Are you ready to tackle safety in a whole new way? Get ready to put on your safety goggles, and let's dive into some fun and effective strategies for enhancing safety in your manufacturing processes.

According to the Occupational Safety and Health Administration (OSHA), over 10,000 workers in the pest control industry are exposed to hazardous chemicals each year, leading to a range of health issues, including respiratory problems, skin irritation, and neurological damage.

To combat these risks, it's essential for pest control chemical manufacturers to prioritize safety in their manufacturing processes. This protects employees and ensures the safety of customers and the general public.

This article will explore various strategies for enhancing safety in pest control chemical manufacturing.

From providing proper training and protective equipment for employees to utilizing advanced technologies such as automation and robotics, we will cover a range of topics to help improve safety in the manufacturing process.

Here's what we shall cover in this post:

- Hazards Associated With Pest Control Chemical Manufacturing

- Importance of Safety in Pest Control Chemical Manufacturing

- Role of Training in Enhancing Safety in Pest Control Chemical Manufacturing

- Safety Equipment and Personal Protective Gear in Pest Control Chemical Manufacturing

- Reducing Chemical Exposure and Minimizing Chemical Waste

- Enhancing Security in Pest Control Chemical Manufacturing Facilities

- Continuous Improvement Strategies for Pest Control Chemical Manufacturing

- Conclusion

- Key Takeaways

Hazards Associated With Pest Control Chemical Manufacturing

Pest control chemicals are used to manage or eradicate pests in various settings, such as residential, commercial, and agricultural spaces. However, the manufacturing and handling of these chemicals can pose significant risks to workers and the environment.

This section will discuss the hazards associated with pest control chemical manufacturing.

Chemical Exposure: Workers involved in pest control chemical manufacturing are exposed to a variety of hazardous chemicals, including pesticides, herbicides, and fungicides.

Exposure can occur through inhalation, ingestion, or skin contact, leading to health risks such as respiratory problems, skin irritation, and long-term health effects like cancer and neurological damage.

Fire and Explosions: Many of the chemicals used in pest control manufacturing are flammable or combustible, making them highly hazardous in case of fire or explosions.

Improper storage or handling of chemicals can lead to fires, explosions, or other catastrophic events, causing severe injuries and damage to property.

Toxic Waste Disposal: Disposing of hazardous waste is a significant challenge in pest control chemical manufacturing. The improper disposal of hazardous waste can lead to contamination of soil and water bodies, posing a threat to human health and the environment.

Therefore, proper waste disposal is essential to ensure the safety of workers and the environment.

Equipment Malfunction: Manufacturing equipment used in pest control chemical production can malfunction, causing accidents, injuries, and even death. Maintenance and proper functioning of equipment are essential to ensure the safety of workers and the environment.

Transportation Risks: The transportation of pest control chemicals from the manufacturing facility to the end user can pose significant risks. Improper packaging, labeling, and handling during transportation can lead to spills, leaks, and other hazardous situations.

Regulatory Compliance: The manufacturing of pest control chemicals is subject to strict regulations and guidelines, and non-compliance can result in fines, legal action, and damage to reputation. It is essential to adhere to all regulations and guidelines to ensure the safety of workers and the environment.

Importance of Safety in Pest Control Chemical Manufacturing

Protecting workers: The safety of workers is of utmost importance in pest control chemical manufacturing. Workers are often exposed to hazardous chemicals, which can cause serious health problems if not handled properly.

Employers can ensure that workers are protected from potential hazards by implementing safety measures and providing training and protective equipment.

Preventing accidents: Accidents can occur during manufacturing, leading to injuries or even fatalities. Safety measures such as properly labeling, storing, and handling chemicals can prevent accidents and minimize risks.

Avoiding environmental damage: Pest control chemicals can have negative effects on the environment if not handled and disposed of properly. Spills or leaks can contaminate soil, water, and air, leading to environmental damage and health hazards.

Implementing safety procedures and proper waste management can minimize the risk of environmental damage.

Compliance with regulations: There are regulations in place to ensure the safety of workers and the environment in pest control chemical manufacturing. Companies must comply with these regulations to avoid fines and legal repercussions.

Compliance also helps to ensure that safety measures are in place to protect workers and the environment.

Protecting public health: Pest control chemicals are designed to eliminate pests that can carry diseases and cause damage to property. However, these chemicals can also have negative effects on human health if not used properly.

By implementing safety measures, manufacturers can ensure that their products are safe for use and minimize potential health risks.

Role of Training in Enhancing Safety in Pest Control Chemical Manufacturing

In order to ensure the safety of all involved in the pest control chemical manufacturing process, it is important to implement proper training programs.

Some of the reasons why training is essential in enhancing safety in pest control chemical manufacturing include:

- Identifying Hazards: Training provides workers with the knowledge and skills to identify potential hazards in the pest control chemical manufacturing process. They will be able to recognize unsafe working conditions, such as exposure to hazardous chemicals, and take appropriate measures to avoid accidents.

- Proper Handling of Chemicals: Workers need to be trained on how to handle chemicals safely, including the correct use of personal protective equipment (PPE) and the proper disposal of hazardous waste. This reduces the risk of chemical exposure and contamination, which can have serious health and environmental consequences.

- Emergency Preparedness: In the event of an accident or emergency, workers need to be prepared to respond appropriately. Proper training can ensure that they know how to act quickly and effectively to minimize the risk of injury and damage to the environment.

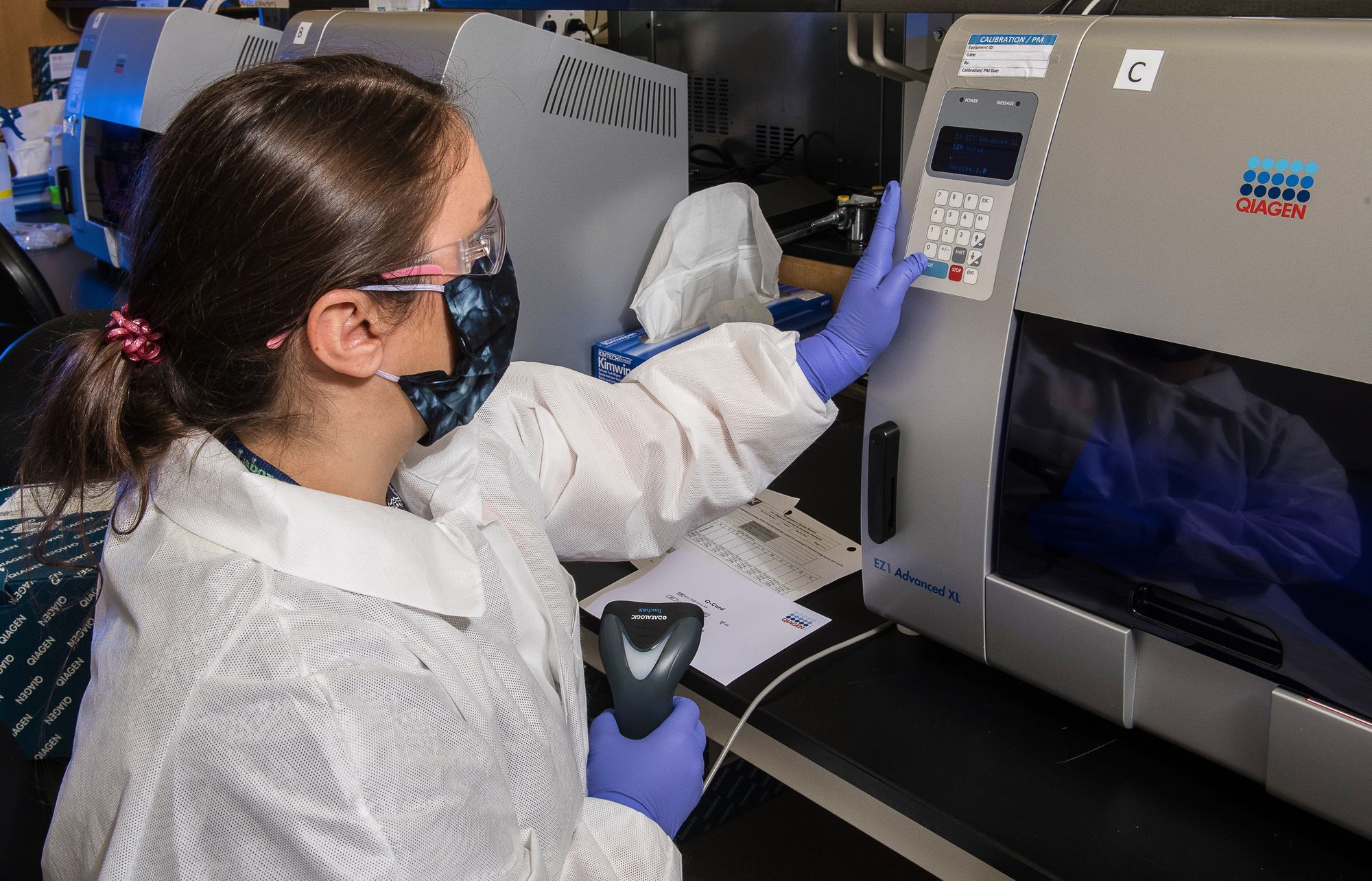

Safety Equipment and Personal Protective Gear in Pest Control Chemical Manufacturing

Types of Safety Equipment

Pest control chemical manufacturing requires the use of various types of safety equipment to protect workers from hazards. This includes but is not limited to, eyewear, respirators, gloves, lab coats, aprons, and safety shoes.

Each piece of equipment specifically protects the worker from hazards such as chemical splashes, dust, and fumes.

Importance of Respirators

Respirators are essential in pest control chemical manufacturing as they protect workers from inhaling harmful substances that can cause respiratory issues.

Respirators come in different types and sizes, and the choice of respirator will depend on the chemicals used and the work being done. Ensuring that the respirator is fitted correctly to the worker to maximize protection is essential.

Importance of Eyewear

Eyewear protects workers from chemical splashes and dust irritating or damaging the eyes. It is essential to use appropriate eyewear, such as goggles or face shields, that provide full protection to the eyes.

Importance of Gloves

Gloves in pest control chemical manufacturing are necessary to protect workers from skin contact with harmful chemicals. Different types of gloves are available, and the choice of gloves will depend on the chemicals used, the work being done, and the duration of exposure.

Changing gloves regularly to avoid contamination and ensure that gloves fit correctly is crucial.

Importance of Lab Coats and Aprons

Lab coats and aprons are used to protect workers' clothing from chemical splashes and spills, reducing the risk of skin contact with hazardous chemicals. It is essential to use appropriate lab coats and aprons made from materials that provide adequate protection against the chemicals used.

Importance of Safety Shoes

Safety shoes are essential in pest control chemical manufacturing to protect workers' feet from chemical spills, sharp objects, and falling objects. It is necessary to use safety shoes that are appropriate for the work being done and provide adequate protection.

Reducing Chemical Exposure and Minimizing Chemical Waste

Here are some ways to reduce chemical exposure and minimize chemical waste in pest control chemical manufacturing:

- Implement a Chemical Management System: A chemical management system can help identify and track chemicals used in the manufacturing process, as well as ensure that they are stored, used, and disposed of properly. This can help minimize exposure to hazardous chemicals and reduce the amount of waste generated.

- Use Safer Chemicals: Using safer chemicals can help reduce the risk of exposure to hazardous chemicals. Safer alternatives, such as biopesticides and non-toxic chemicals, can be used in manufacturing.

- Provide Personal Protective Equipment (PPE): Employees should be provided with appropriate PPE, such as gloves, respirators, and goggles to protect against chemical exposure.

- Minimize Chemical Waste: Chemical waste can be minimized by implementing a waste reduction program that includes the use of reusable containers, recycling, and proper disposal of hazardous waste.

- Implement a Spill Response Plan: A spill response plan should be in place in case of accidental spills. This plan should include procedures for containing and cleaning up spills and notifying authorities if necessary.

- Monitor Air Quality: Regular air quality monitoring can help ensure that employees are not exposed to hazardous chemicals. Monitoring can also help identify potential problems before they become serious.

Enhancing Security in Pest Control Chemical Manufacturing Facilities

Protecting Perimeter and Access Control

It is crucial to protect the perimeter of the manufacturing facility by installing fencing, gates, and other physical barriers to restrict access. Access control systems such as biometric scanners, key cards, and PIN codes can also be implemented to limit entry to authorized personnel only.

Monitoring and Surveillance

Installing cameras, motion detectors, and other monitoring systems can provide real-time surveillance and enhance security. CCTV cameras can also be used to monitor the perimeter and critical areas within the facility.

Background Checks

Conducting background checks on employees and contractors before granting them access to the facility can help prevent security breaches.

Regular Security Audits

Regular security audits should be conducted to identify and address potential vulnerabilities before they can be exploited.

Cybersecurity

Cybersecurity threats are a growing concern in the manufacturing industry, and pest control chemical manufacturing facilities are no exception. Implementing robust cybersecurity measures, including firewalls, antivirus software, and regular software updates can help prevent cyber-attacks.

Continuous Improvement Strategies for Pest Control Chemical Manufacturing

Continuous improvement is an essential aspect of pest control chemical manufacturing that helps companies to remain competitive and profitable. Here are some of the best strategies for achieving continuous improvement:

- Emphasize data-driven decision-making to identify areas for improvement in the manufacturing process.

- Implement Lean Manufacturing principles such as Kaizen events and value stream mapping to optimize workflows and eliminate waste.

- Use Total Productive Maintenance (TPM) to ensure that equipment is well-maintained and operating at peak efficiency.

- Invest in training and development programs to improve employee skills and knowledge.

- Foster a culture of continuous improvement by encouraging employee feedback and engagement.

- Regularly review and update standard operating procedures (SOPs) to reflect best practices and new technologies.

- Continuously monitor and track key performance indicators (KPIs) to measure progress toward goals and identify areas for improvement.

- Utilize technology such as automation and robotics to improve efficiency and productivity.

- Embrace sustainable manufacturing practices that reduce waste and minimize environmental impact.

- Encourage collaboration and knowledge sharing between departments and industry peers to stay current on industry trends and best practices.

How Deskera Can Assist You?

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Conclusion

Safety is a critical concern in pest control chemical manufacturing. Implementing robust safety measures to protect workers, the environment, and consumers from potential hazards associated with pest control chemicals is essential.

Developing a safety culture in pest control chemical manufacturing involves:

- Fostering a mindset that prioritizes safety above everything else.

- Promoting hazard awareness.

- Providing training.

- Implementing safety protocols and procedures.

- Continuous improvement through risk assessments and feedback.

Ensuring that all chemicals used in pest control manufacturing are registered with regulatory agencies and comply with all relevant safety and environmental regulations is equally important.

By adopting a proactive and comprehensive approach to safety, pest control chemical manufacturers can improve their reputation, reduce the risk of accidents, and protect their workers, the environment, and the public.

Key Takeaways

- The safety of workers in the pest control chemical manufacturing industry should always be a top priority for companies, as exposure to these chemicals can have serious health consequences.

- To enhance safety, it is important to have a comprehensive safety plan in place, including procedures for handling and storing chemicals and for responding to accidents and spills.

- All pest control chemical manufacturing workers should be properly trained on safety procedures and given appropriate protective equipment.

- Regular safety audits and assessments should be conducted to identify areas of improvement and ensure compliance with safety regulations.

- Companies should be transparent about the chemicals used in their products and provide safety information and warnings to users.

- In addition to ensuring the safety of workers, companies should also consider the environment's safety and take steps to minimize the impact of chemical manufacturing on the surrounding ecosystem.

- Hazardous waste generated during pest control chemical manufacturing should be disposed of properly per local regulations.

- Companies should strive to use safer and more sustainable chemicals and manufacturing processes, such as using non-toxic alternatives and reducing waste and emissions.

- It is important to stay up-to-date with the latest safety regulations and best practices and to regularly review and update safety procedures as needed.

- Companies should encourage a culture of safety where workers feel comfortable reporting safety concerns and suggestions for improvement.

Related Articles