Measuring the effectiveness of furniture manufacturing is an important part of ensuring that products are of high quality and meet customer expectations. This involves analyzing the processes involved in furniture production, from the materials used to the assembly and finishing processes, to assess the accuracy and cost-efficiency of each step.

This article covers the following:

- Overview of Furniture Manufacturing

- Benefits of Furniture Manufacturing

- Types of Furniture Manufacturing

- Furniture Manufacturing Processes

- Costs of Furniture Manufacturing

- Challenges in Furniture Manufacturing

- Quality Control in Furniture Manufacturing

- Environmental Impact of Furniture Manufacturing

- The Future of Furniture Manufacturing

- How to measure the effectiveness of Furniture Manufacturing?

- How to Increase the Effectiveness of Furniture Manufacturing?

- How Can Deskera Assist You

Overview of Furniture Manufacturing

Furniture manufacturing is a process that involves the skills of design, carpentry, engineering, and craftsmanship. From the selection of raw materials to the assembly of finished products, furniture manufacturing requires a variety of skill sets and processes.

Raw Materials: The raw materials used in furniture manufacturing include wood, fabric, foam, metal, and other materials. Depending on the type of furniture being manufactured, different materials may be used. For example, wooden furniture is often constructed using hardwood such as oak, maple, or cherry.

Fabric furniture may be made from cotton, linen, or synthetic fibers. Design: The design process is the first step in furniture manufacturing. This involves creating a blueprint or plan of the piece of furniture that is to be constructed.

The design must take into account the functionality of the piece and also consider aesthetics, comfort, and material selection. The design process may involve CAD (Computer-Aided Design) software, 3D printing, or hand drawing.

Carpentry: Carpentry is an essential part of furniture manufacturing. This involves the cutting and shaping of the raw materials to create the pieces that will form the furniture. This process can be done by hand or with the help of power tools.

The carpenter must ensure that all pieces are cut to the correct sizes and shapes and that all joints are secure.

Engineering: Furniture engineering is the process of designing and constructing the components of a piece of furniture. This involves selecting the right materials, such as wood, fabric, and foam, and creating components that fit together perfectly.

The engineering process also involves the use of machines to produce the components of the furniture in a precise and efficient manner.

Assembly: Once all the components have been created, they must be assembled to form the finished product. This process requires careful attention to detail and an understanding of how the components fit together.

In some cases, the assembly process may involve the use of tools such as screws, nails, or glue.

Finishing: The finishing process is the final step in furniture manufacturing. This process involves applying a protective coating to the furniture, such as lacquer, wax, or paint.

The finishing process also involves sanding, staining, and polishing the furniture to give it a smooth and attractive finish. Furniture manufacturing is a complex process that requires a variety of skills and processes.

From the selection of raw materials to the assembly of the finished product, furniture manufacturing requires a great deal of attention to detail to ensure that the final product is of the highest quality.

Benefits of Furniture Manufacturing

Furniture manufacturing is a highly rewarding industry that can provide a number of benefits to both the individual and the business alike. Furniture manufacturing is a major contributor to the economy and provides a wide range of job opportunities and a steady source of income.

This industry is also a great way to not only showcase the creativity and skill of craftspeople and artisans but to also create pieces that will last for generations. The Benefits of Furniture Manufacturing.

Job Creation

Furniture manufacturing creates a number of job opportunities for individuals who are looking for work. This industry provides a number of jobs for both skilled and unskilled workers, from designers and craftspeople to factory workers and laborers. This industry provides a steady source of income and opportunities for growth.

Economic Growth

Furniture manufacturing is a major contributor to the economy. The industry provides a number of jobs that generate income, which can help stimulate economic growth. It also helps to promote investment and job creation in other industries, such as transportation, logistics, and customer service.

Quality

Quality is one of the main benefits of furniture manufacturing. When furniture is made with quality materials and craftsmanship, it can last for generations. Quality furniture is also more likely to be appreciated and admired by customers, which leads to higher customer satisfaction.

Design

Furniture manufacturing is a great way to showcase the creativity and skill of craftspeople and artisans. Furniture designers can create unique and attractive pieces that are tailored to customers’ individual needs and tastes. This can lead to increased customer loyalty and satisfaction.

Sustainability

Furniture manufacturing can also be a great way to promote sustainability. Sustainable materials, such as bamboo and recycled wood, can be used to create furniture that is both beautiful and durable.

This helps to reduce the impact of furniture manufacturing on the environment. Furniture manufacturing is an industry that has a lot to offer. It can provide job opportunities, economic growth, quality products, design, and sustainability.

It can also help to showcase the creativity and skill of craftspeople and artisans. Furniture manufacturing is an industry that has a lot of potentials and is sure to continue to grow in the future

Types of Furniture Manufacturing

When it comes to furniture manufacturing, there are several different types of manufacturing processes that are used to create furniture pieces. Each of these different types of manufacturing processes has its own unique features and benefits that can be helpful when designing and creating furniture. Here’s a look at the different types of furniture manufacturing processes and how they work.

CNC Manufacturing

CNC stands for Computer Numerical Control and is a type of manufacturing process that uses computer-controlled machines to create furniture components. CNC machining is a popular choice for furniture manufacturing because it allows for consistent and accurate production of parts.

This type of manufacturing process is great for large-scale production and can be used to create furniture parts quickly and efficiently.

Handcrafted Furniture

Handcrafted furniture is made by skilled artisans using traditional woodworking techniques. This type of manufacturing process allows for unique designs that can’t be created with other types of manufacturing processes. Handcrafted furniture is often made using natural materials such as wood, and the pieces are often intricately detailed and designed.

Veneer Manufacturing

Veneer manufacturing is the process of creating furniture components out of thin layers of wood. Veneer manufacturing is a great choice for furniture manufacturing because it allows for unique designs and intricate details. This type of furniture manufacturing process is often used to create intricate designs and patterns on pieces of furniture.

Laminating Manufacturing

Laminating is a type of furniture manufacturing process that involves bonding two or more layers of materials together to create furniture components. This type of manufacturing process is great for creating furniture components that are strong and durable. It’s also great for creating furniture pieces with unique designs and patterns.

Upholstery Manufacturing

Upholstery manufacturing is a type of furniture manufacturing process that involves using fabrics and other materials to create furniture components. Upholstery manufacturing is great for creating furniture pieces with a comfortable and stylish look and feel. This type of furniture manufacturing process is often used to create furniture components that are comfortable and stylish.

These are just a few of the different types of furniture manufacturing processes that are used to create furniture pieces. Each type of manufacturing process has its own unique features and benefits that can be helpful when designing and creating furniture.

It’s important to understand the different types of furniture manufacturing processes so that you can determine which type of manufacturing process is best for your furniture needs.

Furniture Manufacturing Processes

Furniture manufacturing is a complex process that involves transforming raw materials into finished products. The process typically involves several steps and can range from simple to complex, depending on the type of furniture being made.

From selecting the right materials to ensuring quality and durability, understanding furniture manufacturing processes is essential for anyone looking to create high-quality pieces.

First, the raw materials needed to create furniture must be identified and acquired. This can include wood, metals, fabrics, and other materials. Depending on the type of furniture being made, different types of materials may be needed.

For example, solid wood is often used in the construction of traditional furniture, while modern pieces may require more contemporary materials like metal or synthetic fabrics. Once the materials have been acquired, they must be cut to the correct size and shape.

This can be done with specialized machinery, and the size and shape of the pieces will depend on the design of the furniture being made. For example, a chair may require several pieces of wood to be cut to create the arms, back, and legs. Next, the pieces must be assembled.

This typically involves using dowels and screws to join them together. In some cases, additional materials such as glue or veneer may also be used to ensure a strong bond. Depending on the complexity of the furniture, the assembly process can be done by hand or with the help of specialized machinery.

Once the pieces have been assembled, they must be sanded and stained. Sanding helps to smooth the surfaces and remove any rough edges, while staining helps to give the furniture its desired color.

After the sanding and staining processes are complete, the furniture can then be varnished or finished with a coating to protect it from wear and tear. Finally, the furniture must be inspected and tested to ensure it meets all the required standards.

This includes checking the strength of joints and the overall durability of the furniture. Once the inspection is complete, the furniture can then be packaged and shipped to its final destination.

Furniture manufacturing is a complex process that requires a great deal of skill and precision. Understanding the various steps involved in the process is essential for anyone looking to create high-quality pieces.

From selecting the right materials to ensuring quality and durability, the furniture manufacturing process can help ensure the finished product meets all the necessary requirements.

Costs of Furniture Manufacturing

Furniture manufacturing is an important industry in many countries, and costs of furniture manufacturing can vary widely depending on the type of furniture being made, the materials used, and the complexity of the manufacturing process.

In general, the costs of furniture manufacturing can be broken down into three categories: materials, labor, and overhead. Materials The cost of materials can vary greatly depending on the type of furniture being made and the materials used.

For example, the costs of wood used in furniture production can range from a few dollars per board foot to several hundred dollars for specialty woods. Likewise, upholstery costs can range from a few dollars for basic cloth upholstery to several hundred dollars for designer fabrics.

In addition, hardware and other components used in furniture production can add to the overall cost of materials. Labor costs are another major component of furniture manufacturing costs.

Labor costs can include wages for skilled woodworkers and upholsterers, as well as costs for machine operators and other personnel. These costs vary greatly depending on the size and complexity of the furniture being manufactured.

Overhead costs are those associated with running a business, such as rent, electricity, and insurance. These costs are typically a fixed amount and are not related to the type of furniture being produced.

In conclusion, the costs of furniture manufacturing can vary greatly depending on the type of furniture being made, the materials used, and the complexity of the manufacturing process.

Understanding the costs associated with furniture manufacturing can help you make informed decisions when selecting a manufacturer or choosing materials.

Challenges in Furniture Manufacturing

When it comes to furniture manufacturing, it can be a complex and challenging process. From the sourcing of materials to the actual production of the furniture, there are a number of potential challenges that need to be addressed. Here are some of the most common challenges in furniture manufacturing.

Sourcing Materials

Finding the right materials for furniture production can be a challenge. Quality materials can be expensive, and it can be difficult to track down the right suppliers. Additionally, environmental regulations can impact the sourcing of materials, as some materials may not be sustainable or compliant with certain regulations.

Designing for Quality

Furniture design is a delicate balance between form and function. It can be tricky to create furniture designs that are both aesthetically pleasing and highly functional. Designers must be sure to create designs that are durable, easy to use, and ergonomic.

Cost of Production

Furniture production is a costly process. From sourcing materials to hiring skilled labor, the cost of production can quickly add up. Additionally, the cost of research and development for new designs can be high.

Meeting Regulations

Furniture manufacturers must comply with a variety of regulations, such as environmental regulations, product safety regulations, and labor laws. If a furniture manufacturer does not abide by these regulations, they can face serious consequences.

Keeping up with Trends

In the furniture industry, trends are always changing. To remain competitive, furniture manufacturers must be sure to keep up with the latest trends and incorporate them into their designs.

These are just a few of the many challenges that furniture manufacturers face. By understanding these challenges and taking steps to address them, furniture manufacturers can ensure they remain competitive in the industry.

Quality Control in Furniture Manufacturing

Quality control is essential in furniture manufacturing to ensure that customers receive furniture of the highest quality. Quality control involves a range of processes and procedures to ensure that all furniture is produced in accordance with the necessary standards and specifications.

Quality control begins at the design and planning stage, where all materials, components, and processes are carefully selected to meet the desired quality standards. Throughout the manufacturing process, each piece of furniture is inspected for defects and discrepancies, and all defects are noted and addressed.

Quality control staff inspect raw materials for defects before they are used in the production process, and inspect semi-finished furniture products to ensure they meet quality standards before the final assembly process.

At the end of the production process, the finished furniture is subjected to a final quality control inspection. This inspection involves a series of tests to ensure that the furniture meets the required standards in terms of strength, durability, and aesthetic appeal.

Quality control staff inspect the furniture for defects and make sure that all components are secure and properly assembled. They also check the furniture for any signs of deterioration or wear and tear. Quality control staff also check the packaging of the furniture to make sure it is secure and in good condition.

Finally, the furniture is tested for safety to ensure that it meets the necessary safety standards. Quality control procedures are essential to guarantee that the furniture produced is of the highest quality and that customers receive furniture that meets their expectations.

Quality control is an ongoing process that should be carried out throughout the entire process, from the design and planning stage to the final assembly and packaging of the furniture. Quality control staff are highly trained and experienced in the processes of inspecting and testing furniture to ensure that it meets the necessary standards.

Environmental Impact of Furniture Manufacturing

Furniture manufacturing is a major industry in many countries around the world, with billions of dollars in sales every year. While furniture production has the potential to provide economic benefits, it can also have negative impacts on the environment if not carefully managed.

The most significant environmental impacts of furniture manufacturing come from the use of materials, manufacturing processes, and disposal of furniture products. Materials The materials used in furniture manufacturing have a large impact on the environment.

The most common materials used in furniture production are wood, metal, plastic, and foam. Each of these materials has its own unique environmental impact. Wood is the most popular material used in furniture production and is primarily sourced from forests.

While wood is a renewable material, unsustainable forestry practices can lead to deforestation, loss of habitat, and the release of greenhouse gases due to carbon sequestration. Additionally, wood products often require chemical treatments such as stains, sealants, and glue to make them suitable for furniture production.

These chemicals can have negative environmental impacts if not disposed of properly. Metal furniture production requires large amounts of energy and resources to extract and process the raw materials.

The mining, refining, and smelting of metals can cause air and water pollution, as well as habitat destruction. Plastic furniture production involves the use of petroleum-based polymers, which can release toxic chemicals when heated or burned.

Additionally, plastic furniture can contain hazardous flame-retardant chemicals that can leach into the environment over time. Foam is often used in furniture cushions, and is primarily made from polyurethane.

The production of polyurethane foam involves the use of chemicals that can be toxic to humans and the environment. Additionally, foam furniture can contain toxic flame-retardant chemicals.

The manufacturing processes used in furniture production can also have environmental impacts. The most common processes involve cutting, sanding, and finishing materials.

These processes require large amounts of electricity and can produce noise, dust, and hazardous chemicals. The disposal of wood waste from furniture production is also a major environmental concern.

Unsustainable disposal of wood waste can lead to air and water pollution and can cause soil contamination. Disposal Furniture products are often disposed of in landfills, which can have a range of negative environmental impacts.

The disposal of furniture products can lead to the release of hazardous chemicals into the environment, as well as the release of methane gas, which is a potent greenhouse gas.

Furniture manufacturing has the potential to provide economic benefits, but it can also have a range of environmental impacts. The most significant environmental impacts come from the materials used in furniture production, the manufacturing processes, and the disposal of furniture products.

To reduce the environmental impacts of furniture manufacturing, manufacturers should focus on using sustainable materials, utilizing efficient manufacturing processes, and proper disposal of furniture products.

The Future of Furniture Manufacturing

The furniture industry has been around for centuries and is an essential part of our lives. From the earliest chairs and tables to the most modern designs, furniture has been a part of our lives for many generations.

The furniture industry has grown exponentially in recent years, with new technologies and production methods being developed to make furniture more affordable, more stylish, and more durable.

As the industry continues to evolve, what does the future of furniture manufacturing look like? In the near future, the furniture industry is expected to become increasingly automated.

Automation will make the manufacturing process faster and more efficient, allowing furniture to be produced in larger quantities. It will also reduce costs by reducing labor costs, as fewer workers will be needed to operate the machinery.

Additionally, automation will help to improve the quality of the furniture, as the machines will be able to produce pieces with more precision. The development of new materials is also expected to play a role in the future of furniture manufacturing.

As materials become more advanced, furniture will become more lightweight, more durable, and more affordable. This will make furniture easier to ship, as well as easier to store and assemble.

In addition to new materials, the furniture industry is likely to see an increase in the use of 3D printing. 3D printing allows designers to create furniture with intricate details and shapes that would be impossible to create with traditional manufacturing methods.

This technology will also make it easier to create custom pieces, as designers will be able to create furniture to fit a customer’s exact specifications. Finally, the use of technology in the furniture industry is expected to continue to grow.

The development of virtual reality and augmented reality will allow customers to experience furniture before they buy it. This could help customers to make informed decisions and reduce the number of returns or exchanges.

Additionally, the use of artificial intelligence will allow furniture companies to collect and analyze data to better understand customer wants and needs. The future of furniture manufacturing looks bright.

With the development of new technologies and materials, furniture will become more cost-effective, more stylish, and more durable. Additionally, the use of technology will help to create a more customer-focused experience. As the industry continues to evolve, the future of furniture manufacturing looks to be even brighter.

How to Measure the effectiveness of Furniture Manufacturing?

Furniture manufacturing is an important part of the furniture industry, as it involves the production of furniture pieces from raw materials. From chairs and tables to sofas and beds, furniture is a vital part of the home, and it is important to ensure the manufacturing process is effective and efficient.

Measuring the effectiveness of furniture manufacturing is essential in order to create quality products that meet customer expectations and standards. The first step in measuring the effectiveness of furniture manufacturing is to consider the cost of the materials used.

This includes the cost of wood, metal, fabric, and other materials that are used in the process. Knowing the cost of materials can help you determine the cost-effectiveness of the manufacturing process.

Another important factor to consider is the labor cost associated with the manufacturing process. This includes the cost of hiring and training personnel, as well as the cost of equipment and machinery used in the process.

In addition to the cost of materials and labor, the quality of the finished product is also important. Quality control measures should be in place to ensure that each piece of furniture meets customer expectations.

This includes checking for flaws, such as cracks, knots, and other issues that could affect the overall look and durability of the product. It is also important to measure the speed of production.

Furniture manufacturing should be done efficiently and quickly in order to meet customer demands. Finally, customer feedback should be considered when measuring the effectiveness of furniture manufacturing.

Ask customers for their opinions on the finished product, as well as the process of manufacturing it. This can help you identify areas of improvement and make necessary changes in order to ensure a successful outcome.

By taking the time to measure the effectiveness of furniture manufacturing, you can ensure that the final product meets customer expectations and is cost-effective. This can help to improve the overall quality and efficiency of the manufacturing process, while also helping to ensure customer satisfaction.

How to Increase the Effectiveness of Furniture Manufacturing?

Having an efficient furniture manufacturing process is essential for any business in the industry. From reducing costs to ensuring quality control, effective furniture manufacturing can be the key to success. Here are some tips on how to increase the effectiveness of furniture manufacturing.

Invest in technology

Automation and modern technologies can help streamline manufacturing processes and reduce the amount of time and labor required for furniture production. Investing in the right equipment can help increase efficiency and reduce costs.

Utilize lean principles

Lean manufacturing is a method of production that emphasizes eliminating waste, streamlining processes, and maximizing efficiency. Applying lean principles to your furniture manufacturing process can help reduce costs, speed up production, and ensure quality control.

Optimize your supply chain

Having an efficient supply chain can help ensure that you have the right materials available when you need them. Working closely with suppliers and using technology to better manage inventory can help improve the speed and accuracy of your furniture manufacturing process.

Invest in training

Investing in training for your employees can help ensure that they are up to date on the latest furniture manufacturing techniques. Training can also help reduce errors and improve safety in the workplace.

Adopt green practices

Implementing green practices can help reduce costs and improve the efficiency of your furniture production process. Using sustainable practices like using recycled materials, reducing energy consumption, and using efficient manufacturing processes can help reduce costs and improve the environmental impact of your production.

By following these tips, you can increase the effectiveness of your furniture manufacturing process. Investing in technology, utilizing lean principles, optimizing the supply chain, investing in training, and adopting green practices can all help reduce costs, speed up production, and ensure quality control. With the right approach, you can ensure that your furniture manufacturing process is as effective as possible.

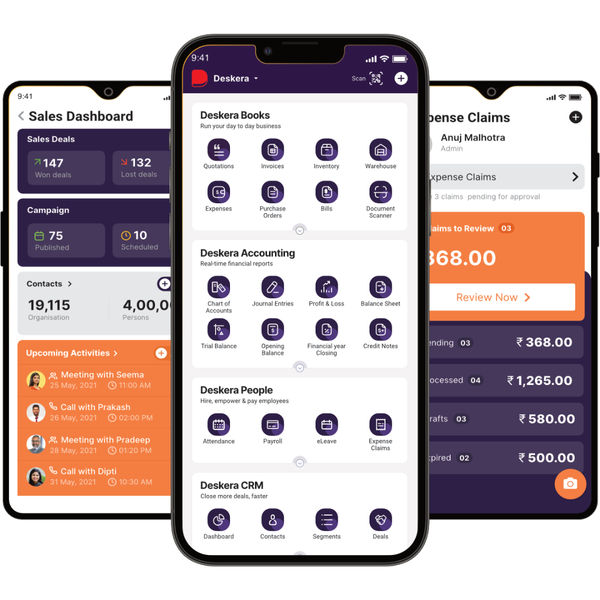

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Measuring the effectiveness of furniture manufacturing is essential in order to create quality products that meet customer expectations and standards.

- The first step in measuring the effectiveness of furniture manufacturing is to consider the cost of the materials used.

- Another important factor to consider is the labor cost associated with the manufacturing process.

- Applying lean principles to your furniture manufacturing process can help reduce costs, speed up production, and ensure quality control.

- Quality control measures should be in place to ensure that each piece of furniture meets customer expectations.

Related Articles: