In the dynamic and demanding landscape of the metal fabrication industry, effective workforce management stands as a cornerstone for success. As businesses strive to meet ever-changing customer demands, maintain stringent quality standards, and navigate complex operational challenges, the role of workforce management cannot be overstated.

Within this context, the integration of metal fabrication ERP systems emerges as a transformative solution, promising to revolutionize how businesses optimize their workforce.

Metal fabrication ERP represents more than just a software solution; it embodies a comprehensive approach to streamlining and enhancing every facet of workforce management within the metal fabrication industry.

By seamlessly integrating core business processes, from production scheduling and inventory management to quality assurance and financial control, metal fabrication ERP systems provide a unified platform for orchestrating workforce operations with unparalleled efficiency and precision.

At its core, the objective of metal fabrication ERP is to empower businesses to leverage technology-driven solutions to overcome workforce management challenges and unlock new levels of productivity, agility, and competitiveness.

Join us on this journey as we delve into the transformative power of metal fabrication ERP in reshaping workforce management paradigms, driving operational efficiency, and propelling businesses toward sustained success in a competitive marketplace.

The topics covered in this article are:

- What is the Metal Fabrication Industry?

- What is Workforce Management?

- Importance of Workforce Management in Metal Fabrication Industry

- Challenges Faced by Businesses in Metal Fabrication Industry

- What is Metal Fabrication ERP?

- Improving Workforce Management with Metal Fabrication ERP

- How can Deskera Improve Workforce Management as a Metal Fabrication ERP?

- Key Takeaways

- Related Articles

What is the Metal Fabrication Industry?

The metal fabrication industry encompasses a wide range of processes involved in shaping, cutting, assembling, and finishing metal materials to create various products and structures. It plays a crucial role in manufacturing sectors such as construction, automotive, aerospace, electronics, and machinery.

Here are some key aspects of the metal fabrication industry:

- Processes and Techniques: Metal fabrication involves various processes and techniques, including cutting, bending, welding, machining, stamping, and assembling. These processes can be performed manually, using hand tools and equipment, or through automated machinery and CNC (Computer Numerical Control) systems.

- Materials: Metal fabrication works with a diverse range of metals, including steel, aluminum, stainless steel, copper, brass, and titanium. These materials come in different forms, such as sheets, plates, bars, tubes, and structural shapes, and can be customized to meet specific design requirements.

- Applications: Metal fabrication produces a wide variety of products and components used in different industries and applications. These include structural steel beams for construction projects, automotive body parts and chassis components, aerospace components and assemblies, industrial machinery and equipment, electronics enclosures and cabinets, and consumer goods such as appliances and furniture.

- Customization and Specialization: Metal fabrication often involves customization and specialization to meet the unique needs of customers and industries. Fabricators work closely with designers, engineers, and clients to develop customized solutions, prototypes, and one-of-a-kind products tailored to specific requirements, dimensions, and performance criteria.

- Advanced Technologies: The metal fabrication industry continuously adopts advanced technologies to improve efficiency, precision, and quality. This includes the use of CNC machining and laser cutting systems, robotic welding and automation, 3D printing and additive manufacturing, CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, and IoT (Internet of Things) for process monitoring and optimization.

- Quality Control and Standards: Quality control is critical in metal fabrication to ensure that products meet industry standards, regulatory requirements, and customer expectations. Fabricators implement quality management systems, inspection procedures, and testing protocols to verify dimensional accuracy, structural integrity, surface finish, and material properties.

- Supply Chain and Collaboration: Metal fabrication often involves collaboration with suppliers, subcontractors, and partners throughout the supply chain. Fabricators source raw materials, components, and specialized services from various vendors, manage inventory, and coordinate logistics to support production schedules and meet customer deadlines.

Overall, the metal fabrication industry is a dynamic and essential sector of manufacturing that produces a wide range of products and components used in diverse applications. It combines skilled craftsmanship with advanced technologies to deliver customized solutions, innovation, and value to customers across various industries.

What is Workforce Management?

Workforce management refers to the strategic approach and set of processes implemented by organizations to optimize the productivity, efficiency, and performance of their workforce. It encompasses various activities aimed at aligning staffing levels, skills, schedules, and resources with business objectives and operational requirements.

The goal of workforce management is to ensure that the right people are in the right place at the right time, performing the right tasks, to meet organizational goals while minimizing costs and maximizing efficiency.

Key components of workforce management include:

- Staffing and Recruitment: This involves identifying workforce needs, recruiting suitable candidates, and ensuring that the organization has the right mix of skills and talent to meet current and future demands.

- Scheduling and Shift Management: Workforce management includes creating and managing employee schedules, assigning shifts, and balancing workload distribution to optimize productivity and ensure adequate coverage.

- Time and Attendance Tracking: Monitoring employee attendance, time-off requests, and absences is crucial for workforce management to ensure compliance with labor regulations, accurately track labor costs, and manage productivity.

- Performance Management: This involves setting performance goals, providing feedback, conducting performance evaluations, and implementing performance improvement plans to maximize individual and team performance.

- Training and Development: Workforce management includes identifying training needs, providing relevant training programs, and fostering employee development to enhance skills, knowledge, and competencies.

- Employee Engagement and Retention: Workforce management encompasses strategies to engage employees, foster a positive work environment, recognize achievements, and address employee concerns to improve employee retention rates and reduce turnover.

- Labor Forecasting and Demand Planning: This involves analyzing historical data, market trends, and operational requirements to forecast workforce demand and plan staffing levels accordingly to meet business needs efficiently.

Overall, effective workforce management enables organizations to optimize their human capital, improve operational efficiency, minimize costs, and achieve strategic objectives.

Importance of Workforce Management in Metal Fabrication Industry

In the metal fabrication industry, where precision, efficiency, and safety are paramount, effective workforce management plays a critical role in ensuring operational excellence and competitiveness.

Here's why workforce management is essential in the metal fabrication industry:

- Optimizing Production Efficiency: Workforce management helps in aligning workforce scheduling, skills, and resources with production demands. By ensuring that the right personnel are available at the right time with the necessary skills and qualifications, metal fabrication companies can maximize production efficiency, minimize downtime, and meet customer demands effectively.

- Ensuring Safety and Compliance: Metal fabrication involves working with heavy machinery, hazardous materials, and complex processes. Proper workforce management involves training employees on safety protocols, ensuring compliance with regulations such as OSHA (Occupational Safety and Health Administration), and implementing measures to minimize workplace accidents and injuries, thus creating a safer work environment.

- Maintaining Quality Standards: Workforce management practices such as performance monitoring, skill tracking, and training ensure that employees have the necessary skills and knowledge to produce high-quality metal fabricated products. By implementing quality assurance measures and continuously improving workforce competencies, companies can maintain consistency in product quality and meet customer expectations.

- Managing Skilled Labor Shortages: The metal fabrication industry often faces challenges in recruiting and retaining skilled labor due to the specialized nature of the work. Effective workforce management involves strategies for recruiting, training, and retaining skilled workers, as well as succession planning to address potential talent gaps. By investing in workforce development and talent management, companies can mitigate the impact of skilled labor shortages on production capabilities.

- Optimizing Resource Utilization: Workforce management helps in optimizing the utilization of resources such as labor, equipment, and materials. By analyzing production data, identifying inefficiencies, and implementing process improvements, companies can minimize waste, reduce costs, and maximize the return on investment in resources.

- Adapting to Market Dynamics: The metal fabrication industry is subject to market fluctuations, changing customer demands, and technological advancements. Effective workforce management enables companies to adapt to market dynamics by adjusting workforce strategies, reallocating resources, and investing in training and development initiatives to stay competitive and agile in a rapidly evolving industry landscape.

- Enhancing Customer Satisfaction: Ultimately, workforce management contributes to enhancing customer satisfaction by ensuring timely delivery of high-quality products that meet or exceed customer expectations. By aligning workforce capabilities with customer needs, metal fabrication companies can build trust, customer loyalty, and long-term relationships with their customers, driving business growth and success.

In summary, workforce management is essential in the metal fabrication industry for optimizing production efficiency, ensuring safety and compliance, maintaining quality standards, managing skilled labor shortages, optimizing resource utilization, adapting to market dynamics, and enhancing customer satisfaction.

By implementing effective workforce management practices, metal fabrication companies can achieve operational excellence, mitigate risks, and thrive in a competitive marketplace.

Challenges Faced by Businesses in Metal Fabrication Industry

In the metal fabrication industry, businesses face several challenges related to workforce management that can impact productivity, efficiency, and overall operations.

Here are some common challenges:

- Skilled Labor Shortages: One of the most significant challenges in the metal fabrication industry is the shortage of skilled workers. Finding qualified welders, machinists, fabricators, and other skilled personnel can be difficult, leading to recruitment challenges and increased competition for talent.

- Training and Development: Keeping the workforce updated with the latest technologies, techniques, and safety protocols is essential in metal fabrication. However, providing ongoing training and development programs can be costly and time-consuming, especially for small and medium-sized businesses with limited resources.

- Safety Compliance: Metal fabrication involves working with heavy machinery, sharp tools, and hazardous materials, posing risks to employee safety. Ensuring compliance with safety regulations, implementing proper safety protocols, and providing adequate training to employees are ongoing challenges for businesses in the industry.

- Workforce Productivity: Maximizing workforce productivity while maintaining quality standards is a balancing act for metal fabrication businesses. Challenges such as inefficient processes, equipment downtime, and lack of workforce motivation or engagement can hinder productivity and impact profitability.

- Workforce Scheduling: Efficiently scheduling shifts, managing overtime, and ensuring adequate staffing levels to meet production demands are common challenges in workforce scheduling. Factors such as fluctuating demand, absenteeism, and turnover can further complicate workforce scheduling efforts.

- Retention and Turnover: Retaining skilled employees and reducing turnover rates is crucial for maintaining consistency in quality and productivity. However, factors such as job dissatisfaction, lack of career advancement opportunities, and competition from other employers can contribute to high turnover rates in the metal fabrication industry.

- Communication and Collaboration: Effective communication and collaboration among teams and departments are essential for seamless operations in metal fabrication. However, challenges such as miscommunication, lack of coordination between shifts or departments, and language barriers in diverse workforces can hinder collaboration efforts.

- Adapting to Technological Changes: Rapid advancements in technology, such as automation, robotics, and digitalization, are transforming the metal fabrication industry. Businesses face challenges in adopting and integrating new technologies into their operations, as well as upskilling existing employees to adapt to technological changes.

- Regulatory Compliance: Metal fabrication businesses must comply with various regulatory requirements, including environmental regulations, workplace safety standards, and labor laws. Staying updated with changing regulations, maintaining compliance, and avoiding penalties can be challenging for businesses, especially smaller ones with limited resources.

- Aging Workforce: The metal fabrication industry often faces an aging workforce, with many experienced workers nearing retirement age. Succession planning, knowledge transfer, and attracting younger talent to the industry are crucial challenges for businesses to ensure continuity and sustainability in the long term.

Addressing these workforce management challenges requires a proactive approach, including investing in training and development programs, implementing efficient scheduling and communication systems, prioritizing safety and compliance, and embracing technological advancements to improve productivity and competitiveness in the metal fabrication industry.

What is Metal Fabrication ERP?

Metal fabrication ERP (Enterprise Resource Planning) is a specialized software solution designed to meet the unique needs and challenges of metal fabrication companies.

It integrates various business processes and functions into a single, unified platform, providing tools and functionalities to streamline operations, improve efficiency, and drive growth in the metal fabrication industry.

Here are the key features and capabilities of metal fabrication ERP:

- Production Management: Metal fabrication ERP helps manage production processes, including job scheduling, work orders, routing, and material planning. It optimizes production workflows, tracks work-in-progress, and ensures on-time delivery of fabricated parts and assemblies.

- Inventory Control: Manufacturing ERP systems for metal fabrication enable efficient inventory management by tracking raw materials, finished goods, and intermediate components. They provide real-time visibility into inventory levels, monitor stock movements, and automate replenishment processes to minimize stockouts and excess inventory.

- Job Costing and Estimation: Metal fabrication ERP facilitates accurate job costing and estimation by capturing costs associated with labor, materials, overhead, and subcontracting. It helps calculate project margins, analyze profitability, and generate competitive quotes to win contracts and projects.

- Quality Assurance: Manufacturing software systems include quality management modules to enforce quality standards, conduct inspections, and manage non-conformance issues. They facilitate traceability of materials and components, document control, and compliance with industry regulations and customer requirements.

- Supply Chain Management: Metal fabrication ERP streamlines supply chain processes, from procurement and supplier management to logistics and shipping. It enables electronic communication with suppliers, tracks vendor performance, and optimizes sourcing strategies to ensure the timely availability of materials and components.

- Resource Planning: MRP software systems for metal fabrication help optimize resource utilization, including equipment, labor, and facilities. They schedule production activities, allocate resources based on availability and capacity, and balance workloads to maximize efficiency and minimize bottlenecks.

- Financial Management: Metal fabrication ERP includes financial modules for accounting, invoicing, billing, and financial reporting. It tracks costs, revenues, and profitability across projects and departments, facilitates budgeting and forecasting, and ensures compliance with accounting standards and tax regulations.

- Customer Relationship Management (CRM): Some metal fabrication ERP systems offer CRM functionalities to manage customer interactions, sales inquiries, and service requests. They help track customer orders, maintain customer profiles, and foster customer satisfaction and loyalty.

- Business Intelligence and Analytics: Metal fabrication ERP provides reporting and analytics tools to monitor key performance indicators (KPIs), analyze production trends, and identify opportunities for improvement. It generates actionable insights to drive strategic decision-making and continuous improvement initiatives.

Overall, metal fabrication ERP is a comprehensive software solution tailored to the specific needs of metal fabrication companies. By integrating core business processes and providing visibility and control over operations, ERP systems help metal fabricators streamline workflows, reduce costs, enhance quality, and maintain competitiveness in the global marketplace.

Improving Workforce Management with Metal Fabrication ERP

Implementing an Enterprise Resource Planning (ERP) system tailored specifically for metal fabrication can significantly enhance workforce management in several ways:

Resource Allocation

Metal fabrication companies face unique challenges in managing their workforce efficiently while maintaining optimal productivity levels. Implementing a tailored metal fabrication ERP solution designed specifically for the metal industry can revolutionize workforce management processes.

Let's delve into how a metal fabrication ERP system improves resource allocation.

- Optimized Resource Allocation: Metal fabrication ERP systems provide real-time visibility into resource availability, enabling precise allocation of workforce, machinery, and materials. With manufacturing software capabilities, ERP systems analyze production schedules, employee skill sets, and project requirements to allocate resources effectively. MRP software integrated within the ERP predicts material requirements based on production schedules, ensuring timely procurement and preventing delays due to material shortages.

- Dynamic Workforce Scheduling: ERP for metal industry streamlines workforce scheduling by considering factors such as machine availability, employee skill levels, and project deadlines. Manufacturing ERP systems automate scheduling processes, minimizing downtime and maximizing throughput by assigning tasks to the most suitable employees at optimal times. Through advanced resource leveling algorithms, metal fabrication ERP solutions balance workloads across teams, preventing the overburdening of certain employees while optimizing overall productivity.

- Agile Capacity Planning: Metal fabrication ERP systems facilitate agile capacity planning by providing insights into current and future workload demands. Manufacturing software integrated within the ERP analyzes historical production data and market trends to forecast demand accurately, enabling proactive capacity adjustments. MRP software capabilities adjust resource allocations dynamically in response to fluctuations in demand, ensuring that production capacity aligns with customer requirements.

- Efficient Labor Utilization: ERP for metal industry enables efficient labor utilization by matching employee skills with task requirements, minimizing training overheads, and maximizing productivity. Manufacturing ERP systems track employee certifications, experience levels, and performance metrics, allowing managers to assign tasks to the most qualified individuals. By optimizing labor utilization, metal fabrication ERP solutions enhance workforce efficiency, reduce idle time, and improve overall operational performance.

- Continuous Improvement Initiatives: Metal fabrication ERP systems support continuous improvement initiatives by providing data-driven insights into workforce performance and resource utilization. Manufacturing software identifies bottlenecks, inefficiencies, and areas for improvement, enabling managers to implement targeted process enhancements. Through integrated analytics and reporting tools, MRP software facilitates performance monitoring, enabling organizations to benchmark workforce management metrics and drive ongoing optimization efforts.

In conclusion, leveraging a metal fabrication ERP system enhances resource allocation, workforce scheduling, capacity planning, labor utilization, and continuous improvement initiatives within metal fabrication companies.

By embracing the capabilities of manufacturing software, organizations can achieve greater efficiency, productivity, and competitiveness in the dynamic metal fabrication industry landscape.

Scheduling and Planning

Efficient scheduling and planning are pivotal for success in the metal fabrication industry, where precision and timeliness are paramount. Metal fabrication ERP systems tailored for the industry offer comprehensive solutions to streamline workforce scheduling and planning processes.

Let's explore how these systems drive productivity and efficiency.

- Automated Scheduling Processes: Metal fabrication ERP systems automate scheduling processes, leveraging manufacturing software functionalities to optimize resource utilization. With ERP for metal industry, managers can create detailed production schedules considering factors such as machine availability, material availability, and workforce capacity. Manufacturing ERP software integrates with production machines to synchronize scheduling with actual machine capabilities, minimizing idle time and maximizing throughput.

- Real-Time Visibility and Adaptability: MRP software systems provide real-time visibility into production schedules, allowing for agile adjustments in response to changing priorities or unforeseen events. Metal fabrication ERP solutions enable managers to monitor progress and identify potential bottlenecks, facilitating proactive interventions to maintain production timelines. Manufacturing software capabilities automatically adjust schedules based on material availability, preventing delays caused by inventory shortages or procurement issues.

- Optimization of Production Sequencing: Manufacturing ERP systems optimize production sequencing by analyzing task dependencies, lead times, and production constraints. With ERP for metal industry, managers can sequence tasks to minimize setup times, reduce changeovers, and optimize machine utilization. MRP software solutions leverage advanced algorithms to prioritize tasks based on factors such as due dates, material availability, and production efficiency.

- Integration with Customer Demands: Metal fabrication ERP systems integrate customer demands and order specifications into production schedules, ensuring alignment with delivery commitments. ERP for metal industry enables organizations to prioritize orders based on customer deadlines, production complexity, and profitability. Manufacturing ERP software facilitates efficient order processing, from initial quotation to final delivery, ensuring customer satisfaction while optimizing resource utilization.

- Enhanced Collaboration and Communication: Manufacturing ERP systems facilitate collaboration and communication among stakeholders involved in scheduling and planning processes. Metal fabrication ERP solutions provide centralized platforms for sharing production schedules, task assignments, and updates in real time. With manufacturing software, teams can collaborate seamlessly, resolving scheduling conflicts and coordinating tasks effectively.

In conclusion, metal fabrication ERP systems revolutionize workforce scheduling and planning by automating processes, providing real-time visibility, optimizing production sequencing, integrating customer demands, and enhancing collaboration.

By leveraging the capabilities of MRP software, metal fabrication companies can achieve greater efficiency, agility, and responsiveness in managing their workforce and production schedules.

Inventory Management

Efficient inventory management is critical for metal fabrication companies to ensure uninterrupted production and timely delivery of products. Metal fabrication ERP systems tailored for the industry offer advanced inventory management capabilities that optimize resource utilization and minimize downtime.

Let's explore how these systems revolutionize inventory management to improve workforce efficiency.

- Real-Time Inventory Tracking: Metal fabrication ERP systems provide real-time visibility into inventory levels, enabling accurate tracking of raw materials, work-in-progress (WIP), and finished goods. With ERP for metal industry, managers can monitor inventory levels across multiple locations or warehouses, facilitating efficient allocation of materials based on project requirements. Manufacturing ERP software integrates with inventory sensors and barcode scanners to update inventory data instantaneously, ensuring accuracy and reliability.

- Demand Forecasting and Planning: MRP software systems leverage functionalities to forecast demand based on historical data, market trends, and customer orders. Metal fabrication ERP solutions analyze demand forecasts to anticipate material requirements and optimize inventory levels accordingly, minimizing excess inventory or stockouts. With manufacturing software integrated within the ERP, organizations can automate replenishment processes, generating purchase orders or production orders based on forecasted demand and lead times.

- Just-in-Time Inventory Management: Metal fabrication ERP systems support just-in-time (JIT) inventory management practices by synchronizing material procurement with production schedules. ERP for metal industry enables organizations to minimize inventory holding costs and storage space requirements by procuring materials precisely when needed for production. Manufacturing ERP software facilitates seamless coordination between procurement, production, and inventory management functions, ensuring optimal inventory levels while reducing waste and inefficiencies.

- Vendor Collaboration and Supplier Integration: Metal fabrication ERP systems enable seamless collaboration with suppliers and integration with vendor systems to streamline procurement processes. Metal fabrication ERP solutions facilitate electronic data interchange (EDI) and automated order processing, enhancing communication and reducing lead times for material procurement. With manufacturing software, organizations can track supplier performance, negotiate contracts, and manage vendor relationships more effectively, ensuring a reliable supply chain and timely delivery of materials.

- Compliance and Quality Control: Metal fabrication ERP systems ensure compliance with regulatory requirements and quality standards by maintaining accurate documentation and traceability of inventory transactions. ERP for metal industry includes features for lot tracking, serial number management, and quality control inspections, ensuring product traceability and adherence to specifications. Manufacturing ERP software provides audit trails and reporting capabilities to monitor inventory movements, identify discrepancies, and implement corrective actions, enhancing quality assurance processes and regulatory compliance.

In conclusion, metal fabrication ERP systems enhance workforce efficiency by streamlining inventory management processes, enabling real-time tracking, demand forecasting, JIT inventory management, vendor collaboration, and compliance with regulatory requirements.

By leveraging the capabilities of manufacturing software, metal fabrication companies can optimize inventory levels, minimize costs, and ensure seamless operations across the supply chain.

Skill Tracking and Training

In the dynamic landscape of metal fabrication, workforce skills play a crucial role in driving productivity and innovation. Metal fabrication ERP systems equipped with robust skill tracking and training functionalities offer a comprehensive solution to develop and nurture talent within the industry.

Let's delve into how these systems elevate workforce management through skill tracking and training initiatives.

- Comprehensive Skill Profiles: Metal fabrication ERP systems maintain detailed skill profiles for each employee, encompassing certifications, qualifications, experience levels, and specialized expertise. With ERP for metal industry, managers can categorize skills based on job roles, departments, or project requirements, enabling targeted skill tracking and analysis. Manufacturing ERP software integrates with HR systems to capture employee training history, performance evaluations, and competency assessments, providing a holistic view of workforce capabilities.

- Gap Analysis and Training Needs Assessment: MRP software systems facilitate gap analysis by comparing required skills for specific job roles or projects with existing workforce capabilities. Metal fabrication ERP solutions identify skill gaps and training needs through automated assessments, performance evaluations, and feedback mechanisms. With manufacturing software, organizations can prioritize training initiatives based on critical skill shortages, emerging technologies, or strategic business objectives.

- Personalized Training Programs: Metal fabrication ERP systems enable the creation of personalized training programs tailored to individual employee development goals and organizational objectives. ERP for metal industry incorporates learning management system (LMS) functionalities to deliver online courses, instructional materials, and interactive modules. Manufacturing ERP software tracks employee progress and performance in training programs, providing insights to trainers and managers for continuous improvement and refinement.

- Competency-based Assessments and Certifications: Manufacturing ERP systems facilitate competency-based assessments to validate employee skills and proficiency levels in specific tasks or job functions. Metal fabrication ERP solutions automate certification tracking and renewal processes, ensuring compliance with industry standards and regulatory requirements. With manufacturing software, organizations can schedule competency assessments, monitor certification expirations, and prompt employees to undergo retraining as needed.

- Performance Recognition and Career Development: Metal fabrication ERP systems recognize and reward employees for skill development achievements and performance milestones. ERP for metal industry integrates performance metrics with incentive programs, fostering a culture of continuous learning, growth, and career advancement. Manufacturing ERP software facilitates career development planning by identifying career paths, skill enhancement opportunities, and succession planning strategies, ensuring a pipeline of skilled talent for future leadership roles.

In conclusion, metal fabrication ERP systems empower workforce development by enabling comprehensive skill tracking, training needs assessment, personalized learning programs, competency-based assessments, and performance recognition initiatives.

By leveraging the capabilities of MRP software, metal fabrication companies can cultivate a skilled workforce, drive employee engagement, and achieve sustainable growth and success in the competitive industry landscape.

Performance Monitoring and KPIs

Monitoring performance and Key Performance Indicators (KPIs) are essential for metal fabrication companies to optimize productivity, quality, and efficiency. Metal fabrication ERP systems equipped with robust performance monitoring capabilities offer comprehensive insights into workforce performance and operational metrics.

Let's explore how these systems empower workforce management through performance monitoring and KPI tracking.

- Real-Time Performance Visibility: Metal fabrication ERP systems provide real-time visibility into key performance metrics, such as throughput, yield, scrap rates, and labor efficiency. With ERP for metal industry, managers can monitor performance dashboards and reports, allowing for immediate identification of performance trends and deviations. Manufacturing ERP software enables stakeholders to access performance data from any location, facilitating timely decision-making and corrective actions.

- Customizable KPI Dashboards: MRP software systems offer customizable KPI dashboards tailored to the specific needs and objectives of metal fabrication businesses. Metal fabrication ERP solutions allow users to define and track KPIs relevant to workforce management, production processes, and business goals. With manufacturing software, organizations can configure threshold alerts and notifications to proactively address performance issues and opportunities.

- Root Cause Analysis and Continuous Improvement: Metal fabrication ERP systems facilitate root cause analysis by correlating performance data with operational parameters and process variables. ERP for metal industry enables organizations to identify underlying factors contributing to performance deviations, such as equipment downtime, material shortages, or skill gaps. Manufacturing ERP software supports continuous improvement initiatives by providing actionable insights and recommendations for optimizing workforce efficiency and operational effectiveness.

- Benchmarking and Comparative Analysis: MRP software systems facilitate benchmarking and comparative analysis by comparing performance metrics against industry benchmarks, best practices, or historical data. Metal fabrication ERP solutions enable organizations to benchmark workforce performance across departments, shifts, or production lines, fostering healthy competition and collaboration. With manufacturing software, managers can identify top performers, analyze variance drivers, and implement strategies to replicate success and address performance gaps.

- Goal Setting and Performance Incentives: Metal fabrication ERP systems support goal setting and performance incentives by aligning individual and team objectives with organizational goals. ERP for metal industry integrates performance metrics with incentive programs, rewarding employees for achieving KPI targets and exceeding performance expectations. Manufacturing ERP software facilitates transparent communication of performance goals, progress tracking, and recognition of achievements, fostering a culture of accountability, engagement, and continuous improvement.

In conclusion, metal fabrication ERP systems empower workforce management through real-time performance monitoring, customizable KPI dashboards, root cause analysis, benchmarking, and goal-driven incentives.

By leveraging the capabilities of manufacturing software, metal fabrication companies can drive operational excellence, maximize workforce productivity, and achieve sustainable growth and competitiveness in the industry.

Integration with HR Systems

Seamless integration between Human Resources (HR) systems and metal fabrication ERP solutions is crucial for optimizing workforce management processes. Metal fabrication ERP systems equipped with HR integration capabilities offer a unified platform for managing employee data, streamlining administrative tasks, and enhancing overall operational efficiency.

Let's explore how these systems drive workforce management excellence through HR integration.

- Unified Employee Database: Metal fabrication ERP systems integrate with HR systems to maintain a centralized employee database, eliminating data silos and duplication of efforts. With ERP for metal industry, organizations can access comprehensive employee profiles, including personal information, contact details, employment history, and performance evaluations. Manufacturing ERP software ensures data accuracy and consistency across HR and operational functions, enabling efficient workforce management and decision-making.

- Streamlined Recruitment and Onboarding: MRP software systems streamline the recruitment and onboarding process by automating job postings, candidate screening, and new employee enrollment. Metal fabrication ERP solutions facilitate seamless communication between HR departments and hiring managers, expediting the recruitment cycle and reducing time-to-hire. With manufacturing software, organizations can track recruitment metrics, such as applicant pipelines, interview feedback, and offer acceptance rates, to optimize recruitment strategies and attract top talent.

- Automated Time Tracking and Attendance: Metal fabrication ERP systems automate time tracking and attendance management, capturing employee work hours, breaks, and overtime accurately. ERP for metal industry integrates with time clock systems or biometric devices to record employee clock-ins and clock-outs, minimizing manual data entry errors and discrepancies. Manufacturing ERP software calculates labor costs and generates payroll reports based on time and attendance data, facilitating payroll processing and compliance with labor regulations.

- Performance Management and Training: MRP software systems support performance management initiatives by facilitating goal setting, performance evaluations, and feedback mechanisms. Metal fabrication ERP solutions enable managers to conduct performance reviews, track employee progress, and identify skill development opportunities. With manufacturing software, organizations can link performance metrics with training programs, enabling targeted skill development and career advancement opportunities for employees.

- Compliance and Regulatory Reporting: Metal fabrication ERP systems ensure compliance with labor laws, regulations, and industry standards by generating accurate and timely regulatory reports. ERP for metal industry automates compliance-related tasks, such as employee certifications, training records, and workplace safety assessments. Manufacturing ERP software provides audit trails and documentation capabilities to support regulatory audits and inspections, mitigating compliance risks and liabilities for the organization.

In conclusion, integration between HR systems and metal fabrication ERP solutions enhances workforce management efficiency by providing a unified platform for employee data management, recruitment, onboarding, time tracking, performance management, and regulatory compliance.

By leveraging the capabilities of manufacturing software and MRP software, metal fabrication companies can streamline HR processes, optimize workforce productivity, and ensure compliance with industry regulations and standards.

Compliance and Regulations

Compliance with regulations and industry standards is paramount for metal fabrication companies to ensure workplace safety, product quality, and legal adherence.

Metal fabrication ERP systems equipped with compliance and regulatory features offer comprehensive solutions to streamline compliance management and mitigate regulatory risks.

Let's explore how these systems enhance workforce management through compliance and regulation adherence.

- Regulatory Documentation and Record-Keeping: Metal fabrication ERP systems facilitate centralized storage and management of regulatory documentation, including permits, licenses, certifications, and safety data sheets. With ERP for metal industry, organizations can maintain up-to-date records of compliance-related documents, ensuring accessibility and traceability for audits and inspections. Manufacturing ERP software automates document version control and expiration tracking, minimizing compliance lapses and penalties associated with outdated or incomplete documentation.

- Safety Compliance and Training: MRP software systems support safety compliance initiatives by providing tools for hazard identification, risk assessment, and safety training management. Metal fabrication ERP solutions enable organizations to track employee training on safety protocols, equipment operation procedures, and emergency response protocols. With manufacturing software integrated within the manufacturing ERP, organizations can schedule safety training sessions, record attendance, and assess employee competency to ensure a safe working environment and regulatory compliance.

- Environmental Compliance and Sustainability: Metal fabrication ERP systems facilitate environmental compliance by tracking environmental permits, emissions data, and waste management practices. ERP for metal industry enables organizations to monitor energy consumption, carbon emissions, and resource usage, aligning with sustainability goals and regulatory requirements. Manufacturing ERP software generates environmental impact reports and sustainability metrics, enabling organizations to measure progress, identify opportunities for improvement, and demonstrate compliance with environmental regulations.

- Quality Management and Certification: MRP software systems support quality management initiatives by facilitating adherence to industry standards, such as ISO certifications and quality management systems (QMS). Metal fabrication ERP solutions integrate quality control processes with production workflows, ensuring that products meet specifications and regulatory requirements. With manufacturing software, organizations can implement corrective and preventive actions (CAPA), conduct root cause analysis, and track non-conformance incidents to maintain product quality and regulatory compliance.

- Audit Trail and Regulatory Reporting: Metal fabrication ERP systems provide audit trail functionalities to track changes to critical data fields, transactions, and system activities. ERP for metal industry generates regulatory reports, compliance dashboards, and audit logs, facilitating transparency and accountability in regulatory reporting. Manufacturing ERP software ensures data integrity and authenticity, enabling organizations to demonstrate compliance with regulatory requirements and respond promptly to audit inquiries.

In conclusion, metal fabrication ERP systems play a crucial role in ensuring regulatory compliance and standards adherence by centralizing documentation management, facilitating safety training, supporting environmental sustainability efforts, enabling quality management practices, and providing audit trail functionalities.

By leveraging the capabilities of manufacturing software and MRP software, metal fabrication companies can mitigate regulatory risks, enhance workforce management efficiency, and uphold their reputation as responsible corporate citizens within the industry.

Communication and Collaboration

Effective communication and collaboration are essential for maximizing productivity and efficiency in metal fabrication operations. Metal fabrication ERP systems equipped with advanced communication and collaboration tools offer a centralized platform for sharing information, coordinating tasks, and fostering teamwork across the organization.

Let's explore how these systems elevate workforce management through enhanced communication and collaboration.

- Centralized Communication Channels: Metal fabrication ERP systems provide centralized communication channels, such as instant messaging, discussion forums, and announcement boards, for disseminating information and updates. With ERP for metal industry, employees can collaborate in real-time, share ideas, and seek clarification on tasks or projects without the need for email or phone communication. Manufacturing ERP software enables managers to broadcast important announcements, policy updates, or safety alerts to all employees simultaneously, ensuring timely communication and alignment.

- Collaborative Task Management: MRP software systems facilitate collaborative task management by assigning tasks, setting deadlines, and tracking progress within the system. Metal fabrication ERP solutions allow teams to create task lists, allocate resources, and prioritize activities based on project requirements and deadlines. With manufacturing software, organizations can monitor task completion status, identify bottlenecks, and reassign resources as needed to ensure project success and on-time delivery.

- Document Sharing and Version Control: Metal fabrication ERP systems support document sharing and version control functionalities, enabling teams to collaborate on project documentation, drawings, and specifications. ERP for metal industry ensures that all stakeholders have access to the latest versions of documents, reducing the risk of errors or discrepancies due to outdated information. Manufacturing ERP software maintains an audit trail of document revisions and changes, providing transparency and accountability in document management processes.

- Cross-Functional Collaboration: MRP software systems facilitate cross-functional collaboration by breaking down silos and enabling seamless communication between different departments or teams. Metal fabrication ERP solutions allow engineers, designers, production managers, and quality control specialists to collaborate on projects, share insights, and resolve issues collaboratively. With manufacturing software, organizations can streamline interdepartmental workflows, improve decision-making processes, and accelerate project timelines through effective collaboration.

- Mobile Accessibility for Remote Collaboration: Metal fabrication ERP systems offer mobile accessibility, allowing employees to collaborate and communicate effectively even when working remotely or in the field. ERP for metal industry enables field technicians to access project information, update task statuses, and communicate with the team in real time using mobile devices. Manufacturing ERP software ensures that employees have secure access to critical data and communication channels from anywhere, enhancing flexibility, responsiveness, and productivity.

In conclusion, metal fabrication ERP systems play a crucial role in fostering seamless communication and collaboration across the organization by providing centralized communication channels, collaborative task management tools, document-sharing capabilities, cross-functional collaboration support, and mobile accessibility for remote collaboration.

By leveraging the capabilities of MRP software, metal fabrication companies can break down communication barriers, improve teamwork, and drive operational excellence in today's dynamic business environment.

Maintenance Planning

Effective maintenance planning is essential for ensuring the optimal performance and longevity of machinery in metal fabrication operations. Metal fabrication ERP systems equipped with robust maintenance planning capabilities offer proactive solutions to schedule preventive maintenance tasks, minimize downtime, and optimize workforce productivity.

Let's explore how these systems elevate workforce management through efficient maintenance planning.

- Proactive Maintenance Scheduling: Metal fabrication ERP systems enable proactive maintenance scheduling by predicting maintenance requirements based on equipment usage, performance data, and manufacturer recommendations. With ERP for metal industry, maintenance tasks are scheduled in advance, preventing unexpected equipment failures and minimizing disruptions to production schedules. Manufacturing ERP software generates maintenance schedules based on predefined criteria, such as equipment runtime, production cycles, or calendar intervals, ensuring that maintenance activities are performed at optimal times.

- Equipment Condition Monitoring: MRP software systems facilitate equipment condition monitoring by capturing real-time data from sensors, monitoring equipment health, and identifying potential issues before they escalate. Metal fabrication ERP solutions integrate with IoT (Internet of Things) devices to collect data on equipment temperature, vibration, and energy consumption, enabling predictive maintenance strategies. With manufacturing software, organizations can analyze equipment performance trends, set threshold alerts, and trigger maintenance tasks based on predefined condition criteria, ensuring proactive equipment maintenance and minimizing unplanned downtime.

- Spare Parts Inventory Management: Metal fabrication ERP systems optimize spare parts inventory management by tracking inventory levels, reorder points, and lead times for critical components. ERP for metal industry automates replenishment processes, generating purchase orders or work orders for spare parts based on maintenance schedules and inventory thresholds. Manufacturing ERP software integrates with suppliers and vendors to streamline procurement processes, ensuring that spare parts are available when needed for maintenance activities, reducing downtime, and enhancing equipment reliability.

- Maintenance Workforce Management: MRP software systems facilitate maintenance workforce management by assigning tasks, scheduling resources, and tracking labor hours for maintenance activities. Metal fabrication ERP solutions optimize labor utilization by assigning maintenance tasks to qualified technicians based on skill sets, availability, and priority. With manufacturing software integrated, organizations can monitor maintenance progress, track work orders, and analyze maintenance costs to optimize workforce productivity and efficiency.

- Performance Analysis and Continuous Improvement: Metal fabrication ERP systems provide performance analysis tools to evaluate the effectiveness of maintenance strategies, identify areas for improvement, and drive continuous optimization. ERP for metal industry generates maintenance performance reports, KPI dashboards, and trend analyses to measure equipment reliability, mean time between failures (MTBF), and overall maintenance efficiency. Manufacturing ERP software enables organizations to implement corrective actions, refine maintenance schedules, and implement best practices to maximize equipment uptime, reduce maintenance costs, and improve overall operational performance.

In conclusion, metal fabrication ERP systems play a vital role in enhancing workforce management through efficient maintenance planning, proactive equipment condition monitoring, spare parts inventory optimization, maintenance workforce management, and performance analysis.

By leveraging the capabilities of manufacturing software, metal fabrication companies can minimize downtime, optimize equipment efficiency, and drive continuous improvement in maintenance operations.

Mobile Accessibility

In today's fast-paced environment, mobile accessibility is crucial for empowering workforce productivity and efficiency, especially in the dynamic metal fabrication industry.

Metal fabrication ERP systems equipped with mobile accessibility features enable employees to access critical information, collaborate with team members, and perform tasks anytime, anywhere.

Let's explore how these systems revolutionize workforce management through mobile accessibility.

- Real-Time Data Access: Metal fabrication ERP systems provide real-time access to important data, such as production schedules, inventory levels, and work orders, via mobile devices. With ERP for metal industry, employees can check project statuses, update task progress, and view performance metrics on the go, ensuring informed decision-making and responsiveness. Manufacturing ERP software ensures data consistency and security, allowing employees to access sensitive information securely from their mobile devices, enhancing operational efficiency and agility.

- Remote Collaboration: MRP software systems facilitate remote collaboration by enabling employees to communicate with team members, share documents, and collaborate on projects from anywhere. Metal fabrication ERP solutions offer mobile communication tools, such as instant messaging, video conferencing, and document sharing, to foster teamwork and collaboration across geographically dispersed teams. With manufacturing software, organizations can conduct virtual meetings, brainstorming sessions, and collaborative problem-solving activities, leveraging mobile technology to enhance productivity and innovation.

- Task Management and Updates: Metal fabrication ERP systems support task management and updates through mobile apps, allowing employees to receive task assignments, update progress, and submit reports in real time. ERP for metal industry enables supervisors to assign tasks, track employee activities, and provide feedback remotely, ensuring continuity of operations and adherence to project timelines. Manufacturing ERP software synchronizes task updates and notifications across devices, ensuring that all stakeholders are informed of changes and updates instantly, minimizing delays and miscommunications.

- Field Service Management: MRP software systems facilitate field service management by providing mobile access to service technicians for equipment inspections, maintenance tasks, and customer interactions. Metal fabrication ERP solutions offer mobile service apps with GPS tracking, route optimization, and customer information, enabling technicians to deliver efficient and personalized service on-site. With manufacturing software, organizations can streamline field service operations, reduce response times, and improve customer satisfaction by leveraging mobile accessibility for service delivery.

- Training and Skill Development: Metal fabrication ERP systems support training and skill development initiatives by delivering mobile learning modules, instructional videos, and quizzes to employees' mobile devices. ERP for metal industry enables employees to access training materials, complete certifications, and track progress toward skill development goals, enhancing workforce capabilities and performance. Manufacturing ERP software ensures that employees have convenient access to training resources anytime, anywhere, fostering a culture of continuous learning and improvement within the organization.

In conclusion, metal fabrication ERP systems enhance workforce management through mobile accessibility by providing real-time data access, enabling remote collaboration, facilitating task management and updates, supporting field service management, and facilitating training and skill development.

By leveraging the capabilities of manufacturing software, metal fabrication companies can empower employees to work efficiently and effectively, regardless of their location or device, driving operational excellence and competitiveness in the industry.

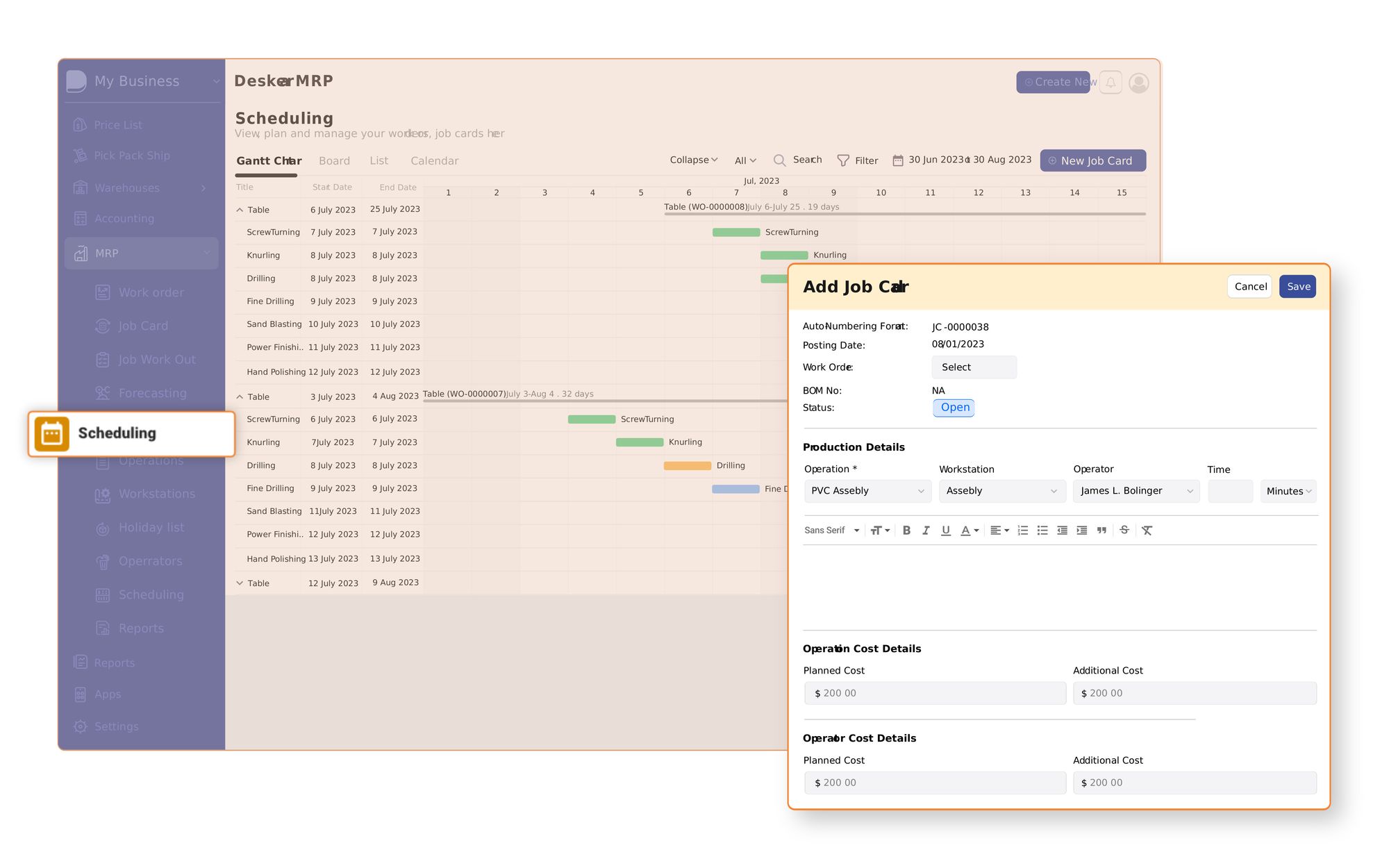

How can Deskera Improve Workforce Management as a Metal Fabrication ERP?

Deskera as a metal fabrication ERP can improve workforce management by offering a comprehensive suite of features tailored to the specific needs and challenges of the metal fabrication industry.

Here's how Deskera can achieve this:

- Customized Production Planning: Deskera can provide production planning modules specifically designed for metal fabrication, allowing businesses to create customized production schedules, manage job orders, and optimize resource allocation based on the unique requirements of metal fabrication processes.

- Inventory Management: Deskera's inventory management system can accommodate the complexities of managing raw materials, semi-finished goods, and finished products in the metal fabrication industry. It can track inventory levels, manage stock movements, and automate replenishment processes to ensure optimal inventory control and minimize stockouts.

- Job Costing and Estimation: Deskera can offer robust job costing and estimation functionalities, enabling metal fabrication businesses to accurately estimate project costs, track expenses, and analyze profitability on a per-job basis. This feature helps businesses make informed decisions and optimize pricing strategies to maximize profitability.

- Quality Control and Compliance: Deskera can incorporate quality control and compliance modules to help metal fabrication businesses maintain quality standards, adhere to industry regulations, and mitigate risks related to product quality and safety. It can facilitate inspection workflows, manage non-conformance issues, and maintain audit trails for compliance purposes.

- Resource Planning and Scheduling: Deskera can provide resource planning and scheduling tools that enable metal fabrication businesses to optimize workforce utilization, schedule production activities, and balance workloads effectively. This feature helps businesses minimize downtime, improve productivity, and meet customer delivery deadlines.

- Business Intelligence and Analytics: Deskera can integrate advanced business intelligence and analytics capabilities into its ERP solution, allowing metal fabrication businesses to gain actionable insights from their data. It can provide real-time dashboards, KPI tracking, and trend analysis tools to help businesses identify opportunities for improvement and make data-driven decisions.

- Mobile Accessibility: Deskera can ensure mobile accessibility for its ERP solution, enabling metal fabrication businesses to manage workforce operations from anywhere, at any time. This feature allows managers and employees to access critical information, collaborate on tasks, and make decisions on the go, enhancing agility and responsiveness.

Key Takeaways

The adoption of metal fabrication ERP represents a pivotal step toward revolutionizing workforce management in the metal fabrication industry.

As businesses navigate the complexities of the modern marketplace, the role of metal fabrication ERP becomes increasingly indispensable. By providing a comprehensive platform for orchestrating workforce operations, metal fabrication ERP lays the foundation for sustained success and growth in the metal fabrication industry.

The 10 ways in which implementation of metal fabrication ERP helps in improving workforce management are:

- Resource Allocation: Metal fabrication ERP systems provide real-time visibility into resource availability, enabling better allocation of workforce, machinery, and materials. This ensures that tasks are assigned efficiently, preventing bottlenecks and optimizing productivity.

- Scheduling and Planning: Metal fabrication ERP software can automate scheduling processes, taking into account factors like machine availability, employee skill sets, and project deadlines. This minimizes downtime and maximizes throughput by ensuring that the right people are working on the right tasks at the right time.

- Inventory Management: Effective inventory management is crucial in metal fabrication to prevent shortages or overstocking of materials. A manufacturing ERP system can track inventory levels in real time, generate automated reorder alerts, and optimize inventory levels to reduce carrying costs while ensuring materials are always available when needed.

- Skill Tracking and Training: Metal fabrication ERP systems can maintain detailed employee records, including skills, certifications, and training history. This information enables managers to identify skill gaps and plan training programs to upskill their workforce, ensuring that employees have the necessary expertise to handle diverse tasks efficiently.

- Performance Monitoring and KPIs: MRP software solutions offer comprehensive reporting and analytics capabilities, allowing managers to track key performance indicators (KPIs) such as throughput, yield, scrap rates, and labor efficiency. By monitoring these metrics, managers can identify areas for improvement and implement strategies to enhance workforce performance.

- Integration with HR Systems: Integrating the ERP system with HR software streamlines administrative processes such as payroll, time tracking, and benefits management. This reduces manual data entry errors and ensures that workforce-related tasks are handled seamlessly within a unified platform.

- Compliance and Regulations: Metal fabrication involves adherence to various regulations and industry standards. An ERP for metal industry can help ensure compliance by providing built-in regulatory features and enabling documentation of processes and certifications, reducing the risk of non-compliance penalties.

- Communication and Collaboration: Metal fabrication ERP systems often include collaboration tools that facilitate communication among team members, suppliers, and customers. This improves coordination, fosters teamwork, and enhances overall efficiency in project execution.

- Maintenance Planning: Implementing maintenance planning within the manufacturing ERP system ensures that machinery operates at optimal levels, minimizing downtime and disruptions to production schedules. By scheduling preventive maintenance tasks based on usage patterns and historical data, the ERP system helps in proactively addressing potential issues before they escalate into costly breakdowns. This proactive approach not only extends the lifespan of equipment but also enhances workforce productivity by providing a reliable and well-maintained operational environment.

- Mobile Accessibility: Enabling mobile accessibility for the metal fabrication ERP system empowers employees to access critical information and perform tasks from anywhere, at any time. Whether it's checking schedules, updating project statuses, or accessing training materials, mobile accessibility ensures that workforce management functions are not bound to a specific location or device. Field technicians can easily input maintenance data, supervisors can monitor progress remotely, and managers can make informed decisions on the go, resulting in improved efficiency and responsiveness across the organization. Additionally, mobile accessibility enhances communication and collaboration among team members, facilitating seamless coordination and enabling swift resolution of any issues that arise during fabrication processes.

In embracing the transformative potential of metal fabrication ERP, businesses not only optimize their workforce management practices but also position themselves as leaders in an ever-evolving industry landscape.

With its myriad benefits and strategic advantages, metal fabrication ERP emerges as a catalyst for driving operational excellence, fostering innovation, and achieving enduring success in the metal fabrication industry.

Deskera's Metal Fabrication ERP streamlines workforce management with customized production planning, inventory management, job costing, and quality control features. It optimizes resource planning and offers mobile accessibility. With advanced analytics, Deskera empowers metal fabrication businesses to enhance efficiency, compliance, and profitability.

Related Articles