To establish a sustainable and scalable E-commerce business, you must master inventory management. Poor inventory management may be a huge obstacle for any E-commerce entrepreneur to overcome.

Irrespective of the skill and the size of their business, inventory management is a priority for all E-commerce businesses. Even if there are few customers to serve, an E-commerce company must streamline its inventory operations.

With the huge costs associated with inventory, you may start thinking about approaches for inventory management. You may want to know how you can achieve a healthy inventory. Essentially, you are seeking a process to optimize inventory management.

Making the wrong decisions about inventory management can be extremely costly. Making the proper decisions can be quite profitable.

So, here is all you need to know about E-commerce inventory management:

- What is E-commerce Inventory Management?

- What are some E-commerce Inventory Management Strategies?

- Importance of Inventory Management in E-commerce

- Challenges with Inventory Management in E-commerce

- Inventory Management for E-commerce

- Important Inventory Metrics and Formulas

- ERP for E-commerce Inventory Management

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What is E-commerce Inventory Management?

E-commerce inventory management is the process of tracking your inventory and ensuring a constant flow of products to your customers. E-commerce inventory management is important for any business that sells its products online. This is because it helps to manage costs and keep an accurate count of inventory being sold through different channels.

E-commerce inventory management is a solution that assists retailers in all aspects of their business. Business owners can use the technology to streamline warehousing operations. Additionally, it helps them make better financial decisions.

We may sum up E-commerce inventory management as a mix of the following tasks:

- Tracking the location of stock

- Tracking the number of products

- Monitor the variety and price of merchandise available

- An essential component of the supply chain

- Serves as a buffer for your suppliers and customers

The E-commerce component also takes into account the requirements of an online retailer. The online retailer may need to maintain inventories for several online sales channels.

The additional factors that E-commerce companies must have are:

- a functional and appealing website

- visibility into their inventory counts

- a good shipping strategy

There are numerous elements that inventory management can help take care of. Everything else comes into place once you know how much inventory you have.

What are some Ecommerce Inventory Management Strategies?

When it comes to E-commerce inventory management, the ‘one-size-fits-all’ theory may not work. All businesses have different requirements. They may necessitate the use of different inventory tracking strategies. Examine the following options to find out a suitable fit for your business strategy.

ABC Analysis

Using the ABC Analysis approach, inventory is divided into three categories. Each category is determined by the profitability of each SKU.

Let us dissect this. Category 1 inventory could include items with a high value but a low quantity. Inventory in Category 2 could be of moderate value and quantity. Finally, inventory in category 3 may be low in value but high in quantity.

When you divide the inventory into categories like this, your company can sell a variety of product lines. You may wonder, what is the significance of this. It is because various product lines allow for personalized replenishment tactics for each category type.

Assume your product is sunglasses. You sell $1,000 sunglasses and $50 accessories in the same store. So, whether in-person or online, you will not employ the same fulfillment tactics for both. One product is worth more than the other.

As a result, using the ABC analysis technique with an inventory management system gives you better control over each product's replenishment.

ABC analysis is all about ranking the products. This is based on demand, cost, and risk data. This assists business leaders in determining which items or services are most important to their organization's financial success.

How Does ABC Inventory Analysis Work?

Calculate ABC inventory by multiplying a specific item's annual sales by its cost. The results indicate which commodities are high priority and which make a low return, allowing you to prioritize labor and capital resources.

For ABC inventory analysis, use the following formula:

Just-in-time Inventory Management

If your company does not require a huge amount of inventory, the just-in-time inventory system is ideal. Businesses that only need to stock orders as they are purchased by customers use this method. The volume of inventory is usually equal to the number of orders filled.

Just-in-Time tries to offer inventory, raw materials, and labor just when they are required. It guarantees that current demand is met by catering to specific needs rather than stockpiling ahead of time.

Companies that sell seasonal items are perfect examples of JIT. As demand for their items grows, they only order enough to fulfill orders. As the season draws to a close, they can clear the shelves without concern of losing money on dead goods.

If your business relies on buyer trends, this technique may not be the right solution. Unexpected jumps in demand can result in costly stockouts.

The JIT system can be beneficial in several ways:

Dropshipping

This is a retail approach used for order fulfillment operations. However, it involves selling products without holding inventory or a warehouse. Drop shippers share customer information with a third party when receiving an order.

All the customer data such as contact number and address is shared. They further handle packaging, labeling, and shipping of those orders to customers.

Also, the key distinction between regular retail fulfillment and dropshipping is the presence of a warehouse. It implies that the dropshippers are not required to own or manage inventory. They also do not have to work in a warehouse to sell products.

Dropshipping is one of the most popular and convenient inventory management solutions. However, it is not precisely an easy inventory process. This is because business owners do not touch the merchandise. Instead, when a consumer places an order, the business owner, completes it through the manufacturer or supplier.

This strategy is applied commonly by first-time E-commerce sellers. It is helpful for them as they seek to eliminate warehouse expenses.

Concern Area: While dropshipping could be a great option, there is a problem. You have zero control over the consumer experience. The entire process after the order is placed is handled by the manufacturer. Also, you would be accountable if a consumer received defective or wrong goods.

First In, First Out

This is useful for retailers who sell goods with expiration dates and prefer the first in, first out method. The term – first in, first out - or FIFO, refers to the fact that the first products to arrive at a warehouse are the first to be fulfilled for customers.

It is not limited to companies that sell perishable items. Any business that wants the products to exit quickly can use this inventory management method. However, pay close attention to the price patterns of your items and materials. You will need to monitor the fluctuation in prices. In such times, there could be a gap between the cost of products received and the cost of items sold. This might result in overstated earnings.

Safety stock

Another frequently used inventory management approach is safety stock. It is employed by businesses to keep additional products on hand when demand suddenly spikes. Unlike the JIT method, safety stock allows you to cover unanticipated delays and changes in demand. Simultaneously, it allows you to maintain consistent output.

Retailers use safety stock to plan for risks such as inaccurate forecasting. They also use it to deal with changes in consumer demand. Also, there could be varying lead times for various raw supplies. Overcoming these obstacles can be easy because you have extra inventory on hand. With safety stock inventory, you can overcome these challenges.

Top 5 Advantages of Inventory Management in E-commerce

While you try to seek exceptional inventory management, understand how it will benefit you. Learn what goals you shall achieve when you have desirable inventory management.

It is crucial to know that inventory management affects almost every area of your company's operations. That makes it immensely essential for your E-commerce business.

A dependable inventory management system assists your clients in having a great purchasing experience. Inventory counts are always precise since the system automates inventory procedures. It also updates quantities throughout your sales channels.

As a result, online counts are appropriately advertised. This further paves the way for the customers to have a better probability of obtaining the correct goods.

Improved Inventory Forecasting

Good inventory management paves the way for efficient inventory forecasting. You can better prepare for demand if you manage your inventory storage levels. and production flow. You will be able to stay up with sales if you analyze your inventory patterns regularly.

Goal-driven Business Decisions and Planning

Inventory management can help you prepare for unexpected supply chain challenges or deficiencies. There could be multiple obstacles while you try to work out the best inventory solutions.

Common unforeseen issues you may face include the following:

- Delay at the manufacturer's end

- You have run out of storage space.

- Cash flow issues

You can construct a safety policy for potential problems by studying your inventory over time. This planning can help to strengthen your firm when you face adversity, which could otherwise have serious consequences for your bottom line.

Do Away with Stockouts, Backorders, and Deadstock

One of the most important aspects of inventory management is determining the appropriate number of product units. You must have a good balance of SKUs to keep in stock at any one time. If your inventory falls too low, you risk running out of products. This can result in missed sales, back orders, and customer service concerns.

On the other hand, having too much inventory might result in having things that are no longer sellable. Such products may face declining demand or become outdated. This is also referred to as dead stock.

Enhance Customer Satisfaction

Acquiring significant insights into your consumers' preferences is crucial. You can achieve this by tracking the shipped amount of product inventory. This shall provide better insights in contrast to the unsold or in-storage inventory. Moreover, there is always some stock that is stuck in the supply chain. However, this data may not be as relevant to enhance customer satisfaction.

Knowing what is frequently ordered offers more information about the demand.

Inventory management also lets you know a certain location where your product is commonly purchased. Furthermore, any spikes or drops in inventory following a product launch will provide valuable feedback. You can work on your advertising efforts and product satisfaction accordingly.

This can reduce lead time as purchase orders arrive. Also, it streamlines operations at your point of sale. This can aid with inventory tracking and control, which is critical for an E-commerce business.

Lower Storage Expenses

If you have too much merchandise, it will most certainly cost you a lot in storage expenses. This money could have gone into branded packaging materials or other fruitful tasks. The amount of physical space your products take up is used to determine how much storage space you need.

The storage fees can vary based on the number of units you need to maintain on hand. By keeping your inventory at the appropriate level, you may save money on storage fees. The savings can be used for other operations of your business.

5 Challenges with Inventory Management in E-commerce

Every E-commerce business owner faces inventory management issues at some point. Knowing these difficulties beforehand can be half the battle won. All you need to do is address them ahead of time.

Here is where you can make all the difference to your business. You may have experienced the impact on an E-commerce business's growth and profitability. Furthermore, you certainly do not want poor inventory management to affect customer experience and retention.

This section will take you through some of the most typical inventory issues.

Lack of Insights

A lack of data insights is a major inventory management issue. You shall need all your inventory data handy. The information that you collect can be used for data analysis. This will further assist your firm in identifying areas for improvement. Achieving objectives that lead to an increase in engagement and revenue will become easier.

You may require these crucial insights:

- Understand the average age of your inventory

- Depicting the preciseness of your inventory

- Minimizing order returns

- Supply chain activities

Use these insights to understand how your inventory fluctuates over time. Learn how demand changes over time to enhance earnings and respond to the demands of your customers. Your insights can help you estimate what your inventory will look like in the future. You will know when to replenish products and when to scale back on products. Additionally, you can better understand where breakdowns in your processes occur.

Overstocking

In E-commerce, you need to have a strong understanding of your inventory and the buying behaviors of your target audience. This can help you accurately stock and sell your products through your online platform.

If you misjudge your clients' needs, supply may fall short of demand. If you overestimate the amount of merchandise you require, you will most likely spend more than you make.

While there are advantages to keeping a big stock of goods on hand, there is also a downside. Especially as the busy season approaches, it can bring some challenges:

Expensive: Overstocks can be costly. Unless you are doing dropshipping, you will need to keep the things you order from manufacturers. As you might expect, having too much inventory and not enough orders can have a negative impact.

Risk of Deadstock: There is a risk of having too much dead stock on hand. D deadstock refers to inventory that cannot be sold because there is too much inventory and not enough demand. It happens when things expire or lose quality, but it can also happen when trends and purchasing habits change.

Overselling

Aside from the above elements, you could run the risk of overselling. What is overselling, you may ask?

Not keeping a close eye on your inventory might lead to unintended overselling. This implies you allowed customers to purchase things that are out of stock. Overselling a product creates customer service and reputation issues. These issues might take time to overcome, damaging the reputation of the platform.

When it comes to interacting with E-commerce retailers, consumers want accountability. They want to know everything about your company. It helps them trust make with their orders. When you oversell inventory, you risk delaying fulfillment. This could even jeopardize the trust you have earned with those who decided to order your goods.

A simple solution would be to mark things as in or out of stock online so customers can view available amounts for themselves.

Lack of Visibility

When you seek to scale your business, you look to different channels to sell your products. This helps you reach out to a wider audience. Naturally, this tends to boost your business.

But, you must keep a close eye on the activities across these channels. Also, there may be multiple warehouses through which you carry out the sale of your products. Often, you may experience a lack of visibility in these areas.

Visibility across channels

When you start selling through different channels, it could get tougher to monitor all aspects. Gradually, you shall realize that things are a lot easier with an ERP system in place.

Most developed ERP systems offer an advanced inventory management module. Without this module, keeping track of sales and orders is challenging. Furthermore, it could even affect your existing inventory.

Visibility across multiple warehouses

As your company expands, you may find yourself collaborating with more manufacturers and warehouses. After all, satisfying the increasing customer demands is a priority.

Your goal is to have merchandise on hand and ready to go when demand spikes unexpectedly. However, without inventory management software, it can be a struggle to maintain track of orders. Moreover, you also need to watch over all warehouses, suppliers, and manufacturers.

It is indeed challenging to know which decisions must be taken without complete visibility. Also, with the growing sales operations, you may miss out on a lot of critical aspects. Also, you must be mindful of maintaining a consistent brand experience across channels.

Let an ERP with integrated inventory management take over the hassles for you.

Manual Management

Scaling is another inventory management issue that many online business owners encounter. Initially, it seems quite straightforward to manually manage and fulfill orders. However, as you strive to scale to match the growing customer expectations, it becomes much more difficult.

Scaling includes selling products on more channels, such as Amazon, eBay, and so on. It also entails collaborating with several partners, dealers, and manufacturers. It may even imply storing inventory in several warehouses around the country.

When you rely solely on manual management methods, taking such efforts to build your E-commerce business is nearly impossible. Manual management also increases the possibility of data errors affecting inventory management.

Here are some instances of ineffective manual inventory management methods:

- No automation: Using an offline program that does not support automatic real-time updates.

- Manual spreadsheets: Inventory numbers are tracked using offline spreadsheets.

- Disparate tools: Using a collection of disparate tools that are not integrated or synchronized with one another.

- Tracking with paper and pen: Manually tracking and fulfilling orders with paper and pencil.

When you are just getting warmed up in the digital marketplace, it can be alluring to control and trace inventory manually to save money and maintain control over all aspects of your business.

To minimize the issues outlined above, you must examine and plan to implement more scalable inventory management methods, tactics, and technologies that support long-term growth.

Important Inventory Metrics and Formulas

You will be able to make wiser business decisions if you understand all sorts of inventory data. You must understand how to plan, manage, and report E-commerce inventory. The following list of inventory measurements and key terminology will help you:

Finished Goods Inventory

The stock available for purchase by consumers and that can be fulfilled is referred to as finished products inventory. Sellers can use the finished goods inventory formula to determine the worth of their goods for sale. Additionally, they may also evaluate the amount of inventory required to avoid stockouts.

Out-of-stock items force buyers to either wait a lengthy period for their purchase or cancel the order entirely. Backorders pose the same challenges. Both backorders and out-of-stock can be avoided. Here is the formula for finished goods inventory:

Finished Goods Formula

Inventory Holding Cost

The whole cost of maintaining unsold goods is known as inventory holding cost. This includes the following aspects:

- Warehousing

- Insurance

- Labor

- Transportation

- Depreciation

- Shrinkage

- Obsolescence

- Opportunity costs

Calculating inventory holding costs can be simple. All you need to do is estimate your storage, personnel, opportunity, and depreciation costs. Once you have those subtotals, add them all up. Then divide the result by the total value of your annual inventory.

This is the combined average value of all inventory that you move in a year. This number or percentage represents your inventory holding cost.

Inventory Holding Cost Formula

Inventory Carrying Cost

The carrying cost is the sum of all inventory-related expenditures such as warehousing, labor, insurance, and rent. It also includes the value of damaged, expired, and outdated products.

Inventory carrying costs are determined by a variety of factors. These include product storage requirements, the total number of SKUs, and inventory turnover rate.

Inventory Safety Stock Formula

Forecasting is crucial to inventory management. It would be difficult to forecast the purchasing trends. Also, any last-minute supplier issues could be impossible to foresee.

However, understanding the inventory safety stock formula might help you avoid an out-of-stock catastrophe. Safety stock is excess merchandise kept on hand in the event of an emergency or a supply chain disruption. It acts as a safety net in your inventory, ensuring that you do not run out of stuff.

Inventory Days on Hand

Inventory days on hand indicate how rapidly a company's inventory levels deplete on average. It effectively allows you to avoid stockouts. With correct stock levels, your clients can buy without having to wait for the product.

This assessment, in conjunction with inventory forecasting, can help you establish how quickly your products are sold on average. Furthermore, it precisely predicts future inventory levels.

In other words, it is better to have fewer days on hand.

Inventory Days on Hand Formula

Inventory Turnover Rate

Measuring inventory turnover can assist you in more successfully managing your supply chain and sales channels. Additionally, it can help you improve your inventory forecasting. It is the ratio that shows how many times inventory is sold and subsequently replenished in a given period.

A high inventory turnover rate may suggest that you are selling a product quickly. Similarly, a low inventory turnover rate may indicate that particular products are not selling. Irrespective of too high or too low, the inventory turnover rate enables you to better regulate inventory difficulties. Business is easier when you have the right means to measure important elements of your inventory.

Inventory Turnover Rate Formula

Inventory Reorder Point Formula

The reorder point is the minimal unit quantity that a company should keep in stock before having to reorder more products. Understanding the inventory reorder point calculation will help you order at the correct time. Furthermore, it can assist you in avoiding ordering too late and running out of stock.

It is done at the SKU level to recognize that each product has a particular sales cycle. This makes it data-driven and accurate. The new-age ERP systems solutions can help you automatically set up reorder points to remind you when it is time to order more goods.

Inventory Reorder Point Formula

Just in Time (JIT) Inventory

Just in Time (JIT) is a supply chain management strategy that aims to reduce costs and boost efficiency. Furthermore, it seeks to reduce waste by acquiring goods just when they are required. The approach comprises having enough inventory to match client demand and quickly stockpiling the remainder.

JIT inventory is most typically utilized in manufacturing, but it can also be employed in E-commerce stores. Reduced storage expenses, increased communication, less waste, and lower inventory investments are some of the benefits. Some drawbacks of this method include difficult implementation and a larger chance of supply chain failure. Also, it requires more preparation and has a higher likelihood of stockouts.

Inventory Shrinkage

Inventory shrinkage occurs when real inventory levels are lower than what accounting has recorded. Consumer theft, employee theft, inventory damage, and management errors are the four most typical causes of inventory shrinkage. There are various techniques to keep inventory from shrinking.

Regular inventory audits, and creating SKUs and barcodes for each time are effective ways to reduce shrinkage. Also, the automation feature of ERP systems can provide huge respite from inventory shrinkage.

Inventory Shrinkage Rate Formula

Inventory Write-off

The accounting procedure of lowering the value of inventory that has lost all of its worth is referred to as inventory write-off. Inventory may lose value due to many reasons. Damage, deterioration, theft, damage in transport, or changes in market demand are some common reasons. Product misplacement can also be included as one of the factors leading to write-offs.

Inventory write-offs are used to achieve accounting accuracy goals while also lowering business owners' tax liabilities. It is accomplished by crediting it to the cost of goods sold or balancing the obsolete inventory allowance in the accounts.

Reorder Quantity Formula

The total number of product units requested from a manufacturer or supplier on an inventory replenishment purchase order is referred to as the reorder quantity.

The exact number should not be so high that you have too much capital locked up in inventory and subsequent storage costs. However, it should also not be so low that you do not have enough safety stock and risk selling out before the next batch of inventory arrives.

Work-in-process Inventory

WIP inventory is a term used in manufacturing and supply chain management. It refers to the overall cost of unfinished items. In a way, it conveys the cost of goods in production currently.

It differs from finished goods, which are objects that are ready to be sold as is. Businesses that sell highly customized products are more likely to supervise the WIP inventory process. Examples could be hand-made goods sold online.

The businesses that buy finished goods directly from a supplier or manufacturer may not monitor WIP closely.

The formula for WIP Inventory

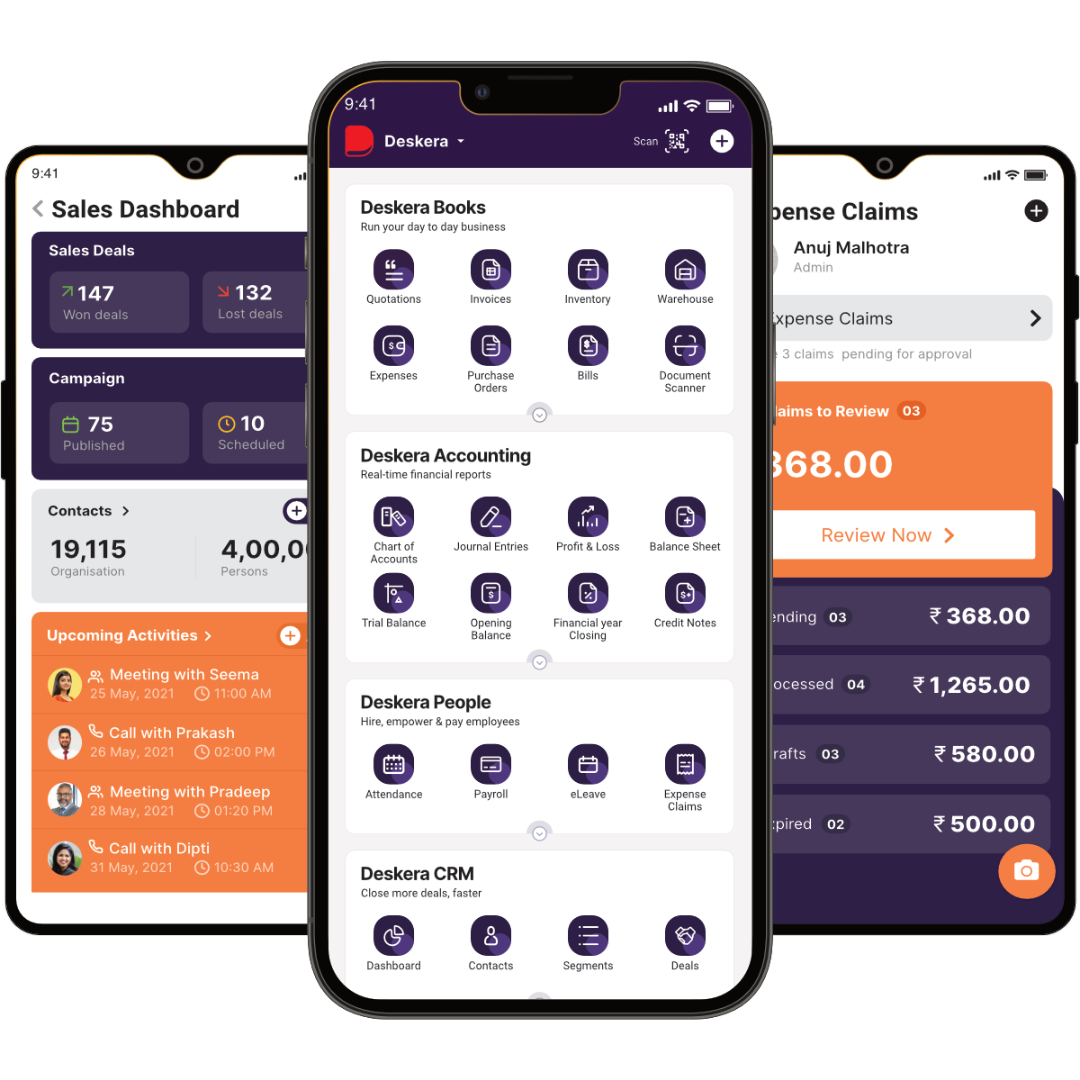

ERP for E-commerce Inventory Management

Have you thought of ERP as a solution for excellent E-commerce inventory management?

We recommend you think about it!

It has an integrated inventory management module. Quickly, here are some of the typical benefits you shall derive from the system:

Single Platform for Everything

One of the key responsibilities of an ERP is to integrate and manage processes across departments. Thus, it serves as s single platform for all operations. ERPs collect data from businesses. This helps to produce a single view of operational, financial, business, and customer data.

Automation

By automating time-consuming and repetitive business operations such as data input, ERP saves time and decreases errors. When automation is used correctly, it saves both time and money.

Financial Management

An ERP system is intended to assist firms in organizing and optimizing their financial planning. These further aids manage expenditure and decision-making processes. It will monitor and analyze financial data for all business accounts. It also helps create budgets and in forecasting requirements.

Customer Relationship Management

ERPs arrange data such as customer information into a searchable database. It also stores prospect status, serial numbers, and order histories. This helps in connecting with the prospects.

In other words, it enables marketing and sales teams to focus on high-converting prospects. Thus, you can reduce lead times and design more effective campaigns.

Besides the above factors, an ERP system can competently assist you with:

- Supply chain management

- Manufacturing management

ERP Inventory Management

A strong ERP system will also automate key functions like the following:

Order Management

When clients pick what they want to buy, effective purchase order management begins. The process ends when the final invoice is paid. A robust ERP system with invoicing and POS connections may automate this process.

It automates the creation of invoices and emails them to customers when they make an order. By integrating billing and order management, the ERP may automatically update to inform the warehouse staff to begin filling the order.

Inventory Control across Various Channels

Retailers utilize multi-channel inventory management to account for merchandise sold through numerous warehouses and outlets in multiple locations.

Warehouse Management

Multi-channel inventory increases sales reach. However, meeting demand or maximizing earnings can get difficult. You may be unable to locate the supplies needed to satisfy orders. It might help you avoid problems like delayed order fulfillment or missing items.

Conclusion

Inventory is your most valuable asset. Therefore, you must implement inventory management tactics for a successful E-commerce business. It can assist with improving purchase decisions and warehouse management. Also, it helps you gain an overall insight into what you have in your warehouse.

All this is nearly impossible without a competent and comprehensive inventory management system. With the automation feature of the system, you can be aware of all the inventory operations.

Inventory management can be a great tool that provides visibility into inventory counts. You can track it from the time it enters your warehouse until the time it reaches your customer. Users can see products that are overstocked, and understocked. They also get to know about the out-of-stock products.

With this level of information, you can better estimate inventory purchases. Additionally, planning for any shortages would be easy.

How can Deskera Help You?

You must maintain track of your inventory stock as a manufacturer. The state of your inventory has a direct impact on production planning, the usage of people and machinery, and demand forecasting.

Deskera ERP and MRP solutions can help you with the following:

- Plan production schedules

- Create a Bill of Materials

- Create detailed reports

- Design your dashboard

Deskera ERP is a comprehensive system for managing suppliers, tracking supply chain activity in real-time, and streamlining a variety of other organizational functions.

Deskera Books enables you to better manage your accounts and finances. It aids in the maintenance of sound accounting practices by automating billing, invoicing, and payment processing activities.

Deskera CRM is a strong solution that helps you organize your sales and finish deals quickly. It helps you to do critical tasks like lead generation via email and gives you a thorough view of your sales funnel.

Deskera People is a simple application for centralizing human resource management tasks. Not only does technology speed up payroll processing, but it also assists you with other activities such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways

- With the huge costs associated with inventory, you may start thinking about approaches for inventory management.

- E-commerce inventory management is the process of tracking your inventory and ensuring a constant flow of products to your customers.

- E-commerce inventory management is important for any business that sells its products online. This is because it helps to manage costs and keep an accurate count of inventory being sold through different channels.

- The E-commerce component also takes into account the requirements of an online retailer. The online retailer may need to maintain inventories for several online sales channels.

- There are numerous elements that inventory management can help take care of.

- ABC analysis is an inventory management technique. Using the ABC Analysis approach, inventory is divided into three categories. Each category is determined by the profitability of each SKU.

- Another method is JIT or just-in-time. If your company does not require a huge amount of inventory, the just-in-time inventory system is ideal. Businesses that only need to stock orders as they are purchased by customers use this method.

- Next is dropshipping which is also an inventory management technique for E-commerce. This is a retail approach used for order fulfillment operations. However, it involves selling products without holding inventory or a warehouse. Drop shippers share customer information with a third party when receiving an order.

- The term – first in, first out - or FIFO, refers to the fact that the first products to arrive at a warehouse are the first to be fulfilled for customers.

- Another frequently used inventory management approach is safety stock. It is employed by businesses to keep additional products on hand when demand suddenly spikes. Simultaneously, it allows you to maintain consistent output.

- There are benefits of inventory management. They are improved inventory and goal-driven business decisions. Also, you may enhance customer satisfaction and lower the storage space in the warehouse.

- The challenges in inventory management include lack of insights, overstocking, overselling, and manual management.

- You may utilize ERP for your E-commerce business. Automation, financial management, customer relationship management are some of the benefits of the ERP system.

- There are various inventory metrics and formulas. Finished goods inventory, inventory holding cost, inventory turnover rate, and inventory days on hand are some of these.

- Inventory is your most valuable asset. Therefore, you must implement inventory management tactics for a successful E-commerce business.

- It can assist with improving purchase decisions and warehouse management. Also, it helps you gain an overall insight into what you have in your warehouse.

Related Articles