Do you want to know how the implementation of industrial machinery equipment ERP will help you streamline inventory management? Are you hoping to maximize your return on investments, boost production efficiency, and increase net profit through this? If your answer to these questions is yes, then you are on the right page.

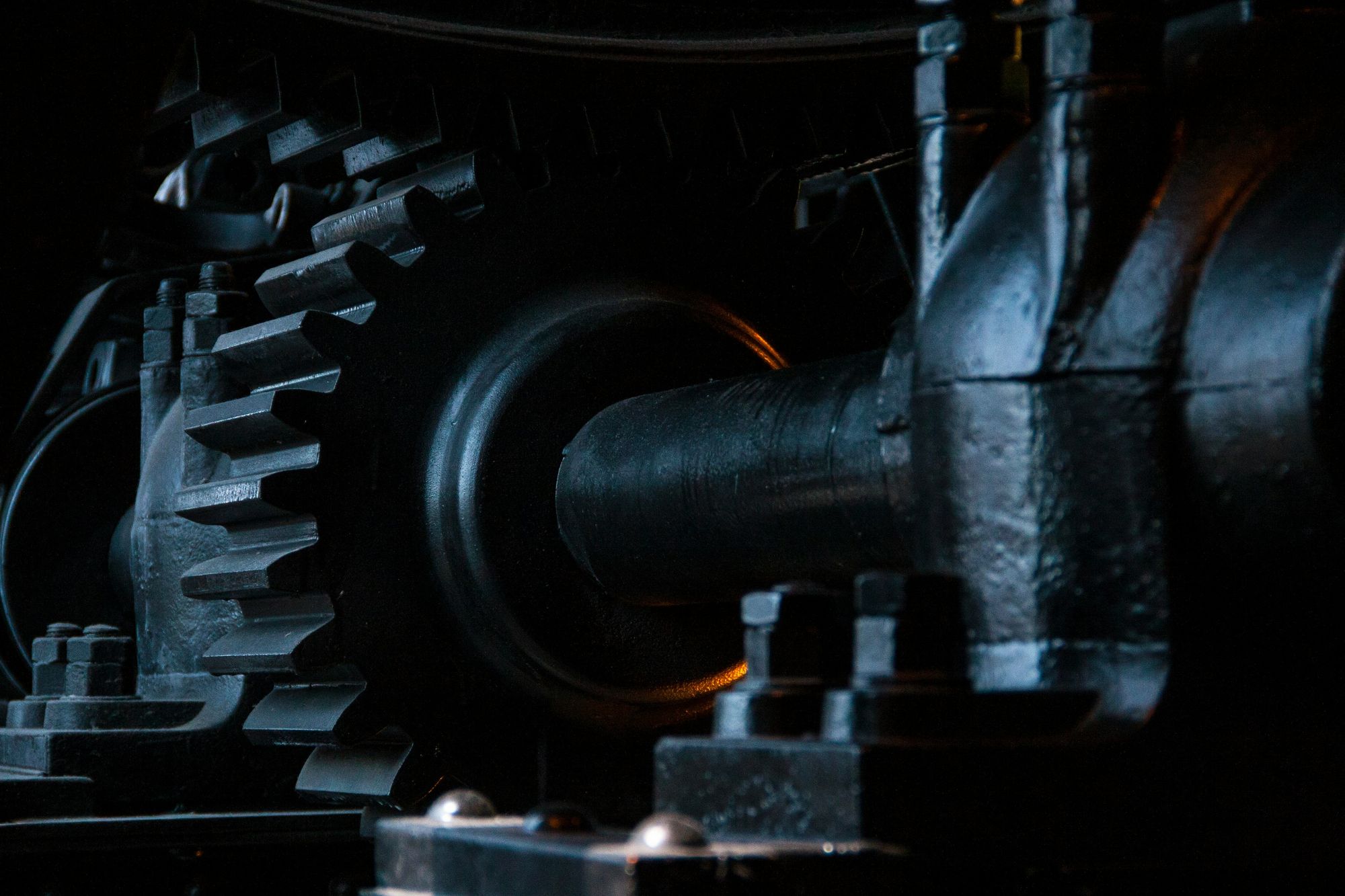

In the fast-paced world of industrial machinery equipment manufacturing, efficiency is not just a goal – it's a necessity. Every cog, gear, and component must seamlessly align to ensure operations run smoothly, deadlines are met, and customers remain satisfied.

At the heart of this intricate machinery lies the backbone of any successful operation: inventory management. Yet, in an industry where precision is paramount and margins are tight, traditional inventory management methods often fall short.

Enter industrial machinery equipment ERP – the game-changer poised to revolutionize how businesses streamline their inventory management processes.

In a landscape where every minute counts and every component matters, industrial machinery equipment ERP offers a comprehensive solution tailored to the unique needs of the industry.

From real-time inventory tracking to demand forecasting, serialized inventory management, and beyond, this sophisticated software promises to transform the way businesses operate, ensuring seamless coordination, optimal resource allocation, and unparalleled efficiency.

The topics covered in this article are:

- What is Inventory Management?

- What is the Industrial Machinery Equipment Industry?

- Importance of Streamlining Inventory Management in the Industrial Machinery Equipment Industry

- What is Industrial Machinery Equipment ERP?

- Streamlining Inventory Management with Industrial Machinery Equipment ERP

- How can Deskera as an Industrial Machinery Equipment ERP Help in Streamlining Inventory Management?

- Key Takeaways

- Related Articles

What is Inventory Management?

Inventory management refers to the process of overseeing and controlling the flow of goods, materials, and products within a business or organization.

It involves efficiently managing the acquisition, storage, tracking, and movement of inventory to ensure optimal levels are maintained to meet customer demand while minimizing costs and maximizing profitability.

Key components of inventory management include:

- Inventory Planning: Forecasting demand and determining optimal inventory levels to meet customer demand without overstocking or understocking.

- Procurement: Sourcing and acquiring raw materials, components, and finished goods from suppliers to maintain inventory levels.

- Storage and Warehousing: Efficiently storing inventory in warehouses or distribution centers, logically organizing inventory, and optimizing warehouse space.

- Inventory Tracking and Monitoring: Keeping track of inventory levels, locations, and movements in real time using inventory management systems or software.

- Order Fulfillment: Processing customer orders, picking, packing, and shipping products accurately and efficiently to meet customer requirements.

- Inventory Control: Implementing policies and procedures to minimize stockouts, prevent overstocking, reduce inventory holding costs, and prevent shrinkage or loss.

- Quality Control: Ensuring the quality and condition of inventory meet predetermined standards and specifications through inspections, testing, and quality assurance measures.

- Demand Forecasting: Analyzing historical data, market trends, and customer demand patterns to forecast future demand accurately and adjust inventory levels accordingly.

Effective inventory management is essential for businesses to optimize cash flow, minimize carrying costs, improve customer satisfaction, and maintain competitiveness in the market. It requires careful planning, coordination, and execution across various departments and functions within an organization.

What is the Industrial Machinery Equipment Industry?

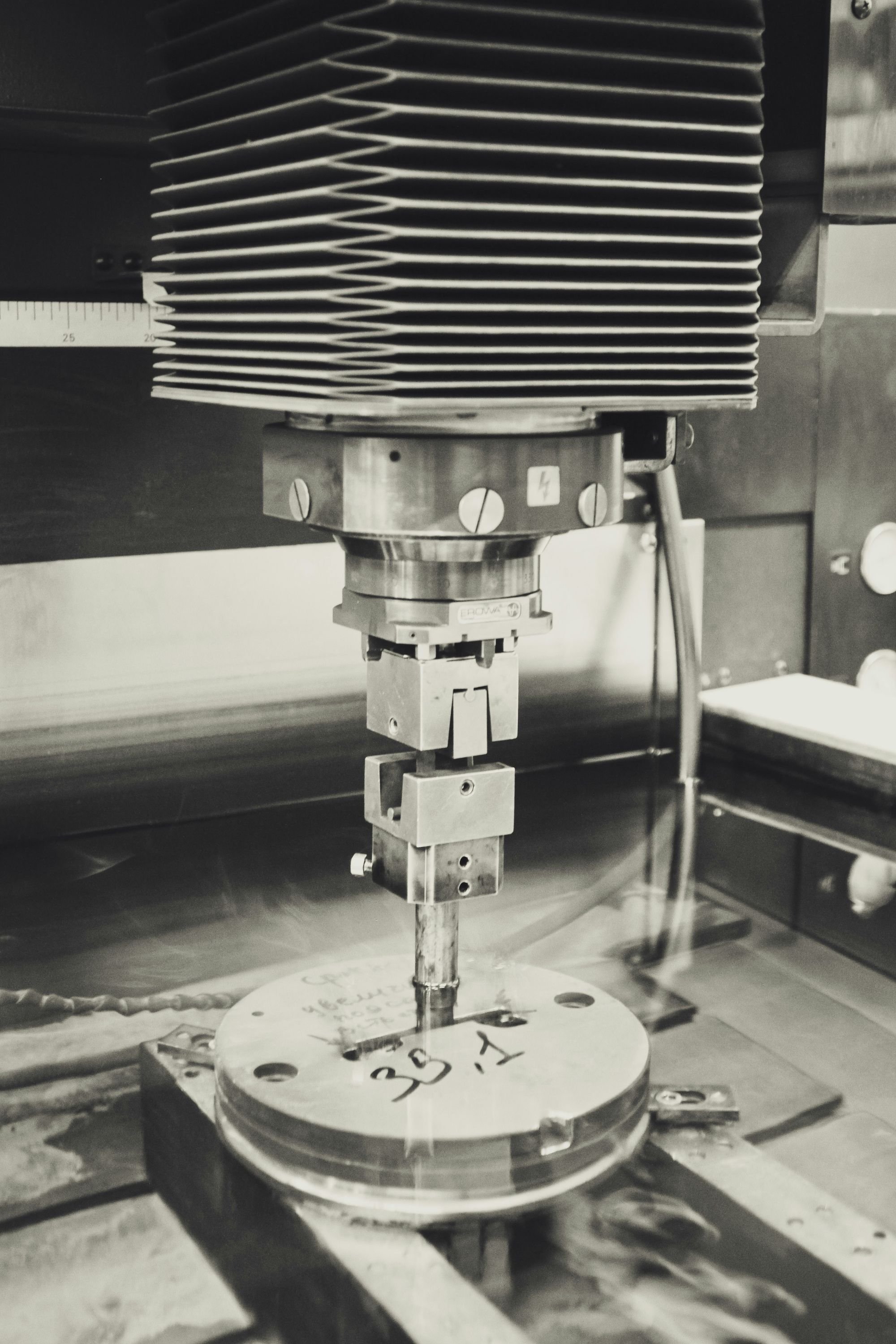

The industrial machinery equipment industry encompasses companies involved in the design, manufacturing, distribution, and maintenance of machinery and equipment used in various industrial sectors.

This industry plays a crucial role in supporting manufacturing processes across a wide range of sectors, including automotive, aerospace, construction, energy, agriculture, and many others.

Industrial machinery and equipment are essential for the production, processing, and assembly of goods across different industries. They include a diverse range of equipment such as machine tools, industrial robots, material handling equipment, construction machinery, agricultural machinery, packaging machinery, and more.

Key characteristics of the industrial machinery equipment industry include:

- Diverse Applications: Industrial machinery and equipment serve diverse applications across multiple industries, including manufacturing, construction, transportation, energy production, and agriculture.

- Advanced Technology: The industry is characterized by the use of advanced technologies such as automation, robotics, artificial intelligence, and the Internet of Things (IoT) to enhance productivity, efficiency, and performance.

- Global Market: The industrial machinery equipment industry operates on a global scale, with companies manufacturing and supplying equipment to markets around the world. Globalization has led to increased competition and collaboration among industry players.

- Customization and Specialization: Many industrial machinery and equipment are customized to meet specific customer requirements and industry standards. Companies often specialize in niche markets or specific types of machinery to cater to unique needs.

- High Capital Investment: Manufacturing industrial machinery and equipment often requires significant capital investment in research and development, manufacturing facilities, and specialized machinery. This creates barriers to entry for new competitors and requires substantial ongoing investment in innovation.

- Supply Chain Integration: The industry relies on a complex supply chain involving suppliers of raw materials, components, and subsystems. Effective supply chain management is crucial for ensuring timely delivery of parts and components to support manufacturing operations.

- Regulatory Compliance: Compliance with safety regulations, industry standards, and environmental regulations is essential in the industrial machinery equipment industry to ensure product quality, safety, and environmental sustainability.

Overall, the industrial machinery equipment industry is a vital component of the global economy, providing the machinery and equipment necessary for the production of goods across various sectors. It is characterized by technological innovation, global competition, and a constant drive for efficiency and productivity improvements.

Importance of Streamlining Inventory Management in the Industrial Machinery Equipment Industry

Streamlined inventory management is of paramount importance in the industrial machinery equipment industry for several reasons:

- Cost Efficiency: Efficient inventory management minimizes holding costs associated with excess inventory, storage, and handling. It ensures that capital is not tied up in surplus inventory, allowing businesses to allocate resources more effectively.

- Optimized Production: Streamlined inventory management ensures that the right materials are available at the right time for production. This minimizes production delays, improves manufacturing efficiency, and helps meet customer demand promptly.

- Reduced Stockouts: Effective inventory management prevents stockouts by ensuring adequate stock levels of critical components and spare parts. This minimizes production downtime and prevents disruptions in customer service.

- Improved Customer Satisfaction: Streamlined inventory management ensures that products are available when customers need them, leading to higher customer satisfaction levels. It reduces lead times, eliminates backorders, and enhances overall service quality.

- Enhanced Supply Chain Efficiency: Efficient inventory management improves supply chain efficiency by optimizing inventory levels, reducing excess inventory, and minimizing stockouts. This leads to smoother logistics operations and better collaboration with suppliers and distributors.

- Better Forecasting and Planning: Streamlined inventory management provides accurate data for demand forecasting and production planning. This enables businesses to anticipate market demand, adjust production schedules accordingly, and minimize inventory holding costs.

- Compliance and Regulatory Requirements: Effective inventory management ensures compliance with regulatory requirements, quality standards, and safety regulations. It enables businesses to track inventory movements, maintain accurate records, and demonstrate compliance during audits and inspections.

- Cost Control and Analysis: Streamlined inventory management facilitates cost control and analysis by providing insights into inventory costs, usage patterns, and procurement strategies. This helps businesses identify cost-saving opportunities, optimize inventory investments, and improve profitability.

- Risk Mitigation: Efficient inventory management mitigates risks associated with inventory obsolescence, shrinkage, and excess inventory. It minimizes the financial impact of inventory write-offs and ensures that inventory is managed in a way that minimizes business risk.

- Competitive Advantage: Businesses with streamlined inventory management practices gain a competitive advantage in the industrial machinery equipment industry. They can respond quickly to market changes, meet customer demands effectively, and operate with greater agility and efficiency compared to their competitors.

In summary, streamlined inventory management is essential for driving cost efficiency, improving production efficiency, enhancing customer satisfaction, and maintaining a competitive edge in the industrial machinery equipment industry.

It enables businesses to operate more effectively, minimize risks, and achieve sustainable growth in a highly competitive market.

What is Industrial Machinery Equipment ERP?

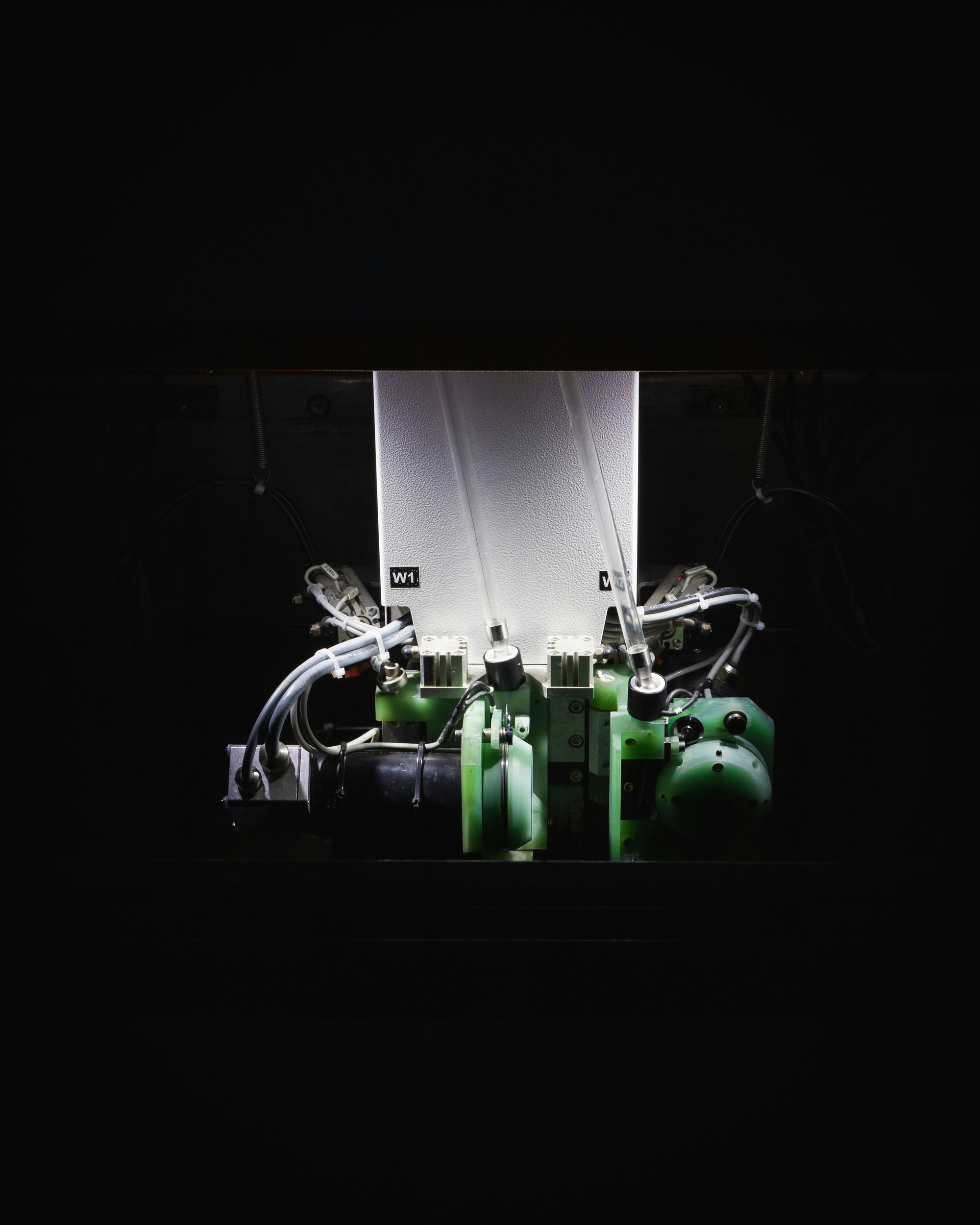

Industrial machinery equipment ERP is a specialized software solution designed to meet the unique needs and challenges of companies operating in the industrial machinery and equipment manufacturing sector.

It integrates various business processes and functions into a single unified system, providing comprehensive tools for managing resources, operations, and data across the organization.

Key features and functionalities of industrial machinery equipment ERP typically include:

- Inventory Management: Manufacturing ERP systems for industrial machinery equipment facilitate efficient management of inventory, including raw materials, components, finished goods, and spare parts. They enable real-time tracking of inventory levels, optimizing stock levels, and ensuring timely replenishment.

- Production Planning and Scheduling: Industrial machinery equipment ERP includes modules for production planning and scheduling, allowing businesses to optimize manufacturing processes, allocate resources effectively, and meet production targets efficiently.

- Supply Chain Management: MRP software systems streamline supply chain management processes by integrating with suppliers, distributors, and logistics providers. They facilitate procurement, order management, supplier collaboration, and logistics optimization to ensure smooth operations throughout the supply chain.

- Quality Management: Industrial machinery equipment ERP systems include quality management modules for monitoring and managing product quality throughout the manufacturing process. They enable quality control inspections, non-conformance tracking, and compliance with industry standards and regulations.

- Equipment Maintenance: Manufacturing software systems facilitate equipment maintenance and asset management by scheduling preventive maintenance tasks, tracking equipment downtime, and managing maintenance schedules and work orders.

- Financial Management: Industrial machinery equipment ERP includes financial management modules for managing accounting, budgeting, invoicing, and financial reporting. They provide insights into financial performance, cost analysis, and profitability tracking.

- Sales and Customer Relationship Management (CRM): Manufacturing ERP systems include modules for sales order management, customer relationship management (CRM), and after-sales service. They enable businesses to manage customer orders, track sales performance, and provide timely support and service to customers.

- Business Intelligence and Analytics: Industrial machinery equipment ERP systems offer business intelligence (BI) and analytics capabilities for analyzing data, generating reports, and gaining insights into key performance indicators (KPIs) related to inventory management, production efficiency, and financial performance.

- Mobile Accessibility: Many industrial machinery equipment ERP systems offer mobile accessibility, allowing users to access system functionalities and data remotely via smartphones or tablets. This enables on-the-go access to critical information and facilitates real-time decision-making.

- Compliance and Regulatory Compliance: MRP software systems help businesses maintain compliance with industry regulations, quality standards, and environmental requirements. They provide tools for documentation management, audit trails, and regulatory reporting to ensure compliance with applicable laws and regulations.

Overall, industrial machinery equipment ERP is a comprehensive software solution designed to streamline operations, improve efficiency, and drive growth in the industrial machinery and equipment manufacturing industry. It enables businesses to optimize resources, enhance productivity, and maintain competitiveness in a rapidly evolving market.

Streamlining Inventory Management with Industrial Machinery Equipment ERP

Implementing an Enterprise Resource Planning (ERP) system tailored for industrial machinery equipment can significantly streamline inventory management processes.

Here's how:

Centralized Inventory Management

Centralized inventory management is a cornerstone feature of industrial machinery equipment ERP systems, offering numerous benefits for businesses in the manufacturing sector:

- Single Source of Truth: Industrial machinery equipment ERP provides a centralized repository for all inventory-related data, eliminating discrepancies and ensuring accuracy across the board.

- Efficient Data Management: With ERP for industrial equipment, businesses can efficiently manage inventory data related to industrial equipment, ensuring seamless tracking of stock levels, locations, and movements.

- Real-time Visibility: ERP for industrial equipment offers real-time visibility into inventory levels and movements, empowering businesses to make informed decisions promptly. This real-time data access is essential for ensuring optimal inventory levels and preventing stockouts.

- Enhanced Collaboration: By centralizing inventory data, industrial machinery ERP fosters enhanced collaboration between different departments within the organization. This facilitates better coordination between production, procurement, and warehouse management teams.

- Streamlined Operations: Industrial machinery equipment ERP streamlines inventory management operations by automating key processes such as stock replenishment, order fulfillment, and inventory reconciliation. This automation minimizes manual errors and improves overall operational efficiency.

- Optimized Inventory Levels: Leveraging advanced features such as demand forecasting and demand planning, industrial machinery ERP helps businesses optimize inventory levels based on anticipated demand. This prevents overstocking or understocking situations, leading to cost savings and improved resource utilization.

- Compliance Management: MRP software systems ensure compliance with industry regulations and standards by enforcing strict inventory control measures. This is particularly crucial in highly regulated industries where adherence to quality and safety standards is paramount.

- Integration with Manufacturing Processes: Industrial machinery ERP seamlessly integrates with manufacturing software and MRP (Material Requirements Planning) systems, ensuring that inventory levels align with production schedules. This synchronization prevents production delays and optimizes resource utilization.

- Improved Decision-making: Centralized inventory management provided by manufacturing software systems equips businesses with actionable insights and analytics. This enables informed decision-making regarding inventory optimization, supplier management, and cost control strategies.

- Scalability and Flexibility: Manufacturing ERP systems are highly scalable and flexible, allowing businesses to adapt to changing inventory management needs as they grow. Whether it's expanding product lines or entering new markets, industrial machinery ERP can accommodate evolving requirements seamlessly.

In essence, centralized inventory management underpins the effectiveness of industrial machinery ERP systems, offering a holistic approach to inventory control and optimization in the manufacturing sector.

By leveraging these capabilities, businesses can streamline operations, enhance collaboration, and drive overall efficiency in managing industrial machinery equipment inventory.

Real-Time Inventory Tracking

Real-time inventory tracking is a pivotal aspect of industrial machinery equipment ERP systems, revolutionizing inventory management practices in the manufacturing sector:

- Instantaneous Data Access: Industrial machinery equipment ERP facilitates real-time access to inventory data, enabling businesses to monitor stock levels, movements, and locations instantly.

- Enhanced Accuracy: With real-time tracking capabilities, industrial machinery ERP ensures the accuracy of inventory data, minimizing errors and discrepancies that may arise from manual record-keeping processes.

- Timely Decision-making: Real-time inventory tracking empowers businesses to make timely decisions based on up-to-date information. This agility is crucial for responding promptly to fluctuations in demand or supply chain disruptions.

- Prevention of Stockouts and Overstocking: By providing real-time visibility into inventory levels, ERP for industrial equipment helps prevent stockouts by alerting stakeholders when stock levels are low. Similarly, it prevents overstocking situations by providing insights into surplus inventory that can be redeployed or liquidated.

- Optimized Warehouse Operations: Real-time inventory tracking streamlines warehouse operations by facilitating efficient picking, packing, and shipping processes. This optimization minimizes idle time and maximizes productivity within the warehouse.

- Improved Customer Satisfaction: Real-time inventory tracking enables businesses to fulfill customer orders promptly, leading to higher customer satisfaction levels. Delays due to stockouts or inventory inaccuracies are minimized, enhancing the overall customer experience.

- Integration with Supply Chain Partners: Manufacturing software systems with real-time tracking capabilities integrate seamlessly with suppliers and distributors, enabling efficient collaboration throughout the supply chain. This integration ensures timely replenishment of inventory and enhances supply chain visibility.

- Data-driven Insights: Real-time inventory tracking generates valuable data insights that businesses can leverage to optimize inventory management strategies. These insights help identify trends, forecast demand accurately, and implement proactive inventory management measures.

- Compliance and Audit Trail: Real-time tracking in MRP software systems ensures compliance with regulatory requirements by maintaining an accurate audit trail of inventory movements. This transparency is essential for demonstrating compliance during audits and inspections.

- Adaptability to Dynamic Environments: Real-time inventory tracking capabilities make manufacturing ERP systems adaptable to dynamic business environments. Whether it's sudden demand spikes or supply chain disruptions, businesses can respond effectively and maintain operational resilience.

In summary, real-time inventory tracking provided by industrial machinery ERP systems enhances operational efficiency, improves decision-making, and ensures customer satisfaction in the manufacturing sector. By leveraging these capabilities, businesses can stay competitive in today's fast-paced business landscape.

Demand Forecasting and Planning

Demand forecasting and planning play a critical role in optimizing inventory management processes within industrial machinery equipment ERP systems, offering several advantages to businesses in the manufacturing sector:

- Accurate Demand Prediction: Industrial machinery ERP systems leverage advanced algorithms and historical data to forecast demand accurately. By analyzing factors such as historical sales data, market trends, and seasonality, businesses can anticipate future demand patterns with precision.

- Optimized Inventory Levels: Based on demand forecasts generated by MRP software, businesses can adjust inventory levels accordingly. This optimization helps prevent overstocking, minimizing excess inventory costs, while also ensuring that adequate stock is available to meet customer demand and prevent stockouts.

- Improved Production Planning: Demand forecasting capabilities integrated into industrial machinery equipment ERP enable better production planning. By aligning production schedules with anticipated demand, businesses can optimize resource utilization, reduce lead times, and enhance production efficiency.

- Enhanced Supply Chain Collaboration: Demand forecasting and planning features in ERP for industrial equipment facilitate collaboration with suppliers and distributors. By sharing demand forecasts and production schedules, businesses can ensure timely delivery of raw materials and components, reducing supply chain bottlenecks.

- Inventory Turnover Optimization: Accurate demand forecasting enables businesses to optimize inventory turnover ratio. By stocking the right quantities of inventory based on anticipated demand, businesses can minimize holding costs and improve cash flow.

- Reduction of Stockouts and Backorders: By forecasting demand accurately, manufacturing software systems help businesses avoid stockouts and backorders. This improves customer satisfaction by ensuring that products are available when needed, leading to higher sales and repeat business.

- Seasonal Demand Management: MRP software systems can identify seasonal demand patterns and adjust inventory levels accordingly. This proactive approach ensures that businesses are prepared to meet increased demand during peak seasons while avoiding excess inventory during slow periods.

- Cost Reduction: Effective demand forecasting and planning result in cost savings across the supply chain. By minimizing excess inventory, reducing stockouts, and optimizing production schedules, businesses can lower carrying costs, improve inventory turnover ratios, and enhance overall profitability.

- Data-driven Decision-making: Demand forecasting and planning capabilities in industrial machinery equipment ERP systems provide businesses with actionable insights. By analyzing demand forecasts and inventory data, businesses can make informed decisions regarding procurement, production, and inventory management strategies.

- Continuous Improvement: Manufacturing ERP systems allow businesses to refine demand forecasting models over time. By analyzing forecast accuracy and adjusting forecasting parameters, businesses can continuously improve their demand forecasting capabilities, leading to more reliable inventory management outcomes.

In summary, demand forecasting and planning functionalities offered by industrial machinery ERP systems are essential for optimizing inventory management processes, improving production efficiency, and enhancing overall business performance in the manufacturing sector. By leveraging these capabilities, businesses can stay ahead of market demand, reduce costs, and drive sustainable growth.

Integrated Supply Chain Management

Integrated supply chain management is a cornerstone feature of industrial machinery equipment ERP systems, offering numerous benefits for businesses in the manufacturing sector:

- Seamless Communication: Industrial machinery ERP facilitates seamless communication and collaboration across the entire supply chain, including suppliers, manufacturers, distributors, and customers.

- End-to-end Visibility: ERP for industrial equipment provides end-to-end visibility into supply chain processes, enabling businesses to track inventory movements, monitor supplier performance, and manage logistics operations effectively.

- Efficient Procurement: Integrated supply chain management features in industrial machinery equipment ERP streamline procurement processes by automating purchase orders, vendor management, and supplier negotiations. This ensures timely procurement of raw materials and components at optimal costs.

- Demand-Driven Planning: Manufacturing ERP integrates demand forecasting and planning functionalities with supply chain management processes, allowing businesses to align procurement and production activities with anticipated demand. This minimizes inventory holding costs and reduces the risk of stockouts.

- Inventory Optimization: Integrated supply chain management in MRP software helps optimize inventory levels throughout the supply chain. By synchronizing inventory levels with demand forecasts and production schedules, businesses can minimize excess inventory and improve inventory turnover ratios.

- Supplier Collaboration: Manufacturing software facilitates collaboration with suppliers through features such as electronic data interchange (EDI) and supplier portals. This enables real-time exchange of information, electronic order processing, and proactive management of supplier relationships.

- Order Fulfillment Efficiency: Integrated supply chain management ensures efficient order fulfillment processes by automating order processing, inventory allocation, and shipment tracking. This improves order accuracy, reduces lead times, and enhances customer satisfaction.

- Transportation Management: Industrial machinery ERP systems often include transportation management modules that optimize freight costs, route planning, and carrier selection. This minimizes transportation expenses and improves delivery reliability.

- Risk Mitigation: Integrated supply chain management in manufacturing ERP helps businesses identify and mitigate supply chain risks proactively. By monitoring supplier performance, identifying alternative sources of supply, and implementing contingency plans, businesses can minimize the impact of disruptions.

- Data-driven Decision-making: Integrated supply chain management provides businesses with actionable insights and analytics derived from real-time supply chain data. This enables data-driven decision-making regarding inventory management, supplier selection, and logistics optimization.

In summary, integrated supply chain management offered by industrial machinery ERP systems streamlines inventory management processes, improves supply chain visibility, and enhances collaboration across the entire supply chain. By leveraging these capabilities, businesses can achieve operational excellence, reduce costs, and gain a competitive edge in the manufacturing industry.

Optimized Warehouse Management

Optimized warehouse management is a crucial aspect of streamlining inventory management processes within industrial machinery equipment ERP systems, offering several benefits for businesses in the manufacturing sector:

- Efficient Space Utilization: Industrial machinery equipment ERP systems optimize warehouse space by organizing inventory based on factors such as size, weight, and demand frequency. This maximizes storage capacity and minimizes wasted space.

- Strategic Inventory Placement: Warehouse management features in MRP software enable businesses to strategically place inventory items within the warehouse. High-demand items can be placed in easily accessible locations to minimize picking times and improve order fulfillment efficiency.

- Automated Replenishment: Manufacturing software systems automate replenishment processes by triggering reorder points or generating replenishment orders based on inventory levels and demand forecasts. This ensures that stock levels are maintained at optimal levels, minimizing stockouts and excess inventory.

- Optimized Picking Processes: Warehouse management functionalities in manufacturing ERP optimize picking processes by organizing inventory logically and defining efficient picking routes. This reduces travel time for warehouse staff and improves overall productivity.

- Barcode and RFID Integration: Industrial machinery ERP systems integrate with barcode and RFID technology for efficient inventory tracking and management. This enables real-time visibility into inventory movements and facilitates accurate inventory counts during receiving, picking, and shipping processes.

- Cycle Counting: Industrial machinery equipment ERP automates cycle counting processes by periodically counting a subset of inventory items. This ensures inventory accuracy without the need for time-consuming and disruptive physical inventory counts.

- Cross-Docking: Industrial machinery ERP facilitates cross-docking, allowing incoming inventory to be directly transferred from receiving docks to outbound shipping docks without intermediate storage. This minimizes handling and storage costs while accelerating order fulfillment.

- Lot and Serial Number Tracking: MRP software systems offer lot number and serial number tracking capabilities, enabling businesses to trace individual components throughout their lifecycle. This is crucial for quality control, warranty management, and product recalls.

- Real-time Inventory Visibility: Warehouse management features in ERP for industrial equipment provide real-time visibility into inventory levels, locations, and movements. This enables accurate inventory management decisions and reduces the risk of stockouts or overstocking.

- Integration with Material Handling Equipment: Manufacturing ERP systems integrate with material handling equipment such as forklifts and conveyors, optimizing warehouse operations and reducing manual handling errors. This improves safety, efficiency, and accuracy in warehouse operations.

In summary, optimized warehouse management provided by industrial machinery ERP systems enhances inventory management efficiency, improves order fulfillment accuracy, and reduces operating costs in the manufacturing sector. By leveraging these capabilities, businesses can achieve greater operational efficiency and maintain a competitive edge in the market.

Serialized Inventory Tracking

Serialized inventory tracking is a vital feature within industrial machinery equipment ERP systems, offering significant advantages for inventory management in the manufacturing sector:

- Unique Identification: Serialized inventory tracking assigns a unique serial number to each item or component, allowing for precise identification and traceability throughout its lifecycle.

- Improved Traceability: With serialized inventory tracking in industrial machinery ERP, businesses can track the movement and usage history of each serialized item. This enhances traceability for warranty purposes, product recalls, and quality control measures.

- Enhanced Quality Control: Industrial machinery equipment ERP systems with serialized inventory tracking enable businesses to monitor and trace the quality of individual components or products. This facilitates early detection of quality issues and ensures compliance with quality standards.

- Effective Warranty Management: Serialized inventory tracking enables businesses to link each serialized item to its specific warranty information. This simplifies warranty management processes, allowing businesses to track warranty expiration dates and manage warranty claims efficiently.

- Precise Inventory Management: Serialized inventory tracking provides precise visibility into the inventory levels of individual items or components. This allows businesses to monitor stock levels accurately, prevent stockouts, and optimize inventory replenishment strategies.

- Compliance with Regulatory Requirements: Serialized inventory tracking helps businesses comply with regulatory requirements by providing accurate documentation of inventory movements and usage history. This is particularly important in industries with stringent regulatory standards, such as aerospace and defense.

- Effective Asset Management: Serialized inventory tracking extends beyond finished products to include serialized components and spare parts. This enables businesses to effectively manage assets, track usage, and plan for maintenance and replacement activities.

- Efficient Recalls and Returns: In the event of product recalls or returns, serialized inventory tracking facilitates rapid identification and retrieval of affected items. This minimizes the impact on customers and reduces the costs associated with recalls and returns.

- Integration with Maintenance Management: Manufacturing ERP systems often integrate serialized inventory tracking with maintenance management modules. This allows businesses to link serialized components to maintenance schedules, track service history, and schedule preventive maintenance tasks efficiently.

- Enhanced Customer Satisfaction: Serialized inventory tracking contributes to improved customer satisfaction by ensuring product authenticity, facilitating accurate order fulfillment, and providing transparent warranty and service information.

In summary, serialized inventory tracking provided by industrial machinery equipment ERP systems enhances inventory management precision, facilitates compliance with regulatory requirements, and contributes to overall operational efficiency in the manufacturing sector.

By leveraging these capabilities, businesses can streamline inventory processes and deliver superior products and services to their customers.

Compliance and Quality Management

Compliance and quality management are essential components of Inventory Management within industrial machinery equipment ERP systems, offering several benefits for businesses in the manufacturing sector:

- Regulatory Compliance: Industrial machinery ERP systems ensure compliance with industry regulations and standards by enforcing strict inventory control measures. This includes adhering to regulations related to product safety, environmental impact, and quality assurance.

- Traceability: Manufacturing software systems for industrial machinery equipment enable businesses to trace the origin and usage history of each component or product through serialized inventory tracking. This traceability is crucial for demonstrating compliance with regulatory requirements and quality standards.

- Documentation Management: Industrial machinery equipment ERP systems streamline documentation management processes by maintaining accurate records of inventory movements, inspections, and quality control measures. This documentation serves as evidence of compliance during audits and inspections.

- Quality Assurance: Manufacturing ERP systems integrate quality management functionalities, such as inspection checklists, quality control workflows, and non-conformance tracking. This ensures that products meet stringent quality standards before being released into the market, reducing the risk of defects and recalls.

- Supplier Management: ERP for industrial equipment facilitates supplier management by tracking supplier performance metrics, conducting supplier audits, and managing supplier contracts. This ensures that suppliers comply with quality standards and deliver components that meet specifications.

- Risk Mitigation: Manufacturing software systems for industrial machinery equipment identify and mitigate quality and compliance risks proactively. By monitoring key performance indicators (KPIs), analyzing quality data, and implementing corrective actions, businesses can reduce the likelihood of compliance issues and quality defects.

- Training and Certification Management: MRP software systems manage employee training and certification records to ensure that personnel are qualified to perform inventory management tasks. This ensures that employees understand and comply with quality standards and regulatory requirements.

- Continuous Improvement: Manufacturing ERP systems facilitate continuous improvement initiatives by capturing feedback, analyzing performance data, and implementing corrective actions. This enables businesses to identify opportunities for process optimization and quality enhancement throughout the inventory management lifecycle.

- Auditing and Reporting: Industrial machinery ERP systems generate comprehensive audit trails and reports to demonstrate compliance with regulatory requirements and quality standards. This includes documentation of inventory transactions, inspection results, and quality control activities.

- Customer Satisfaction: Compliance and quality management efforts contribute to improved customer satisfaction by ensuring that products meet or exceed customer expectations. By delivering high-quality products that comply with regulatory standards, businesses can enhance customer trust and customer loyalty.

In summary, compliance and quality management functionalities provided by industrial machinery equipment ERP systems ensure adherence to regulatory requirements, mitigate risks and drive continuous improvement in inventory management processes.

By leveraging these capabilities, businesses can enhance product quality, mitigate compliance risks, and maintain a competitive edge in the manufacturing sector.

Cost Control and Analysis

Cost control and analysis are pivotal aspects of inventory management within industrial machinery equipment ERP systems, offering numerous benefits for businesses in the manufacturing sector:

- Cost Tracking: Industrial machinery equipment ERP systems enable businesses to track inventory costs accurately, including purchase costs, carrying costs, and obsolescence costs. This provides visibility into the total cost of inventory ownership and helps identify opportunities for cost reduction.

- Inventory Valuation: ERP for industrial equipment offers sophisticated inventory valuation methods, such as FIFO (First-In-First-Out) and LIFO (Last-In-First-Out). This ensures accurate valuation of inventory on the balance sheet and income statement, reflecting the true cost of goods sold and inventory levels.

- ABC Analysis: Industrial machinery ERP systems often include ABC (Activity-Based Costing) analysis tools that classify inventory items based on their importance and contribution to overall costs. This helps businesses prioritize inventory management efforts and allocate resources efficiently.

- Optimized Procurement: Cost analysis features in manufacturing ERP systems help businesses identify cost-effective procurement strategies. By analyzing supplier pricing, lead times, and quality metrics, businesses can make informed decisions to minimize procurement costs while maintaining quality standards.

- Inventory Turnover Ratios: Manufacturing software systems facilitate the calculation of inventory turnover ratios, indicating how quickly inventory is being sold or used within a specific period. This metric helps businesses assess the efficiency of inventory management practices and identify areas for improvement.

- Obsolete Inventory Management: Industrial machinery equipment ERP systems assist businesses in identifying and managing obsolete inventory. By analyzing inventory aging and obsolescence trends, businesses can take proactive measures to minimize write-offs and liquidate obsolete inventory efficiently.

- Variance Analysis: MRP software systems enable businesses to conduct variance analysis to compare actual inventory costs against standard or budgeted costs. This helps identify discrepancies and deviations from expected costs, enabling businesses to take corrective actions to control costs effectively.

- Activity-Based Costing (ABC): Industrial machinery equipment ERP systems utilize ABC to allocate overhead costs to inventory items based on the activities that drive those costs. This provides a more accurate picture of the true cost of inventory and helps in pricing decisions and profitability analysis.

- Forecasting and Budgeting: Manufacturing ERP systems support cost forecasting and budgeting processes, enabling businesses to plan and allocate resources effectively. By analyzing historical cost data and market trends, businesses can create accurate cost projections and budgets for inventory management.

- Profitability Analysis: MRP software systems facilitate profitability analysis by integrating inventory cost data with sales revenue and expense information. This enables businesses to assess the profitability of individual products, customers, or market segments and make strategic decisions to optimize profitability.

In summary, cost control and analysis functionalities provided by industrial machinery equipment ERP systems enable businesses to optimize inventory costs, improve profitability, and make informed decisions to drive business success in the manufacturing sector.

By leveraging these capabilities, businesses can achieve cost savings, enhance financial performance, and maintain a competitive edge in the market.

Streamlined Production Planning

Streamlined production planning is a key feature of industrial machinery equipment ERP systems, offering several advantages for businesses in the manufacturing sector:

- Integration with Inventory Management: Industrial machinery equipment ERP systems seamlessly integrate production planning with inventory management, ensuring that production schedules align with inventory levels and demand forecasts.

- Real-time Inventory Visibility: Manufacturing ERP systems provide real-time visibility into inventory levels, enabling production planners to make informed decisions about raw material procurement, production scheduling, and inventory replenishment.

- Demand Forecasting: Industrial machinery ERP systems incorporate demand forecasting tools that analyze historical data and market trends to predict future demand accurately. This allows businesses to adjust production plans accordingly, minimizing the risk of stockouts or excess inventory.

- Optimized Resource Allocation: ERP for industrial equipment systems optimizes resource allocation by matching production capacity with demand forecasts. This ensures that resources such as labor, equipment, and materials are utilized efficiently, reducing production costs and maximizing profitability.

- Synchronized Production Schedules: MRP software systems enable businesses to synchronize production schedules with customer orders, demand forecasts, and inventory levels. This minimizes production bottlenecks, reduces lead times, and improves on-time delivery performance.

- Just-in-Time (JIT) Manufacturing: Industrial machinery equipment ERP systems support JIT manufacturing principles by enabling businesses to produce goods based on actual customer demand. This reduces excess inventory holding costs and minimizes the risk of obsolete inventory.

- Capacity Planning: Manufacturing software systems include capacity planning tools that help businesses optimize production capacity based on demand forecasts and resource availability. This ensures that production facilities operate at optimal efficiency, maximizing output while minimizing costs.

- Resource Optimization: MRP software systems analyze resource utilization data to identify opportunities for optimization. This includes identifying underutilized equipment, optimizing production schedules, and balancing workloads to maximize productivity and minimize costs.

- Inventory Cost Reduction: Streamlined production planning reduces inventory holding costs by aligning production schedules with demand forecasts. This minimizes the need for excess inventory storage and reduces the risk of inventory obsolescence.

- Continuous Improvement: Industrial machinery equipment ERP systems facilitate continuous improvement initiatives by capturing production performance data, analyzing efficiency metrics, and identifying areas for optimization. This ensures that production planning processes are continually refined to achieve optimal results.

In summary, streamlined production planning provided by industrial machinery equipment ERP systems enhances efficiency, reduces costs, and improves overall inventory management in the manufacturing sector.

By leveraging these capabilities, businesses can optimize production processes, maximize profitability, and maintain a competitive edge in the market.

Mobile Accessibility

Mobile accessibility is a critical feature of industrial machinery equipment ERP systems, offering several advantages for streamlining inventory management in the manufacturing sector:

- Remote Access: Industrial machinery ERP systems provide mobile accessibility, allowing inventory managers and warehouse staff to access inventory data and perform tasks remotely from any location with an internet connection.

- On-the-Go Inventory Management: Mobile accessibility enables users to perform inventory management tasks on the go, such as checking stock levels, updating inventory records, and initiating replenishment orders, using smartphones or tablets.

- Real-time Updates: Manufacturing ERP systems for industrial machinery equipment offer real-time synchronization between mobile devices and the central ERP database, ensuring that inventory data is up to date across all devices. This enables users to access the latest inventory information instantaneously.

- Barcode Scanning: Mobile accessibility includes barcode scanning functionality, allowing users to scan barcodes or QR codes to quickly retrieve inventory details, perform stock counts, and track inventory movements with accuracy.

- Efficient Order Fulfillment: Mobile accessibility streamlines order fulfillment processes by enabling warehouse staff to pick, pack, and ship orders using mobile devices. This improves order accuracy, reduces fulfillment times, and enhances overall customer satisfaction.

- Inventory Visibility: Mobile accessibility provides real-time visibility into inventory levels, locations, and movements, empowering users to make informed decisions about inventory management, procurement, and production planning while on the move.

- Task Management: MRP software systems for industrial machinery equipment offer task management features on mobile devices, allowing users to assign, track, and prioritize inventory-related tasks efficiently. This ensures that inventory management operations run smoothly and effectively.

- Alerts and Notifications: Mobile accessibility includes alerts and notifications functionality, notifying users of critical inventory-related events such as stockouts, low inventory levels, or pending orders. This enables users to take immediate action to address inventory issues.

- Collaboration and Communication: Mobile accessibility facilitates collaboration and communication among team members by enabling them to share inventory-related information, updates, and tasks in real time via mobile devices. This enhances teamwork and coordination within the inventory management department.

- Adaptability and Flexibility: Mobile accessibility makes inventory management processes more adaptable and flexible, allowing users to respond quickly to changing inventory needs, customer demands, and market trends while being away from their desks.

In summary, mobile accessibility provided by industrial machinery equipment ERP systems enhances flexibility, efficiency, and responsiveness in inventory management processes.

By leveraging these capabilities, businesses can streamline inventory operations, improve productivity, and maintain a competitive edge in the manufacturing sector.

How can Deskera as an Industrial Machinery Equipment ERP Help in Streamlining Inventory Management?

Deskera, as an Industrial Machinery Equipment ERP, can help streamline inventory management in several ways:

- Real-time Inventory Tracking: Deskera provides real-time visibility into inventory levels, locations, and movements. This allows businesses to monitor stock levels accurately and make informed decisions about inventory management.

- Demand Forecasting: Deskera offers demand forecasting tools that analyze historical data and market trends to predict future demand accurately. This helps businesses optimize inventory levels, reduce stockouts, and minimize excess inventory.

- Serialized Inventory Tracking: Deskera enables serialized inventory tracking, assigning unique serial numbers to individual items or components. This enhances traceability, improves quality control, and facilitates compliance with regulatory requirements.

- Warehouse Management: Deskera includes warehouse management functionalities for optimizing warehouse operations. It streamlines receiving, picking, packing, and shipping processes, improving order fulfillment efficiency and reducing errors.

- Mobile Accessibility: Deskera offers mobile accessibility, allowing users to access inventory data and perform tasks remotely via smartphones or tablets. This enhances flexibility and enables on-the-go inventory management.

- Cost Control and Analysis: Deskera provides tools for cost control and analysis, enabling businesses to track inventory costs, analyze cost drivers, and identify opportunities for cost reduction. This helps optimize inventory investments and improve profitability.

- Compliance Management: Deskera helps businesses maintain compliance with regulatory requirements, quality standards, and industry regulations. It provides tools for documentation management, audit trails, and regulatory reporting to ensure compliance.

- Integrated Solution: Deskera integrates inventory management with other business processes such as sales, procurement, production, and finance. This streamlines operations, improves data accuracy, and enhances overall efficiency.

- Analytics and Reporting: Deskera offers analytics and reporting capabilities for analyzing inventory data, generating reports, and gaining insights into key performance indicators (KPIs). This enables data-driven decision-making and continuous improvement in inventory management processes.

Key Takeaways

Streamlining inventory management with industrial machinery equipment ERP systems is crucial for businesses operating in the manufacturing sector. These sophisticated software solutions offer a comprehensive array of tools and functionalities designed to optimize inventory management processes, enhance operational efficiency, and drive business success.

Industrial machinery equipment ERP helps in streamlining inventory management in the following ways:

- Centralized Inventory Management: A manufacturing ERP system centralizes inventory data, providing a single source of truth for all inventory-related information. This includes tracking stock levels, locations, movements, and associated costs. With centralized data, you can avoid discrepancies and ensure accurate inventory counts.

- Real-time Inventory Tracking: MRP software systems offer real-time visibility into inventory levels and movements. With automated data capture through barcode scanning or RFID technology, you can monitor stock levels accurately and instantly identify any discrepancies or shortages.

- Demand Forecasting and Planning: Advanced manufacturing software systems often include forecasting and planning modules that use historical data and predictive analytics to forecast demand accurately. This helps in optimizing inventory levels, preventing stockouts, and minimizing excess inventory.

- Integrated Supply Chain Management: Manufacturing ERP systems integrate with suppliers and distributors, enabling seamless communication and collaboration throughout the supply chain. This integration facilitates automated replenishment processes, supplier performance tracking, and timely delivery of raw materials and components.

- Optimized Warehouse Management: MRP software systems streamline warehouse operations by optimizing storage space, organizing picking routes, and automating replenishment tasks. With features such as bin tracking and lot management, you can ensure efficient handling of inventory within the warehouse.

- Serialized Inventory Tracking: For complex machinery and equipment, serialization is crucial for tracking individual components throughout their lifecycle. MRP software systems offer serialized inventory tracking capabilities, enabling you to trace each component's history, warranty information, and maintenance records.

- Compliance and Quality Management: Manufacturing software systems help ensure compliance with industry regulations and quality standards by enforcing strict inventory controls and documentation processes. This is particularly important in industries with stringent safety and regulatory requirements.

- Cost Control and Analysis: With integrated financial modules, manufacturing ERP systems provide insights into inventory costs, including purchase costs, carrying costs, and obsolescence costs. By analyzing these costs, you can identify opportunities for cost reduction and make informed decisions about inventory management strategies.

- Streamlined Production Planning: Industrial machinery equipment ERP systems synchronize inventory levels with production schedules, ensuring that raw materials are available when needed for manufacturing. This minimizes production delays and optimizes production efficiency.

- Mobile Accessibility: Many modern manufacturing ERP systems offer mobile applications that enable employees to access inventory data and perform tasks remotely. This enhances flexibility and productivity by allowing staff to manage inventory from anywhere, at any time.

In summary, implementing a manufacturing ERP system tailored for industrial machinery equipment can revolutionize inventory management by providing centralized control, real-time visibility, and automation across the supply chain. This leads to improved efficiency, cost savings, and better decision-making capabilities for businesses in this sector.

Ultimately, industrial machinery equipment ERP systems empower businesses to meet customer demands, maintain regulatory compliance, and achieve sustainable growth in an increasingly competitive market landscape.

Overall, Deskera as an industrial machinery equipment ERP helps businesses streamline inventory management processes, optimize inventory levels, improve efficiency, and maintain compliance with regulatory requirements. It enables businesses to enhance productivity, reduce costs, and achieve operational excellence in the manufacturing sector.

Related Articles