A well-run lean warehouse can reduce total inventory costs by up to 40%.

Lean warehouse management helps companies reduce costs by increasing efficiency, reducing errors and improving customer satisfaction. It helps reduce inventory costs, improve order accuracy and eliminate waste.

It also provides a more accurate inventory control system to ensure the right product is delivered to the right customer at the right time.

Additionally, lean warehouse management provides better visibility into warehouse operations, allowing for quicker decision-making. This helps to reduce lead times and increase customer satisfaction by improving service levels. Moreover, lean warehouse management helps companies improve their bottom line by reducing costs associated with storing, picking and shipping products.

This article helps us learn the basics of lean warehousing and how it can help businesses.

- What is Lean Warehousing?

- Benefits of Lean Warehousing

- How are Lean Manufacturing and Lean Warehousing Related?

- How can Lean Warehousing Increase Efficiency?

- Lean Warehousing Principles

- Best Practices for Lean Warehousing

- How can Lean Warehousing help Manufacturers?

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What is Lean Warehousing?

Lean warehousing is a type of warehouse management system that emphasizes efficiency and eliminating waste. The goal of lean warehousing is to reduce costs, streamline processes, and increase customer satisfaction.

It is based on the lean manufacturing principles of eliminating waste, reducing inventory levels, and improving operational efficiency. Lean warehousing typically incorporates technologies such as automated storage and retrieval systems (AS/RS), warehouse control systems (WCS), and warehouse management systems (WMS).

Key principles of lean warehousing include the following:

- Minimizing waste in warehouse processes

- Reducing or eliminating unnecessary inventory

- Improving operational efficiency

- Ensuring accuracy and quality of data

- Improving customer satisfaction

Benefits of Lean Warehousing

Warehouse management is important because it is responsible for the efficient flow of products, goods, and services within a warehouse and its surrounding environment. This includes the receipt, storage, retrieval, and distribution of products and materials. Warehouse management ensures that goods are stored and moved in an efficient manner. Also, organizations can be sure that inventory levels are maintained at optimal levels.

Let’s look at the benefits of lean warehousing here:

- Improved Efficiency: Lean warehousing focuses on eliminating waste and improving the efficiency of processes. This helps to reduce costs and improve customer service levels.

- Better Productivity: Lean warehousing improves productivity by streamlining processes and reducing the time it takes to move products from point A to point B.

- Reduced Inventory: Lean warehousing helps to reduce inventory levels by ensuring that only the necessary items are stocked, eliminating the need to store excess materials.

- Enhanced Quality: Lean warehousing helps to reduce defects and improve quality by ensuring that processes are properly monitored and tracked.

- More Agility: Lean warehousing helps to increase the flexibility of the supply chain by allowing for faster response times and more efficient management of inventory levels.

- Improved Safety: Lean warehousing helps to reduce safety risks by eliminating unnecessary handling of materials and improving process safety.

- Eliminate Waste: Lean warehousing can eliminate waste by reducing the number of SKUs stored in the warehouse, using automated technology to track inventory more efficiently, and utilizing barcoding and RFID technology to reduce manual data entry.

How are Lean Manufacturing and Lean Warehousing Related?

Lean manufacturing and lean warehousing are related in that they both focus on streamlining processes and reducing waste. In lean manufacturing, this is achieved through the use of lean principles such as the following:

- 5S System

- Kaizen

- Value Stream Mapping

Lean warehousing, on the other hand, looks to reduce costs and improve efficiency by utilizing lean principles such as Just in Time (JIT), Kanban, and Heijunka.

Both lean manufacturing and lean warehousing strive to reduce waste and improve efficiency, but with slightly different approaches.

Understanding Lean Manufacturing

Lean manufacturing is a production system that is focused on eliminating waste, increasing efficiency, and reducing costs. It is based on the principles of the Toyota Production System, which is also known as the "Just in Time" production system.

Lean manufacturing emphasizes the continuous improvement of processes, reducing inventories, improving quality, and creating a culture of continuous improvement. It also involves identifying and eliminating sources of waste, such as overproduction and unnecessary motion.

How can Lean Warehousing Increase Efficiency?

We have spoken in detail about the lean warehousing process. We have also been mentioning that it improves efficiency. This section explains to us the route lean warehousing takes to achieve efficiency.

- Automate Warehouse Processes: Automating warehouse processes can help increase efficiency by reducing manual labor, streamlining workflows and eliminating data entry errors. Automated systems can also help reduce labor-intensive tasks such as picking and packing by using robots or automated carts.

- Implement a Warehouse Management System (WMS): A warehouse management system is a software system that helps companies manage their warehouse operations and optimize inventory levels. A WMS can help increase efficiency by tracking inventory, monitoring warehouse operations, and automating processes.

- Use Lean Practices: Lean practices can help streamline processes and reduce waste in the warehouse. Lean practices such as 5S, Kaizen and Kanban can help improve efficiency by reducing cycle times and improving flow.

- Utilize Technology: Technology can help increase efficiency in the warehouse by streamlining processes, reducing errors and eliminating manual labor. Technologies such as automated conveyors, voice picking and RFID tracking can help increase accuracy, reduce cycle times and improve throughput.

- Optimize Space Utilization: Optimizing the use of space can help increase efficiency by reducing clutter and improving organization. It can also help reduce the labor needed to move and store items in the warehouse. It can also reduce the need for additional storage space.

Lean Warehousing Principles

Lean warehousing can be summarized with a basic premise which is given as "just enough to get the job done." Inventories should arrive exactly before they need to be transported out and in sufficient numbers to cover any losses due to damage in transportation.

Handling should be kept to a minimum, and staff and management should look for methods to increase efficiency at every stage of the process. In this sense, lean warehousing methods are a philosophy as well as a management strategy, and they provide a great deal of flexibility in implementation.

The 5S organization concept, which can be applied to practically any facility, is an excellent place to start when implementing lean in the warehouse. A Japanese corporation pioneered the "5S" principles, which aim to boost warehouse productivity.

The letters "5S" stand for "seiri," "seiton," "seiso," "seiketsu," and "shitsuke" in Japanese. Sort, streamline, shine, standardize, and sustain are the English equivalents.

Sort

The most critical step in introducing lean methods to the warehouse is arranging it, and not just physically. You can break down warehouse operations by inventory and task type by obtaining a broad, bird's-eye perspective of them. The key to lean warehouse procedures is to decrease the number of stages in these tasks to the absolute bare minimum.

We can take an example of a distribution center. It may keep equivalent commodities handled in the same manner in various locations since they come from different manufacturers.

Consolidating these things in a single place would cut storage and retrieval times while also maximizing warehouse space.

Streamline

After you've reduced the number of warehouse operations required for success, you can arrange warehouse inventory, storage, and equipment so that each duty takes the least amount of time to accomplish. When you locate distinct places where you may condense, arrange them in such a way that all of your processes can be maximized.

Placement of heavy or delicate objects closer to loading docks or in locations where they require the least amount of movement to reach the area from which they are shipped is an example of this.

Reducing handling and procedures for various operations can allow you and your staff to do more each day. It may even allow you to hire fewer people.

Shine and Clean

Shine refers to the care and maintenance that goes into running a lean warehouse. You won't be able to work at your most efficient capacity if you don't keep your warehouse clean and maintained. Creating a maintenance and cleaning reporting routine is the best approach to maximize the shine of your warehouse operations.

Plan for large all-team quarterly clean-ups as well as weekly or monthly smaller clean-ups. This way, you can ensure all systems are in working order and your facility is constantly clean.

Standardize Processes

The goal of standardization is to create uniform systems and training so that all of your staff are aware of all of the processes. Communication and consistency throughout warehouse operations will assist your staff in completing duties more efficiently.

Regular training and an in-depth onboarding procedure for new workers are the greatest ways to ensure that correct standardized processes are in place. You won't be able to ensure that every process is known by every employee unless you educate them about it.

Warehouses must comply with numerous paperwork, labeling, and packing standards. To maximize a lean warehouse, keep everything standardized.

Sustain

To maintain your lean warehousing processes, you must sustain all of these distinct practices. Continuously evaluate each of these five criteria to ensure that your warehouse is as efficient and successful as possible.

Continuous enhancement of your lean warehousing techniques is required. This becomes significant for the growing and scaling companies.

The 5s system isn't always as comprehensive as some warehouses require in their lean warehouse management plan. However, it is an excellent beginning point for all warehouses, and these methods are applicable to a wide range of organizations. It is critical to maintain a lean and focused strategy in order to accomplish effective work, keep team members productive, and maximize revenue.

Challenge with Lean Warehousing Principles

The challenge in applying lean warehousing principles is that each supply chain and facility within those supply channels is unique. Not every business would be able to respond in the same manner. The principles of lean warehousing should be adjusted to each site and each process within that location.

Best Practices for Lean Warehousing

If you wish to attain great outcomes with lean warehousing, you must implement the best practices for the same. Let’s walk through some of the significant best practices you can follow:

Utilize Lean Tools

Lean tools such as 5S, Kaizen, and Value Stream Mapping can be used to identify and eliminate waste in the warehouse. These tools will help you to identify inefficiencies and take action to improve processes.

Implement Automation

Automation can be used to streamline processes and reduce the need for manual labor. Automated systems can be used to reduce the time and energy required for tasks such as order picking, packing, and shipping.

Invest in Technology

Technology can help reduce the time and effort required for manual processes. Investing in warehouse management systems, automated picking systems, and other software and hardware solutions can help optimize warehouse operations.

Improve Space Utilization

Maximizing the use of space in the warehouse can help reduce costs and improve efficiency. Utilizing vertical space, optimizing aisle space, and implementing lean storage solutions can help to create a more efficient workspace.

Re-evaluate Inventory

Regularly evaluating inventory levels and storage solutions can help to reduce costs and optimize operations. Implementing a Just-In-Time inventory system can help to reduce the amount of inventory stored in the warehouse.

Monitor Performance

Continuous improvement is essential for lean warehousing operations. Monitoring performance metrics such as lead times and throughput can help to identify areas of improvement and optimize operations.

Optimize Order Fulfillment Processes

Optimizing order fulfillment processes is a best practice for Lean warehousing that involves streamlining the order fulfillment process to reduce time, costs, and manual labor. This includes reducing the number of steps required to complete the order, eliminating manual processes, automating tasks, and reducing the distance required to move inventory.

Optimizing the order fulfillment process can help reduce overall costs and improve customer satisfaction, as orders are fulfilled faster and more accurately. Additionally, it can help warehouse operators identify areas where they can improve efficiency, such as by introducing new technologies or rethinking the layout of the warehouse.

Implement Cross-Docking

Cross-docking is a best practice for lean warehousing that involves the direct transfer of goods from an incoming delivery to an outgoing shipment. This eliminates the need for warehousing, as goods are quickly and efficiently moved from one truck to another with minimal handling and processing.

Cross-docking lowers labor associated with the storage and handling of inventory, resulting in improved order fulfillment and customer service. It also allows for greater flexibility and responsiveness to customer demands and reduces the risk of product damage and obsolescence. Cross-docking also reduces the amount of space required for warehousing and improves the safety and security of goods.

Utilize Barcoding

Barcoding allows for the efficient tracking of inventory. Barcodes provide a quick, accurate way to identify, count, and track inventory, allowing for improved inventory accuracy, speed of movement, and reduced labor costs.

Barcoding also reduces the chances of errors and increases visibility into the supply chain, providing better customer service and ensuring customer satisfaction.

How can Lean Warehousing help Manufacturers?

Manufacturers can benefit from lean warehousing by lowering costs, increasing efficiency, and process improvements. Lean warehousing is a waste-reduction and efficiency-improvement system that involves reducing inventory, maximizing space utilization, and streamlining procedures.

This can help manufacturers conserve money on inventory expenditures, shorten the time it takes to process orders, and improve order fulfillment accuracy. Furthermore, lean warehousing can assist firms in minimizing their environmental impact by reducing waste and emissions connected with transportation and storage.

Conclusion

In conclusion, lean warehousing is a powerful tool for streamlining the warehouse operations and improving efficiency and profitability. It can help reduce costs, improve customer service and increase productivity.

By using lean warehousing techniques, businesses can reduce inventory costs and improve their overall performance. With careful planning and implementation of lean warehousing, businesses can see significant savings and improved customer satisfaction.

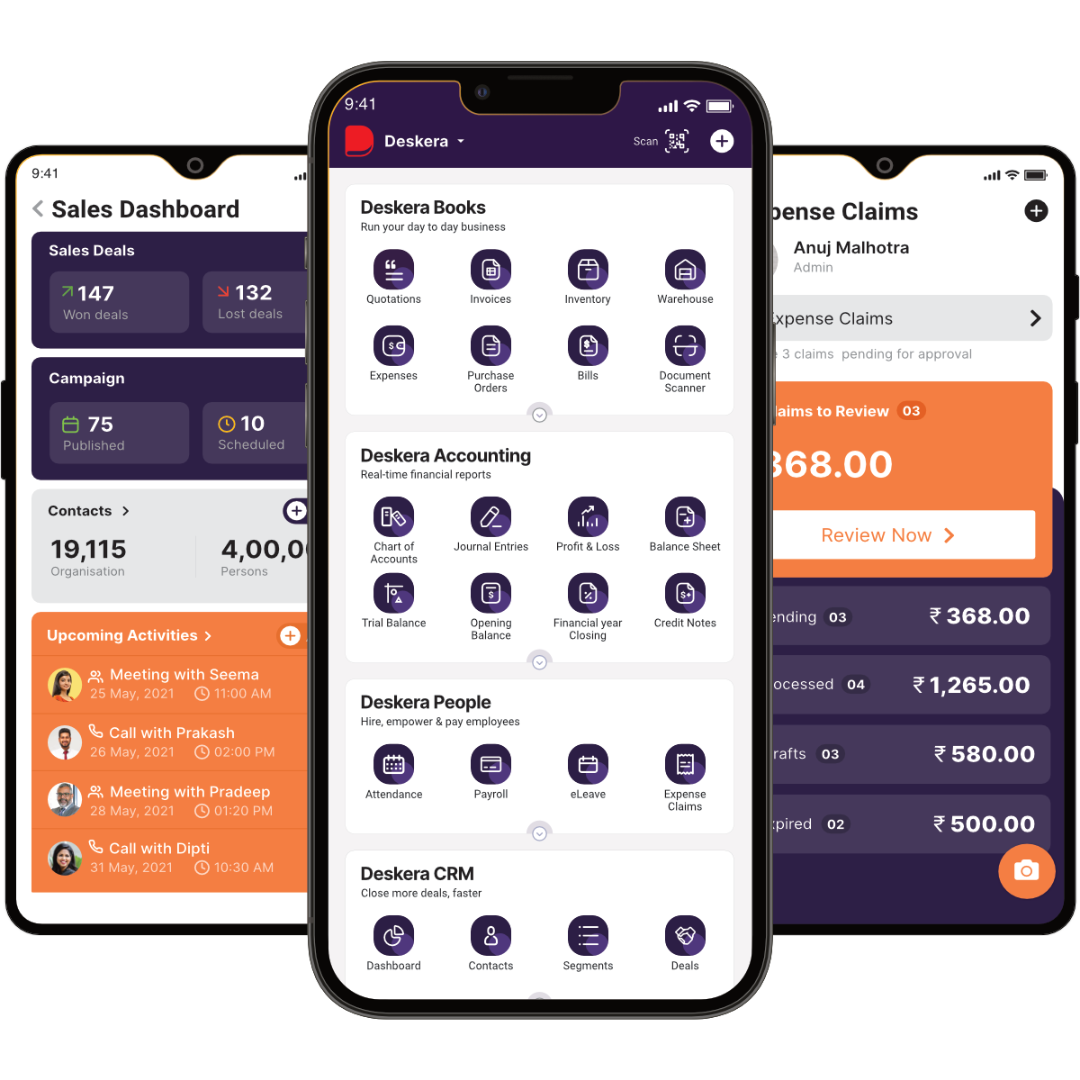

How can Deskera Help You?

A manufacturing business can profit from Deskera's cloud-based ERP and MRP systems in a variety of ways. It can assist you in visualizing and managing your inventory, production schedules, costs, and other resources.

The system performs the following primary functions:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials.

- Produce thorough reports

- Make your own dashboards

Deskera Books is accounting software designed to help small businesses manage their finances and accounts. It is a cloud-based solution that can be used from anywhere and at any time.

Deskera People provides employee onboarding, leave and shift management, time and attendance monitoring, payroll processing, benefits administration, and other features and capabilities. The solution supports firms in more efficiently managing their HR activities.

Deskera CRM is a full-service customer relationship management (CRM) solution that enables businesses of all sizes to better manage their client relationships. Contact management, marketing automation, sales and customer service tracking, and interaction with other company systems are all supported by the platform.

Key Takeaways

- Lean warehousing is a type of warehouse management system that emphasizes efficiency and eliminating waste.

- The goal of lean warehousing is to reduce costs, streamline processes, and increase customer satisfaction.

- Key principles of lean warehousing include minimizing waste in warehouse processes and reducing or eliminating unnecessary inventory.

- A Japanese corporation pioneered the "5S" principles, which aim to boost warehouse productivity. The letters "5S" stand for "seiri," "seiton," "seiso," "seiketsu," and "shitsuke" in Japanese. Sort, streamline, shine, standardize, and sustain are the English equivalents.

- Sort: The key to lean warehouse procedures is to decrease the number of stages in these tasks to the absolute bare minimum.

- Shine refers to the care and maintenance that goes into running a lean warehouse. You won't be able to work at your most efficient capacity if you don't keep your warehouse clean, up-to-date, and maintained.

- The goal of standardization is to create uniform systems and training so that all of your staff are aware of all of the processes.

- Final principle is sustaining. To maintain your lean warehousing processes, you must sustain all of these distinct practices.

Related Articles