“Intermittent production situations are those where the facilities must be flexible enough to handle a variety of products and sizes, or where the basic nature of the activity imposes change of important characteristics of the input (e.g., change in product design)” — According to E.S Buffa

Intermittent production is a method of manufacturing. In this method, different products are produced on the same production line according to irregular production schedules.

Businesses have started employing intermittent manufacturing techniques as a result of the increase in product variability.

Therefore, increasing the effectiveness of these systems has assumed important significance. Even though this objective is usually unattainable, long-term growth should strive to realize distinct production with the effectiveness and lower costs of mass production.

In today’s guide, we’ll dig into intermittent production and its associated concepts. Let’s take a look at the table of content:

- What is Intermittent Production?

- Features of Intermittent Production

- Different Types of Intermittent Production

- Intermittent Production Vs Continuous Production

- Advantages and Disadvantages of Intermittent Production

- Example of Intermittent Production

- Conclusion

- How Deskera Can Assist You?

- Final Takeaways

Let's begin!

What is Intermittent Production?

The word ‘intermittent’ means — something that begins and ends at irregular or random intervals (time gaps).

Let’s understand intermittent production now.

An umbrella term — Intermittent production — is a manufacturing process that involves producing various goods on the same production line in accordance with irregular production schedules.

Here, goods are produced in response to consumer demand. Remember that these goods are produced on a small scale. And the production flow is intermittent (irregular).

In other words, the flow of production is not constant. In this system, numerous product variations are generated.

Further, these items are available in a range of sizes. The designs of these goods are always changing. It varies continuously depending on the product's size and design. As a result, this system is incredibly flexible.

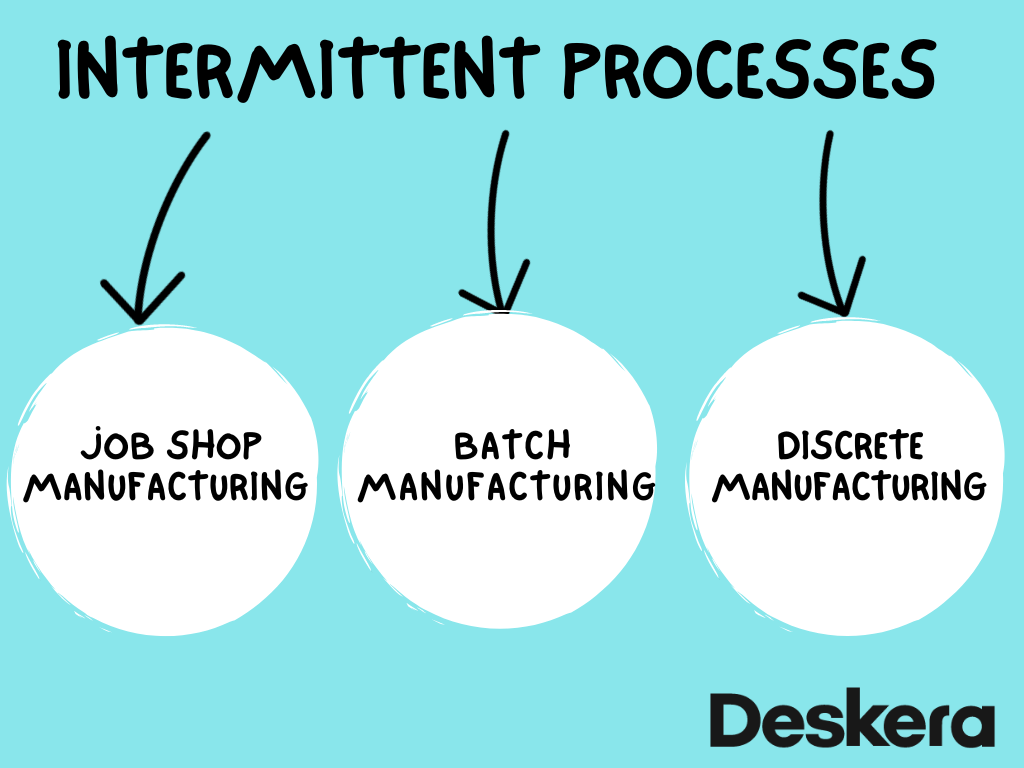

The following intermittent production processes apply this technique:

- Batch manufacturing

- Job shop manufacturing

- Discrete manufacturing

Now, let’s learn about the features of intermittent production.

Features of Intermittent Production

Utilizing irregular processes, an intermittent manufacturing system produces goods for the consumer. The characteristics of intermittent production systems and processes are as follows:

- Only a small amount of goods is produced by the producing unit.

- Numerous process plans are developed in order to produce products that satisfy client demands.

- Wide types of products are produced.

- The production unit can accept different inputs due to its location and design.

- The customer's orders determine the product's quantity, size, shape, design, etc.

- The product is made or produced at irregular periods depending on the desire or demand of the buyer.

- Depending on customer demand, the same production unit can produce a range of products.

- The order of operations is constantly changing to reflect changes in the product's design.

- The inputs and the processes can both be altered in various ways to better suit the needs of the customer.

Different Types of Intermittent Production

Following we’ve discussed different types of intermittent production. Let’s learn:

Job Shop Manufacturing

Manufacturing that calls itself a "job shop" identifies itself as a workspace with standardized tools, facilities, and equipment.

According to the demands of the customer, it requires producing a single full object employing a variety of operators and techniques. This product is "special order" in nature.

While a product is being created, several tasks are carried out at the various workstations. The final items are made in small batches.

Customers modify their orders to meet their specific needs. This implies that a business will produce a select few non-standard products.

Shop floors have a distinct design and set of operational procedures. It is because of the level of customization provided by the workshop process.

Products from a corporation might not all follow the same path. indicating that things will move to the next phase differently and might even return to the same workstation.

Job shop owners have the option of selling their goods directly to customers, doing business with wholesalers, or producing components for other businesses.

Organizations that use job shop production typically use just-in-time (JIT) inventory management. This helps to effectively fulfill client orders.

Example:

Now that we are clear on what job shop production is, let's look at an example.

Small cake shops often make batches of up to 100 of their regular cakes. Wedding cakes and other high-end goods are manufactured one at a time. They are constantly personalized and regarded as innovative items.

Staff members might spend the entirety of their shift working on one cake, depending on the order.

Benefits of Job Shop Manufacturing

The manufacturing process used in workshops has various advantages, much like any production methods. Check below:

1. Better Flexibility:

Since the machinery isn't intended to make just one kind of product, you can create and produce a far wider selection of things.

2. Operators acquire high-level abilities and knowledge:

Since machines are organized by department, every operator can focus on one machine and learn this department. This might increase the output and productivity of each department.

3. Better Equipment Utilization:

When using the job shop method, every piece of equipment is used as fully as is practical. Large machines and expensive machinery are therefore not as necessary.

4. Improved Supervision:

In job shop production, the departments are in charge of organizing the machines into functional groups. Each department's manager has more extensive knowledge to ensure more productive days.

Disadvantages of Job Shop Manufacturing

There are rarely one-size-fits-all remedies with no unfavorable side effects, just like with anything else. In job shops, the product is the same.

Although there are many obvious advantages, you should also consider a few disadvantages. It will help you to deciding whether this method of production is suitable for your company.

1. Hard to Organize

Planning your manufacturing flow can be challenging. It is because products go through a variety of processes. Although some orders could be rather straightforward, others might have a big bill of materials (BOM) that will use up a lot of your resources.

2. Increased Production Lead Time

Each batch component needs to get finalized in order for the product to go on to the next production stage. If one component is running late, the entire batch will as well, resulting in a long lead time and low production rates.

3. Cost of Material Handling

Transportation, storage, and product damage are just a few of the issues that may affect your business when you use job shop manufacturing.

In lean manufacturing, it’s referred to as 'Muda' (waste). And it is viewed as an action that doesn't add value to the customer's sale.

Transport is a simple example: -

Moving the item around the factory floor consumes resources without adding any value.

4. Flow of Material

The parts must be transferred to the following department for completion. It is because job shop manufacturing is carried out by departments.

In order to perform an activity, components must be moved across the entire facility. Hence the flow of materials is high in job shop production.

5. High cost of Managing Materials:

In manufacturing, managing the materials can be expensive and difficult. If one machine is not ready to take on a job or the machine operator is not accessible, materials must be shifted, which could be confusing.

Batch Manufacturing

The manufacture of products in specified groups or amounts that each go through a series of processes to produce the desired product is known as batch production in the manufacturing industry.

This form of production has a deadline and is used to guarantee specific quality improvements. This method enables batch production of mass-produced commodities with fixed changes.

A product can go through any necessary adjustments, such as variations in colors, sizes, or styles, during batch processing in manufacturing. Batch manufacturing can be used to ensure that every change is made with the same level of quality if a product needs to be modified in any way.

Example:

Typically, manufactured goods that are produced with a batch process management system include the following:

- Computer software

- Molds

- Material coating

- Newspaper and/or magazines

- Machines, tools, and equipment

Benefits of Batch Manufacturing

The effectiveness of the batch manufacturing method for the company is frequently questioned. Despite the fact that it is widely used. Let's discuss some advantages of batch production in light of this:

- This allows for a high level of quality control.

- Makes using machinery and equipment more efficient.

- With batch process management, the danger of concentrating only on one product at a time gets decreased. It ultimately leads to more staff time.

- With batch process management, the danger of concentrating only on one product at a time gets decreased. It ultimately leads to more staff time.

- Uses machinery only when absolutely necessary to reduce costs, not constantly.

- Lowers waste by producing the exact quantity of things required.

Disadvantages of Batch Manufacturing

It is clear that batch production is not the ideal method for all industrial processes. To further understand the disadvantages of batch production, consider the following:

- Production takes longer to complete since each step of batch process manufacturing requires people, and each batch is closely watched.

- The conditions within the process are constantly changing in batch processing. This necessitates additional employee time.

- Collaboration among employees also increases the possibility of human error in the production process.

- Lost time and money will result from mistakes in the batch that was produced.

Discrete Manufacturing

Discrete manufacturing is the process of making various parts of a product from a bill of materials (BOM). These are then put together to make the finished product. This process enables producers to complete many separate processes.

Final products are produced using parts, components, and sub-assemblies in this kind of manufacturing process.

Examples of discrete manufacturing could include:

● Smartphones

● Vehicles

● Aircraft

● Cookware

● Clothing

● Cabling

Additionally, it could include auxiliary components like nuts, brackets, and bolts.

Each of these component parts can be counted as a separate unit or recognized as a number. The majority of the time, once something is made, it cannot be broken down again into its component elements.

Discrete manufacturing can be referred to as unit production. Units can be produced in low complexity and high volume, such as nuts or bolts, or in high complexity and low volume, such as computers or aircraft.

Benefits of Discrete Manufacturing

You should think about the following advantages of discrete manufacturing when you decide whether or not to look for one:

- Greater supplier relationships

- Increased productivity

- Minimized machine downtime and enhanced raw material and product quality

- High-quality customer service

Intermittent Production Vs Continuous Production

There exists a counterpart of intermittent production called continuous production.

But what distinguishes intermittent from continuous manufacturing processes?

There are several factors that distinguish intermittent production and continuous production. Let’s discuss:

Advantages and Disadvantages of Intermittent Production

Following we’ve discussed some advantages and disadvantages of intermittent production. Let’s learn:

Advantages of Intermittent Production

1. The same machinery can be used to produce a variety of goods at the same price.

2. Customer satisfaction rises as a result of the production units' ability to adjust to each customer's specific needs. Also, provides the customer a range of items.

3. You can always improve quality control and streamline the production process by focusing on a smaller range of goods.

4. The training the employees receive helps them develop a wider range of skills.

5. You can reduce your manufacturing expenses since workers can concentrate on certain activities and your machines and tools can be used for several product configurations.

6. Due to the items' small quantity production runs, they are extremely adaptable to changing trends.

7. Repeat orders results in a more stable and effective manufacturing flow.

9. There will be downtime for a workstation, saving you money on energy.

10. You can adapt to modifications in a product's design and prevent bottlenecks if a machine or tool malfunctions because another workstation can carry out the similar tasks.

Disadvantages of Intermittent Production

The following are only a few of the many disadvantages of intermittent manufacturing systems:

- Due to process modifications that must be made in order to fulfill customer needs, the work may occasionally become problematic.

- Although customization is an option, it is a challenging procedure that increases the items' manufacturing lead times.

- Production planning and scheduling are difficult as a result of manufacturing orders (MOs) having irregular arrivals.

- Making a lot of goods is difficult and requires a lot of laborers and time.

- Inventories of raw materials and work-in-progress (WIP) are high as a result of the irregular workflow.

- Accessibility to a variety of raw materials is necessary to produce a variety of goods.

Although, you can more easily mitigate these drawbacks by implementing Deskera software. It gives your corporation the power of smart manufacturing.

Example of Intermittent Production

Suppose you run a sweet & dessert shop.

Even though most of the techniques required to manufacture sweets and desserts are the same. However, certain sweets and dessert will be prepared differently than others.

The material that can be made in large quantities will be used for all of your sweets & desserts. The majority of the material from a batch will be used to create them that will be sold in your physical store.

On the other hand, you receive an online request for a personalized dessert for the wedding ceremony.

The batch can continue to be made for your store by you or a coworker. Meanwhile, someone else manages the custom order that might make use of some of the material. However, icing and other decorating techniques are required for this dessert.

As you can see, as the dessert moved between various locations, production would stop and start, and supplies would go through numerous workstations.

The jamming station is the sole technique that the batch and dessert might share.

Conclusion

We have concluded that a business has the ability to initiate and terminate the production process. Due to intermittent manufacturing, the business can operate at a pace that minimizes costs regardless of the demand condition.

In order to offset transaction costs brought on by irregular production, the corporation expands the range of products it offers. It also shows that economies of scale arise as a result of these expenses. This indicates that economies of scale are more of an economic than a technological nature.

How Deskera Can Assist You?

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- An umbrella term — Intermittent production — is a manufacturing process that involves producing various goods on the same production line in accordance with irregular production schedules.

- Manufacturing that calls itself a "job shop" identifies itself as a workspace with standardized tools, facilities, and equipment.

- According to the demands of the customer, it requires producing a single full object employing a variety of operators and techniques. This product is "special order" in nature.

- The manufacture of products in specified groups or amounts that each go through a series of processes to produce the desired product is known as batch production in the manufacturing industry.

- Discrete manufacturing is the process of making various parts of a product from a bill of materials (BOM). These are then put together to make the finished product. This process enables producers to complete many separate processes.

- A product can go through any necessary adjustments, such as variations in colors, sizes, or styles, during batch processing in manufacturing.

- Batch manufacturing can be used to ensure that every change is made with the same level of quality if a product needs to be modified in any way.

Related Articles