According to Allied Market Research, the global market for pest control chemicals is projected to reach $28.9 billion by 2027, growing at a CAGR of 5.1% from 2020 to 2027. According to a 2021 survey of pest management professionals, the top three pests causing the most problems in the United States were ants (37%), bed bugs (28%), and cockroaches (17%). (Source: Pest Control Technology)

As per the Environmental Protection Agency, the most commonly used active ingredients in commercial pest control products in the United States are pyrethroids, accounting for 54.2% of all active ingredient use.

Also, as per Mordor Intelligence, the global demand for biopesticides, which are derived from natural sources and considered to be less harmful to the environment than traditional chemical pesticides, is expected to grow at a CAGR of 14.7% from 2020 to 2027.

These statistics highlight the prevailing trends revolving around pest control manufacturing and the chemicals being used in it. These statistics also reflect the complexities involved in selecting the right pest control chemical for your manufacturing process.

However, to help you select the right pest control chemical for your manufacturing process, this article covers the following topics:

- How to Select the Right Pest Control Chemical for Your Manufacturing Process?

- What are Some Active Ingredients Used in Pest Control Chemicals?

- What is the Importance of Choosing the Right Pest Control Chemical for the Manufacturing Process?

- How can Deskera Help in Selecting the Right Pest Control Chemical for Your Pesticide Manufacturing Process?

- Key Takeaways

- Related Articles

How to Select the Right Pest Control Chemical for Your Manufacturing Process?

It's important to note that selecting the right pest control chemical for your manufacturing process can be a complex process that requires careful consideration of multiple factors. It may be helpful to consult with a pest control professional or a chemical supplier to ensure that you select the most effective and appropriate chemical for your needs.

Some general guidelines on how to select the right pest control chemical for your manufacturing process:

Identify the Pest

The first step in selecting the right pest control chemical is to identify the pest you are dealing with. This will help you determine which types of chemicals are most effective in controlling that particular pest.

Identifying the pest is a critical step in selecting the right pest control chemical for your pesticide manufacturing process. Different pests require different control measures, and using the wrong chemical or methods can result in ineffective pest control, wasted resources, additional business expenses, and potential harm to human health and the environment.

Here are some factors to consider when identifying the pest for selecting the right pest control chemical:

- Pest species: Identify the pest species and determine its biology, behavior, and lifecycle. This information will help determine the most effective pest control methods and chemicals.

- Pest population level: Determine the level of pest infestation and its distribution within the area. This will help determine the appropriate pest control method, such as spot treatment or broadcast application.

- Pest location: Determine the location of the pest, including areas of activity, harborage sites, and entry points. This will help determine the appropriate application method and the type of chemical to use.

- Pest damage: Evaluate the extent of damage caused by the pest and the potential for future damage. This will help determine the urgency and frequency of treatment, as well as the appropriate control measures.

- Regulations: Check all relevant regulations and guidelines for pesticide use and disposal, as well as any restrictions on the use of certain chemicals for certain pests.

Overall, identifying the pest is a critical step in selecting the right pest control chemical for your pesticide manufacturing process. It is important to use a variety of pest control methods and chemicals, as well as to regularly monitor and adjust the pest control program to ensure its effectiveness and safety.

Consider the Mode of Action

Different pest control chemicals work in different ways, so it's important to consider the mode of action of each chemical before selecting one. For example, some chemicals work by disrupting the pest's nervous system, while others interfere with its reproductive system.

The mode of action is an important factor to consider when selecting the right pest control chemical for your pesticide manufacturing process. The mode of action refers to how the chemical affects the target pest, and different modes of action can have varying levels of effectiveness and potential for resistance development.

Here are some factors to consider when evaluating the mode of action for selecting the right pest control chemical:

- Target pest: The mode of action should be appropriate for the target pest. For example, if the target pest is a chewing insect, a chemical with a contact or stomach poison mode of action may be more effective than a chemical with a repellent mode of action.

- Resistance development: Overuse of chemicals with the same mode of action can lead to the development of resistance in the target pest population. It is important to rotate chemicals with different modes of action to reduce the likelihood of resistance development.

- Persistence: The persistence of the chemical in the environment can affect its effectiveness and potential for off-target effects. Chemicals with a short residual life may require more frequent applications, while chemicals with a longer residual life may have greater potential for environmental impact.

- Safety: The mode of action should prioritize safety for both humans and non-target organisms. Chemicals with low toxicity to non-target organisms may be more suitable for environmentally sensitive areas.

- Regulations: The mode of action should comply with all relevant regulations and guidelines for pesticide use and disposal.

Overall, selecting the right pest control chemical with an appropriate mode of action requires careful consideration of all the above factors, as well as proper training and experience in the use of pesticides. It is also important to regularly review and update the chosen chemical and mode of action to ensure continued effectiveness and safety.

Evaluate the Safety Risks

Pest control chemicals can be hazardous to human health and the environment, so it's important to evaluate the safety risks associated with each chemical. This includes considering factors such as toxicity, exposure, and potential for environmental contamination.

When selecting the right pest control chemical for the pesticide manufacturing process, it is important to evaluate the potential safety risks associated with the use of pesticides. Here are some of the safety risks to consider:

- Toxicity to humans and animals: Pesticides can be toxic to humans and animals, including pets and wildlife. Exposure to high levels of pesticides can cause health problems ranging from skin irritation to neurological damage or even death. It is important to select chemicals with the lowest possible toxicity that are still effective against the target pests.

- Environmental impact: Pesticides can have a negative impact on the environment, including polluting soil and water, harming wildlife, and disrupting ecosystems.

- Residues: Some pest control chemicals can leave residues on crops or surfaces that can pose health risks to humans or animals. It is important to select chemicals that break down quickly and do not persist in the environment.

- Regulations: There are regulations and guidelines for the use and disposal of pest control chemicals that must be followed to ensure safety. Failure to follow these regulations can result in legal liability and harm to human health and the environment.

- Exposure: Exposure to pest control chemicals can occur during manufacturing, application, and disposal. Exposure can result in short-term effects, such as irritation or nausea, or long-term effects, such as cancer or reproductive harm.

- Resistance: Overuse of pesticides can lead to the development of resistance in pests, making the pesticides less effective over time.

- Handling and storage: Pesticides can be dangerous if mishandled or improperly stored, leading to accidental spills or exposure to chemicals.

To evaluate safety risks when selecting the right pest control chemical, it is important to conduct a thorough risk assessment that considers all potential hazards and exposure pathways.

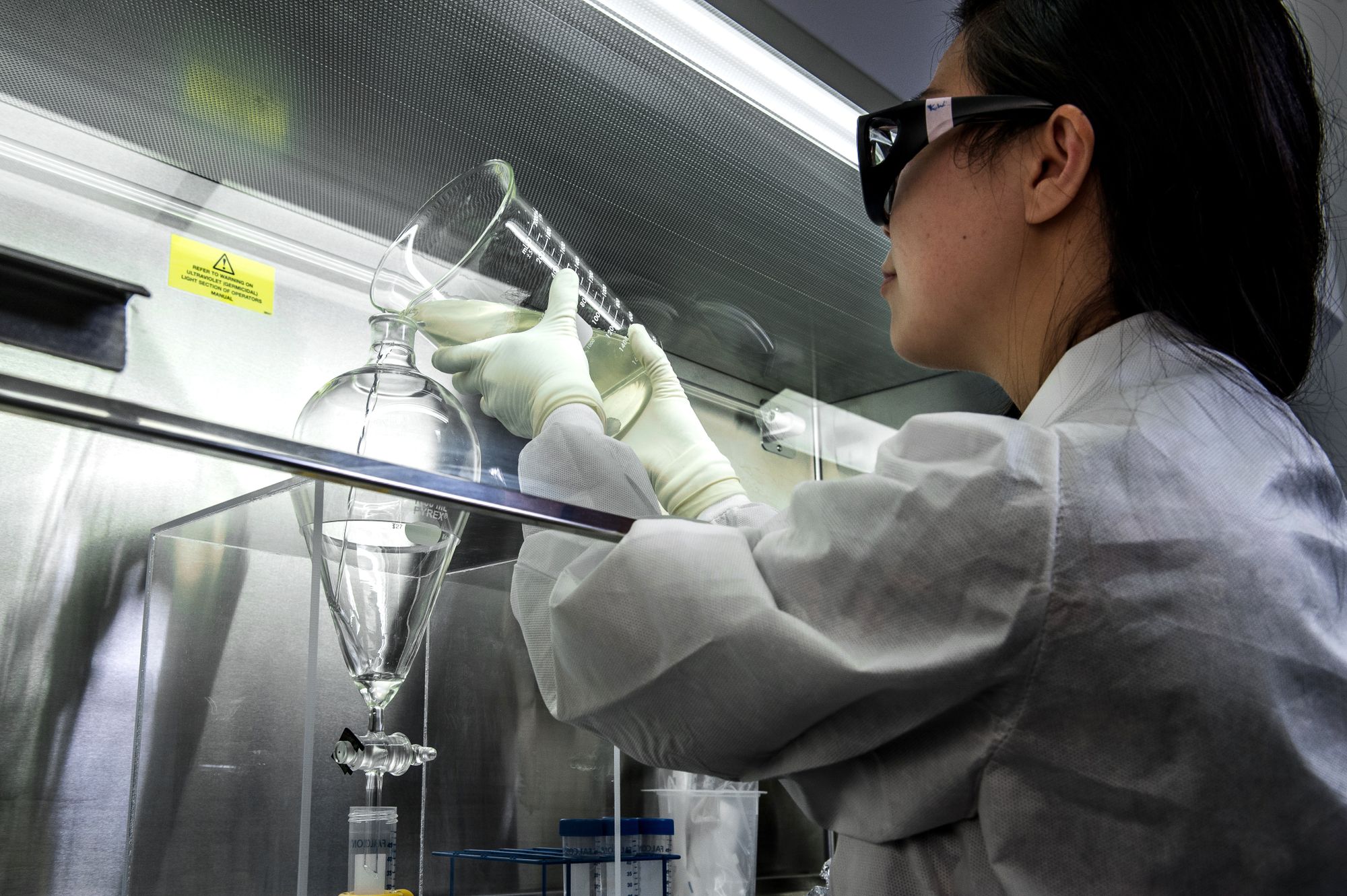

This should include testing the chemical in a controlled environment to assess its toxicity, as well as proper training for manufacturing, application, and disposal.

Additionally, it is important to follow all relevant regulations and guidelines to minimize safety risks. It is important to carefully evaluate the potential risks associated with the use of pesticides and to follow all label instructions for proper use, storage, and disposal. This includes wearing appropriate personal protective equipment, using the correct amount of pesticide, and disposing of unused pesticides properly.

Persistence

Persistence is an important factor to consider when selecting the right pest control chemical for your pesticide manufacturing process. Persistence refers to the length of time that the chemical remains active in the environment after application.

The persistence of a chemical can affect its effectiveness in controlling the target pest, as well as its potential for off-target effects, such as harm to non-target organisms and environmental contamination.

Here are some factors to consider when evaluating persistence for selecting the right pest control chemical:

- Target pest: The persistence of the chemical should be appropriate for the target pest. For example, pests with a short life cycle may require a chemical with a shorter persistence, while pests with a longer life cycle may require a chemical with a longer persistence.

- Environmental impact: The persistence of the chemical can affect its potential for environmental impacts, such as contamination of soil, water, or air. Chemicals with a longer persistence may have a greater potential for environmental impact.

- Application method: The persistence of the chemical can also be affected by the application method. For example, chemicals applied to the soil may have a longer persistence than those applied as foliar spray.

- Regulations: The persistence of the chemical should comply with all relevant regulations and guidelines for pesticide use and disposal.

- Resistance management: The persistence of the chemical can also affect its potential for resistance development in the target pest population. It is important to rotate chemicals with different persistence and modes of action to reduce the likelihood of resistance development.

Overall, selecting the right pest control chemical with an appropriate persistence requires careful consideration of all the above factors, as well as proper training and experience in the use of pesticides. It is also important to regularly review and update the chosen chemical and control measures to ensure continued effectiveness and safety.

Determine the Application Method

Some pest control chemicals are designed for use in specific application methods, such as sprays or baits. Consider the application method that is most appropriate for your manufacturing process and select a chemical that is compatible with that method.

When selecting the right pest control chemical for the pesticide manufacturing process, it is important to consider the appropriate application method to ensure maximum efficacy and safety. The application method should be selected based on the type of pest being targeted, the location of the infestation, and the physical characteristics of the manufacturing facility. Here are some common application methods to consider:

- Spray: Spraying is a common application method for controlling pests in large open areas or on surfaces. This method involves using a handheld or mechanized sprayer to apply the pesticide directly to the targeted area.

- Fumigation: Fumigation is an effective method for controlling pests in enclosed spaces. This method involves releasing gas or vapor into the target area, which penetrates all surfaces and kills the pests.

- Baiting: Baiting is a targeted method for controlling pests in specific areas. This method involves placing bait, such as a gel or granule, in areas where the pests are likely to be found. The bait is then consumed by the pests, leading to their death.

- Trapping: Trapping is another targeted method for controlling pests in specific areas. This method involves using a trap to capture and kill the pests.

- Dusting: Dusting is an application method that involves applying a fine powder directly to the targeted area. This method is often used for controlling pests in cracks and crevices where other application methods may not be effective.

The application method is an important factor to consider when selecting the right pest control chemical for your pesticide manufacturing process. Different pest control chemicals may have different application methods, and the chosen method can affect the effectiveness and safety of the chemical.

Here are some factors to consider when determining the application method for selecting the right pest control chemical:

- Target pest: The application method should be appropriate for the target pest. For example, if the target pest is located in a hard-to-reach area, such as inside a wall void, a dust or foam application method may be more effective than a liquid spray.

- Environmental conditions: The application method should also consider the environmental conditions of the application site, such as wind speed, temperature, and humidity. For example, a liquid spray may be less effective on a windy day, while a granular application may be better suited for a dry, sunny day.

- Safety: The application method should prioritize safety for both the applicator and non-target organisms. For example, a fogger application method may not be appropriate in an area with high levels of occupancy, as it can cause respiratory problems.

- Regulations: The application method should comply with all relevant regulations and guidelines for pesticide use and disposal. For example, certain application methods may not be allowed in certain locations, such as near water sources.

Ultimately, selecting the right pest control chemical and application method requires careful consideration of all the above factors, as well as proper training and experience in the use of pesticides. It is also important to regularly review and update the chosen method to ensure continued effectiveness and safety.

Consider the Cost

Pest control chemicals can vary widely in cost, so it's important to consider the cost-effectiveness of each option. This includes considering factors such as the effectiveness of the chemical, the frequency of application required, and the potential for long-term savings.

In fact, selecting the right pest control chemical for your pesticide manufacturing process can have significant cost implications, both in terms of financial expenses and environmental impact.

- Financial cost: The cost of selecting the wrong pest control chemical can be high, as it can result in the need for additional testing, potential product recalls, and legal liability. It may also result in a delay in product development, which can affect revenue as well as customer loyalty.

- Environmental cost: The environmental cost of using the wrong pest control chemical can be significant. It can lead to contamination of the soil, water, and air, as well as harm to non-target organisms such as bees and birds. The use of certain chemicals can also result in long-term health effects for humans.

To avoid these costs, it is essential to conduct thorough research on the available pest control chemicals and their potential impacts.

This should include consideration of the target pest, the environmental conditions of the application site, and the potential risks to non-target organisms and human health.

It is also important to comply with all relevant regulations and guidelines for pesticide use and disposal.

Resistance Management

Resistance management is an important factor to consider when selecting the right pest control chemical for your pesticide manufacturing process. Resistance can occur when a pest population develops the ability to survive exposure to a chemical that previously controlled it.

Overuse or misuse of pesticides can lead to the development of resistance in pest populations, which can result in decreased effectiveness of the chemical and increased pest damage.

Here are some factors to consider when evaluating resistance management for selecting the right pest control chemical:

- Mode of action: Using chemicals with the same mode of action repeatedly can increase the likelihood of resistance development in the target pest population. It is important to rotate chemicals with different modes of action to reduce the likelihood of resistance development.

- Chemical group: Chemicals within the same group may have similar modes of action, so it is important to rotate chemicals across different chemical groups to reduce the likelihood of resistance development.

- Application method: The application method can affect the likelihood of resistance development, as pests may be exposed to sublethal doses of the chemical if the application is not thorough. It is important to follow proper application procedures and timing to ensure effective control.

- Monitoring: Regular monitoring of pest populations can help detect the early signs of resistance development, allowing for timely action to be taken.

- Regulations: Compliance with all relevant regulations and guidelines for pesticide use and disposal is important to prevent the overuse or misuse of chemicals.

Overall, selecting the right pest control chemical for your pesticide manufacturing process with appropriate resistance management requires careful consideration of all the above factors, as well as proper training and experience in the use of pesticides. It is also important to regularly review and update the chosen chemical and control measures to ensure continued effectiveness and safety.

What are Some Active Ingredients Used in Pest Control Chemicals?

The specific chemicals required for pest control chemical manufacturing will depend on the pests being targeted and the specific formulation of the product. It is important to carefully consider the properties and potential risks of each chemical and choose the most appropriate one for the intended use.

There are many active ingredients used in pest control chemicals. Here are some common examples:

- Pyrethrins and pyrethroids: These are insecticides derived from the chrysanthemum flower. They work by attacking the nervous system of insects, causing paralysis and death.

- Neonicotinoids: These insecticides work by binding to and activating the nicotinic acetylcholine receptors in the nervous system of insects, leading to paralysis and death.

- Organophosphates: These insecticides work by inhibiting the activity of an enzyme called acetylcholinesterase, which is necessary for proper nerve function. This causes overstimulation of the nervous system, leading to paralysis and death.

- IGRs (insect growth regulators): These chemicals interfere with the normal development of insects, preventing them from reaching maturity and reproducing.

- Fumigants: These are chemicals that are used to control pests in enclosed spaces by filling the space with gas. They work by suffocating or poisoning the pests.

- Rodenticides: These are chemicals used to control rodents, such as mice and rats. They work by causing internal bleeding or interfering with the blood's ability to clot.

It's important to note that many of these active ingredients can be harmful to humans and other animals if not used properly, so it's essential to follow the instructions on the product label and take appropriate safety precautions when handling and applying pest control chemicals. Additionally, regulatory requirements should be carefully considered when choosing and using pest control chemicals.

What is the Importance of Choosing the Right Pest Control Chemical for the Manufacturing Process?

Choosing the right pest control chemical is essential for the manufacturing process for several reasons:

- Safety: The safety of employees and consumers should be the top priority. Choosing the wrong pest control chemical can cause harm to people, animals, and the environment. It is important to select chemicals that are safe and effective for the intended purpose.

- Compliance: The use of pest control chemicals in manufacturing is regulated by various agencies, such as the Environmental Protection Agency (EPA). Choosing the wrong chemical can lead to non-compliance with regulations, resulting in fines and other legal consequences.

- Cost-effectiveness: Using the right pest control chemical can help reduce costs associated with pest control. The correct chemical will eliminate pests effectively and efficiently, reducing the need for repeated treatments or excessive use of chemicals.

- Impact on the environment: The use of pest control chemicals can have an impact on the environment, including soil, air, and water. Choosing the right chemical can help minimize the environmental impact of pest control measures.

- Product quality: Pest infestations can damage products, resulting in lower quality and potentially causing product recalls. Choosing the right pest control chemical can help maintain product quality and avoid product recalls.

Overall, choosing the right pest control chemical is critical for the success of the manufacturing process. It is important to consider factors such as safety, compliance, cost-effectiveness, environmental impact, and product quality when selecting a pest control chemical.

How can Deskera Help in Selecting the Right Pest Control Chemical for Your Pesticide Manufacturing Process?

Deskera MRP is a cloud-based software solution that offers various features to help in selecting the right pest control chemical for your pesticide manufacturing process. Here are some ways in which Deskera can assist in this process:

- Inventory management: Deskera provides a robust inventory management system that allows you to track your stock of different chemicals and their expiration dates. This feature ensures that you have the right amount of each chemical on hand and can identify expired chemicals that need to be replaced.

- Compliance management: Deskera includes compliance management features that help you stay up-to-date with the latest regulations and guidelines for pesticide use and disposal. This feature ensures that you are using chemicals in a safe and responsible manner.

- Analytics: Deskera provides various analytics features that can help you analyze the performance of different pest control chemicals in your manufacturing process. This feature allows you to evaluate the effectiveness of each chemical and identify any potential issues that may require attention.

- Workflow management: Deskera's workflow management features allow you to automate and streamline various processes involved in selecting the right pest control chemical, such as requisitioning and approval workflows. This feature ensures that your team is working efficiently and effectively.

- Collaboration: Deskera provides a collaborative platform that allows team members to share information, documents, and data in real time. This feature facilitates communication and collaboration among team members involved in selecting the right pest control chemical.

Key Takeaways

Selecting the right pest control chemical for your pesticide manufacturing process involves considering multiple factors to ensure effectiveness and safety. Here are some of the most important factors to consider:

- Pest species: Different pests require different control measures, and using the wrong chemical or method can result in ineffective pest control.

- Mode of action: The mode of action of the chemical is an important factor to consider, as different modes of action can have varying levels of effectiveness and potential for resistance development.

- Safety: Safety should be a top priority when selecting a pest control chemical to minimize harm to humans and non-target organisms. This includes selecting chemicals with low toxicity and following all relevant regulations and guidelines for pesticide use and disposal.

- Persistence: The persistence of the chemical in the environment can affect its effectiveness and potential for off-target effects. Chemicals with a short residual life may require more frequent applications, while chemicals with a longer residual life may have greater potential for environmental impact.

- Application method: The application method can affect the efficacy of the chemical, as well as the potential for human and environmental exposure. The appropriate application method will depend on the target pest, the location of the pest, and other factors.

- Cost: The cost of the chemical and associated application methods should be considered, as well as the potential cost of pest damage if the control measures are not effective.

- Resistance management: Overuse of chemicals with the same mode of action can lead to the development of resistance in the target pest population. It is important to rotate chemicals with different modes of action to reduce the likelihood of resistance development.

Overall, selecting the right pest control chemical for your pesticide manufacturing process requires careful consideration of all the above factors, as well as proper training and experience in the use of pesticides. It is also important to regularly review and update the chosen chemical and control measures to ensure continued effectiveness and safety.

Deskera MRP can assist in selecting the right pest control chemical for your pesticide manufacturing process by providing a comprehensive software solution that streamlines various processes and ensures compliance with regulations and guidelines.

Related Articles