What if your procurement strategy could predict risks, optimize costs, and ensure supply chain resilience—without human intervention? That future is closer than you think. The manufacturing industry is experiencing a seismic shift in procurement, driven by digital transformation, AI, and sustainability initiatives. Traditional procurement models that rely on manual processes and static supplier relationships are being replaced by dynamic, tech-driven solutions that enhance efficiency and profitability.

Manufacturing executives are now prioritizing procurement as a strategic function rather than a cost center. With supply chain disruptions, fluctuating material costs, and increasing regulatory requirements, businesses must adopt forward-thinking procurement strategies to stay competitive. Emerging trends such as AI-powered analytics, blockchain for supply chain transparency, and sustainable sourcing are reshaping the procurement landscape, making it more agile, resilient, and cost-effective.

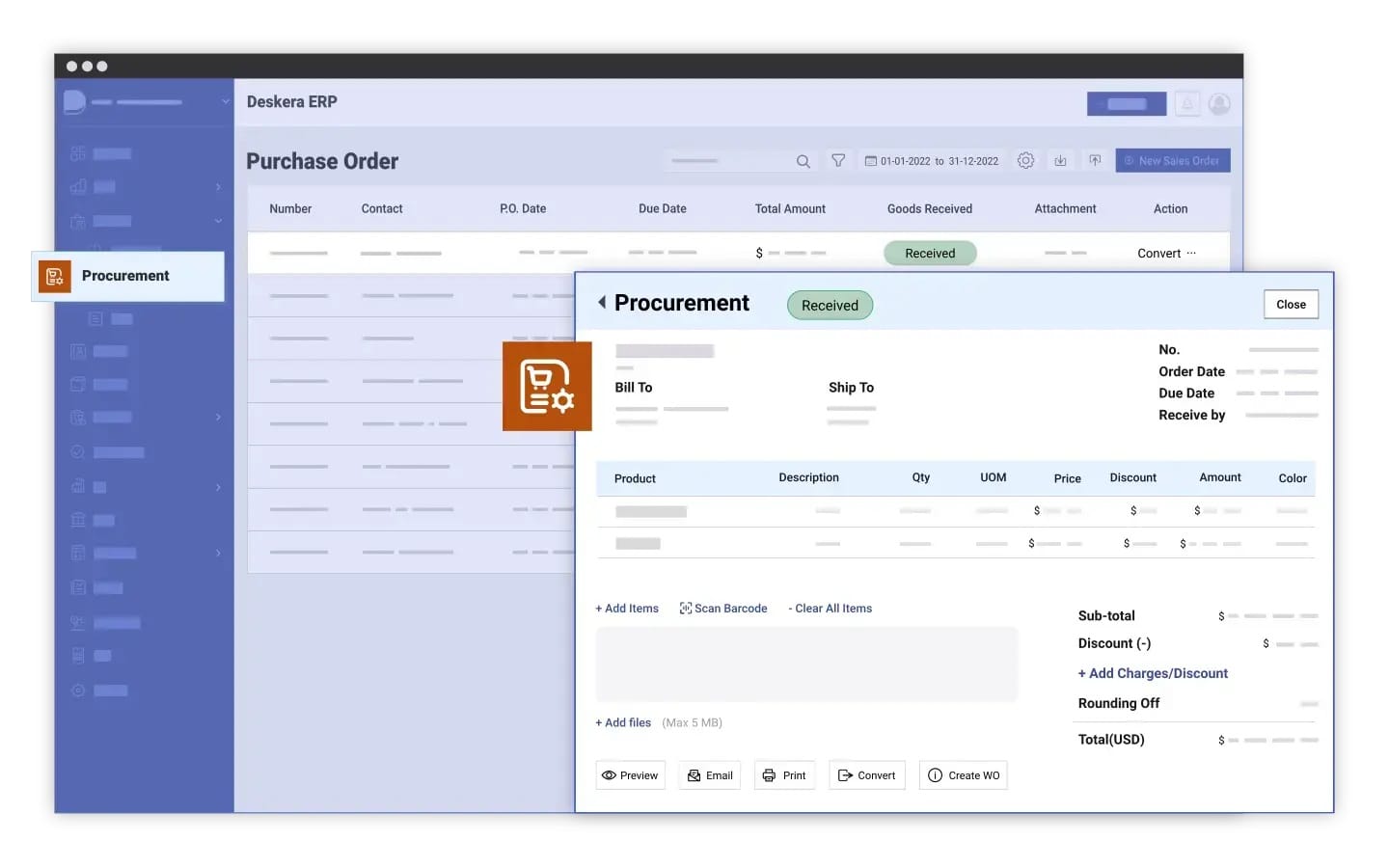

One way businesses can stay ahead is by leveraging ERP solutions that integrate procurement with inventory, production, and financial management. Deskera ERP, for instance, offers an advanced procurement module that automates supplier management, streamlines purchase orders, and provides real-time insights into spending.

By using AI-driven demand forecasting and smart approval workflows, Deskera ERP helps manufacturers reduce costs, improve supplier collaboration, and mitigate procurement risks.

In this blog, we will explore the key procurement trends that every manufacturing executive should know. Let’s dive in and uncover how businesses can adapt to these changes and gain a competitive edge.

Future Trends in Procurement: Embracing Innovation and Strategic Evolution

Procurement is undergoing a significant transformation driven by technological advancements, evolving business needs, and global economic shifts. Organizations are no longer viewing procurement as a cost-cutting function but as a strategic enabler of growth, resilience, and sustainability.

The increasing integration of AI, automation, and data-driven decision-making is reshaping procurement practices, making them more efficient, agile, and future-ready. As businesses navigate market volatility and supply chain disruptions, adopting these emerging trends will be crucial to staying competitive.

Here’s a closer look at the key trends that will shape the future of procurement.

1. AI and Automation Will Dominate

Procurement is entering the era of intelligent automation, where AI-driven solutions are optimizing every stage of the purchasing lifecycle.

- Generative AI in Procurement: Procurement platforms will use generative AI to analyze supplier data, identify cost-saving opportunities, and generate real-time market insights. AI-driven assistants will help procurement professionals make informed decisions with predictive analytics.

- Automating Routine Tasks: Processes such as purchase order creation, invoice reconciliation, and contract management will be fully automated, reducing manual errors and improving efficiency.

- AI-Driven Smart Decision-Making: AI will process vast datasets in real time, enabling faster and more strategic decisions related to supplier selection, pricing, and risk assessment.

Impact: Increased procurement efficiency, reduced human errors, and faster decision-making will enhance business agility.

2. Sustainability Will Be a Core Priority

Sustainability in procurement will no longer be optional—it will be a fundamental business requirement.

- ESG Compliance: Companies will prioritize ethical sourcing, sustainable supply chains, and adherence to environmental, social, and governance (ESG) standards.

- Carbon Footprint Tracking: Procurement teams will leverage technology to monitor the sustainability impact of their suppliers, ensuring compliance with carbon reduction targets.

- Green Procurement Strategies: Organizations will integrate sustainability into supplier selection by focusing on eco-friendly materials, energy-efficient processes, and sustainable packaging.

Impact: Businesses will not only meet regulatory and compliance requirements but also enhance their brand reputation and customer trust.

3. Hyper-Personalized and Intelligent Procurement Platforms

The future of procurement lies in platforms that adapt to the unique needs of each organization.

- AI-Powered User Experiences: Procurement software will offer customized dashboards, intelligent contract recommendations, and dynamic supplier insights tailored to an organization’s requirements.

- End-to-End System Integration: Seamless integration with ERP, finance, and supply chain systems will enhance procurement efficiency and data transparency.

- Real-Time Market Intelligence: Platforms will provide real-time updates on market trends, commodity prices, and geopolitical risks, allowing procurement teams to make proactive decisions.

Impact: Increased agility and adaptability in procurement processes, ensuring companies stay ahead of market fluctuations.

4. Data-Driven Procurement with Predictive Analytics

Procurement is becoming increasingly data-centric, with predictive analytics playing a key role in decision-making.

- Predictive Spend Analytics: AI-driven analytics will anticipate purchasing needs, helping organizations optimize budgets and reduce unnecessary spending.

- Supplier Risk Assessment: Procurement teams will use real-time data to assess supplier reliability, financial stability, and potential risks, enabling proactive mitigation strategies.

- Dynamic Price Forecasting: AI will analyze historical data and market conditions to predict pricing trends for raw materials and services, ensuring cost optimization.

Impact: Enhanced procurement planning, reduced supply chain risks, and improved financial efficiency.

5. Strengthening Supplier Collaboration and Innovation

Organizations are shifting from a transactional approach to procurement towards long-term, strategic supplier partnerships.

- Collaborative Supplier Networks: Companies will foster deeper collaboration with suppliers to drive innovation, improve efficiency, and create joint value.

- Supplier Performance Monitoring: Advanced analytics and AI-driven dashboards will enable real-time tracking of supplier performance based on key metrics such as quality, delivery timelines, and compliance.

- Vendor Diversity Initiatives: Businesses will diversify their supplier base by engaging with small and minority-owned businesses, improving resilience and inclusivity.

Impact: Stronger supplier relationships, enhanced supply chain resilience, and increased innovation opportunities.

6. Enhanced Focus on Cybersecurity in Procurement

With procurement becoming increasingly digital, cybersecurity will be a major concern.

- Securing Procurement Systems: Companies will invest in advanced security measures to protect sensitive procurement data from cyber threats and breaches.

- Third-Party Risk Management: Procurement teams will enforce strict cybersecurity policies for vendors, ensuring compliance with data protection standards.

Impact: Improved security in procurement processes, safeguarding businesses from cyber threats and data leaks.

7. Agile Procurement Strategies for Market Adaptability

Organizations will embrace flexible procurement strategies to navigate market volatility and supply chain disruptions.

- Nearshoring and Localization: Businesses will increasingly source from local suppliers to reduce reliance on global supply chains and mitigate risks.

- Adaptive Contracting: Procurement teams will favor short-term, flexible contracts that allow quick responses to market changes and unforeseen disruptions.

- On-Demand Procurement Models: Companies will leverage just-in-time procurement strategies to optimize inventory and minimize excess stock.

Impact: Increased procurement flexibility, cost savings, and reduced supply chain risks.

8. Procurement as a Strategic Business Function

Procurement will evolve from an operational role to a key driver of business strategy.

- Increased C-Suite Collaboration: Procurement leaders will work closely with CFOs, CTOs, and COOs to align procurement strategies with broader business goals.

- Revenue-Generating Procurement: Beyond cost savings, procurement teams will contribute to revenue growth by identifying new supplier-driven opportunities and market innovations.

Impact: A more integrated and strategic approach to procurement, positioning it as a critical business function.

9. Data Governance and Supplier Data Management

Managing supplier data securely and effectively will be critical to procurement success.

- Data-Driven Decision-Making: Organizations will implement structured data governance policies to ensure accuracy, compliance, and security in supplier data management.

- Supplier Risk Mitigation: With reliable data, procurement teams can assess supplier stability, prevent fraud, and ensure compliance with industry regulations.

Impact: Improved procurement transparency, better risk management, and enhanced compliance with data protection laws.

The future of procurement is dynamic, data-driven, and strategic. Organizations that embrace AI, sustainability, cybersecurity, and agile procurement models will gain a competitive edge.

By integrating advanced procurement technologies and fostering strong supplier partnerships, businesses can optimize costs, reduce risks, and enhance overall efficiency in an ever-evolving global market.

10. Procurement as a Service (PaaS)

The rise of Procurement as a Service (PaaS) is transforming the way businesses handle procurement functions.

- Outsourced Procurement Expertise: Companies will rely on third-party procurement service providers to manage sourcing, supplier negotiations, and procurement strategy.

- Scalable and Flexible Solutions: PaaS allows businesses to scale procurement operations up or down based on demand without maintaining an in-house team.

- Cost and Time Savings: Outsourcing procurement activities will help organizations reduce operational costs and focus on core business functions.

Impact: Improved procurement efficiency, access to expert knowledge, and cost-effective procurement operations.

11. Blockchain for Supply Chain Transparency

Blockchain technology will revolutionize procurement by ensuring security, traceability, and transparency.

- Immutable Transaction Records: Blockchain will provide an unalterable ledger of procurement transactions, reducing fraud and improving auditability.

- End-to-End Supply Chain Visibility: Businesses can track product movement in real time, ensuring ethical sourcing and compliance with sustainability goals.

- Smart Contracts: Automated blockchain-based contracts will reduce paperwork, improve accuracy, and streamline supplier agreements.

Impact: Enhanced supply chain security, reduced fraud, and improved trust between buyers and suppliers.

12. Data-Driven Procurement with Advanced Analytics and KPI Monitoring

Procurement analytics will become more sophisticated, enabling businesses to make real-time, data-backed decisions.

- Predictive Spend Analytics: AI-powered tools will analyze historical purchasing patterns to optimize budgets and prevent overspending.

- Supplier Performance Monitoring: Organizations will track KPIs such as delivery times, quality scores, and compliance rates to manage supplier relationships effectively.

- Dynamic Cost Optimization: Advanced analytics will provide real-time pricing trends, allowing procurement teams to negotiate better deals.

Impact: Better procurement efficiency, improved supplier management, and enhanced cost control.

Preparing for the Future of Procurement: Key Strategies for Success

As procurement evolves with technological advancements and changing business priorities, organizations must proactively adapt to stay competitive. Preparing for these trends requires a strategic approach that combines technology adoption, skill development, and process optimization.

Here’s how businesses can effectively prepare for the future of procurement:

1. Invest in AI and Automation

To leverage AI and automation in procurement, businesses should:

- Adopt AI-Powered Procurement Tools: Implement AI-driven procurement platforms for automated supplier selection, risk assessment, and demand forecasting.

- Automate Routine Tasks: Use robotic process automation (RPA) to streamline repetitive tasks like invoice processing and purchase order approvals.

- Train Teams on AI Integration: Equip procurement professionals with the knowledge to work alongside AI-driven systems for enhanced decision-making.

2. Develop a Sustainable Procurement Strategy

To align with sustainability goals, organizations should:

- Establish Clear ESG Policies: Define sustainability goals for procurement, such as reducing carbon footprints and sourcing from ethical suppliers.

- Monitor Supply Chain Impact: Use sustainability tracking tools to measure and improve supplier compliance with green procurement standards.

- Engage in Supplier Collaboration: Work closely with suppliers to implement eco-friendly manufacturing and packaging practices.

3. Leverage Procurement as a Service (PaaS)

To integrate PaaS effectively, companies should:

- Assess Outsourcing Needs: Determine which procurement functions can be outsourced to enhance efficiency and cost savings.

- Partner with Specialized Providers: Choose PaaS providers that offer expertise in procurement strategy, contract management, and supplier negotiations.

- Ensure Seamless Integration: Implement technology solutions that enable smooth collaboration between in-house teams and PaaS providers.

4. Adopt Blockchain for Enhanced Transparency

To implement blockchain in procurement, businesses should:

- Pilot Blockchain-Based Solutions: Test blockchain technology for supplier contracts, payments, and transaction verification.

- Implement Smart Contracts: Automate procurement agreements using blockchain-based contracts to improve accuracy and reduce disputes.

- Ensure Supplier Participation: Encourage suppliers to adopt blockchain for real-time supply chain visibility and traceability.

5. Strengthen Procurement Analytics and KPI Monitoring

To become more data-driven, organizations should:

- Implement Advanced Analytics Tools: Use predictive analytics and AI-driven dashboards to track spending, supplier performance, and cost savings.

- Define Key Procurement KPIs: Establish metrics such as supplier delivery reliability, cost efficiency, and contract compliance.

- Develop a Data-Driven Culture: Train procurement teams to analyze and act on data insights for better decision-making.

6. Build Strong Supplier Relationships

To foster supplier collaboration and innovation, businesses should:

- Adopt Supplier Performance Scorecards: Regularly assess suppliers based on quality, reliability, and compliance.

- Encourage Joint Innovation Projects: Partner with suppliers to co-develop new products and cost-effective solutions.

- Diversify Supplier Base: Expand supplier networks to reduce dependence on single vendors and improve supply chain resilience.

7. Strengthen Cybersecurity Measures in Procurement

To mitigate cyber risks, organizations should:

- Secure Procurement Data: Implement advanced encryption, access controls, and cybersecurity training for procurement teams.

- Conduct Supplier Cybersecurity Audits: Ensure suppliers follow robust security protocols to prevent data breaches.

- Implement Multi-Factor Authentication (MFA): Protect procurement systems from unauthorized access and fraud.

8. Increase Agility in Procurement Processes

To adapt to market volatility, businesses should:

- Embrace Nearshoring and Local Sourcing: Reduce reliance on global suppliers to mitigate geopolitical risks and shipping delays.

- Adopt Flexible Contracting Models: Use shorter, adaptable contracts to respond quickly to pricing fluctuations and supply disruptions.

- Leverage On-Demand Procurement: Utilize just-in-time (JIT) strategies to reduce excess inventory and optimize cash flow.

9. Elevate Procurement as a Strategic Business Function

To position procurement as a key driver of business success, companies should:

- Involve Procurement in Business Strategy: Align procurement decisions with broader company goals and financial planning.

- Enhance Cross-Department Collaboration: Improve communication between procurement, finance, and operations teams for integrated decision-making.

- Leverage Procurement for Revenue Growth: Identify procurement-driven opportunities to enhance profitability and competitive advantage.

How Deskera ERP Enhances Procurement Efficiency

Deskera ERP is a comprehensive solution designed to streamline procurement by integrating automation, real-time analytics, and AI-driven insights. Whether managing supplier relationships, optimizing purchase orders, or ensuring compliance, Deskera ERP empowers businesses to enhance procurement efficiency.

Here’s how:

1. Automated Purchase Order Management

Deskera ERP automates the entire purchase order process, from requisition to approval, reducing manual errors and delays.

- Auto-generate purchase orders based on inventory levels and demand forecasts.

- Set up approval workflows to ensure compliance and cost control.

- Track order status in real-time for better visibility.

2. Supplier Management and Vendor Insights

Managing suppliers effectively is crucial for cost savings and risk mitigation. Deskera ERP provides a centralized supplier database with performance tracking.

- Maintain supplier records, contracts, and pricing agreements.

- Analyze supplier performance using historical data and KPIs.

- Enable seamless vendor communication and negotiation.

3. Real-Time Procurement Analytics and KPI Monitoring

Data-driven procurement is essential for cost optimization and strategic decision-making. Deskera ERP offers advanced analytics and real-time dashboards.

- Monitor procurement spend, supplier performance, and contract compliance.

- Generate reports on cost savings, delivery timelines, and purchasing trends.

- Utilize AI-powered insights for better demand planning.

4. Inventory and Procurement Synchronization

Deskera ERP connects procurement with inventory management to prevent overstocking or shortages.

- Auto-trigger purchase requisitions based on inventory levels.

- Avoid stockouts by predicting demand fluctuations.

- Optimize procurement costs by consolidating bulk purchases.

5. Cost Control and Budgeting

Deskera ERP enables businesses to set procurement budgets and track expenses in real time.

- Define procurement budgets and get alerts for overspending.

- Automate invoice matching to prevent billing discrepancies.

- Reduce procurement costs through AI-based supplier recommendations.

6. Multi-Location and Multi-Currency Procurement

For businesses operating across multiple regions, Deskera ERP ensures seamless multi-location and multi-currency procurement management.

- Standardize procurement workflows across global operations.

- Automate tax and compliance calculations based on region.

- Enable procurement teams to transact in multiple currencies.

Key Takeaways

- AI-Powered Procurement Automation – Artificial intelligence is transforming procurement by automating supplier selection, purchase orders, and contract management, leading to greater efficiency and cost savings.

- Predictive Procurement and Demand Forecasting – Advanced analytics and AI-driven demand forecasting help businesses anticipate supply needs, minimize risks, and optimize procurement strategies.

- Sustainable and Ethical Sourcing – Companies are prioritizing sustainability in procurement by sourcing eco-friendly materials, reducing waste, and ensuring compliance with ethical labor standards.

- Supplier Risk Management and Resilience – Businesses are adopting data-driven risk assessment models to evaluate suppliers, ensuring continuity during disruptions and enhancing supply chain resilience.

- Hyper-Personalization in Procurement – AI and real-time data analytics enable customized procurement strategies tailored to specific business needs, improving supplier collaboration and cost efficiency.

- Cloud-Based Procurement Solutions – Cloud-based procurement platforms streamline vendor management, contract negotiations, and real-time collaboration, offering scalability and accessibility across locations.

- Procurement as a Service (PaaS) – Companies are outsourcing procurement functions to specialized service providers, leveraging expertise, technology, and cost efficiencies to optimize procurement operations.

- Blockchain for Supply Chain Transparency – Blockchain technology enhances procurement transparency by ensuring tamper-proof record-keeping, improving supplier trust, and reducing fraud.

- Advanced Procurement Analytics and KPI Monitoring – Businesses are leveraging AI-driven analytics and dashboards to monitor procurement KPIs, optimize spending, and improve supplier performance.

- Data-Driven Supplier Collaboration – Real-time data sharing and AI-driven insights enhance collaboration with suppliers, driving efficiency, reducing costs, and improving procurement agility.

- Procurement’s Role in Regulatory Compliance – Compliance automation tools ensure procurement aligns with industry regulations, mitigating risks and avoiding penalties.

Integration of ERP for End-to-End Procurement Management – ERP solutions like Deskera ERP integrate procurement with inventory, finance, and supplier management, automating workflows and improving efficiency.

Related Articles