations, such as marketing or travel expenses.

Next, prioritize your essential expenses based on their impact on your business goals. For example, if your goal is to increase production, investing in new equipment or hiring additional staff may be a priority. If your goal is to reduce costs, renegotiating supplier contracts or finding more cost-effective ingredients may be a priority.

When it comes to non-essential expenses, prioritize those that will have the most significant impact on your business goals while minimizing unnecessary spending. For example, if your goal is to expand your product line, investing in marketing or research and development may be a priority, while unnecessary travel expenses may be cut back.

In summary, prioritizing expenditures based on your business goals and objectives is a crucial step in managing your food manufacturing budget effectively. It allows you to allocate resources to the areas of your business that will provide the most significant return on investment while minimizing unnecessary spending. By prioritizing expenditures, you can ensure that your business is on track to achieve its goals and grow over time.

Maximizing Efficiency in Food Manufacturing Operations

Maximizing efficiency in food manufacturing operations is essential to reduce costs and improve productivity. By optimizing resources and reducing waste, you can improve your business's bottom line while delivering high-quality products to your customers. Here are some tips for maximizing efficiency in food manufacturing operations:

- Streamline your production process: Analyze your manufacturing process to identify areas where you can streamline workflows, reduce wait times, and eliminate unnecessary steps. By doing so, you can minimize bottlenecks and maximize productivity.

- Optimize your inventory management: Keeping a close eye on your inventory levels can help you reduce waste and optimize resources. Use software tools to track inventory levels in real-time, and create reorder points to ensure that you always have enough materials on hand without overstocking.

- Improve equipment maintenance: Regularly scheduled equipment maintenance can help reduce downtime and improve efficiency. Schedule maintenance checks and repairs during off-peak hours to minimize production disruptions.

- Automate certain tasks: Automating repetitive tasks can help reduce labor costs and improve efficiency. Consider investing in automated systems for tasks such as packaging or labeling.

- Reduce waste: Identify areas where you can reduce waste, such as excessive packaging or overproduction. Implement strategies such as recycling, composting, or donating excess food to reduce waste and improve sustainability.

- Train employees: Properly trained employees can help improve efficiency by reducing errors and improving productivity. Provide regular training and refresher courses to ensure that your team is up-to-date on the latest techniques and best practices.

By maximizing efficiency in food manufacturing operations, you can improve your business's profitability and deliver high-quality products to your customers. It requires a concerted effort to optimize workflows, minimize waste, and invest in the right equipment and training. However, the payoff is well worth the effort.

Investing in the Right Equipment and Technology

Investing in the right equipment and technology is a critical factor in increasing profit margins for food manufacturing companies. Upgrading to modern equipment and adopting new technologies can help companies reduce labor costs, increase production efficiency, and improve product quality. By improving these key areas, companies can reduce costs, increase revenue, and improve profitability.

Here are some ways that investing in the right equipment and technology can help food manufacturing companies increase their profit margins:

- Reduce labor costs: By investing in automation and robotics technology, companies can reduce labor costs associated with repetitive tasks and improve production efficiency.

- Increase production efficiency: By adopting new technologies and upgrading to modern equipment, companies can increase production speed and reduce waste, improving overall efficiency and reducing costs.

- Improve product quality: By investing in new equipment and technology, companies can improve product quality and reduce defects, reducing the costs associated with rework or product recalls.

- Enhance food safety: By adopting new technologies and equipment designed for food safety, companies can improve compliance with food safety regulations and reduce the risk of foodborne illness outbreaks, improving brand reputation and reducing the costs associated with product recalls.

- Increase capacity: By investing in new equipment and technology, companies can increase their production capacity, allowing them to produce more products and generate more revenue.

By improving production efficiency, reducing labor costs, and improving product quality and safety, companies can reduce costs, increase revenue, and position themselves for long-term success in a highly competitive industry.

How to Increase Profit Margins in Food Manufacturing?

To increase profit margins in food manufacturing, companies must adopt a multifaceted approach that includes reducing costs, improving efficiency, increasing revenue, optimizing pricing, improving product quality, and building a strong brand.

By implementing these strategies, food manufacturing companies can stay competitive, increase profitability, and position themselves for long-term success in a rapidly changing industry.

Here are 5 ways in which you can increase the profit margins in food manufacturing:

Improve Inventory Visibility

Improving inventory visibility and inventory control is a key strategy that can help food manufacturing companies increase their profit margins. When a company has better visibility into their inventory, they can optimize their production process, minimize waste, and reduce the risk of stockouts.

Here are some ways that improving inventory visibility can help increase profit margins in food manufacturing:

- Optimize production planning: By having real-time visibility into inventory levels, companies can optimize their production planning. This means they can produce the right amount of product at the right time, reducing the need for excess inventory and minimizing waste.

- Reduce carrying costs: Carrying costs, such as storage and handling fees, can add up quickly. By having better visibility into inventory levels, companies can reduce the amount of excess inventory they hold, reducing carrying costs and improving profitability.

- Minimize stockouts: Stockouts can result in lost sales and revenue. By having better visibility into inventory levels, companies can minimize the risk of stockouts and ensure they have enough product on hand to meet customer demand.

- Improve supply chain efficiency: Better inventory visibility can also improve supply chain efficiency by reducing lead times and ensuring timely deliveries of raw materials and finished goods.

- Analyze inventory data: Analyzing inventory data can provide insights into inventory trends and patterns, helping companies make more informed decisions about inventory management and production planning.

Stay Innovative to Tackle Rising Energy Costs

Rising energy costs can be a major challenge for food manufacturing companies looking to increase their profit margins. One way to tackle this challenge is to stay innovative and adopt new technologies and practices that can help reduce energy usage and costs.

Here are some ways that staying innovative can help increase profit margins in food manufacturing:

- Adopt energy-efficient technologies: Companies can invest in new technologies and equipment that are designed to be more energy-efficient, such as LED lighting, energy-efficient HVAC systems, and high-efficiency motors.

- Implement renewable energy solutions: Renewable energy solutions, such as solar panels and wind turbines, can help companies generate their own energy and reduce their reliance on expensive grid electricity.

- Monitor energy usage: By monitoring energy usage in real-time, companies can identify areas where energy usage is high and implement strategies to reduce it. For example, they can adjust production schedules to run during off-peak hours or implement energy-saving measures during periods of high energy demand.

- Implement energy management systems: Energy management systems can help companies track and manage energy usage across multiple locations and identify opportunities for improvement.

- Foster a culture of energy efficiency: By promoting a culture of energy efficiency among employees, companies can encourage everyone to take small steps to reduce energy usage, such as turning off lights and equipment when not in use.

Staying Ahead of Market and Consumer Trends

This is a critical strategy that can help food manufacturing companies increase their profit margins. By understanding what consumers want and staying ahead of emerging market trends, companies can position themselves to capture market share and increase revenue.

Here are some ways that staying ahead of market and consumer trends can help increase profit margins in food manufacturing:

- Identify emerging trends: By monitoring trends in the food industry, companies can identify emerging trends and develop products that cater to changing consumer preferences. For example, if there is a growing demand for plant-based products, companies can develop new products that cater to this trend.

- Innovate with new products: By staying ahead of market and consumer trends, companies can develop innovative new products that capture consumer interest and generate excitement. This can help companies differentiate themselves from competitors and capture market share.

- Build a strong brand: By staying ahead of market and consumer trends, companies can build a strong brand that is associated with innovation, quality, and customer satisfaction. This can help attract and retain customers, increase customer loyalty, and drive revenue growth.

- Optimize pricing: By understanding consumer preferences and market trends, companies can optimize their pricing strategies to ensure they are competitive and profitable. For example, if there is a growing demand for premium products, companies can adjust their pricing to reflect this trend.

- Improve marketing and promotion: By staying ahead of market and consumer trends, companies can develop more effective marketing and promotion strategies that resonate with their target audience. This can help increase brand awareness, drive customer engagement, and increase revenue.

Boost Your Average Order Value

Boosting the average order value is an effective way for food manufacturing companies to increase their profit margins. By increasing the amount that customers spend per order, companies can generate more revenue and improve profitability.

Here are some ways that companies can boost their average order value and increase their profit margins:

- Offer bundle deals: Companies can bundle complementary products together and offer them at a discount, encouraging customers to purchase more items in a single order.

- Implement upselling and cross-selling techniques: By recommending additional products or upgrades that complement the customer's purchase, companies can encourage customers to spend more per order.

- Offer free shipping for larger orders: By offering free shipping for orders that exceed a certain value, companies can encourage customers to purchase more items in a single order to take advantage of the offer.

- Implement loyalty programs: By rewarding customers for making repeat purchases or spending more per order, companies can incentivize customers to increase their order value.

- Offer personalized recommendations: By analyzing customer data and offering personalized recommendations based on their purchase history, companies can encourage customers to add more items to their cart and increase their order value.

Improving Supplier Relationships

This factor can help food manufacturing companies increase their profit margins in several ways. By developing strong relationships with suppliers, companies can negotiate better pricing and payment terms, reduce lead times, improve product quality, and streamline their supply chain operations. These improvements can help companies increase efficiency, reduce costs, and improve profitability.

Here are some specific ways that improving supplier relationships can help increase profit margins in food manufacturing:

- Negotiate better pricing: By developing strong relationships with suppliers, companies can negotiate better pricing for raw materials and other inputs, reducing their overall cost of goods sold and improving profit margins.

- Improve payment terms: By working closely with suppliers to improve payment terms, companies can better manage their cash flow and reduce the impact of late payments or other financial issues.

- Reduce lead times: By working with suppliers to improve lead times for raw materials and other inputs, companies can reduce inventory costs, improve production planning, and increase efficiency.

- Improve product quality: By developing close relationships with suppliers, companies can work together to improve product quality and reduce defects, reducing the costs associated with rework or product recalls.

- Streamline supply chain operations: By working closely with suppliers to improve supply chain operations, companies can reduce costs associated with logistics, warehousing, and transportation.

5 Tips to Save Money in Food Manufacturing

As a food manufacturer, saving money is essential to maintain profitability and remain competitive in the market. Here are five tips to help you save money in food manufacturing:

Optimize Your Ingredient Sourcing

Optimizing your ingredient sourcing is a crucial tip to save money in food manufacturing. By finding cost-effective ingredients without sacrificing quality, you can reduce your production costs and increase your bottom line.

To optimize your ingredient sourcing, start by analyzing your current suppliers and their pricing. Consider negotiating contracts with suppliers to secure better pricing, especially if you buy ingredients in bulk.

Additionally, you can look for alternative ingredients that are more cost-effective. This may involve working with your research and development team to find substitutes for more expensive ingredients that don't compromise the quality or taste of your products. For example, you might substitute a more expensive type of cheese with a less expensive variety that has similar flavor and texture.

It's also important to ensure that you're not overstocking on ingredients, as this can lead to waste and increased costs. Implement an inventory management system to track your ingredient usage and ordering patterns, and set up reorder points to ensure that you're only ordering what you need.

Minimize Waste

Minimizing waste is another important tip to save money in food manufacturing. Food waste is not only costly, but it also has a negative impact on the environment. Here are a few ways to minimize waste in food manufacturing:

- Implement a lean manufacturing approach: Lean manufacturing is a systematic approach to reducing waste and improving efficiency. By eliminating unnecessary steps in your production process, you can reduce waste, improve quality, and lower costs.

- Optimize inventory management: Keeping track of your inventory levels and usage can help you reduce waste. Analyze your inventory patterns to identify areas where you might be over-ordering or overstocking. Set up reorder points and adjust your ordering frequency to ensure that you're only ordering what you need.

- Reduce overproduction: Overproduction can lead to food waste and excess costs. Analyze your production levels to ensure that you're only producing what you need. You can also implement strategies such as just-in-time production to reduce overproduction.

- Implement recycling and composting programs: Recycling and composting can help you reduce waste and improve sustainability. Identify recyclable materials such as cardboard, plastic, and glass, and set up a recycling program. You can also compost food waste to create nutrient-rich soil for your garden or sell it to a local composting facility.

Improve Energy Efficiency

Improving energy efficiency is an essential tip to save money in food manufacturing. Energy usage is a significant expense for food manufacturers, but there are several strategies you can implement to reduce your energy costs:

- Upgrade to energy-efficient equipment: Energy-efficient equipment, such as refrigerators, ovens, and lighting systems, can significantly reduce your energy usage. Look for equipment that has been certified by organizations such as Energy Star to ensure that you're purchasing the most efficient products.

- Reduce water usage: Water usage is another significant expense for food manufacturers. Implement strategies such as reducing water pressure, repairing leaks promptly, and using recycled water for non-food-related tasks to reduce your water usage.

- Optimize lighting systems: Lighting is another significant source of energy usage in food manufacturing facilities. Switch to LED lighting systems, which are more energy-efficient than traditional lighting systems. Additionally, consider installing motion sensors to turn lights off when a room is not in use.

- Implement energy management systems: An energy management system can help you track your energy usage and identify areas where you can reduce your consumption. You can also use this system to set energy usage targets and monitor your progress towards meeting them.

These strategies require an initial investment, but the long-term savings can be significant. Moreover, improving energy efficiency can also help you reduce your carbon footprint and contribute to a healthier planet.

Streamline Production

Streamlining production is a crucial tip to save money in food manufacturing. The more efficient your production process is, the lower your costs will be. Here are a few ways to streamline your production process:

- Implement a lean manufacturing approach: Lean manufacturing is a systematic approach to reducing waste and improving efficiency. By eliminating unnecessary steps in your production process, you can reduce waste, improve quality, and lower costs.

- Automate processes: Automation can help you streamline your production process and reduce labor costs. Consider automating tasks such as packaging, labeling, and filling.

- Optimize your production schedule: Analyze your production schedule to ensure that you're producing the right products at the right times. Consider implementing a just-in-time production approach to reduce overproduction and excess inventory.

- Standardize processes: Standardizing your production processes can help you improve efficiency and reduce errors. Create standard operating procedures for each task in your production process, and train your employees to follow them consistently.

- Improve communication: Communication is crucial in food manufacturing. Ensure that all departments are communicating effectively and that everyone is on the same page regarding production goals and timelines.

By streamlining your production process, you can reduce costs, improve quality, and increase efficiency. These strategies require careful planning and implementation, but the benefits are well worth the effort. By streamlining your production process, you can create a more sustainable and profitable food manufacturing operation.

Invest in Technology

Investing in technology is another important tip to save money in food manufacturing. Technology can help you automate processes, improve efficiency, and reduce waste. Here are a few ways to invest in technology to save money in food manufacturing:

- Implement a food manufacturing management system: A food manufacturing management system can help you track inventory levels, manage production schedules, and monitor quality control. This system can help you reduce waste, optimize production, and improve efficiency.

- Use data analytics: Data analytics can help you identify areas where you can improve efficiency and reduce costs. Analyze your production data to identify patterns and trends that can help you optimize your production process.

- Use predictive maintenance: Predictive maintenance technology can help you identify potential issues with your equipment before they become a problem. By detecting issues early, you can prevent costly downtime and reduce maintenance costs.

- Implement automation: Automation technology, such as robotics and conveyor systems, can help you automate tasks such as packaging, labeling, and filling. By automating these tasks, you can reduce labor costs and improve efficiency.

- Use energy-efficient equipment: Energy-efficient equipment can significantly reduce your energy costs. Consider investing in energy-efficient refrigerators, ovens, and lighting systems to reduce your energy usage.

By implementing these tips, you can save money in food manufacturing without sacrificing quality or productivity. It requires a concerted effort to optimize sourcing, reduce waste, improve energy efficiency, streamline production, and invest in technology. However, the payoff is well worth the effort, allowing you to maintain profitability and remain competitive in the market.

How can MRP and ERP systems assist in Saving Cost in Food Manufacturing Industry?

MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems can assist in saving costs in the food manufacturing industry in several ways:

- Improved Inventory Management: MRP and ERP systems can help in maintaining optimum inventory levels, ensuring that raw materials and finished goods are always available when needed, and reducing inventory carrying costs.

- Streamlined Production Processes: MRP and ERP systems can assist in streamlining production processes, minimizing waste, and maximizing efficiency. This can lead to reduced production costs and increased productivity.

- Better Demand Planning: MRP and ERP systems can help in forecasting demand for products, enabling manufacturers to plan production and raw material procurement more accurately. This can prevent overproduction, minimize inventory carrying costs, and reduce the risk of stockouts.

- Efficient Procurement: MRP and ERP systems can automate the procurement process, helping manufacturers to identify the best suppliers, negotiate better prices, and reduce lead times. This can lead to lower procurement costs and improved supplier relationships.

- Enhanced Quality Control: MRP and ERP systems can help in ensuring that quality standards are met, reducing the risk of product recalls, and avoiding the costs associated with defective products.

Overall, the use of MRP and ERP systems in the food manufacturing industry can lead to significant cost savings, improved efficiency, and better customer service.

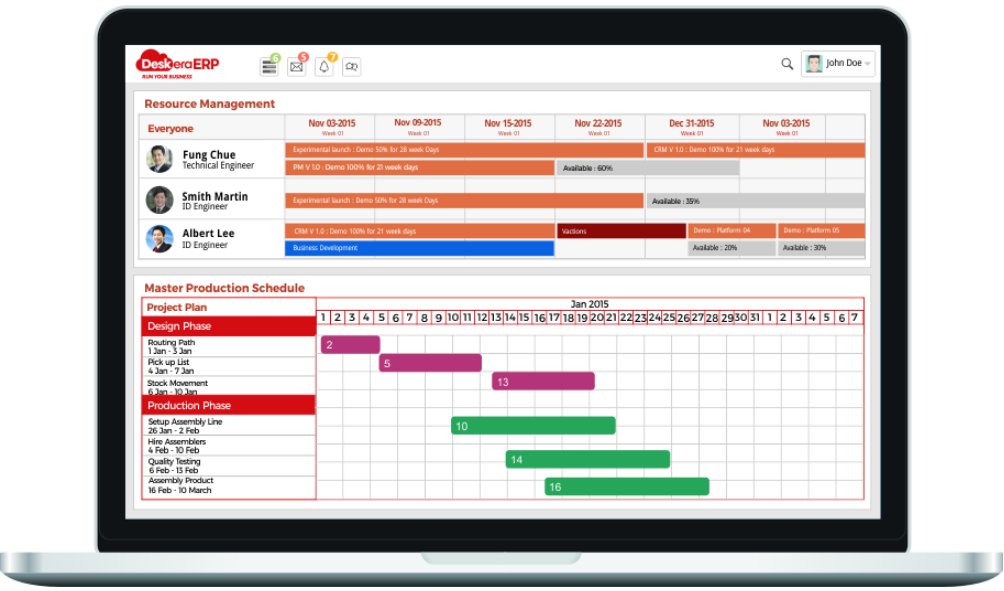

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Conduct a thorough analysis of your current budget and identify areas where you can cut costs without compromising quality or safety.

- Invest in technology and automation to streamline your production processes and reduce labor costs.

- Leverage economies of scale by purchasing raw materials in bulk and negotiating favorable pricing with suppliers.

- Implement a just-in-time (JIT) inventory system to minimize waste and reduce storage costs.

- Optimize your production schedule to maximize throughput and minimize downtime.

- Implement a comprehensive quality control program to ensure that your products meet or exceed regulatory and customer requirements.

- Develop a culture of continuous improvement and encourage employee engagement in cost-saving initiatives.

- Monitor key performance indicators (KPIs) such as production costs, inventory turnover, and yield to identify areas for improvement.

- Collaborate with your supply chain partners to identify opportunities for cost savings and efficiency gains.

- Stay up-to-date with industry trends and best practices to ensure that you are maximizing

Related Articles