Every organization, regardless of its size or industry, relies on procurement to sustain operations. While direct procurement focuses on acquiring raw materials for production, indirect procurement plays an equally crucial role by covering non-production-related expenses such as office supplies, IT services, marketing, and facility management.

Though often overlooked, indirect procurement significantly impacts cost control, efficiency, and overall business profitability. Without a well-structured approach, businesses may struggle with uncontrolled spending, inefficient supplier management, and lack of visibility into procurement processes.

Managing indirect procurement can be complex due to its decentralized nature. Unlike direct procurement, which typically follows a structured sourcing and supply chain strategy, indirect procurement involves multiple departments making purchases independently.

This decentralized approach can lead to fragmented supplier relationships, duplicate purchases, and difficulties in tracking overall spending. To mitigate these challenges, companies must adopt strategic procurement practices that centralize spending, optimize supplier selection, and leverage technology to improve efficiency.

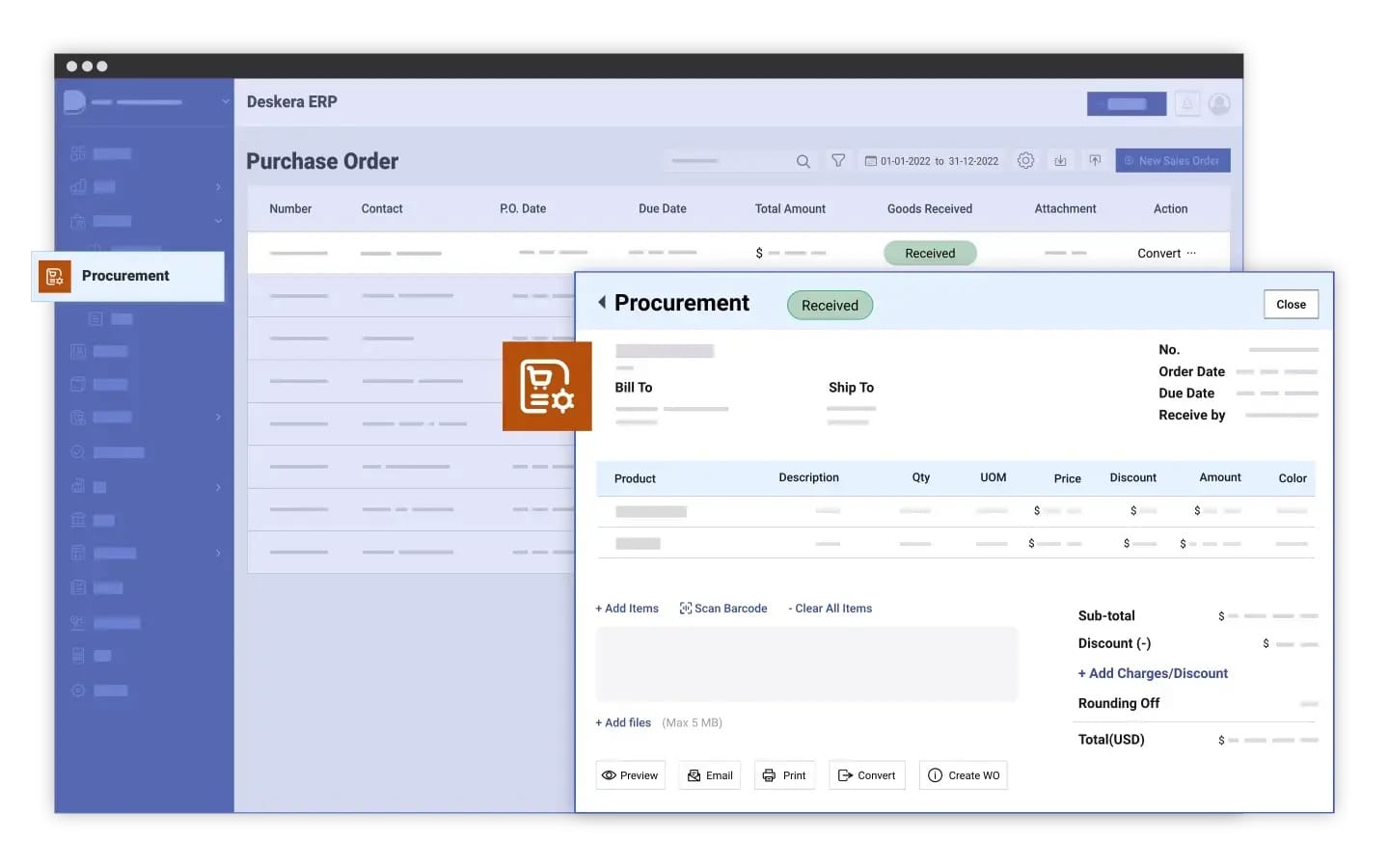

Technology is transforming indirect procurement by enabling businesses to automate workflows, improve spend visibility, and enforce procurement policies. Enterprise Resource Planning (ERP) systems like Deskera ERP provide businesses with real-time tracking, automated approval workflows, and robust reporting capabilities to streamline procurement processes.

With features such as demand forecasting, supplier management, and financial reporting, Deskera ERP helps organizations gain better control over indirect procurement, ensuring cost savings and compliance with procurement policies.

In this comprehensive guide, we will explore the fundamentals of indirect procurement, its key challenges, and best practices to optimize costs and efficiency. We will also discuss how technology, particularly ERP solutions, can help businesses overcome procurement inefficiencies and drive long-term success.

Whether you are a procurement professional or a business leader looking to enhance your procurement strategy, this guide will provide valuable insights to refine your approach to indirect procurement.

What is Indirect Procurement?

Indirect procurement refers to the process of acquiring goods and services that support a company's daily operations but are not directly involved in the production of goods or services sold to customers.

Unlike direct procurement, which focuses on raw materials and components essential for manufacturing, indirect procurement covers a wide range of operational expenses such as office supplies, IT services, marketing, facility management, and professional consulting.

Since indirect procurement does not contribute directly to revenue generation, it is often deprioritized compared to direct procurement. However, inefficient management of indirect procurement can lead to excessive costs, supplier redundancies, and operational inefficiencies. Businesses that fail to track and optimize their indirect spending may face budget overruns, compliance risks, and fragmented supplier relationships.

To address these challenges, organizations adopt strategic procurement management practices that centralize purchasing, implement cost control measures, and leverage technology for automation and analytics.

Enterprise Resource Planning (ERP) solutions, such as Deskera ERP, help businesses streamline indirect procurement by offering features like spend analysis, supplier management, and automated approvals, ensuring better visibility and control over expenses.

Effective indirect procurement not only helps reduce operational costs but also improves process efficiency, compliance, and overall business performance. By optimizing how these purchases are managed, businesses can enhance profitability while maintaining seamless operations.

Indirect vs. Direct Procurement: Key Differences

While both direct and indirect procurement play essential roles in business operations, they serve distinct purposes and require different management strategies. Understanding these differences helps organizations optimize their procurement processes for efficiency and cost savings.

In summary, direct procurement is essential for production and revenue generation, while indirect procurement ensures smooth business operations. Managing both effectively is crucial for cost optimization and operational efficiency.

ERP systems like Deskera ERP help organizations streamline both procurement types by providing centralized tracking, automated approvals, and supplier management features.

Key Categories of Indirect Procurement

Indirect procurement encompasses a wide range of goods and services that support business operations but do not contribute directly to product manufacturing. Below are the main categories of indirect procurement:

1. Office Supplies and Facility Management

- Stationery, printers, and office furniture

- Cleaning services and maintenance

- Utilities (electricity, water, internet)

- Rent and property management

2. IT and Software Services

- Hardware (laptops, servers, networking equipment)

- Software licenses and cloud subscriptions

- Cybersecurity solutions

- IT support and managed services

3. Marketing and Advertising

- Digital and print advertising

- Social media management and SEO

- Branding, graphic design, and content creation

- Event sponsorships and public relations

4. Professional Services

- Legal and compliance consulting

- HR and recruitment services

- Financial and auditing services

- Training and employee development

5. Travel and Employee Benefits

- Business travel (flights, hotels, transportation)

- Employee wellness programs and insurance

- Corporate gifts and recognition programs

- Meal and entertainment expenses

6. Logistics and Supply Chain Support

- Third-party logistics (3PL) and warehousing

- Packaging materials for internal use

- Transportation and fleet management

- Customs brokerage and freight forwarding

7. Research and Development (R&D) Support

- Laboratory equipment and testing services

- Industry reports and market research

- External R&D partnerships and consultancy

Managing these categories effectively requires procurement automation and spend tracking. ERP solutions like Deskera ERP enable businesses to centralize procurement, streamline approvals, and gain visibility into indirect spending, ensuring cost control and operational efficiency.

Advantages of Indirect Procurement

Effective indirect procurement can drive significant cost savings, improve supplier relationships, and enhance operational efficiency. By leveraging procurement automation, spend visibility, and strategic supplier management, businesses can optimize their indirect procurement processes.

Here are the key advantages:

1. Cost Savings and Efficiency

Implementing procurement best practices and automation helps reduce unnecessary spending and improve cost control. By centralizing purchases from pre-approved suppliers, businesses can eliminate maverick spending—unauthorized purchases that lead to budget overruns. Procurement automation tools also enable bulk purchasing, contract renegotiation, and early payment discounts, further reducing expenses.

Additionally, consolidating indirect purchases across multiple departments allows businesses to leverage volume discounts, reducing overall procurement costs. For example, a company purchasing office supplies for multiple locations at once may secure better pricing than buying separately for each department.

2. Improved Spend Visibility

A lack of transparency in indirect procurement can lead to inefficient spending. Modern procurement automation systems, especially those integrated with ERP solutions like Deskera ERP, provide real-time tracking of expenditures by vendor, category, and department. AI-powered analytics and dashboards help businesses identify cost-saving opportunities, monitor trends, and prevent overspending.

With centralized document management, companies can store and access contracts, purchase orders (POs), and invoices in a single system, enabling better financial forecasting and budget allocation. This level of transparency also helps prevent fraud and unauthorized purchases.

3. Greater Supplier Availability and Flexibility

Unlike direct procurement, which often involves long-term supplier contracts, indirect procurement allows companies to explore a broader pool of vendors. This flexibility enables businesses to compare prices, negotiate competitive terms, and quickly switch suppliers in case of disruptions. Maintaining multiple supplier relationships reduces risks associated with shortages or delays.

For instance, if an office equipment supplier experiences logistical delays, businesses can easily pivot to alternative suppliers without affecting operations. Having multiple vendor relationships also ensures better pricing competition, which can lead to cost reductions.

4. Stronger Supplier Relationships

Effective supplier relationship management (SRM) ensures long-term collaboration and improved service quality. By tracking key performance indicators (KPIs) such as on-time deliveries, product quality, and pricing trends, businesses can identify high-performing suppliers and foster long-term strategic partnerships. A well-managed supplier network results in better service levels, cost reductions, and joint innovation opportunities.

By maintaining ongoing communication and performance reviews, businesses can work collaboratively with suppliers to develop new solutions, negotiate better contracts, and improve operational efficiencies.

5. Enhanced Supplier Performance Evaluation

Indirect procurement involves diverse vendors providing a range of services. Specialized procurement software enables continuous vendor assessment, ensuring that only the best suppliers are retained. Supplier scoring systems evaluate factors such as delivery timelines, financial stability, and price competitiveness, helping businesses maintain optimal supplier portfolios.

With AI-powered procurement systems, companies can automate supplier performance tracking, ensuring that vendors consistently meet contractual obligations and service level agreements (SLAs). This proactive approach minimizes disruptions and improves procurement efficiency.

6. Competitive Advantage and Agility

Strategic management of indirect procurement allows companies to adapt quickly to market changes and secure innovative products and services ahead of competitors. Businesses that establish strong supplier partnerships may gain priority access to new technologies, customized solutions, and exclusive discounts, enhancing their market position.

For example, an IT company with strong procurement relationships may gain early access to the latest software solutions, giving them a competitive edge in adopting new technology.

7. Support for Sustainability and Corporate Responsibility

Companies can integrate Environmental, Social, and Governance (ESG) principles into their procurement policies. By selecting suppliers committed to sustainable sourcing, ethical labor practices, and diversity initiatives, businesses can reduce their environmental footprint and enhance their corporate social responsibility (CSR) efforts. Many organizations now include sustainability clauses in supplier contracts and evaluate adherence to these standards.

For example, a company may prioritize suppliers using biodegradable packaging or partner with vendors that promote fair labor practices, aligning with corporate sustainability goals.

8. Reduced Administrative Workload

Procurement automation streamlines manual, time-consuming tasks such as vendor management, purchase order approvals, and contract negotiations. By using cloud-based procurement platforms, businesses can centralize processes, reducing paperwork and eliminating inefficiencies.

With automated workflows and approval hierarchies, procurement teams can focus on strategic decision-making rather than routine administrative work, improving overall productivity.

9. Risk Mitigation and Compliance

Indirect procurement plays a crucial role in minimizing business risks by ensuring compliance with regulatory standards and internal policies. Procurement automation platforms help businesses monitor contract terms, supplier credentials, and industry regulations, reducing exposure to legal and financial risks.

For example, companies in heavily regulated industries such as healthcare and finance can automate compliance checks and reporting, ensuring that vendors meet industry-specific standards.

10. Standardization Across Departments

Without a structured indirect procurement strategy, different departments may source suppliers independently, leading to inconsistent pricing, contract terms, and product quality. A centralized procurement system ensures uniformity in supplier selection, pricing structures, and procurement workflows.

By standardizing procurement processes, businesses can eliminate inefficiencies, reduce redundancies, and improve overall procurement governance.

Challenges in Indirect Procurement

Indirect procurement plays a crucial role in business operations, encompassing purchases that do not directly contribute to the production process but are essential for running an organization.

Unlike direct procurement, which focuses on raw materials and production inputs, indirect procurement covers categories such as office supplies, IT services, marketing, and facilities management. This distinction presents several unique challenges, requiring dedicated strategies and efficient processes.

Below are some of the key obstacles businesses face in managing indirect procurement.

1. Sheer Scale and Complexity

Indirect procurement involves a broad range of spending categories, from small office purchases to large-scale service contracts. Managing multiple vendors, negotiating various contracts, and ensuring compliance with company policies make it a highly complex process. The scale of indirect procurement often results in inefficiencies, making it challenging to maintain cost control and operational efficiency.

2. Poor Spend Visibility

A significant challenge in indirect procurement is the lack of visibility into expenditures. Since purchases are often decentralized across departments, it becomes difficult to track, monitor, and analyze spending patterns.

Without transparency, organizations risk overspending, redundant purchases, and difficulty identifying cost-saving opportunities. Implementing centralized procurement technology can enhance visibility and streamline spending.

3. Maverick Spending

Maverick spending refers to unauthorized or uncontrolled purchases made outside the standard procurement process. Employees may bypass procurement guidelines due to convenience, urgency, or lack of awareness.

This unregulated approach leads to budget overruns, compliance risks, and missed opportunities for negotiated pricing. Organizations need to establish clear procurement policies and automate compliance measures to curb maverick spending.

4. Lack of Procurement Policies

Without well-defined policies, indirect procurement can become disorganized, resulting in inconsistent purchasing decisions and higher costs. Policies ensure that purchases align with company goals, budget constraints, and supplier agreements.

Businesses should implement structured procurement guidelines that offer both oversight and flexibility, allowing employees to make informed purchasing decisions while maintaining cost control.

5. Data Silos and Fragmentation

Many organizations struggle with data fragmentation in indirect procurement. When procurement data is scattered across different systems or departments, it becomes difficult to gain a holistic view of expenditures.

Inconsistent data collection limits financial forecasting, reporting accuracy, and strategic decision-making. Businesses must integrate procurement data into centralized platforms to enable better analysis and cost management.

6. Inefficiencies in Spend Management

Indirect procurement often involves frequent, low-volume purchases across various departments. Without a consolidated approach, organizations miss out on volume discounts, vendor negotiations, and cost efficiencies.

Inefficient spend management also increases administrative burdens, leading to higher operational costs. Implementing spend analytics and automation can help optimize procurement processes and improve cost-effectiveness.

7. Supplier Relationship Challenges

Unlike direct procurement, where supplier relationships are more structured, indirect procurement suppliers often lack dedicated oversight. When multiple stakeholders interact with vendors without a unified approach, it becomes difficult to manage contracts, monitor performance, and ensure supplier compliance. Establishing a centralized supplier management system can help strengthen relationships, negotiate better terms, and reduce third-party risks.

8. Compliance and Risk Management

Indirect procurement often involves services and software purchases that may come with regulatory, security, or contractual risks. Without proper compliance measures, businesses may face legal challenges, data security vulnerabilities, or financial penalties. Organizations must establish clear compliance protocols, conduct vendor risk assessments, and ensure all purchases align with regulatory requirements.

9. Surpluses and Redundant Purchases

Due to a lack of coordination and forecasting, businesses frequently end up with surplus inventory or redundant services. This inefficient allocation of resources ties up capital and leads to unnecessary expenditures. Leveraging procurement analytics and demand forecasting tools can help prevent excess purchases and optimize resource utilization.

10. Absence of Key Performance Indicators (KPIs)

Tracking procurement performance is essential for cost control and process improvement. Without defined KPIs, businesses struggle to measure efficiency, identify areas for savings, and enhance procurement strategies.

Establishing measurable KPIs—such as cost savings, contract compliance, supplier performance, and procurement cycle times—ensures continuous improvement in procurement operations.

How to Address Indirect Procurement Challenges

Indirect procurement challenges can lead to inefficiencies, cost overruns, and compliance risks if not managed properly. Organizations must take a strategic approach to improve visibility, streamline procurement processes, and ensure compliance.

Below are key strategies to address and overcome these challenges.

1. Enhancing Spend Visibility

- Implement procurement technology to centralize and track all indirect purchases in real time.

- Standardize procurement processes by establishing consistent procedures for requisition approvals, purchase tracking, and reporting.

- Improve data integration by consolidating procurement data across departments using ERP systems for better oversight and analysis.

Solution in Action: A company implementing AI-driven procurement analytics can detect spending patterns and identify cost-saving opportunities.

2. Controlling Maverick Spending

- Enforce procurement policies by establishing clear spending guidelines that mandate approved vendor usage and contract compliance.

- Automate purchase approvals using workflow automation to ensure every purchase goes through the correct approval chain.

- Educate employees on procurement policies to prevent unauthorized spending.

Solution in Action: Deploying AI-driven procurement bots can flag out-of-policy purchases in real time, reducing unauthorized transactions.

3. Improving Supplier Management

- Centralize supplier data using Supplier Relationship Management (SRM) tools to monitor vendor performance and contract compliance.

- Optimize vendor contracts by consolidating suppliers where possible to leverage bulk discounts and improve negotiation power.

- Conduct regular supplier audits to maintain quality and service standards.

Solution in Action: A business using automated supplier scorecards can track vendor performance and make data-driven decisions for contract renewals.

4. Standardizing Procurement Policies

- Develop a formal procurement framework that defines approval workflows, spending limits, and contract terms.

- Align procurement with business goals to ensure that purchasing decisions support cost efficiency and compliance with company objectives.

- Increase cross-department collaboration to standardize procurement policies across all teams, preventing duplication and inefficiencies.

Solution in Action: Using a self-service procurement portal allows employees to select from pre-approved vendors, reducing policy violations.

5. Leveraging Spend Analytics

- Use data-driven insights by implementing spend analytics software to identify unnecessary expenses and optimize purchasing decisions.

- Monitor key metrics such as cost savings, contract compliance, and supplier performance to drive procurement efficiency.

- Eliminate redundant purchases by conducting regular spend audits to detect and eliminate surplus or duplicate orders.

Solution in Action: Companies using predictive spend analytics can forecast procurement needs more accurately and prevent excess inventory.

6. Mitigating Compliance and Risk Issues

- Automate compliance checks by implementing AI-powered compliance monitoring tools to flag policy violations and regulatory risks.

- Conduct regular risk assessments to evaluate vendor financial stability, cybersecurity policies, and contract adherence.

- Ensure regulatory alignment with GDPR, ISO, and industry-specific procurement regulations.

Solution in Action: Automating compliance tracking ensures all purchases follow legal and corporate standards, reducing risk exposure.

7. Implementing Procurement Automation

- Use AI and machine learning to deploy AI-driven procurement assistants that handle routine tasks like invoice processing and supplier matching.

- Digitize purchase orders by replacing manual paperwork with e-invoicing and automated approvals for faster procurement cycles.

- Enable self-service procurement, allowing departments to order pre-approved products through procurement marketplaces while maintaining compliance.

Solution in Action: Automating repetitive procurement tasks reduces human errors, speeds up approvals, and enhances procurement efficiency.

Best Practices for Efficient Indirect Procurement

Indirect procurement—covering goods and services that support business operations—can significantly impact cost efficiency, supplier relationships, and operational agility.

Unlike direct procurement, which focuses on raw materials and production inputs, indirect procurement includes categories like IT services, office supplies, utilities, and marketing expenses.

To optimize this often-overlooked area, organizations should adopt best practices that enhance control, visibility, and cost-effectiveness.

1. Centralize Procurement with Digital Solutions

Why It Matters:

- A decentralized procurement approach leads to maverick spending, compliance issues, and inefficiencies.

- Manual processes are prone to errors, delays, and a lack of visibility into organizational spending.

Best Practices:

- Implement an e-procurement system to centralize purchasing, approvals, and supplier management.

- Use AI-driven analytics to monitor spending patterns and identify cost-saving opportunities.

- Integrate procurement with ERP systems for seamless data sharing across departments.

2. Establish Clear Procurement Policies and Compliance Guidelines

Why It Matters:

- Without well-defined policies, employees may bypass preferred suppliers, leading to increased costs and compliance risks.

- Regulatory and contractual compliance are crucial to avoiding legal and financial penalties.

Best Practices:

- Develop and enforce a standardized procurement policy that covers approvals, spending limits, and preferred suppliers.

- Regularly audit procurement activities to ensure compliance with company policies and industry regulations.

- Use automated contract management systems to track vendor performance and adherence.

3. Strengthen Supplier Relationship Management (SRM)

Why It Matters:

- Building strong partnerships with suppliers leads to better pricing, service quality, and reliability.

- Poor supplier relationships can cause delays, hidden costs, and supply chain disruptions.

Best Practices:

- Conduct supplier performance evaluations based on metrics like lead time, service quality, and cost efficiency.

- Foster collaborative relationships through long-term contracts and transparent communication.

- Diversify suppliers to reduce dependency and mitigate supply chain risks.

4. Optimize Cost Control and Spend Visibility

Why It Matters:

- Uncontrolled indirect procurement can lead to unnecessary expenses and budget overruns.

- Many companies struggle with maverick spend, where employees purchase outside of approved channels.

Best Practices:

- Use spend analytics tools to track spending trends and identify cost-saving opportunities.

- Implement category management to consolidate spending and negotiate bulk discounts.

- Set budget thresholds and enforce spend approval workflows to prevent unnecessary purchases.

5. Automate Procurement Workflows for Efficiency

Why It Matters:

- Manual procurement processes are time-consuming and lead to errors, duplicate invoices, and payment delays.

- Automation enhances productivity, speeds up approvals, and reduces operational costs.

Best Practices:

- Automate purchase order approvals to reduce procurement cycle times.

- Use AI-driven invoice processing to minimize errors and late payments.

- Implement self-service procurement portals to allow employees to order pre-approved items without lengthy approvals.

6. Improve Demand Forecasting and Inventory Management

Why It Matters:

- Poor forecasting leads to overstocking or stockouts, increasing costs and disrupting operations.

- Accurate demand planning helps optimize procurement schedules and reduce waste.

Best Practices:

- Leverage AI-powered demand forecasting to anticipate procurement needs accurately.

- Maintain real-time inventory tracking to avoid unnecessary purchases.

- Establish just-in-time procurement strategies to reduce excess inventory holding costs.

7. Enhance Sustainability and Ethical Sourcing

Why It Matters:

- Sustainable procurement aligns with corporate social responsibility (CSR) goals and enhances brand reputation.

- Ethical sourcing prevents legal issues and supports environmentally responsible suppliers.

Best Practices:

- Source from suppliers with strong ESG (Environmental, Social, and Governance) credentials.

- Prioritize eco-friendly products and services to minimize environmental impact.

- Monitor supplier compliance with sustainability standards to ensure ethical sourcing.

5 Top KPIs for Tracking Indirect Procurement Performance

To understand the improvement in the indirect procurement process, it’s essential to monitor relevant metrics over time. While numerous KPIs exist for procurement performance tracking, the following five provide a comprehensive view of efficiency, cost management, and overall procurement effectiveness.

1. Spend Under Management (SUM)

Definition: This KPI measures the percentage of total organizational spend that is actively managed by the procurement and finance teams. It includes direct, indirect, and services spending.

Why It Matters:

- A higher spend under management reflects better procurement control, improved cost efficiency, and stronger supplier relationships.

- Unmanaged spend, often called maverick spend, can lead to increased costs, compliance risks, and inefficiencies.

- Companies with higher SUM typically negotiate better contracts and gain greater visibility into spending patterns.

How to Improve:

- Implement automated procurement systems to centralize spend tracking.

- Establish clear procurement policies and enforce compliance across departments.

- Encourage employees to use preferred suppliers and procurement platforms.

2. Cost Per Invoice

Definition: This metric quantifies the total cost to process a single invoice, factoring in labor, technology, and administrative costs.

Why It Matters:

- A lower cost per invoice signals a more efficient procurement process.

- Manual invoice processing is time-consuming and prone to errors, increasing operational costs.

- Businesses with high invoice processing costs often struggle with bottlenecks in approval workflows.

How to Improve:

- Automate invoice processing to reduce manual labor and approval delays.

- Implement electronic invoicing (e-invoicing) to streamline accounts payable functions.

- Use AI-driven procurement tools to flag duplicate invoices and prevent overpayments.

3. Supplier Lead Time

Definition: Supplier lead time measures the time between placing a purchase order and receiving the goods or services.

Why It Matters:

- Longer lead times can disrupt operations, delay project timelines, and increase holding costs.

- 60% of manufacturers in Deloitte’s 2022 survey reported that shipping delays had the biggest impact on their operations.

- Companies with optimized lead times can achieve better supply chain resilience and competitive market advantages.

How to Improve:

- Build stronger supplier relationships by maintaining consistent communication and performance evaluations.

- Implement demand forecasting tools to anticipate needs and place orders proactively.

- Diversify suppliers to mitigate the risk of delays due to supply chain disruptions.

4. Compliance Rate

Definition: Compliance rate measures a vendor’s adherence to procurement policies, contractual obligations, and regulatory requirements.

Why It Matters:

- Ensures alignment with corporate governance, industry standards, and legal requirements.

- Helps reduce third-party risk exposure, including data breaches, fraud, and regulatory violations.

- Enhances supplier accountability, preventing financial penalties and reputational damage.

How to Improve:

- Automate compliance tracking with supplier risk management software.

- Conduct regular supplier audits to assess contract adherence and policy alignment.

- Train procurement teams on compliance best practices and reinforce policies.

5. Procurement ROI

Definition: Procurement return on investment (ROI) assesses the cost-effectiveness of procurement activities by comparing savings and benefits against procurement expenses.

Why It Matters:

- Demonstrates how well procurement contributes to overall business profitability.

- Highlights cost savings from supplier negotiations, contract optimizations, and strategic sourcing.

- Helps organizations allocate budgets effectively based on procurement efficiency.

How to Improve:

- Use spend analytics tools to track cost savings and identify areas for improvement.

- Negotiate better supplier contracts to maximize value from procurement activities.

- Reduce procurement cycle times with automation and AI-driven decision-making.

The Role of Technology in Indirect Procurement

Indirect procurement, which covers non-production-related goods and services such as office supplies, IT, and professional services, plays a critical role in operational efficiency and cost control. Managing indirect procurement effectively requires visibility, compliance, and cost optimization, all of which can be enhanced through technology.

1. Digital Procurement Platforms for Centralized Control

Why It Matters: Decentralized procurement leads to inefficiencies, maverick spending, and compliance risks. Technology enables a centralized procurement process, improving spend visibility and cost control.

Key Benefits:

- E-procurement systems automate purchasing, approvals, and supplier management.

- Real-time dashboards provide insights into spending patterns and cost-saving opportunities.

- Integration with ERP systems ensures seamless data sharing across departments.

2. Artificial Intelligence (AI) and Machine Learning for Smart Decision-Making

Why It Matters: AI-powered analytics provide actionable insights, helping procurement teams make informed decisions about supplier selection, pricing, and cost control.

Key Benefits:

- AI-driven spend analysis identifies wasteful expenditures and potential savings.

- Machine learning algorithms predict demand, optimizing procurement cycles.

- Automated contract analysis ensures supplier compliance and reduces risks.

3. Robotic Process Automation (RPA) for Efficiency and Accuracy

Why It Matters: Manual procurement processes are slow, error-prone, and resource-intensive. RPA automates repetitive tasks, improving speed and accuracy.

Key Benefits:

- Automates purchase requisitions, approvals, and invoice processing.

- Reduces human errors and prevents duplicate or incorrect payments.

- Improves vendor onboarding by streamlining documentation and compliance checks.

4. Cloud-Based Procurement Solutions for Flexibility and Scalability

Why It Matters: Cloud-based procurement technology enables businesses to manage procurement processes remotely, ensuring agility and adaptability.

Key Benefits:

- Provides real-time access to procurement data from anywhere.

- Scales easily as business needs grow without heavy infrastructure costs.

- Enhances collaboration with suppliers through shared digital platforms.

5. Blockchain for Transparency and Security

Why It Matters: Indirect procurement involves multiple suppliers, contracts, and compliance requirements. Blockchain ensures secure, transparent, and tamper-proof transactions.

Key Benefits:

- Provides a verifiable audit trail for all procurement transactions.

- Enhances contract management through smart contracts, reducing disputes.

- Strengthens cybersecurity by preventing fraudulent transactions.

6. Internet of Things (IoT) for Real-Time Tracking

Why It Matters: IoT enhances procurement efficiency by providing real-time tracking of purchased assets, maintenance schedules, and usage patterns.

Key Benefits:

- Tracks office equipment and IT assets to optimize procurement decisions.

- Monitors energy and utility consumption to improve cost efficiency.

- Reduces downtime through predictive maintenance alerts.

7. Data Analytics for Improved Spend Management

Why It Matters: Data-driven procurement decisions help organizations identify cost-saving opportunities, assess supplier performance, and improve budget allocation.

Key Benefits:

- Tracks procurement performance KPIs, such as cost per invoice and compliance rate.

- Identifies cost reduction strategies through predictive analytics.

- Improves supplier selection by analyzing past performance and risk factors.

How Deskera ERP Enhances Indirect Procurement Efficiency

Indirect procurement involves managing non-production-related purchases such as office supplies, IT services, and utilities. While often overlooked, these expenses can significantly impact a company’s bottom line.

Deskera ERP streamlines indirect procurement by offering automation, visibility, and compliance control, ensuring cost efficiency and operational agility.

1. Centralized Procurement Management

Deskera ERP consolidates all procurement activities into a single platform, providing a unified view of indirect spending. This centralization helps businesses control costs, reduce maverick spending, and enforce procurement policies.

2. Automated Purchase Requisition and Approval Workflows

Manual purchase requests can cause delays and inefficiencies. Deskera ERP automates requisition approvals, ensuring that purchases align with budgetary constraints and organizational policies.

3. Real-Time Spend Visibility and Reporting

Tracking indirect spend is critical for cost control. Deskera ERP provides real-time dashboards and customizable reports, helping businesses analyze spending patterns, identify savings opportunities, and optimize supplier contracts.

4. Supplier Management and Compliance Tracking

Deskera ERP simplifies supplier evaluation and contract management by maintaining supplier performance records, ensuring adherence to compliance standards, and reducing third-party risks.

5. Integration with Accounting and Inventory

Indirect procurement often involves multiple departments. Deskera ERP seamlessly integrates procurement with accounting and inventory management, ensuring smooth invoice processing, accurate cost allocation, and optimized stock levels.

6. Mobile Accessibility for Remote Approvals

With Deskera’s mobile-friendly ERP, procurement teams can manage approvals, track orders, and monitor supplier performance from anywhere, ensuring agility and efficiency.

Key Takeaways

- Indirect procurement focuses on purchasing goods and services that do not directly contribute to production but are essential for business operations. Managing it effectively can drive cost savings and operational efficiency.

- Direct procurement involves purchasing raw materials and components for production, while indirect procurement covers goods and services that support daily operations. Managing both efficiently requires different strategies, processes, and supplier relationships.

- Effective indirect procurement enhances cost savings, operational efficiency, supplier relationships, and compliance while ensuring businesses have the necessary goods and services to function smoothly.

- Common challenges include lack of visibility, maverick spending, poor spend analytics, and inadequate procurement policies. Addressing these issues is crucial for cost control and compliance.

- Implementing centralized procurement processes, leveraging data analytics, automating workflows, and enforcing procurement policies can help overcome key challenges and enhance efficiency.

- Standardizing procurement workflows, consolidating suppliers, integrating procurement with finance, and using digital tools improve efficiency and cost-effectiveness.

- Key performance indicators such as spend under management, cost per invoice, supplier lead time, compliance rate, and procurement ROI help businesses assess and improve their procurement strategies.

- Automation, AI-driven analytics, cloud-based procurement platforms, and integration with ERP systems enhance visibility, compliance, and efficiency in managing indirect procurement.

- Deskera ERP streamlines indirect procurement by providing centralized management, automated approvals, real-time spend visibility, supplier performance tracking, and seamless integration with accounting and inventory systems.

Related Articles