Businesses are always seeking for methods to increase efficiency and cut costs in today's highly competitive manufacturing environment. Controlling inventories is one area with a lot of room for improvement.

Traditional inventory management methods are often manual and time-consuming and can lead to inaccurate data and stockouts. IoT (Internet of Things) technology can help to automate and streamline inventory management, providing businesses with real-time data and insights that can help them to optimize their inventory levels and improve their bottom line.

The IoT refers to the network of interconnected devices and sensors that collect and exchange data over the Internet. In the context of manufacturing, IoT-enabled devices can be embedded in various assets, such as machinery, vehicles, and inventory storage systems.

These devices capture and transmit real-time data, providing manufacturers with unprecedented insights into their inventory levels, location, condition, and movement.

According to a recent study by the Aberdeen Group, businesses that use IoT for inventory management can expect to see a 15% reduction in inventory costs and a 10% increase in inventory turns. The study also found that IoT can help businesses to improve their customer service by reducing the time it takes to fulfill orders and by increasing the accuracy of inventory data.

Whether you are a small or large manufacturing organization, understanding the transformative power of the IoT in inventory control can unlock significant benefits, including cost savings, improved customer satisfaction, and streamlined operations.

So, join us on this journey as we dive into the world of IoT-enabled inventory control and discover the endless possibilities for your manufacturing business.

Here is what we shall cover in this post:

- Introduction to IoT and Inventory Control

- Automated Inventory Replenishment With Iot Sensors

- Proactive Maintenance and Reduced Downtime

- Enhanced Traceability and Product Recalls

- IoT-Powered Predictive Analytics for Inventory Control

- Future Trends: Advancements in IoT for Inventory Control

- Overcoming Challenges and Implementing IoT Solutions

- How Deskera Can Assist You?

- Conclusion

- Key Takeaways

Introduction to IoT and Inventory Control

The Internet of Things (IoT) refers to a network of interconnected devices, objects, and systems that can collect, exchange, and analyze data. These devices are embedded with sensors, software, and connectivity capabilities, enabling them to communicate with each other and perform various tasks autonomously.

IoT technology enables the seamless integration of the physical and digital worlds, facilitating data-driven decision-making and automation.

Inventory control is the process of overseeing and managing the flow of goods and materials within an organization. It involves maintaining optimal inventory levels, minimizing stockouts and overstock situations, and ensuring the timely fulfillment of customer orders.

IoT technology can significantly enhance inventory control processes by providing real-time visibility, data analytics, and automation capabilities.

IoT can be used for inventory control in a variety of ways. Here are a few examples:

- Real-time tracking: IoT devices can be used to track the location and status of inventory in real-time. This information can be used to optimize inventory levels, prevent stockouts, and improve the efficiency of the supply chain.

- Predictive analytics: IoT data can be used to generate predictive analytics that can help businesses to forecast demand and optimize inventory levels. This can help to reduce costs and improve customer service.

- Automated replenishment: IoT devices can be used to trigger automated replenishment orders when inventory levels reach a certain threshold. This can help to prevent stockouts and improve the efficiency of the supply chain.

IoT-Enabled Real-Time Inventory Tracking

IoT-enabled real-time inventory tracking leverages the power of interconnected devices and sensors to collect and transmit data on inventory items in real time.

It involves the integration of IoT devices, such as RFID tags, barcodes, and sensors, with inventory management systems to provide accurate and up-to-date information on the location, status, and movement of inventory items throughout the supply chain.

Implementing IoT-enabled real-time inventory tracking brings numerous benefits to organizations:

- Enhanced Inventory Visibility: Real-time inventory tracking provides organizations with complete visibility into their inventory levels, locations, and status at any given moment. This visibility enables better decision-making, reduces stockouts, avoids overstock situations, and improves overall inventory management.

- Accurate Inventory Data: Traditional inventory tracking methods often rely on manual data entry or periodic audits, which are prone to errors and delays. IoT-enabled systems automate data capture, ensuring accurate and up-to-date inventory information. This accuracy leads to improved order accuracy, reduced discrepancies, and enhanced customer satisfaction.

- Improved Efficiency and Productivity: Real-time inventory tracking eliminates the need for manual counts and physical searches for inventory items. This streamlines inventory management processes, reduces manual labor, and allows employees to focus on more value-added tasks. The result is increased efficiency, productivity, and cost savings.

- Timely Replenishment and Demand Planning: With real-time visibility into inventory levels, organizations can proactively identify low-stock situations and trigger timely replenishment. This minimizes stockouts, reduces lost sales, and optimizes inventory levels based on demand fluctuations. Accurate demand planning leads to improved customer service and reduced carrying costs.

- Enhanced Supply Chain Collaboration: Real-time inventory tracking facilitates seamless collaboration among supply chain partners. With accurate and real-time inventory information, suppliers, manufacturers, distributors, and retailers can make data-driven decisions, synchronize production, optimize logistics, and improve overall supply chain efficiency.

How IoT-enabled Real-Time Inventory Tracking Works

IoT-enabled real-time inventory tracking systems use a variety of sensors, RFID tags, and cloud computing to track inventory in real time.

- Sensors: Sensors are devices that can measure physical quantities, such as temperature, pressure, and movement. Sensors can be used to track the location, movement, and condition of inventory items.

- RFID tags: RFID tags are small, electronic tags that can be attached to inventory items. RFID tags can be used to identify and track inventory items using radio waves.

- Cloud computing: Cloud computing is a way of storing and accessing data over the internet. Cloud computing can be used to store and process the data collected by sensors and RFID tags.

The data collected by sensors and RFID tags is sent to the cloud, where it is stored and processed. The processed data is then used to generate reports and alerts that can be used by businesses to improve inventory management.

Implementation Considerations for IoT-Enabled Real-Time Inventory Tracking

Infrastructure Requirements

Implementing IoT-enabled real-time inventory tracking necessitates a robust infrastructure to support the connectivity and data transmission of IoT devices. The following infrastructure requirements should be considered:

- Network Connectivity: A reliable and stable internet connection is essential for IoT devices to transmit data in real time. Organizations need to ensure that their network infrastructure can handle the increased data flow generated by IoT devices.

- Wireless Network: Many IoT devices rely on wireless connectivity, such as Wi-Fi, Bluetooth, or cellular networks, to communicate and transmit data. Organizations should assess their existing wireless infrastructure and ensure it can support the connectivity needs of IoT devices.

- Data Storage and Processing: Real-time inventory tracking generates a vast amount of data. Organizations should consider their data storage and processing capabilities to accommodate the increased volume of data. Cloud-based solutions or on-premises infrastructure may be required to handle the data storage and processing requirements.

Device Selection and Integration

Choosing the right IoT devices and integrating them into existing inventory management systems is crucial for successful implementation. Consider the following factors:

- Device Functionality: Different IoT devices, such as RFID tags, barcodes, and sensors, offer distinct functionalities. Organizations should carefully evaluate their specific requirements and select the devices that best suit their needs. For example, RFID tags provide real-time tracking and location data, while sensors can monitor environmental conditions or product quality.

- Device Compatibility: Organizations should ensure that the chosen IoT devices are compatible with their existing inventory management systems. Seamless integration allows for the smooth flow of data between IoT devices and the inventory management system, enabling real-time tracking and reporting.

- Device Placement and Installation: The physical placement of IoT devices is critical to ensure accurate data collection. Devices should be strategically positioned to capture relevant data, such as scanning points for barcodes or RFID readers at key locations. Installation procedures should be followed to ensure proper functionality and reliability.

- Device Maintenance and Support: Organizations should consider the maintenance and support requirements of IoT devices. This includes firmware updates, battery replacements, and troubleshooting procedures. Adequate support channels, including vendor support or internal resources, should be established to address any device-related issues promptly.

Data Security and Privacy

Real-time inventory tracking involves the collection and transmission of sensitive data. To ensure data security and privacy, organizations should consider the following:

- Data Encryption: Data transmitted between IoT devices and inventory management systems should be encrypted to protect it from unauthorized access. Secure protocols, such as HTTPS or MQTT with Transport Layer Security (TLS), should be implemented to safeguard data during transmission.

- Access Control: Access to IoT devices and the inventory management system should be restricted to authorized personnel. Role-based access control mechanisms should be implemented to ensure that only authorized individuals can access and manipulate the data.

- Data Privacy Compliance: Organizations must comply with applicable data privacy regulations, such as the General Data Protection Regulation (GDPR) or the California Consumer Privacy Act (CCPA). They should establish procedures and policies to protect personal data and ensure compliance with the relevant legal requirements.

Automated Inventory Replenishment With Iot Sensors

IoT sensors provide a solution to these problems. IoT sensors can be placed on shelves or in containers to track inventory levels in real-time. This data can be transmitted to a central system, where it can be used to forecast demand and automatically trigger replenishment orders.

Implementing automated inventory replenishment with IoT sensors offers several significant benefits for businesses. Let's explore some of the key advantages:

- Real-Time Inventory Visibility: IoT sensors provide real-time visibility into inventory levels, locations, and conditions. This real-time data allows businesses to monitor inventory more accurately and proactively, ensuring that stock levels are always optimized.

- Elimination of Manual Processes: Automated inventory replenishment reduces the reliance on manual processes such as physical counts and manual data entry. This eliminates the potential for human errors, increases efficiency, and saves time and resources that can be allocated to other critical tasks.

- Timely Replenishment: With IoT sensors, businesses can set up automatic reorder triggers based on predefined thresholds. When inventory levels reach a certain point, the sensors send signals to the inventory management system, initiating the reorder process. This ensures that replenishment orders are placed promptly, reducing the risk of stockouts and ensuring continuous availability of products.

- Improved Accuracy: Manual inventory management processes are susceptible to errors, including data entry mistakes, miscounts, and discrepancies. IoT sensors provide accurate and reliable data, reducing the likelihood of errors and enabling businesses to make more informed decisions based on accurate information.

- Cost Reduction: Automated inventory replenishment helps businesses avoid overstocking and stockouts, minimizing the carrying costs of excess inventory and lost sales due to stockouts. By maintaining optimal inventory levels, businesses can reduce storage costs, minimize the risk of obsolescence, and improve overall cost-effectiveness.

IoT-Enabled Demand Forecasting and Planning

Demand forecasting and planning play a crucial role in ensuring the efficient and effective management of inventory and supply chains. Accurate demand forecasts enable businesses to optimize inventory levels, minimize stockouts, and meet customer demands on time.

Traditional demand forecasting methods often rely on historical sales data and statistical models, which may not capture real-time market dynamics and customer preferences. However, with the emergence of Internet of Things (IoT) technology, businesses now have access to a wealth of real-time data that can significantly enhance demand forecasting and planning processes.

For example, businesses can use IoT data to track:

- Product usage: This data can be used to identify trends in product usage, which can help businesses to forecast future demand.

- Customer location: This data can be used to identify customer preferences, which can help businesses to target their marketing efforts more effectively.

- Customer feedback: This data can be used to identify customer satisfaction levels, which can help businesses to improve their products and services.

Here are some key components of IoT-enabled demand forecasting and planning:

- Connected Devices: IoT relies on connected devices that collect data from the physical environment. These devices can include sensors, beacons, smart shelves, RFID tags, and other IoT-enabled devices that capture information on customer behavior, product movement, and environmental conditions.

- Data Analytics: The data collected from IoT devices is processed and analyzed using advanced analytics techniques. Machine learning algorithms, predictive modeling, and data mining are used to extract insights, identify patterns, and generate accurate demand forecasts.

- Real-Time Data: Unlike traditional demand forecasting methods that rely on historical data, IoT-enabled demand forecasting leverages real-time data. Real-time data provides businesses with up-to-date information on market trends, customer preferences, and inventory levels, enabling them to make more accurate and timely decisions.

- Integration with Supply Chain Systems: IoT-enabled demand forecasting and planning systems are integrated with other supply chain management systems, such as inventory management, procurement, and production planning. This integration ensures that demand forecasts are effectively translated into actionable plans across the supply chain.

Here are some additional tips for businesses that are considering implementing IoT-enabled demand forecasting and planning:

- Start small: Don't try to implement this technology all at once. Start with a small pilot project and learn from your experience before rolling it out to the rest of your business.

- Get buy-in from stakeholders: This technology will require changes to the way your business operates. Get buy-in from all stakeholders, including employees, customers, and suppliers.

- Invest in the right tools and processes: IoT data can be complex and difficult to manage. Invest in the right tools and processes to collect, store, and analyze IoT data.

- Protect your data: IoT data can be sensitive and confidential. Take steps to protect the security and privacy of IoT data.

Proactive Maintenance and Reduced Downtime

Equipment failure and unexpected downtime can have significant financial implications, disrupt production schedules, and impact customer satisfaction. Traditional maintenance practices often follow a reactive approach, addressing issues after they occur.

However, with the emergence of Internet of Things (IoT) technology, organizations can now adopt a proactive maintenance approach, leveraging real-time data and predictive analytics to identify potential equipment failures and minimize downtime.

Proactive maintenance, also known as predictive maintenance or condition-based maintenance, focuses on anticipating and preventing equipment failures before they occur.

This approach relies on real-time data collection, advanced analytics, and machine learning algorithms to monitor equipment health, detect anomalies, and predict potential failures. IoT technology plays a crucial role in enabling proactive maintenance by connecting sensors, devices, and equipment to collect and analyze data.

Here are some key components of proactive maintenance with IoT:

- Data Collection and Analysis: The data collected by IoT sensors is processed and analyzed using advanced analytics techniques. Machine learning algorithms and predictive models are employed to detect patterns, identify anomalies, and predict potential equipment failures.

- Predictive Analytics: By analyzing historical data and patterns, IoT-powered predictive analytics can forecast the remaining useful life of equipment, estimate failure probabilities, and recommend maintenance actions. This enables organizations to schedule maintenance activities proactively, reducing unplanned downtime.

- Integration with Maintenance Systems: IoT-enabled proactive maintenance systems are integrated with maintenance management software, enterprise asset management systems, and other operational systems. This integration ensures seamless data flow, enables automated work order generation, and facilitates efficient scheduling of maintenance activities.

Downtime is costly for businesses. It can lead to lost sales, production delays, and customer dissatisfaction. IoT can help us to reduce downtime by identifying potential problems early and taking corrective action before they cause a breakdown.

The Internet of Things (IoT) has the potential to revolutionize the way we maintain our equipment. By connecting devices to the internet, we can collect real-time data about their performance. This data can be used to identify potential problems before they cause downtime.

How IoT Can Improve Maintenance

Traditionally, maintenance has been a reactive process. We wait for something to break down before we fix it. This can lead to costly repairs and lost productivity. IoT can help us to move to a more proactive approach to maintenance.

By collecting data about equipment performance, we can identify potential problems before they cause downtime. This gives us time to take corrective action before the problem becomes a major issue.

Downtime is costly for businesses. It can lead to lost sales, production delays, and customer dissatisfaction. IoT can help us to reduce downtime by identifying potential problems early and taking corrective action before they cause a breakdown.

There are several benefits to using IoT for proactive maintenance. These benefits include:

- Reduced downtime: IoT can help to reduce downtime by identifying potential problems early and taking corrective action before they cause a breakdown.

- Increased uptime: IoT can help to increase uptime by ensuring that equipment is properly maintained and that potential problems are identified and addressed before they cause a breakdown.

- Improved asset performance: IoT can help to improve asset performance by ensuring that equipment is properly maintained and that potential problems are identified and addressed before they cause a breakdown.

- Reduced costs: IoT can help to reduce costs by reducing downtime, increasing uptime, and improving asset performance.

Streamlined Supply Chain Management With IoT Data

The Internet of Things (IoT) is revolutionizing supply chain management. By connecting physical devices to the internet, IoT can provide real-time data and insights that can help businesses to improve efficiency, reduce costs, and increase customer satisfaction.

Here are some key areas where IoT plays a crucial role in supply chain management:

- Tracking and Traceability: IoT sensors and devices can be deployed to track and monitor goods throughout the supply chain. By attaching sensors to products, packages, or containers, organizations can obtain real-time information on location, temperature, humidity, and other relevant parameters. This enables better inventory management, reduces the risk of lost or damaged goods and enhances supply chain traceability.

- Inventory Management: IoT devices can be used to monitor inventory levels, track stock movements, and automatically trigger reordering when stock levels reach predefined thresholds. This real-time visibility into inventory helps organizations optimize their stock levels, reduce stockouts, and improve overall inventory management efficiency.

- Demand Sensing and Forecasting: IoT data can provide valuable insights into customer behavior and demand patterns. By analyzing data from connected devices, social media platforms, and other sources, organizations can accurately sense demand fluctuations, forecast future demand, and align their production and supply chain activities accordingly.

- Condition Monitoring: IoT sensors can monitor the condition and performance of equipment, vehicles, and infrastructure within the supply chain. This enables proactive maintenance, reduces equipment downtime, and improves overall operational efficiency. By detecting anomalies and predicting potential failures, organizations can schedule maintenance activities, optimize asset utilization, and reduce costly disruptions.

- Supply Chain Visibility and Collaboration: IoT facilitates real-time data sharing and collaboration among supply chain partners. With interconnected devices and systems, organizations can share information on inventory levels, production status, logistics updates, and other relevant data. This enhances visibility, promotes transparency, and enables effective collaboration between suppliers, manufacturers, distributors, and retailers.

Here are some specific examples of how IoT is being used to streamline supply chain management:

- Walmart: Walmart is using IoT to track the movement of goods throughout its supply chain. This data is used to improve inventory management, optimize transportation routes, and prevent fraud.

- UPS: UPS is using IoT to track the movement of its packages. This data is used to improve customer service, reduce delivery times, and prevent lost packages.

- Amazon: Amazon is using IoT to track the movement of its products in its warehouses. This data is used to improve picking and packing operations, reduce warehouse space, and increase efficiency.

These are just a few examples of how IoT is being used to streamline supply chain management. As technology continues to evolve, we can expect to see even more innovative ways to use IoT to improve the efficiency and effectiveness of supply chains.

IoT has the potential to improve efficiency, reduce costs, improve customer service, increase agility, and increase sustainability. As technology continues to evolve, we can expect to see even more innovative ways to use IoT to improve the efficiency and effectiveness of supply chains.

Enhanced Traceability and Product Recalls

Product traceability and recall management are critical aspects of supply chain management, ensuring consumer safety, regulatory compliance, and brand reputation.

Traditionally, traceability and recall processes have been complex and time-consuming, often relying on manual record-keeping and batch identification methods. However, with the advent of Internet of Things (IoT) technology, organizations can leverage real-time data and connectivity to enhance traceability and streamline product recall processes.

Traceability refers to the ability to track and trace the movement of products and components throughout the supply chain. IoT technology plays a crucial role in enhancing traceability by providing real-time data on product location, condition, and other relevant parameters.

Here are some key areas where IoT contributes to enhanced traceability:

Product Identification: IoT sensors and devices can be used to attach unique identifiers, such as RFID tags or barcodes, to products and components. These identifiers can be scanned and tracked at various stages of the supply chain, providing real-time information on the location and movement of each item.

This level of visibility enables organizations to trace products from their origin to the end consumer.

Supply Chain Integration: IoT facilitates the seamless integration of supply chain partners by enabling data sharing and collaboration. With interconnected devices and systems, organizations can exchange information on product movements, quality inspections, and other relevant data.

This integration ensures transparency and accountability across the supply chain, enhancing traceability.

Blockchain Technology: IoT can be combined with blockchain technology to create an immutable and transparent record of product transactions. Blockchain provides a decentralized and secure platform for recording and verifying product-related data, ensuring its integrity and preventing tampering.

This technology enhances traceability by creating a trusted and auditable chain of custody for products.

Implementing IoT for enhanced traceability offers numerous benefits for organizations. Let's explore some of the key advantages:

- Improved Product Safety: IoT enables organizations to monitor and control product conditions throughout the supply chain. Real-time data on temperature, humidity, and other parameters help identify potential quality issues or deviations from safety standards. By proactively addressing these issues, organizations can ensure the safety and integrity of their products.

- Efficient Recall Management: In the event of a product recall, IoT technology simplifies and accelerates the recall process. With enhanced traceability, organizations can quickly identify the affected products, pinpoint their locations, and notify customers or retailers. This improves the speed and effectiveness of recall management, reducing potential risks and liabilities.

Here are some examples of how IoT is being used to improve traceability and product recalls:

- Nestlé: Nestlé is using IoT to track the movement of its coffee beans. This data is used to ensure that the beans are sourced from sustainable farms and that they are not contaminated.

- General Electric: General Electric is using IoT to track the movement of its medical devices. This data is used to identify potential problems with the devices and to initiate recalls quickly.

These are just a few examples of how IoT is being used to improve traceability and product recalls. As technology continues to evolve, we can expect to see even more innovative ways to use IoT to improve the safety and quality of products.

Optimized Inventory Storage and Space Utilization

Efficient inventory management is essential for the success of any organization. Properly storing and utilizing inventory space is crucial for reducing costs, improving productivity, and enhancing customer satisfaction.

With the advent of Internet of Things (IoT) technology, organizations now have the opportunity to optimize their inventory storage and space utilization processes.

Inventory management involves overseeing the storage, tracking, and control of goods throughout the supply chain. IoT technology plays a pivotal role in transforming traditional inventory management processes by providing real-time data, automation, and connectivity.

Here are some key areas where IoT contributes to optimized inventory storage and space utilization:

- Automated Inventory Replenishment: IoT-enabled inventory management systems can automatically trigger replenishment orders based on predefined rules and thresholds. When inventory levels reach a specified threshold, IoT devices can send alerts or generate purchase orders to ensure timely replenishment. This automation eliminates the need for manual intervention, reduces stockouts, and avoids overstocking, leading to optimal space utilization.

- Space Utilization Optimization: IoT technology enables organizations to optimize their use of storage space by providing insights into space utilization patterns. By deploying sensors and smart shelves, organizations can track the occupancy of storage areas and identify underutilized or inefficiently arranged spaces. This information allows organizations to reconfigure their storage layouts, implement better space allocation strategies, and maximize the use of available storage space.

- Condition Monitoring: IoT sensors can monitor environmental conditions, such as temperature, humidity, and light exposure, in storage areas. This information is crucial for preserving the quality and integrity of inventory, especially for goods that are sensitive to environmental factors. By continuously monitoring these conditions, organizations can detect and address any deviations that could impact the quality or shelf life of their inventory.

There are several benefits to using IoT for inventory storage and space utilization, including:

- Reduced space costs: IoT can help to reduce space costs by identifying areas where space is being underutilized and by optimizing the placement of inventory.

- Reduced labor costs: IoT can help to reduce labor costs by automating warehouse tasks.

- Improved accuracy: IoT can help to improve accuracy by providing real-time inventory data.

- Increased efficiency: IoT can help to increase efficiency by automating tasks and providing real-time data.

- Improved customer service: IoT can help to improve customer service by providing real-time inventory data and by automating tasks.

Here are some additional tips for optimizing inventory storage and space utilization with IoT:

- Use RFID tags: RFID tags can be attached to products, and sensors can be placed throughout the warehouse. This data can be collected and used to create a real-time inventory map. This map can be used to identify areas where space is being underutilized and to optimize the placement of inventory.

- Automate warehouse tasks: IoT devices can be used to automate warehouse tasks, such as picking and packing. This can free up employees to focus on other tasks, such as customer service and inventory management.

- Use data analytics: IoT data can be used to analyze trends and identify areas where there is a risk of problems. This information can be used to take preventive measures to avoid problems.

- Invest in the right technology: IoT technology is constantly evolving, so it is important to invest in the right technology for your needs. Make sure to work with a reputable vendor who can help you choose the right devices and software.

IoT-Powered Predictive Analytics for Inventory Control

In the era of digital transformation, organizations are leveraging advanced technologies to enhance their inventory control processes. One such technology that has revolutionized inventory management is the Internet of Things (IoT).

By combining IoT with predictive analytics, organizations can gain valuable insights into their inventory control operations, enabling them to make data-driven decisions and optimize their inventory levels.

IoT devices can be used to collect a variety of data on the movement of goods, including:

- Product location: IoT devices can track the location of products throughout the supply chain, from the factory to the customer. This data can be used to identify areas where inventory is being underutilized or where there is a risk of stockouts.

- Product condition: IoT devices can monitor the condition of products, such as temperature and humidity. This data can be used to identify products that are at risk of spoilage or damage.

- Product demand: IoT devices can collect data on customer demand for products. This data can be used to predict future demand and optimize inventory levels.

There are several benefits to using IoT-powered predictive analytics for inventory control, including:

- Reduced inventory costs: By predicting future demand, businesses can reduce the amount of inventory they need to carry. This can lead to significant savings in terms of both storage and carrying costs.

- Improved customer service: By ensuring that inventory levels are optimized, businesses can improve customer service by reducing stockouts and ensuring that customers can always get the products they need.

- Increased efficiency: By automating the inventory management process, businesses can increase efficiency and free up employees to focus on other tasks.

Here are some additional tips for using IoT-powered predictive analytics for inventory control:

- Invest in the right technology: IoT technology is constantly evolving, so it is important to invest in the right technology for your needs. Make sure to work with a reputable vendor who can help you choose the right devices and software.

- Collect the right data: Not all data is created equal. Make sure you are collecting the right data to support your inventory management goals.

- Get buy-in from stakeholders: IoT-powered predictive analytics can be a complex undertaking. Make sure you get buy-in from all stakeholders before you start.

Increased Operational Efficiency and Cost Savings

IoT can be used to improve operational efficiency and cost savings in a variety of industries, including manufacturing, healthcare, retail, and transportation.

Manufacturing

In manufacturing, IoT can be used to track the location of goods in real-time, monitor the performance of machines, and predict when maintenance is needed. This can help to improve production efficiency, reduce waste, and prevent costly downtime. For example, General Electric has used IoT to reduce the time it takes to repair locomotives by 50%.

Healthcare

In healthcare, IoT can be used to monitor patients' vital signs, track the location of medical equipment, and manage inventory. This can help to improve patient care, reduce costs, and prevent medical errors. For example, the Mayo Clinic has used IoT to reduce the number of infections in patients by 30%.

Retail

In retail, IoT can be used to track inventory levels, monitor customer behavior, and personalize shopping experiences. This can help to improve customer service, increase sales, and reduce theft. For example, Walmart has used IoT to increase sales by 10%.

Transportation

In transportation, IoT can be used to track the location of vehicles, monitor traffic conditions, and manage fleets. This can help to improve transportation efficiency, reduce traffic congestion, and improve safety. For example, UPS has used IoT to reduce the number of accidents by 50%.

IoT can also be used to improve operational efficiency and cost savings in a variety of other industries, including agriculture, energy, and government. As IoT continues to develop, it is likely to become even more widely used in a variety of industries.

- Energy Management: IoT devices can monitor and control energy consumption in buildings, factories, and other facilities. Sensors collect data on energy usage, lighting, temperature, and occupancy, allowing organizations to optimize energy consumption and reduce wastage. Automated systems can adjust energy usage based on occupancy patterns, control lighting based on natural light availability, and optimize heating and cooling systems. These energy-saving measures lead to lower utility bills and decreased overall energy costs.

- Energy Efficiency: IoT sensors and systems can monitor and optimize energy consumption in buildings, factories, and other facilities. By collecting data on energy usage patterns, businesses can identify areas of inefficiency and implement measures to reduce energy consumption. This leads to significant cost savings and sustainability benefits.

- Remote Operations and Maintenance: IoT enables businesses to remotely monitor and control operations and equipment. This eliminates the need for on-site personnel, reduces travel costs, and enables businesses to extend their operations globally without significant infrastructure investments. Remote monitoring and maintenance also reduce response times and minimize equipment downtime, leading to cost savings and improved customer satisfaction.

Improved Order Fulfillment and Customer Satisfaction

IoT technologies can greatly enhance warehouse management processes, leading to improved order fulfillment. RFID tags and sensors can be attached to inventory items, enabling automated tracking and monitoring. Warehouse personnel can easily locate and retrieve items using handheld devices or smart glasses that are connected to the IoT network.

This automation reduces the time spent searching for items, minimizes errors, and speeds up the picking and packing processes. Furthermore, IoT-enabled devices can optimize warehouse layout and storage, ensuring that popular items are easily accessible and reducing the need for excessive manual handling.

IoT-powered devices, such as GPS trackers and telematics systems, provide real-time visibility into the location and status of delivery vehicles. Businesses can track the movement of vehicles, monitor traffic conditions, and optimize routing based on real-time data.

This optimization leads to more efficient delivery routes, reduced transit times, and improved on-time delivery rates. Additionally, businesses can proactively communicate with customers, providing them with accurate information about the status and estimated arrival time of their orders. This transparency enhances customer satisfaction and allows customers to plan accordingly.

Future Trends: Advancements in IoT for Inventory Control

The Internet of Things (IoT) has revolutionized various industries, and inventory control is no exception. By leveraging IoT technologies, businesses can achieve real-time visibility, optimize inventory levels, streamline operations, and enhance overall supply chain management.

As IoT continues to evolve, new advancements and trends are shaping the future of IoT for inventory control.

Edge Computing and Edge Analytics

One of the emerging trends in IoT for inventory control is the adoption of edge computing and edge analytics. Edge computing involves processing data at the edge of the network, closer to the source of data generation, rather than relying on cloud-based processing.

This approach reduces latency and enables real-time decision-making. In the context of inventory control, edge computing allows businesses to process data from IoT devices located in warehouses, distribution centers, or retail stores, enabling faster response times and more efficient inventory management.

Additionally, edge analytics enables businesses to gain insights from the data at the edge, reducing the need for data transmission to the cloud for analysis. This trend is expected to enhance the speed and efficiency of inventory control processes.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are key technologies that are driving advancements in IoT for inventory control. AI and ML algorithms can analyze large volumes of IoT data to identify patterns, detect anomalies, and predict demand patterns.

By integrating AI and ML capabilities into inventory control systems, businesses can automate decision-making processes, optimize inventory levels, and improve demand forecasting accuracy. For example, AI algorithms can analyze historical sales data, customer behavior, and external factors to generate accurate demand forecasts and suggest optimal replenishment strategies.

As AI and ML technologies continue to advance, they will play a crucial role in improving the efficiency and effectiveness of inventory control processes. AI can be used to improve inventory control in many ways, including:

- Identifying potential problems

- Optimizing inventory levels

- Automating inventory tasks

Blockchain for Supply Chain Transparency

Blockchain technology has gained significant attention in recent years for its potential to improve supply chain transparency and traceability. In the context of inventory control, blockchain can provide an immutable record of every transaction and movement of goods throughout the supply chain.

This ensures transparency and trust among all stakeholders, including suppliers, manufacturers, distributors, and customers. By leveraging blockchain technology, businesses can verify the authenticity of products, track inventory movements in real-time, and detect and prevent counterfeit or unauthorized goods.

This trend will have a profound impact on inventory control by enhancing visibility, reducing the risk of fraud, and improving supply chain collaboration.

Enhanced Sensor Technologies

As IoT evolves, sensor technologies are becoming more advanced and sophisticated. New sensors are being developed that can capture a wide range of data, including temperature, humidity, light levels, pressure, and even chemical compositions.

These sensors provide more granular and accurate data, allowing businesses to monitor inventory conditions in real-time. For example, temperature sensors can ensure the integrity of perishable goods, while humidity sensors can prevent damage to sensitive products.

The advancements in sensor technologies will enable businesses to have better control over inventory quality and reduce the risk of product spoilage or damage.

Integration with Robotics and Automation

The integration of IoT with robotics and automation technologies is another significant trend in the field of inventory control. Robotic systems equipped with IoT sensors can perform tasks such as inventory counting, sorting, and picking with high precision and speed.

IoT-enabled robots can communicate with inventory control systems to provide real-time updates on stock levels, locations, and conditions. This integration enhances the accuracy and efficiency of inventory management processes, reduces human errors, and increases overall productivity.

With the advancement of robotics and automation technologies, businesses can expect to see increased adoption of IoT-enabled robotic systems for inventory control.

Overcoming Challenges and Implementing IoT Solutions

The Internet of Things (IoT) has emerged as a transformative technology with the potential to revolutionize various industries. By connecting devices, sensors, and systems, IoT enables the collection, analysis, and utilization of vast amounts of data for improved decision-making and operational efficiency.

However, implementing IoT solutions comes with its own set of challenges.

Connectivity and Infrastructure

One of the primary challenges in implementing IoT solutions is establishing reliable and secure connectivity across devices and systems. IoT devices require seamless communication and integration with each other and the backend infrastructure.

This requires robust network infrastructure, including high-speed internet connectivity and reliable wireless protocols. Businesses must invest in the necessary infrastructure to ensure uninterrupted connectivity for IoT devices.

Additionally, implementing strong security measures, such as encryption and authentication protocols, is crucial to protect IoT systems from cyber threats.

To overcome connectivity challenges, businesses can partner with reliable network providers, deploy a mix of wired and wireless technologies, and implement network redundancy measures to ensure continuous connectivity.

Furthermore, adopting industry standards and protocols, such as MQTT (Message Queuing Telemetry Transport) and CoAP (Constrained Application Protocol), can facilitate interoperability and seamless integration between IoT devices and systems.

Data Management and Analytics

IoT generates vast amounts of data, and managing and analyzing this data can be a daunting task. Businesses need to develop robust data management strategies to handle the volume, velocity, and variety of IoT data. This involves collecting, storing, and processing data efficiently and securely.

Data analytics plays a crucial role in extracting actionable insights from IoT data. Implementing advanced analytics techniques, such as machine learning and artificial intelligence, can help businesses uncover patterns, detect anomalies, and make informed decisions.

To address data management challenges, businesses can leverage cloud computing platforms that offer scalable storage and computing resources. Cloud-based IoT platforms provide the necessary infrastructure and tools to manage and analyze IoT data effectively.

Additionally, implementing data governance practices, such as data quality assurance and data lifecycle management, ensures the reliability and usability of IoT data.

Interoperability and Standardization

The IoT ecosystem comprises diverse devices, sensors, and systems from different manufacturers and vendors. Ensuring interoperability and seamless integration between these components is a significant challenge.

A lack of standardized protocols and communication frameworks can hinder the compatibility and interoperability of IoT devices and systems. This can result in fragmented IoT deployments and limited scalability.

To overcome interoperability challenges, businesses should prioritize the adoption of industry standards and protocols. Standards such as MQTT, CoAP, and OPC UA (Open Platform Communications Unified Architecture) facilitate interoperability and data exchange between devices and systems.

Collaborating with industry consortia and participating in standardization efforts can also help drive the development of common frameworks and protocols.

Scalability and Flexibility

As businesses expand their IoT deployments, scalability becomes a crucial consideration. IoT solutions need to accommodate the growing number of devices, sensors, and data streams. Scalability also includes the ability to handle increasing data volumes and processing requirements.

To achieve scalability and flexibility, businesses should design IoT architectures that are modular and scalable. This involves adopting scalable cloud-based platforms, utilizing containerization technologies, and leveraging microservices architecture.

By designing IoT systems with scalability and flexibility in mind, businesses can accommodate future growth and seamlessly adapt to changing needs.

Data Security and Privacy

Data security and privacy are critical concerns in IoT implementations. With the proliferation of connected devices and the exchange of sensitive data, ensuring the security of IoT networks and protecting user privacy becomes paramount.

IoT devices are vulnerable to cyber-attacks, and a breach in security can have severe consequences. To address these challenges, businesses should implement robust security measures such as encryption, authentication, access controls, and regular security audits.

They should also comply with data protection regulations and establish clear policies for data collection, storage, and sharing to safeguard user privacy.

How Deskera Can Assist You?

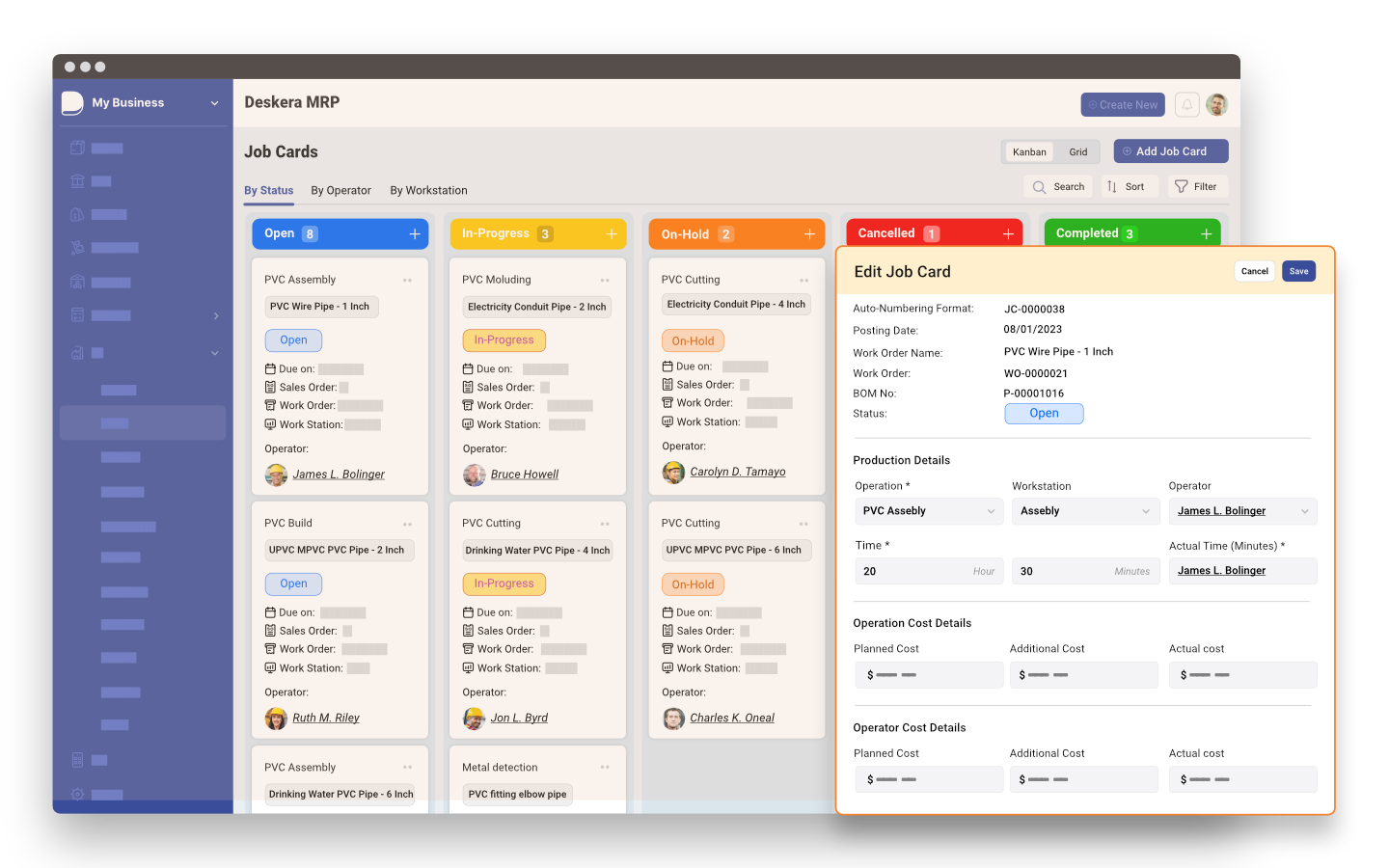

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Conclusion

The Internet of Things (IoT) has had a significant impact on inventory control in the manufacturing industry, revolutionizing the way inventory is monitored, managed, and optimized. With the ability to connect various devices and sensors, collect real-time data, and enable seamless communication between systems, the IoT has brought unprecedented visibility and efficiency to inventory control processes.

IoT technology also facilitates automation and process optimization in inventory control. By integrating IoT devices with inventory management systems, manufacturers can automate data collection, inventory counting, and reordering processes.

This automation reduces human error, streamlines operations, and enables real-time updates to inventory levels. It also enables automatic replenishment triggers based on predefined thresholds, ensuring optimal inventory levels at all times.

Integration with existing systems and infrastructure is another challenge in adopting IoT for inventory control. Compatibility issues, data integration complexities, and the need for system upgrades or replacements may arise.

Manufacturers must carefully plan and execute the integration process to minimize disruptions and ensure a smooth transition.

Key Takeaways

- IoT facilitates inventory accuracy and traceability through RFID tags and other tracking mechanisms, enhancing recall management, quality control, and supply chain transparency.

- Improved collaboration and communication between stakeholders are enabled by IoT, allowing manufacturers, suppliers, and distributors to synchronize efforts and reduce lead times.

- IoT integration with existing systems such as ERP and CRM ensures a unified view of inventory data and seamless information flow across different departments.

- Data security and privacy are critical considerations in IoT-enabled inventory control, requiring robust cybersecurity measures and compliance with regulations.

- The integration of IoT in inventory control may involve challenges such as data integration complexities and compatibility issues with existing infrastructure.

- Careful planning and execution are necessary for successful IoT implementation in inventory control, minimizing disruptions, and ensuring a smooth transition.

- IoT-powered inventory control helps manufacturers reduce costs, improve efficiency, and enhance customer satisfaction by providing accurate and timely inventory information.

- IoT-driven predictive analytics enable better demand forecasting, reducing stockouts and improving overall inventory management.

- Real-time monitoring and visibility offered by IoT in inventory control help manufacturers respond quickly to supply chain disruptions and make informed decisions.

- As IoT technology continues to evolve, its impact on inventory control in manufacturing will only grow, enabling manufacturers to optimize operations, reduce waste, and stay competitive in a rapidly changing market.

Related Articles