The United States is the second-largest producer of paper and cardboard, producing over 70 million metric tons in 2020.

From ancient scrolls to modern day newspapers, paper has been an integral part of human history for over two thousand years. However, with the rise of digital technology and the shift towards a more environmentally conscious society, the future of paper manufacturing is uncertain. Will we continue to rely on this versatile material or will it become a relic of the past?

The history of paper manufacturing is a fascinating tale of innovation and adaptation, from its humble beginnings in ancient China to its spread across the world and impact on society and culture. Today, the paper industry faces new challenges as it strives to balance the need for sustainability with the demand for paper products. Meanwhile, new technologies and innovations are emerging that could revolutionize the way we produce and use paper.

In this article, we will explore the rich history of paper manufacturing and delve into the current state of the industry. We will also take a look at the exciting possibilities for the future of paper, and how it could continue to shape our world for generations to come.

- Paper and its Importance

- History of Paper Manufacturing

- Current State of Paper Manufacturing

- Future of Paper Manufacturing

- Trends in Paper Manufacturing

- How can MRP and ERP systems Assist the Paper Manufacturers?

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Paper and its Importance

Paper is a versatile and widely-used material made from cellulose fibers, usually derived from wood pulp. It has been an integral part of human society for over two thousand years, with a vast range of applications including writing, printing, packaging, and more.

The importance of paper lies in its ability to convey information and ideas, as well as its convenience and accessibility. Paper is lightweight, easy to transport, and can be produced in large quantities at a relatively low cost. It has played a critical role in the development and dissemination of knowledge, allowing for the spread of ideas and information across vast distances and time periods.

In addition to its communicative and informational properties, paper also has practical applications in everyday life. It is used in packaging for products ranging from food to electronics, providing protection and stability during transportation and storage. Paper products such as tissues and hygiene products are also an essential part of personal care and hygiene.

Overall, paper's versatility and accessibility have made it a fundamental material in modern society. While digital technology has led to a decline in certain paper products, such as newspapers and magazines, it remains a crucial component of many industries and will continue to be so for the foreseeable future.

History of Paper Manufacturing

The history of paper manufacturing can be traced back over two thousand years to ancient China, where the first paper was invented by Cai Lun in 105 AD. This early paper was made from a mixture of mulberry bark, hemp, and rags, which were pounded into a pulp and then flattened into sheets.

The invention of paper soon spread to other parts of the world, with the technique arriving in Japan in the 7th century and later in the Middle East and Europe in the 8th and 12th centuries, respectively. In Europe, the first paper mill was established in Spain in the 12th century, followed by the first mill in England in the 15th century.

During the Renaissance period, paper became more widely available and affordable, leading to an explosion in printing and publishing. This, in turn, helped to disseminate knowledge and ideas, contributing to the cultural and intellectual development of Europe.

The Industrial Revolution of the 18th and 19th centuries brought about significant changes in paper manufacturing technology. The invention of the Fourdrinier machine in 1803 revolutionized paper production, allowing for the mass production of paper and the creation of new types of paper products.

Today, paper manufacturing is a global industry, with China being the world's largest producer of paper and cardboard. The industry faces challenges such as sustainability and the shift towards digitalization, but continues to evolve and adapt to meet the needs of modern society.

Current State of Paper Manufacturing

The current state of paper manufacturing is a complex and evolving landscape that is influenced by a range of economic, environmental, and social factors.

One of the most pressing concerns facing the paper industry is the need to balance production with sustainability. The industry is a significant consumer of natural resources, particularly wood fiber, and is a major contributor to deforestation and habitat destruction. In response, many paper companies have implemented sustainable forestry practices, such as using recycled or certified wood pulp, and reducing their carbon footprint through energy-efficient technologies.

Another challenge facing the paper industry is the shift towards digitalization, which has led to a decline in demand for certain types of paper products such as newspapers and magazines. However, the industry has adapted by diversifying into new areas, such as packaging, tissue products, and specialty papers.

The COVID-19 pandemic has also impacted the paper industry, with disruptions to supply chains and fluctuations in demand for certain products. The pandemic has highlighted the critical role of paper products, particularly in the area of hygiene and sanitation, with increased demand for tissue products and packaging for medical supplies.

Despite these challenges, the paper industry continues to grow, with a projected increase in global demand for paper products of 1.8% per year until 2030. The industry remains an essential component of many sectors, including publishing, printing, packaging, and personal care.

Advances in technology, such as nanotechnology and biorefinery, hold promise for the development of new, sustainable paper products that could further enhance the industry's position in the global marketplace.

Future of Paper Manufacturing

The future of paper manufacturing is likely to be shaped by a range of economic, environmental, and technological trends, as well as changing consumer preferences.

One of the key drivers of change in the paper industry is sustainability. With increasing awareness of the environmental impact of paper production, many companies are exploring new ways to reduce waste and their carbon footprint and enhance the sustainability of their products. This includes the use of alternative fibers, such as agricultural waste or recycled textiles, as well as innovations in processing and production that reduce water usage and waste.

Another trend that is likely to shape the future of paper manufacturing is the continued shift towards digitalization. While the decline of print media has been a significant challenge for the industry, the growth of e-commerce and other online industries has created new opportunities for paper products, particularly in the area of packaging.

Advances in technology, such as nanotechnology and biorefinery, are also likely to have a significant impact on the future of paper manufacturing. These technologies hold the potential to create new, high-performance paper products with enhanced properties such as strength, durability, and water resistance, while also reducing the environmental impact of production.

Finally, changing consumer preferences and behaviors are likely to shape the future of the paper industry. For example, the growing demand for eco-friendly products and packaging is likely to drive innovation in sustainable paper products. Similarly, the trend towards personalization and customization in consumer products may create new opportunities for specialty papers and printing.

Overall, the future of paper manufacturing is likely to be shaped by a range of factors, including sustainability, digitalization, technology, and changing consumer preferences. While the industry will continue to face challenges, it is also likely to continue to evolve and adapt to meet the changing needs of society.

Trends in Paper Manufacturing

Here are some potential future trends for paper manufacturing:

- Sustainable production: The demand for sustainable products continues to increase, and paper manufacturing is no exception. In the future, we are likely to see an increased focus on using renewable energy sources, reducing waste and emissions, and sourcing raw materials responsibly.

- Digitalization: As the world becomes more digital, the paper industry is likely to shift towards producing high-value specialty papers, such as those used in packaging or printing, rather than commodity paper products like newspapers or copy paper. This shift will require the adoption of new technologies and processes to produce these higher-value products.

- Advanced materials: Advances in materials science and nanotechnology are likely to enable the creation of new types of paper products with enhanced properties, such as improved strength, water resistance, or flexibility. These advanced materials may also allow paper products to be used in new applications beyond traditional printing and packaging.

- Circular economy: The concept of a circular economy, in which waste is minimized and resources are reused or recycled, is gaining traction in many industries. In the future, paper manufacturers may increasingly adopt circular economy principles, such as using recycled paper and finding ways to reuse or recycle paper products at the end of their useful life.

- Industry consolidation: The paper industry is currently highly fragmented, with many small and medium-sized companies operating independently. However, we may see increasing consolidation in the industry as larger companies acquire smaller ones to achieve economies of scale and improve efficiencies.

Overall, the future of paper manufacturing is likely to be shaped by a range of trends, including sustainability, digitalization, advanced materials, circular economy, and industry consolidation. Companies that are able to adapt to these changes and invest in new technologies and processes will be best positioned to thrive in the future.

How can MRP and ERP systems Assist the Paper Manufacturers?

MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems can assist paper manufacturers in several ways, including:

- Streamlining production processes: MRP and ERP systems can help paper manufacturers optimize production processes by tracking and managing raw materials, inventory, and production schedules. This can help ensure that materials and resources are used efficiently, reducing waste and improving productivity.

- Enhancing supply chain management: MRP and ERP systems can improve supply chain management by providing real-time visibility into inventory levels and supplier performance. This can help paper manufacturers make more informed decisions about purchasing and logistics, reducing lead times and improving delivery times.

- Improving quality control: MRP and ERP systems can help paper manufacturers monitor and control quality by tracking raw materials and finished products through the production process. This can help identify quality issues early on, reducing the risk of defects and improving customer satisfaction.

- Enhancing financial management: MRP and ERP systems can provide paper manufacturers with real-time financial data, helping them manage costs and profitability. This can help identify areas where costs can be reduced and where investments can be made to improve efficiency and productivity.

- Providing data for decision-making: MRP and ERP systems can provide paper manufacturers with valuable data and analytics that can inform strategic decision-making. This can help manufacturers identify areas for improvement and make informed decisions about investments in new technologies or processes.

MRP and ERP systems can help paper manufacturers improve efficiency, reduce costs, and enhance the overall performance of their operations. By providing real-time visibility into key production and financial data, these systems can help manufacturers make more informed decisions and respond quickly to changing market conditions.

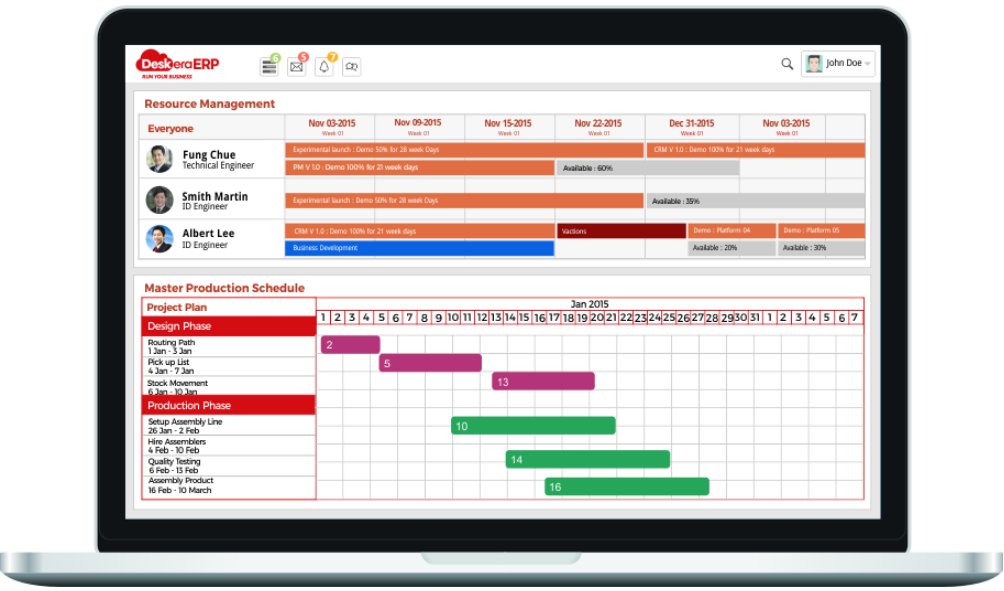

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- The history of paper manufacturing dates back to ancient China, where it was made from natural fibers such as mulberry bark and hemp.

- The invention of the printing press in the 15th century spurred the growth of the paper industry, as demand for paper increased to accommodate the widespread dissemination of printed materials.

- The Industrial Revolution in the 18th and 19th centuries brought significant advancements to the paper industry, including the invention of the Fourdrinier machine, which allowed for mass production of paper.

- Environmental concerns over deforestation and pollution have led to efforts to make paper manufacturing more sustainable, including the use of recycled fibers and the development of new technologies to reduce energy consumption and waste.

- The digital age has had a significant impact on the paper industry, as many traditional paper-based products have been replaced by digital alternatives. However, there is still a demand for paper products in industries such as packaging, printing, and hygiene.

- Advances in biotechnology and nanotechnology are expected to transform the paper industry in the future, with the potential to create new types of paper with enhanced properties such as strength, durability, and biodegradability.

- As the world becomes more environmentally conscious, the paper industry will continue to evolve to meet the demands of consumers who are looking for sustainable and eco-friendly alternatives to traditional paper products.

Related Articles