Are you looking for ways to increase the competitive edge of your manufacturing business in the industry of industrial machinery equipment? Do you feel the answer lies in boosting production efficiency? If your answer to these questions is yes, then you are on the right page.

In the fast-paced and competitive landscape of industrial machinery equipment manufacturing, achieving optimal production efficiency is paramount. Every minute, every resource, and every process counts towards ensuring that manufacturing operations are running smoothly and delivering high-quality products to customers on time.

To navigate these challenges and maximize efficiency, manufacturers increasingly turn to specialized software solutions known as industrial machinery equipment ERP systems.

Industrial machinery equipment ERP systems are tailored to meet the unique needs of manufacturers in this sector, offering a comprehensive suite of tools and functionalities designed to streamline operations, optimize resource utilization, and drive continuous improvement.

From production planning and scheduling to inventory management, quality control, and maintenance, these ERP solutions empower manufacturers to boost production efficiency across every aspect of their operations.

In this guide, we will explore the critical role of industrial machinery equipment ERP in boosting production efficiency within the industrial machinery equipment industry.

The topics covered in this article are:

- What is the Industrial Machinery Equipment Industry?

- What is Production Efficiency?

- Importance of Production Efficiency in Industrial Machinery Equipment Industry

- What is Industrial Machinery Equipment ERP?

- Boosting Production Efficiency with Industrial Machinery Equipment ERP

- How can Deskera as an Industrial Machinery Equipment ERP Help in Boosting Production Efficiency?

- Key Takeaways

- Related Articles

What is the Industrial Machinery Equipment Industry?

The industrial machinery equipment industry encompasses companies involved in the design, manufacturing, distribution, and maintenance of machinery and equipment used in various industrial sectors.

This industry plays a critical role in supporting production processes across a wide range of sectors, including manufacturing, construction, mining, agriculture, and energy.

Industrial machinery and equipment include a diverse range of products, such as machine tools, heavy machinery, industrial robots, material handling equipment, agricultural machinery, construction equipment, and power generation equipment.

These products are essential for enabling various industrial processes, from manufacturing goods to constructing infrastructure and extracting natural resources.

The industrial machinery equipment industry is characterized by its focus on delivering high-quality, reliable, and efficient machinery to meet the diverse needs of industrial customers.

Key considerations in this industry include production efficiency, product performance, durability, safety, and compliance with industry regulations and standards.

To enhance production efficiency and competitiveness, companies in the industrial machinery equipment industry often leverage specialized software solutions such as industrial machinery equipment ERP.

These software platforms provide comprehensive tools for managing production processes, optimizing resource utilization, streamlining supply chain operations, ensuring regulatory compliance, and driving continuous improvement initiatives.

Overall, the industrial machinery equipment industry plays a vital role in supporting global economic development by providing essential machinery and equipment for various industrial applications.

Through a focus on production efficiency and the adoption of advanced technologies such as manufacturing ERP systems, companies in this industry strive to meet the evolving needs of industrial customers while maintaining a competitive edge in the market.

What is Production Efficiency?

Production efficiency refers to the ratio of output achieved to the input utilized in a production process. It measures how well resources such as labor, materials, time, and energy are utilized to produce goods or services.

Higher production efficiency indicates that a company is producing more output with the same level of input or producing the same output with fewer resources, thereby reducing manufacturing costs and increasing productivity.

Key aspects of production efficiency include:

- Optimal Resource Utilization: Efficient production processes ensure that resources such as labor, materials, and equipment are utilized effectively and without waste. This involves minimizing idle time, reducing material scrap and rework, and maximizing equipment uptime.

- Minimized Downtime: Production efficiency aims to minimize downtime by addressing factors that can disrupt production, such as equipment breakdowns, maintenance activities, and supply chain disruptions. Reduced downtime ensures continuous operation and higher overall productivity.

- Streamlined Workflows: Efficient production processes are characterized by streamlined workflows that minimize bottlenecks, delays, and unnecessary steps. This involves optimizing production sequences, eliminating non-value-added activities, and improving process flow to increase throughput and reduce manufacturing cycle times.

- Quality Assurance: Production efficiency includes measures to ensure product quality and minimize defects. By implementing quality control processes, performing inspections, and addressing root causes of defects, manufacturers can maintain high product quality standards and reduce the need for rework or customer returns.

- Effective Planning and Scheduling: Efficient production requires effective planning and scheduling of production activities to optimize resource allocation and meet production targets. This involves creating realistic production schedules, balancing production capacity with demand, and proactively addressing potential bottlenecks or resource constraints.

- Continuous Improvement: Production efficiency is a continuous improvement process that involves identifying opportunities for optimization, implementing changes, and monitoring results to achieve ongoing improvements in productivity, quality, and cost-effectiveness.

Overall, production efficiency is essential for maximizing profitability, competitiveness, and customer satisfaction in manufacturing operations.

By optimizing resource utilization, minimizing downtime, streamlining approval workflows, ensuring quality, and embracing continuous improvement, companies can enhance their production efficiency and achieve sustainable growth in today's dynamic business environment.

Importance of Production Efficiency in Industrial Machinery Equipment Industry

Production efficiency is paramount in the industrial machinery equipment industry, and it directly impacts the profitability, competitiveness, and sustainability of manufacturing operations.

Here's why production efficiency holds such significance:

- Cost Reduction: Efficient production processes help minimize operating costs by reducing waste, optimizing resource utilization, and maximizing output per unit of input. This cost reduction is essential for maintaining competitiveness in the market, especially in industries with tight profit margins.

- Improved Profitability: Higher production efficiency directly translates to improved profitability. By reducing production costs and increasing output, manufacturers can achieve higher profit margins and financial performance, ensuring the long-term viability of their business.

- Enhanced Competitiveness: In today's global marketplace, manufacturers face intense competition from both domestic and international players. Efficient production processes enable manufacturers to offer competitive pricing, shorter manufacturing lead times, and superior product quality, thereby gaining a competitive edge in the market.

- Meeting Customer Demand: Production efficiency is crucial for meeting customer demand promptly. Efficient manufacturing processes ensure that products are delivered to customers on schedule, reducing the risk of stockouts, backorders, or delayed deliveries, which can negatively impact customer satisfaction and customer loyalty.

- Capacity Utilization: Maximizing production efficiency allows manufacturers to make the most of their production capacity. By optimizing resource utilization and minimizing idle time, manufacturers can produce more goods within the same timeframe, thereby increasing overall throughput and revenue generation.

- Adaptability to Market Changes: Efficient production processes enable manufacturers to respond quickly to changes in market demand, supply chain disruptions, or regulatory requirements. With streamlined operations and agile manufacturing capabilities, manufacturers can adjust production volumes, product configurations, and delivery schedules to meet evolving market conditions.

- Sustainability: Production efficiency is closely linked to sustainability goals. By reducing energy consumption, minimizing waste generation, and optimizing material usage, manufacturers can minimize their environmental footprint and contribute to sustainable development goals while also improving operational efficiency.

- Risk Mitigation: Inefficient production processes pose operational risks, such as production delays, quality issues, and cost overruns. Production efficiency mitigates these risks by ensuring that manufacturing operations are well-planned, controlled, and executed, reducing the likelihood of disruptions and financial losses.

- Employee Morale and Safety: Efficient production processes contribute to a positive work environment by reducing stress, frustration, and fatigue associated with inefficient workflows. Additionally, streamlined operations often result in safer working conditions, as employees are less likely to be exposed to hazards or accidents caused by poorly designed processes.

- Continuous Improvement: Production efficiency is not a one-time achievement but rather an ongoing pursuit of excellence. By prioritizing production efficiency, manufacturers cultivate a culture of continuous improvement, where processes are constantly evaluated, optimized, and refined to achieve higher levels of efficiency and performance.

In conclusion, production efficiency is of paramount importance in the industrial machinery equipment industry, driving cost reduction, profitability, competitiveness, customer satisfaction, sustainability, and operational resilience.

Leveraging tools such as MRP software is essential for optimizing production processes and achieving these goals effectively.

What is Industrial Machinery Equipment ERP?

Industrial machinery equipment ERP refers to a specialized enterprise resource planning (ERP) system designed specifically to meet the unique needs of companies in the industrial machinery and equipment industry.

This type of manufacturing ERP software is tailored to address the complexities of managing production processes, resource optimization, supply chain management, and regulatory compliance within the industrial machinery sector.

Industrial machinery equipment ERP systems typically offer a range of features and functionalities to support various aspects of manufacturing operations, including:

- Production Planning and Scheduling: Industrial machinery equipment ERP systems help manufacturers plan and schedule production activities efficiently. This includes optimizing production schedules, managing work orders, and allocating resources such as labor, equipment, and materials.

- Inventory Management: These manufacturing ERP systems facilitate effective inventory management by tracking raw materials, components, and finished goods throughout the production process. They provide visibility into inventory levels, automate reorder processes, and optimize inventory turnover ratio to minimize stockouts and excess inventory.

- Supply Chain Management: MRP software systems streamline supply chain processes by integrating procurement, logistics, and supplier management activities. They enable manufacturers to collaborate with suppliers, manage supplier contracts, and ensure timely delivery of materials and components.

- Quality Control and Compliance: These manufacturing software systems include features for managing quality control processes and ensuring compliance with industry regulations and standards. They facilitate inspection, testing, and non-conformance management to maintain product quality and meet regulatory requirements.

- Maintenance Management: Industrial machinery equipment ERP systems support proactive maintenance management by scheduling preventive maintenance tasks, tracking equipment maintenance history, and managing spare parts inventory. This helps minimize equipment downtime and optimize asset performance.

- Data Analytics and Reporting: These manufacturing ERP systems provide robust reporting and analytics capabilities to monitor key performance indicators (KPIs), analyze production data, and identify areas for improvement. They enable manufacturers to make data-driven decisions and drive continuous improvement initiatives.

- Integration with Other Systems: Industrial machinery equipment ERP systems can integrate with other business systems such as CRM, financial management, and CAD/CAM software to streamline operations and ensure data consistency across the organization.

Overall, manufacturing software systems are designed to help manufacturers in the industrial machinery and equipment industry optimize production efficiency, improve operational visibility, and maintain competitiveness in a rapidly evolving market landscape.

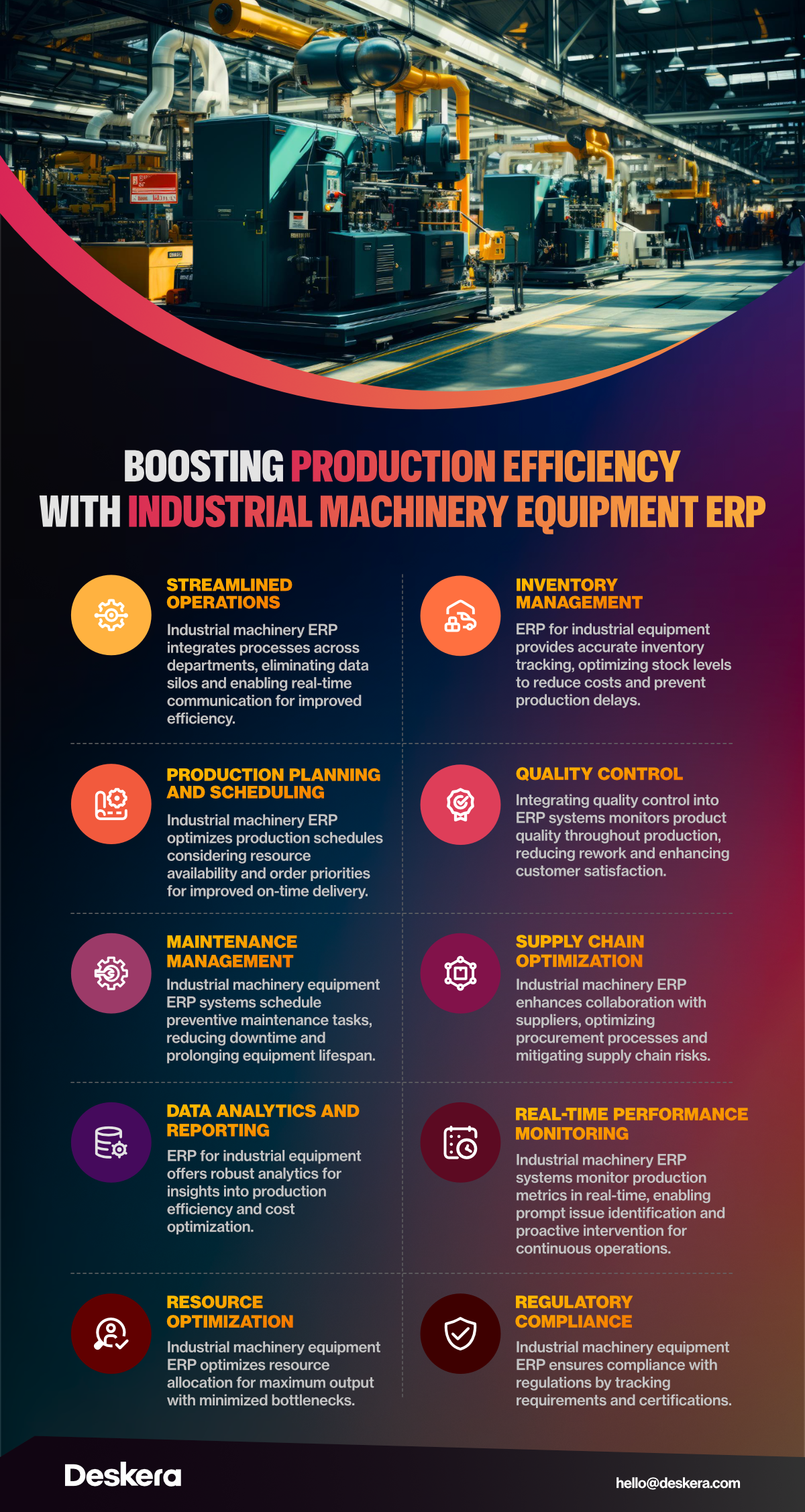

Boosting Production Efficiency with Industrial Machinery Equipment ERP

Implementing an MRP software system tailored to industrial machinery equipment can significantly boost production efficiency in several ways:

Streamlined Operations

Streamlined operations play a pivotal role in enhancing production efficiency within the industrial machinery sector, and leveraging a manufacturing ERP for industrial equipment is integral to achieving this objective.

This MRP software serves as a centralized platform that integrates various facets of operations, including production planning, inventory management, supply chain logistics, and financials.

- Consolidation of Data and Processes: Implementing an industrial machinery equipment ERP system eliminates inefficiencies associated with disparate systems and manual processes. This consolidation enables seamless communication and collaboration across departments, providing stakeholders with real-time information critical for decision-making.

- Efficient Resource Utilization: Industrial machinery equipment ERP facilitates efficient resource utilization by providing insights into equipment availability, workforce allocation, and material requirements. Manufacturing software capabilities optimize production schedules based on factors such as order priorities, lead times, and resource constraints, minimizing idle time and production bottlenecks.

- Streamlined Procurement Processes: The industrial machinery ERP system streamlines procurement processes by automating requisition workflows, supplier communication, and inventory management. By maintaining optimal stock levels and minimizing material shortages, manufacturers reduce production downtime and meet customer demand effectively.

- Standardized and Automated Workflows: Manufacturing ERP for industrial equipment standardizes and automates workflows, ensuring consistency and adherence to best practices across the organization. Automation features eliminate manual data entry tasks, reduce errors, and accelerate transaction processing times, enhancing overall efficiency.

- Integrated Data Flow: The integrated nature of MRP software for industrial equipment enables seamless data flow between different functional areas. This integration eliminates data silos, enables accurate reporting and analysis, and empowers decision-makers with actionable insights into production performance, cost trends, and resource utilization.

In summary, the adoption of industrial machinery equipment ERP is instrumental in streamlining operations and boosting production efficiency in the manufacturing sector.

By consolidating processes, optimizing resource utilization, automating workflows, and facilitating data-driven decision-making, manufacturing ERP systems empower manufacturers to achieve higher levels of operational excellence and competitive advantage in today's dynamic marketplace.

Inventory Management

Inventory management is a critical component of boosting production efficiency within the industrial machinery sector, and leveraging an industrial machinery equipment ERP system is paramount for achieving optimal inventory control.

This specialized manufacturing ERP solution offers robust features tailored to address the unique inventory challenges faced by manufacturers in this industry.

- Real-time Visibility: Industrial machinery equipment ERP systems offer real-time visibility into inventory levels, movements, and requirements, ensuring accurate and up-to-date information on raw materials, components, and finished goods.

- Inventory Optimization: These manufacturing ERPs for industrial equipment provide sophisticated tools for inventory optimization, analyzing demand forecasts, lead times, and supplier performance data to generate accurate replenishment recommendations and maintain optimal stock levels while minimizing carrying costs.

- Process Automation: Manufacturing ERP solutions automate tasks such as order processing, receiving, and stock transfers, reducing manual effort and errors. Integration with barcode scanning and RFID technologies improves inventory tracking accuracy and reduces discrepancies.

- Multi-level Bill of Materials (BOM) Management: MRP software for industrial equipment supports effective management of complex BOM structures, tracking component usage, and ensuring the availability of the right materials at each production stage to minimize delays and maximize efficiency.

- Integration with Other Functional Areas: Industrial machinery equipment ERP integrates inventory management with production planning, purchasing, and sales processes, enabling better coordination and alignment across the supply chain. This integration ensures that inventory decisions are based on accurate demand forecasts and production schedules, improving production efficiency and customer satisfaction.

In summary, industrial machinery equipment ERP plays a crucial role in boosting production efficiency by providing comprehensive inventory management capabilities.

By offering real-time visibility, inventory optimization tools, process automation, multi-level BOM management, and seamless integration with other functional areas, MRP software systems empower manufacturers to achieve optimal inventory control and streamline operations for maximum efficiency and profitability.

Production Planning and Scheduling

Production planning and scheduling are crucial aspects of boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems play a vital role in optimizing these processes.

This specialized manufacturing ERP solution offers advanced features tailored to address the unique production planning and scheduling challenges faced by manufacturers in this industry.

- Comprehensive Visibility: Industrial machinery equipment ERP provides comprehensive visibility into production capacity, resource availability, and order priorities. By integrating data from various sources like sales orders, forecasts, and inventory levels, the manufacturing software system helps develop accurate production plans that balance customer demand with available resources.

- Sophisticated Scheduling Tools: Industrial machinery ERP systems offer sophisticated production scheduling tools to optimize production sequences, minimize setup times, and maximize equipment utilization. Advanced algorithms and optimization techniques generate efficient production schedules considering production constraints, lead times, and resource dependencies.

- Collaborative Planning and Coordination: Manufacturing ERP solutions facilitate collaborative production planning and scheduling by enabling communication and coordination among different departments and stakeholders. Shared calendars, task assignments, and real-time notifications ensure alignment on production priorities and timelines, minimizing delays and disruptions.

- What-if Analysis and Scenario Planning: Industrial machinery equipment ERP supports what-if analysis and scenario planning, allowing manufacturers to simulate different production scenarios. This capability helps assess the impact of changes in demand, capacity, or resource availability on production schedules, enabling proactive decision-making and risk mitigation.

- Integration with Other Functional Areas: Manufacturing ERP for industrial equipment integrates production planning and scheduling with other functional areas like inventory management, procurement, and quality control. This integration ensures better coordination and alignment across the supply chain, enabling smooth and efficient execution of production plans to improve production efficiency and customer satisfaction.

In summary, industrial machinery equipment ERP plays a critical role in boosting production efficiency by providing advanced production planning and scheduling capabilities.

By offering comprehensive visibility, sophisticated scheduling tools, collaborative features, what-if analysis capabilities, and seamless integration with other functional areas, MRP software systems empower manufacturers to optimize production processes and maximize efficiency for sustainable growth and competitiveness.

Quality Control

Quality control is a critical aspect of boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems play a pivotal role in ensuring product quality while optimizing manufacturing processes.

This specialized MRP software offers robust features tailored to address the unique quality control challenges faced by manufacturers in this industry.

- Comprehensive Visibility: Industrial machinery equipment ERP provides comprehensive visibility into quality parameters and performance metrics throughout the production process. Integration with production workflows and inspection processes enables monitoring of product quality from raw material inspection to final product testing.

- Sophisticated Quality Control Tools: Industrial machinery ERP systems offer sophisticated quality control tools to implement and enforce quality standards effectively. Features such as configurable inspection checklists, statistical process control (SPC) charts, and non-conformance management workflows facilitate proactive identification and resolution of quality issues, minimizing rework, scrap, and warranty claims.

- Traceability and Accountability: Manufacturing ERP solutions establish traceability and accountability for quality control activities by maintaining comprehensive audit trails and documentation. Capturing data on production processes, inspection results, and corrective actions within the ERP system ensures compliance with regulatory requirements and customer specifications, enhancing trust and credibility in products.

- Continuous Improvement Initiatives: ERP for industrial equipment supports continuous improvement initiatives through data analysis and reporting. Analysis of quality performance metrics within the ERP system identifies trends, root causes, and areas for improvement. This data-driven approach enables proactive total quality management and drives ongoing process optimization efforts, improving overall product quality and customer satisfaction.

- Integration with Other Functional Areas: MRP software integration with other functional areas enhances operational efficiency. Quality control data seamlessly links with production planning, inventory management, and supplier management processes, ensuring better coordination and alignment across the supply chain. Embedding quality considerations throughout the production process leads to higher production efficiency and fewer disruptions.

In summary, industrial machinery equipment ERP plays a crucial role in boosting production efficiency by providing comprehensive quality control capabilities.

By offering visibility, sophisticated tools, traceability features, data analysis capabilities, and seamless integration with other functional areas, manufacturing ERP systems empower manufacturers to ensure product quality while optimizing manufacturing processes for sustainable growth and competitiveness.

Maintenance Management

Maintenance management is a fundamental aspect of boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems play a crucial role in optimizing equipment maintenance processes.

This specialized industrial machinery ERP offers robust features tailored to address the unique maintenance challenges faced by manufacturers in this industry.

- Comprehensive Visibility: Industrial machinery equipment ERP provides comprehensive visibility into equipment performance, maintenance schedules, and maintenance history. Integration with maintenance workflows and scheduling processes enables monitoring of critical assets' condition and proactive planning of maintenance activities.

- Sophisticated Maintenance Management Tools: Manufacturing ERP systems offer sophisticated tools for implementing preventive maintenance programs effectively. Features such as asset tracking, maintenance scheduling, and work order management facilitate the planning and execution of routine maintenance tasks, minimizing unplanned downtime and production disruptions.

- Optimization of Spare Parts Inventory Management: Manufacturing ERP solutions optimize spare parts inventory management and procurement processes to support maintenance activities. Accurate inventory data and reorder triggers ensure critical spare parts availability, minimizing equipment downtime and maximizing production efficiency.

- Support for Predictive Maintenance Strategies: Industrial machinery equipment ERP supports predictive maintenance strategies through advanced analytics and machine learning capabilities. Analysis of equipment performance data enables predictive maintenance alerts and recommendations, allowing proactive intervention to address issues before they impact production.

- Integration with Other Functional Areas: Manufacturing ERP for industrial equipment integration with other functional areas enhances operational efficiency. Maintenance schedules seamlessly link with production planning, inventory management, and procurement processes, ensuring better coordination and alignment across the supply chain. This integration prioritizes maintenance activities based on production requirements and resource availability, leading to higher production efficiency and fewer disruptions.

In summary, industrial machinery equipment ERP plays a critical role in boosting production efficiency by providing comprehensive maintenance management capabilities.

By offering visibility, preventive maintenance tools, predictive maintenance capabilities, spare parts inventory optimization, and seamless integration with other functional areas, MRP software systems empower manufacturers to optimize equipment reliability, minimize downtime, and maximize production efficiency for sustainable growth and competitiveness.

Supply Chain Optimization

Supply chain optimization is a critical aspect of boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems play a pivotal role in achieving this objective.

This specialized manufacturing ERP solution offers robust features tailored to address the unique supply chain challenges faced by manufacturers in this industry.

- Comprehensive Visibility: MRP software for industrial equipment provides comprehensive visibility into supply chain processes, including raw material procurement and product delivery. Integration of data from suppliers, production facilities, warehouses, and distribution channels allows real-time monitoring of supply chain performance and identification of improvement opportunities.

- Sophisticated Planning and Forecasting Tools: Industrial machinery ERP systems offer advanced supply chain planning and forecasting tools to optimize inventory levels, production schedules, and procurement activities. Features like demand forecasting, inventory optimization, and production planning align supply chain activities with production requirements, ensuring the timely availability of materials and resources.

- Collaboration and Communication Enhancement: Manufacturing software solutions facilitate collaboration with suppliers and partners through features like electronic data interchange (EDI) and supplier portals. Seamless information exchange streamlines procurement processes, reduces lead times, and minimizes supply chain risks, enhancing production efficiency and on-time delivery performance.

- Support for Lean Manufacturing Principles: Industrial machinery equipment ERP supports lean manufacturing principles and continuous improvement initiatives by analyzing supply chain data. Identification of waste, inefficiencies, or bottlenecks enables the implementation of strategies to streamline processes, reduce costs, and improve supply chain agility and responsiveness.

- Integration with Other Functional Areas: Manufacturing ERP integration with other functional areas enhances operational efficiency. Supply chain planning data seamlessly links with production scheduling, inventory management, and customer order fulfillment processes, ensuring better coordination and alignment across the supply chain. This integration aligns supply chain decisions with production priorities and customer demand, leading to higher production efficiency and customer satisfaction.

In summary, industrial machinery equipment ERP plays a crucial role in boosting production efficiency by providing comprehensive supply chain optimization capabilities.

By offering visibility, planning tools, collaboration features, lean manufacturing support, and seamless integration with other functional areas, MRP software systems empower manufacturers to optimize their supply chains, minimize costs, and maximize production efficiency for sustainable growth and competitiveness.

Data Analytics and Reporting

Data analytics and reporting are essential components of boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems play a crucial role in leveraging data-driven insights to drive continuous improvement.

This specialized MRP software offers robust features tailored to address the unique data analytics and reporting needs of manufacturers in this industry.

- Comprehensive Visibility: Industrial machinery equipment ERP provides comprehensive visibility into key performance metrics across the production process. Integration of data from various sources like production operations, inventory management, and quality control enables real-time monitoring and analysis of production efficiency, equipment utilization, and critical performance indicators.

- Sophisticated Data Analytics Tools: ERP for industrial equipment offers sophisticated data analytics tools to gain insights into production trends and identify areas of inefficiency. Customizable dashboards, ad-hoc reporting, and data visualization tools empower users to analyze large volumes of data quickly and make informed decisions to optimize production processes.

- Standard Reports and Compliance Documentation: Manufacturing software solutions enable the generation of standard reports and compliance documentation to meet regulatory requirements and customer specifications. Automated report generation and distribution processes save time and resources, ensuring stakeholders have timely and accurate information for decision-making and regulatory compliance.

- Predictive and Prescriptive Analytics: Industrial machinery ERP supports predictive and prescriptive analytics capabilities by analyzing historical production data and identifying patterns. Predictive insights and recommendations guide future decision-making and drive continuous improvement initiatives.

- Integration with Other Functional Areas: Manufacturing ERP integration with other functional areas enhances operational efficiency. Production performance data seamlessly links with quality control, maintenance management, and supply chain optimization processes, enabling better coordination and alignment across the organization. Leveraging data-driven insights drives improvements in all aspects of production, leading to higher production efficiency and competitiveness.

In summary, industrial machinery equipment ERP plays a crucial role in boosting production efficiency by providing comprehensive data analytics and reporting capabilities.

By offering visibility, analytics tools, compliance reporting, predictive insights, and seamless integration with other functional areas, manufacturing ERP systems empower manufacturers to leverage data-driven insights to optimize production processes, reduce costs, and maximize efficiency for sustainable growth and competitiveness.

Regulatory Compliance

Ensuring regulatory compliance is a critical aspect of boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems play a vital role in helping manufacturers meet regulatory requirements efficiently.

This specialized industrial machinery ERP offers robust features tailored to address the unique regulatory compliance challenges faced by manufacturers in this industry.

- Centralized Compliance Management: Industrial machinery equipment ERP centralizes and streamlines compliance management processes by integrating regulatory requirements, certifications, and documentation within the system. This ensures easy access to up-to-date information, reducing the risk of non-compliance and associated penalties.

- Automated Compliance Activities: ERP for industrial equipment automates compliance checks and approvals for production processes, ensuring activities meet regulatory standards. They generate audit trails and documentation to demonstrate compliance, facilitating regulatory audits and inspections.

- Stay up-to-date with Regulatory Changes: MRP software solutions provide automated alerts and notifications for changing regulatory requirements. Configured to monitor regulatory updates relevant to operations, they enable proactive compliance management and prevent disruptions to production activities.

- Support for Industry-specific Compliance: Industrial machinery equipment ERP supports industry-specific compliance frameworks and standards. Built-in features cater to highly regulated industries, ensuring compliance with product safety, environmental impact, and workplace safety regulations without additional customization.

- Integration with Functional Areas: Manufacturing ERP systems integrate regulatory compliance management with other functional areas like production planning, quality control, and supply chain management. This coordination ensures compliance considerations are embedded throughout the production process, reducing the risk of non-compliance-related delays or disruptions.

In summary, industrial machinery equipment ERP plays a crucial role in boosting production efficiency by providing comprehensive support for regulatory compliance management.

By offering centralized compliance management, automated compliance checks, industry-specific support, and seamless integration with other functional areas, manufacturing software systems empower manufacturers to meet regulatory requirements efficiently while maximizing production efficiency and competitiveness.

Resource Optimization

Resource optimization is a key factor in boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems are instrumental in achieving this goal.

This specialized manufacturing ERP solution offers robust features tailored to address the unique challenges of resource management in manufacturing operations.

- Comprehensive Visibility: ERP for industrial equipment provides comprehensive visibility into resource availability, utilization rates, and capacity constraints. Integration of data from production schedules, workforce schedules, and equipment maintenance logs enables real-time monitoring and analysis of resource utilization.

- Sophisticated Resource Planning Tools: Industrial machinery ERP systems offer sophisticated resource planning tools to optimize labor, equipment, and material allocation. Features like capacity planning, resource leveling, and skill-based scheduling maximize production efficiency while minimizing idle time and bottlenecks.

- Accurate Resource Forecasting: Manufacturing ERP solutions enable accurate resource forecasting based on production forecasts, order volumes, and historical data. Analysis of demand patterns and production trends within the ERP system allows proactive adjustment of resource allocations to meet changing production needs and minimize shortages or overages.

- Scenario Planning and What-if Analysis: Industrial machinery equipment ERP supports scenario planning and what-if analysis. Manufacturers can simulate different production scenarios to assess the impact of changes in resource availability, production schedules, or demand forecasts on production efficiency, enabling proactive decision-making and risk mitigation.

- Integration with Other Functional Areas: Manufacturing software integration with other functional areas enhances operational efficiency. Resource planning data seamlessly links with production scheduling, inventory management, and procurement processes, ensuring better coordination and alignment across the organization. This integration ensures resource decisions are aligned with production priorities and customer demand, leading to higher production efficiency and customer satisfaction.

In summary, industrial machinery equipment ERP plays a crucial role in boosting production efficiency by providing comprehensive support for resource optimization.

By offering visibility, planning tools, forecasting capabilities, scenario analysis, and seamless integration with other functional areas, MRP software systems empower manufacturers to optimize the allocation of resources, minimize costs, and maximize efficiency for sustainable growth and competitiveness.

Real-Time Performance Monitoring

Real-time performance monitoring is a critical aspect of boosting production efficiency within the industrial machinery sector, and industrial machinery equipment ERP systems play a pivotal role in providing timely insights into production performance metrics.

This specialized industrial machinery ERP offers robust features tailored to address the unique challenges of real-time monitoring in manufacturing operations.

- Comprehensive Visibility: Industrial machinery equipment ERP provides comprehensive visibility into production processes, equipment status, and key performance indicators (KPIs) in real time. Integration of data from production sensors, machine interfaces, and control systems enables continuous monitoring and issue identification.

- Customizable Dashboards and Reporting Tools: Industrial machinery ERP systems offer customizable dashboards and real-time reporting tools for visualizing and analyzing production data. Features like live data feeds, interactive charts, and customizable alerts provide stakeholders instant access to critical metrics, facilitating performance monitoring, trend identification, and informed decision-making.

- Tracking Key Performance Indicators (KPIs): Manufacturing ERP solutions enable real-time tracking of KPIs related to production efficiency, equipment utilization, and downtime. Automated alerts and notifications allow proactive identification of performance deviations, facilitating corrective actions to minimize disruptions and maximize efficiency.

- Support for Predictive Analytics: Industrial machinery equipment ERP supports predictive analytics and prescriptive insights by analyzing historical production data. By identifying patterns indicative of potential issues or opportunities, the manufacturing software system generates predictive insights and recommendations for proactive decision-making and continuous improvement initiatives.

- Integration with Other Functional Areas: Real-time performance monitoring integrates seamlessly with other functional areas within the MRP software system, enhancing operational efficiency. Production data links with production planning, inventory management, and maintenance processes, ensuring better coordination and alignment across the organization. This integration ensures production decisions are based on accurate, up-to-date information, leading to higher efficiency and customer satisfaction.

In summary, industrial machinery equipment ERP plays a crucial role in boosting production efficiency by providing comprehensive support for real-time performance monitoring.

By offering visibility, reporting tools, predictive insights, and seamless integration with other functional areas, manufacturing ERP systems empower manufacturers to monitor production performance continuously, identify opportunities for improvement, and optimize production processes for sustainable growth and competitiveness.

How can Deskera as an Industrial Machinery Equipment ERP Help in Boosting Production Efficiency?

Deskera, as an industrial machinery equipment ERP solution, can significantly contribute to boosting production efficiency in several ways:

- Streamlined Production Planning and Scheduling: Deskera ERP facilitates efficient production planning and scheduling by providing tools to optimize production schedules, allocate resources effectively, and balance production capacity with demand. This ensures that production processes run smoothly and that resources are utilized optimally.

- Enhanced Inventory Management: Deskera ERP helps manufacturers manage inventory efficiently by providing real-time visibility into inventory levels, automating reorder processes, and optimizing inventory turnover. This ensures that the right materials are available when needed, minimizing stockouts and excess inventory carrying costs.

- Improved Supply Chain Management: Deskera ERP streamlines supply chain processes by integrating procurement, logistics, and supplier management activities. It enables manufacturers to collaborate with suppliers, manage supplier contracts, and ensure timely delivery of materials and components, thereby reducing supply chain bottlenecks and disruptions.

- Effective Quality Control and Compliance Management: Deskera ERP includes features for managing quality control processes and ensuring compliance with industry regulations and standards. It facilitates inspection, testing, and non-conformance management to maintain product quality and meet regulatory requirements, reducing the risk of defects and production delays.

- Proactive Maintenance Management: Deskera ERP supports proactive maintenance management by scheduling preventive maintenance tasks, tracking equipment maintenance history, and managing spare parts inventory. This helps minimize equipment downtime, optimize asset performance, and reduce maintenance costs.

- Comprehensive Data Analytics and Reporting: Deskera ERP provides robust reporting and analytics capabilities to monitor key performance indicators (KPIs), analyze production data, and identify areas for improvement. It enables manufacturers to make data-driven decisions, drive continuous improvement initiatives, and optimize production processes for increased efficiency and profitability.

- Integration with Other Systems: Deskera ERP can integrate with other business systems such as CRM, financial management, and other relevant integrations to streamline operations and ensure data consistency across the organization. This integration enhances visibility, collaboration, and efficiency throughout the entire production process.

Key Takeaways

Industrial machinery equipment ERP systems play a pivotal role in boosting production efficiency within the industrial machinery equipment industry.

By providing a comprehensive suite of tools and functionalities tailored to the unique needs of manufacturers, these MRP software systems empower companies to streamline operations, optimize resource utilization, ensure compliance and quality assurance, and drive continuous improvement.

The 10 ways in which industrial machinery equipment ERP will help in boosting production efficiency are:

- Streamlined Operations: A manufacturing ERP system integrates various processes across departments like manufacturing, inventory management, supply chain, and finance. This integration eliminates data silos and facilitates real-time communication, leading to streamlined operations and improved efficiency.

- Inventory Management: MRP software systems provide accurate and real-time inventory tracking, helping companies maintain optimal stock levels. With better visibility into inventory levels, manufacturers can reduce excess inventory costs while ensuring that necessary components are always available, minimizing production delays.

- Production Planning and Scheduling: Industrial machinery equipment ERP software enables effective production planning and scheduling by considering factors like resource availability, order priorities, and lead times. Advanced planning tools within ERP systems can optimize production schedules, minimize idle time, and improve on-time delivery performance.

- Quality Control: Integrating quality control processes into the MRP software system allows manufacturers to monitor product quality at every stage of production. By identifying and addressing quality issues early, companies can reduce rework, scrap, and warranty claims, ultimately improving overall product quality and customer satisfaction.

- Maintenance Management: Manufacturing ERP systems can incorporate maintenance management functionalities to schedule preventive maintenance tasks, track equipment downtime, and manage spare parts inventory. Proactive maintenance planning helps minimize unplanned downtime, prolong equipment lifespan, and reduce repair costs.

- Supply Chain Optimization: Industrial machinery ERP systems facilitate better collaboration with suppliers and partners through features like electronic data interchange (EDI) and supplier portals. Enhanced supply chain visibility enables manufacturers to anticipate demand fluctuations, optimize procurement processes, and mitigate supply chain risks.

- Data Analytics and Reporting: Manufacturing ERP platforms offer robust reporting and analytics capabilities, allowing companies to gain insights into key performance metrics such as production efficiency, equipment utilization, and production costs. Data-driven decision-making based on these insights can drive continuous improvement initiatives and optimize production processes further.

- Regulatory Compliance: Many industries have stringent regulatory requirements regarding product safety, environmental impact, and workplace safety. ERP for industrial equipment can help companies ensure compliance with these regulations by providing tools for tracking and managing regulatory requirements, certifications, and documentation.

- Resource Optimization: Manufacturing software systems help optimize resource allocation by providing visibility into resource availability, utilization rates, and capacity constraints. With this information, manufacturers can better allocate labor, equipment, and materials to maximize production output while minimizing idle time and bottlenecks.

- Real-Time Performance Monitoring: Industrial machinery equipment ERP systems offer real-time monitoring of production performance metrics such as equipment uptime, cycle times, and production yields. This real-time visibility enables operators and managers to promptly identify inefficiencies, troubleshoot issues, and implement corrective actions to maintain optimal production efficiency. Additionally, predictive analytics capabilities within MRP software systems can anticipate potential production disruptions, allowing proactive intervention to mitigate risks and ensure continuous operations.

Through enhanced visibility, control, and collaboration, manufacturing ERP technology enables manufacturers to overcome challenges, seize opportunities, and achieve new levels of efficiency, productivity, and competitiveness.

As the industrial machinery equipment industry continues to evolve and adapt to changing market dynamics, MRP software systems will remain indispensable tools for manufacturers seeking to thrive in today's fast-paced and demanding business environment.

Overall, Deskera as an industrial machinery equipment ERP solution empowers manufacturers to optimize production efficiency, improve operational visibility, and maintain competitiveness in today's dynamic business environment.

By leveraging Deskera ERP's comprehensive features and functionalities, manufacturers can streamline production processes, minimize costs, and maximize productivity for sustainable growth and success.

Related Articles