Furniture manufacturing is a highly competitive industry that demands high quality, durable and visually appealing products. To meet these demands, furniture manufacturers rely on a wide range of materials and techniques, including the use of additives.

Additives are essential chemicals that can be added to furniture materials, such as wood, plastics, or coatings, to improve their properties and performance. This article will explore the role of additives in furniture manufacturing and its related concepts.

Let’s take a look at the table of content below:

- Meaning of Additives in Furniture Manufacturing

- Types of Additives Used in Furniture Manufacturing

- Examples of Additives Commonly Used in Furniture Manufacturing

- Additives for Wood Protection

- Additives for Color and Appearance

- Additives for Flame Retardancy

- Additives for Performance Enhancement

- Sustainability and Environmental Impact of Additives in Furniture Manufacturing

- Frequently Asked Questions (FAQs) Associated with Furniture Manufacturing Additives

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Meaning of Additives in Furniture Manufacturing

Additives are chemical substances that are added to furniture manufacturing materials such as wood, metal, plastic, and textiles to improve their performance, appearance, and functionality.

Furthermore, additives can enhance the durability, strength, color, texture, and flame retardancy of furniture materials. They can also protect furniture from decay, mold, and other environmental factors.

In furniture manufacturing, additives are often used to customize the properties of raw materials to meet specific design and performance requirements. Different types of additives may be used depending on the type of furniture, the intended use, and the desired outcome.

Types of Additives Used in Furniture Manufacturing

There are several types of additives used in furniture manufacturing. Some of the most commonly used additives include:

Wood Protection Additives:

These additives are used to protect wood furniture from environmental factors such as moisture, insects, and decay. Common wood protection additives include borates, copper compounds, and organic biocides.

Purpose:

The purpose of wood protection additives is to protect wood furniture from environmental factors such as moisture, insects, and decay. The benefits of using wood protection additives include improved durability and longevity of the furniture, reduced maintenance costs, and increased resistance to wear and tear.

Color and Appearance Additives:

These additives are used to enhance the color and appearance of furniture materials. Pigments, dyes, and opacifying agents are common color and appearance additives.

Purpose:

The purpose of color and appearance additives is to enhance the visual appeal of furniture materials. The benefits of using color and appearance additives include improved aesthetic value, increased customization options, and enhanced durability of the finish.

Flame Retardant Additives:

These additives are used to improve the fire safety of furniture. Flame retardant additives can slow down or prevent the spread of fire in furniture materials. Examples of flame-retardant additives include halogenated compounds, phosphorous compounds, and nitrogen-based compounds.

Purpose:

The purpose of flame-retardant additives is to improve the fire safety of furniture. The benefits of using flame retardant additives include reduced fire risk and improved safety for occupants of buildings.

Performance Enhancement Additives:

These additives are used to improve the performance and functionality of furniture materials. Lubricants, plasticizers, and UV stabilizers are common performance enhancement additives.

Purpose:

The purpose of performance enhancement additives is to improve the performance and functionality of furniture materials. The benefits of using performance enhancement additives include improved resistance to wear and tear, increased flexibility, improved stability, and increased lifespan.

Processing Additives:

These additives are used during the manufacturing process to improve processing efficiency and quality. Examples include lubricants, mold release agents, and viscosity modifiers.

Purpose:

The purpose of processing additives is to improve manufacturing efficiency and product quality. The benefits of using processing additives include improved productivity, reduced manufacturing costs, and improved product quality.

The specific additives used in furniture manufacturing will depend on the materials being used, the desired outcome, and the intended use of the furniture.

Examples of Additives Commonly Used in Furniture Manufacturing

Some common additives used in furniture manufacturing include:

Polyurethane: Polyurethane is a polymer that is used as a coating or finish on wood furniture to enhance its durability, water resistance, and appearance.

Pigments: Pigments are color additives that are used to enhance the color and appearance of furniture materials. Pigments can be natural or synthetic and can be used to create a wide range of colors.

Flame retardants: Flame retardants are additives that are used to reduce the flammability of furniture materials. They can include halogenated compounds, phosphorus compounds, and nitrogen-based compounds.

Biocides: Biocides are additives that are used to protect wood furniture from decay and insect damage. They can include borates, copper compounds, and organic biocides.

Plasticizers: Plasticizers are additives that are used to improve the flexibility and durability of plastic materials used in furniture manufacturing.

Lubricants: Lubricants are additives that are used to reduce friction during the manufacturing process, improving the efficiency and quality of production.

The specific additives used in furniture manufacturing will depend on the type of furniture being produced and the materials being used.

Additives for Wood Protection

There are various additives available for wood protection, which can enhance the durability, performance, and aesthetic appeal of wood products. Some of the commonly used additives for wood protection are:

Preservatives: These are chemicals that can prevent the growth of fungi, bacteria, and insects, which can cause decay, rot, and other types of damage to the wood. Some of the common preservatives used in wood protection are copper-based compounds, such as copper azole, copper naphthenate, and ACQ (alkaline copper quaternary).

Stabilizers: These are additives that can prevent the degradation of wood caused by exposure to UV radiation and other environmental factors. Some of the common stabilizers used in wood protection are hindered amine light stabilizers (HALS) and UV absorbers.

Fungicides and insecticides: These are chemicals that can kill or repel fungi and insects, which can cause damage to the wood. Some of the common fungicides and insecticides used in wood protection are borates, permethrin, and cypermethrin.

Water repellents: These are additives that can reduce the ability of water to penetrate the wood, which can prevent the growth of fungi and other microorganisms. Some of the common water repellents used in wood protection are silicone-based compounds, wax emulsions, and hydrophobic coatings.

Fire retardants: These are chemicals that can reduce the flammability of wood and prevent it from catching fire. Some of the common fire retardants used in wood protection are ammonium phosphate, ammonium sulfate, and boron compounds.

Colorants: These are additives that can enhance the aesthetic appeal of wood products by adding color and improving the uniformity of the surface. Some of the common colorants used in wood protection are iron oxide pigments, carbon black, and titanium dioxide.

It is important to note that the selection and use of additives for wood protection should be done with care, taking into account the specific application, the environmental conditions, and the health and safety implications. It is also important to follow the manufacturer's instructions and regulations governing the use of these chemicals.

Purpose and Benefits of Wood Protection Additives

The purpose of wood protection additives is to enhance the durability, performance, and aesthetic appeal of wood products. These additives can provide various benefits, including:

Preventing decay and rot: Preservatives such as copper-based compounds can prevent the growth of fungi, bacteria, and insects that can cause decay and rot in wood.

Reducing the effects of UV radiation: Stabilizers such as hindered amine light stabilizers (HALS) and UV absorbers can prevent the degradation of wood caused by exposure to UV radiation and other environmental factors.

Protecting against insects and pests: Fungicides and insecticides can kill or repel fungi and insects, which can cause damage to the wood.

Reducing water absorption: Water repellents can reduce the ability of water to penetrate the wood, which can prevent the growth of fungi and other microorganisms.

Enhancing fire resistance: Fire retardants can reduce the flammability of wood and prevent it from catching fire.

Improving appearance: Colorants can enhance the aesthetic appeal of wood products by adding color and improving the uniformity of the surface.

In addition to these benefits, wood protection additives can also extend the service life of wood products, reduce maintenance costs, and promote sustainable forestry practices by minimizing the need for replacement or disposal of damaged wood products. Overall, the use of wood protection additives can help ensure that wood products remain a durable and sustainable material for construction, furniture, and other applications.

Additives for Color and Appearance

Additives for color and appearance are used to enhance the aesthetic appeal of various materials, including wood. Some of the commonly used additives for color and appearance in wood products are:

Pigments: These are finely ground particles that can be mixed with a binder to create a paint or stain. Pigments can provide a wide range of colors and can also enhance the durability and UV resistance of the coating.

Dyes: These are soluble colorants that can penetrate the wood fibers to create a translucent color effect. Dyes can provide a rich, deep color that highlights the natural grain and texture of the wood.

Opacifiers: These are additives that can be used to create an opaque or semi-opaque finish, such as in white or pastel-colored coatings.

Gloss agents: These are additives that can provide a glossy or shiny finish to the wood surface. Gloss agents can enhance the depth and richness of the color and create a smooth, reflective surface.

Matting agents: These are additives that can be used to create a matte or low-gloss finish on the wood surface. Matting agents can help reduce glare and create a more natural, organic look.

Fillers: These are additives that can be used to fill in small cracks or imperfections in the wood surface. Fillers can create a smooth, even surface that enhances the appearance of the coating.

Anti-settling agents: These are additives that can prevent settling or separation of the pigments or other additives in the coating. Anti-settling agents can ensure that the coating remains consistent in color and texture over time.

Ultimately, the use of these additives can provide various benefits, such as enhancing the aesthetic appeal and durability of the wood surface, improving the UV resistance, and reducing the risk of cracking or fading. Furthermore, it is important to choose the right additives based on the specific application, type of wood, and desired appearance, and to follow the manufacturer's instructions for optimal results.

Examples of Additives Used for Color and Appearance in Furniture Manufacturing

There are various additives used for color and appearance in furniture manufacturing. Some of the commonly used additives for color and appearance in furniture manufacturing are:

Stains: Stains are a type of pigment that can be used to color the wood and enhance the natural grain and texture. They can provide a wide range of colors, from light to dark, and can also enhance the durability and UV resistance of the coating.

Lacquers: Lacquers are a type of coating that can provide a high-gloss, shiny finish to the wood surface. They can be tinted with pigments or dyes to provide a variety of colors.

Paints: Paints are a type of coating that can provide a solid color or opaque finish to the wood surface. They can be applied in various sheens, from high-gloss to matte, and can also be tinted with pigments to provide a wide range of colors.

Varnishes: Varnishes are a type of coating that can provide a clear, glossy finish to the wood surface. They can enhance the natural beauty of the wood and provide a durable, protective layer.

Toners: Toners are a type of coating that can be used to enhance the natural color of the wood and provide a subtle, translucent finish. They can be tinted with dyes to create a variety of colors and can also enhance the durability of the coating.

Sealers: Sealers are a type of coating that can be used to seal the wood surface and provide a clear, protective layer. They can be tinted with pigments or dyes to provide a subtle color effect.

Glazes: Glazes are a type of coating that can be used to create a layered, textured finish on the wood surface. They can be tinted with pigments to create a variety of colors and can also enhance the natural grain and texture of the wood.

Ultimately, the use of these additives in furniture manufacturing can provide various benefits, such as enhancing the appearance and durability of the furniture, providing a protective layer against moisture and UV damage, and creating a unique, customized look. The selection of the right additives should be based on the specific type of wood, desired appearance, and intended use of the furniture.

Purpose and Benefits of Color and Appearance Additives

The purpose of color and appearance additives is to enhance the aesthetic appeal of various materials, such as wood, plastics, and coatings. These additives can provide a wide range of colors, textures, and finishes that can help create a unique, customized look for the product.

Some of the benefits of color and appearance additives are:

Enhanced aesthetic appeal: The use of color and appearance additives can enhance the beauty and visual appeal of the material. The additives can be used to create a variety of colors, textures, and finishes that can make the product stand out and look more attractive.

Protection against environmental factors: Some color and appearance additives, such as UV stabilizers and anti-oxidants, can help protect the material from damage caused by exposure to sunlight, moisture, and other environmental factors. This can help extend the life of the product and improve its durability.

Improved functionality: Color and appearance additives can also improve the functionality of the material. For example, slip agents can be added to coatings to reduce friction and improve wear resistance, while matting agents can be added to create a non-slip surface.

Customization: Color and appearance additives can be customized to suit specific needs and preferences. This can help create a unique, customized look for the product that sets it apart from others.

Cost-effective: Color and appearance additives can be a cost-effective way to enhance the appearance of the product. Rather than using expensive materials, such as exotic woods or metals, additives can be used to create a similar look at a lower cost.

Overall, the use of color and appearance additives can provide numerous benefits for materials and products. The selection of the right additives should be based on the specific application, desired appearance, and intended use of the product.

Additives for Flame Retardancy

Flame retardant additives are used to reduce the flammability and slow down the spread of fire in various materials, including plastics, textiles, and building materials. Some examples of flame-retardant additives include:

Halogenated compounds: These compounds, such as brominated and chlorinated flame retardants, work by releasing free radicals when exposed to high temperatures. These free radicals help to break the chain reaction of combustion and prevent the material from catching fire.

Phosphorus-based compounds: These compounds, such as ammonium polyphosphate and red phosphorus, work by releasing phosphoric acid when exposed to heat. The phosphoric acid forms a protective layer that prevents oxygen from reaching the material and slows down the spread of fire.

Inorganic fillers: Inorganic fillers, such as aluminum hydroxide and magnesium hydroxide, work by releasing water vapor when exposed to heat. The water vapor helps to cool down the material and prevent it from catching fire.

Intumescent additives: These additives, such as ammonium polyphosphate and pentaerythritol, work by expanding and forming a protective layer when exposed to high temperatures. The layer acts as an insulator and prevents oxygen from reaching the material, thus slowing down the spread of fire.

Examples of Flame-Retardant Additives Used in Furniture Manufacturing

In furniture manufacturing, flame retardant additives are often added to materials like foam, fabric, and wood to improve fire safety. Some examples of flame retardant additives used in furniture manufacturing include:

Chlorinated and brominated flame retardants: These are commonly used in polyurethane foam to make it more fire-resistant. They work by releasing free radicals that interrupt the combustion process.

Phosphorus-based flame retardants: These are often used in upholstery fabrics and wood products. They work by releasing phosphoric acid when exposed to high temperatures, which forms a protective layer that slows down the spread of fire.

Aluminum trihydrate: This inorganic filler is commonly used in polyester resin-based products, such as countertops and decorative moldings. It works by releasing water vapor when exposed to heat, which cools the material and reduces its flammability.

Intumescent coatings: These are often used on wood products to make them more fire-resistant. The coatings contain ammonium polyphosphate and pentaerythritol, which expand and form a protective layer when exposed to high temperatures.

Melamine cyanurate: This flame retardant is often used in plastic products like chairs and tables. It works by releasing nitrogen gas when exposed to high temperatures, which dilutes the oxygen in the air and slows down the spread of fire.

Overall, the use of flame-retardant additives is an important safety measure in furniture manufacturing. The selection of the right additive should be based on the specific material and application, as well as the desired level of fire resistance.

Purpose and Benefits of Flame Retardant Additives

The purpose of flame retardant additives is to reduce the flammability of materials and slow down the spread of fire. They achieve this by interrupting the combustion process and creating a protective layer that prevents the material from catching fire.

The benefits of flame-retardant additives include:

Improved safety: Flame retardant additives can help prevent fires and reduce the risk of injury or death in case of a fire. This is particularly important in applications where flammable materials are used, such as in furniture manufacturing.

Compliance with regulations: Many industries are required by law to use flame retardant materials. The use of flame-retardant additives can help these industries meet regulatory requirements.

Protection of property: Flame retardant additives can help prevent property damage and reduce the risk of loss in the event of a fire.

Extended product life: Flame retardant additives can improve the durability and lifespan of materials by reducing the risk of fire damage.

Reduced insurance costs: Using flame retardant additives can reduce insurance premiums for businesses and individuals by reducing the risk of fire damage.

Ultimately, the use of flame retardant additives is an important safety measure in various industries and applications. The selection of the right additive should be based on the specific material and the desired level of flame retardancy.

Additives for Performance Enhancement

Additives for performance enhancement are substances added to materials to improve their properties and performance in various applications. The goal is to modify the material to meet specific performance criteria or to improve processing characteristics.

The use of additives for performance enhancement is common in many industries, such as plastics, coatings, and composites. The selection of the right additive depends on the specific application and the desired performance properties.

Examples of Performance Enhancement Additives used in Furniture Manufacturing

There are several performance enhancement additives used in furniture manufacturing. Some examples include:

Impact modifiers: These additives improve the impact resistance of materials, making them less likely to crack or break. They are often used in chair components, such as armrests and legs.

Anti-slip agents: These additives increase the friction between materials, making them less likely to slip or slide. They are often used in furniture feet to prevent sliding and protect floors.

UV stabilizers: These additives protect materials from UV degradation, preventing them from fading or becoming brittle. They are often used in outdoor furniture, such as patio chairs and tables.

Flame retardants: These additives reduce the flammability of materials, slowing down the spread of fire. They are often used in upholstered furniture to meet fire safety regulations.

Anti-static agents: These additives reduce the buildup of static electricity on surfaces, preventing dust and dirt from adhering to furniture. They are often used in electronic furniture, such as computer desks and TV stands.

Fillers and reinforcements: These additives improve the mechanical properties of materials, increasing their strength and stiffness. They are often used in furniture frames to improve their durability and weight-bearing capacity.

Overall, the use of performance enhancement additives in furniture manufacturing can improve the durability, safety, and functionality of furniture, while also providing aesthetic benefits. The selection of the right additive should be based on the specific material and the desired performance properties.

Purpose and Benefits of Performance Enhancement Additives

Performance enhancement additives are used to improve the properties and performance of materials in various applications. The purpose of these additives is to modify the material to meet specific performance criteria or to improve processing characteristics.

The benefits of performance enhancement additives are numerous and can vary depending on the specific additive and the material it is added to.

Some of the benefits include:

Improved mechanical properties: Performance enhancement additives can improve the stiffness, strength, and wear resistance of materials, making them more durable and longer-lasting.

Increased efficiency: Additives can improve the processing characteristics of materials, reducing the time and cost required to produce finished products.

Improved aesthetics: Some additives can improve the appearance of materials by providing color, gloss, and other visual properties.

Increased safety: Additives such as flame retardants can improve the safety of materials by reducing the flammability of the material.

Extended lifespan: Additives such as anti-oxidants and UV stabilizers can protect materials from degradation and extend their lifespan.

Enhanced functionality: Additives such as anti-static agents can improve the functionality of materials by reducing static electricity build-up.

Overall, the use of performance enhancement additives can provide significant benefits for various industries and applications. The selection of the right additive should be based on the specific material and the desired properties and performance. By adding performance enhancement additives, materials can be tailored to meet specific needs, improve efficiency, and reduce costs.

Sustainability and Environmental Impact of Additives in Furniture Manufacturing

The use of additives in furniture manufacturing can have both positive and negative environmental impacts. Some additives can improve the sustainability of furniture by extending its lifespan and reducing the need for replacement.

For example, the use of UV stabilizers can protect furniture from sun damage, while flame retardants can improve the safety of furniture and reduce the risk of fires.

However, some additives may have negative environmental impacts, such as contributing to the accumulation of plastic waste or emitting harmful chemicals during production or disposal.

For example, the use of plasticizers in furniture manufacturing can contribute to the accumulation of plastic waste, and some flame retardants can release toxic fumes during disposal.

Overview of Environmental Concerns Related to Additives

The use of additives in various industries has raised environmental concerns due to the potential impact on human health and the environment. Some of the main environmental concerns related to additives include:

Pollution: Additives can contribute to pollution during production and disposal. For example, some additives may release toxic fumes during production, and improper disposal of additives can contaminate soil and water.

Waste: Some additives may contribute to the accumulation of waste, especially if they are not biodegradable or recyclable. This can lead to landfill overuse and pollution.

Resource depletion: The production of some additives requires non-renewable resources, such as fossil fuels or minerals. This can contribute to resource depletion and increase the carbon footprint of the production process.

Health risks: Some additives may pose health risks to workers involved in the production or handling of the materials. For example, some flame retardants have been linked to cancer and reproductive disorders.

Environmental degradation: Additives may contribute to environmental degradation, such as water pollution or soil contamination. This can impact biodiversity and ecological systems.

To address these environmental concerns, there is a growing demand for sustainable additives and production practices. This includes the use of biodegradable or recyclable additives, closed-loop production systems, and safer production practices that minimize health and environmental risks. By adopting sustainable production practices and using environmentally-friendly additives, industries can reduce their environmental impact and promote a more sustainable future.

Discussion of Sustainable Additive Options

Sustainable additive options are becoming increasingly popular in various industries due to their reduced environmental impact compared to traditional additives. Some of the sustainable additive options include:

Bio-based additives: Bio-based additives are made from renewable sources such as plants and animals. These additives are often biodegradable and can help reduce reliance on fossil fuels.

Recycled additives: Recycled additives are made from post-consumer waste and can help reduce the amount of waste sent to landfills. For example, recycled plastics can be used as an additive in the production of new plastics.

Green chemistry additives: Green chemistry additives are designed to be less toxic and less harmful to the environment. These additives are often made using non-toxic or low-toxicity materials and processes.

Nanoparticle additives: Nanoparticle additives are engineered at the nanoscale to have unique properties. These additives can improve performance and reduce the amount of material needed, which can result in a reduced environmental impact.

Natural additives: Natural additives are derived from natural sources such as plant extracts, minerals, and animal products. These additives are often biodegradable and can be used in place of traditional synthetic additives.

By using sustainable additive options, industries can reduce their environmental impact and promote a more sustainable future. However, it is important to note that not all sustainable additives are created equal, and some may still have negative environmental impacts.

Moreover, it is important for companies to conduct thorough research and choose the most sustainable and environmentally-friendly options available to them.

Comparison of Different Types of Additives in Terms of their Environmental Impact

Different types of additives can have varying environmental impacts depending on their chemical composition, production methods, and disposal practices. Here is a comparison of different types of additives in terms of their environmental impact:

Bio-based additives: Bio-based additives have a lower environmental impact compared to traditional additives since they are made from renewable sources such as plants and animals.

They also have the potential to biodegrade, reducing the amount of waste sent to landfills. However, the production of some bio-based additives may require large amounts of land and resources, which can impact biodiversity and ecosystems.

Recycled additives: Recycled additives have a lower environmental impact compared to traditional additives since they are made from post-consumer waste. The use of recycled additives also helps to reduce waste sent to landfills.

However, the production of recycled additives may require energy-intensive processes to transform waste into usable materials.

Green chemistry additives: Green chemistry additives are designed to be less toxic and less harmful to the environment. They are often made using non-toxic or low-toxicity materials and processes, which reduces the amount of harmful chemicals released during production and disposal.

However, the production of green chemistry additives may still require the use of non-renewable resources, and some green chemistry additives may not biodegrade easily.

Nanoparticle additives: Nanoparticle additives can improve performance and reduce the amount of material needed, resulting in a reduced environmental impact.

However, the production of nanoparticles may require energy-intensive processes, and their small size may make them difficult to remove from the environment if released.

Natural additives: Natural additives are derived from natural sources such as plant extracts, minerals, and animal products. They often have a lower environmental impact compared to synthetic additives since they are biodegradable and made from renewable sources.

However, the production of natural additives may still require large amounts of land and resources, which can impact biodiversity and ecosystems.

Overall, the choice of additive can significantly impact the environmental impact of a product. Industries should carefully consider the environmental impact of each type of additive before choosing which one to use. It is also important to consider the entire life cycle of the product, from production to disposal, to minimize the environmental impact as much as possible.

Frequently Asked Questions (FAQs) Associated with Furniture Manufacturing Additives

Following, we’ve discussed some crucial frequently asked questions (FAQs) associated with furniture manufacturing additives. Let’s learn:

Que 1: How do additives improve the properties of furniture materials?

Ans: Additives can improve the properties of furniture materials in a number of ways. For example, flame retardants can make furniture materials less flammable, while UV stabilizers can help protect against the harmful effects of sunlight.

Furthermore, colorants can be used to create a wider range of colors, and lubricants can improve the flow of materials during production. Antimicrobial agents can help prevent the growth of bacteria and other harmful microorganisms.

Que 2: How are additives added to furniture materials?

Ans: Additives can be added to furniture materials in a number of ways, depending on the type of material and the specific additive being used.

For example, additives can be mixed into the raw materials before they are formed into the final product, or they can be applied as a coating or surface treatment after the product has been formed.

Que 3: How do furniture manufacturers choose which additives to use?

Ans: Furniture manufacturers choose additives based on the specific needs and requirements of the furniture being produced. Factors such as durability, fire resistance, color, and antimicrobial properties are all taken into consideration when selecting additives.

In addition, manufacturers may also consider the cost and availability of different additives, as well as any environmental or health concerns associated with their use.

Que 4: Are there any regulations governing the use of furniture additives?

Ans: Yes, there are regulations governing the use of furniture additives in many countries. These regulations may limit the types and amounts of additives that can be used, as well as require manufacturers to disclose the use of certain additives to consumers. Manufacturers must also ensure that their products comply with any relevant safety and environmental standards.

Wrapping Up

In conclusion, additives play an important role in the manufacturing of furniture by enhancing the properties and performance of the materials used. From flame retardants to colorants and antimicrobial agents, there are a variety of additives available to furniture manufacturers to meet the specific needs of their products.

However, it is important for manufacturers to consider the environmental and health concerns associated with certain additives and to comply with any relevant regulations and standards.

As the demand for sustainable and eco-friendly furniture increases, it is likely that manufacturers will continue to explore new and innovative additives to meet these evolving needs.

How Deskera Can Assist You?

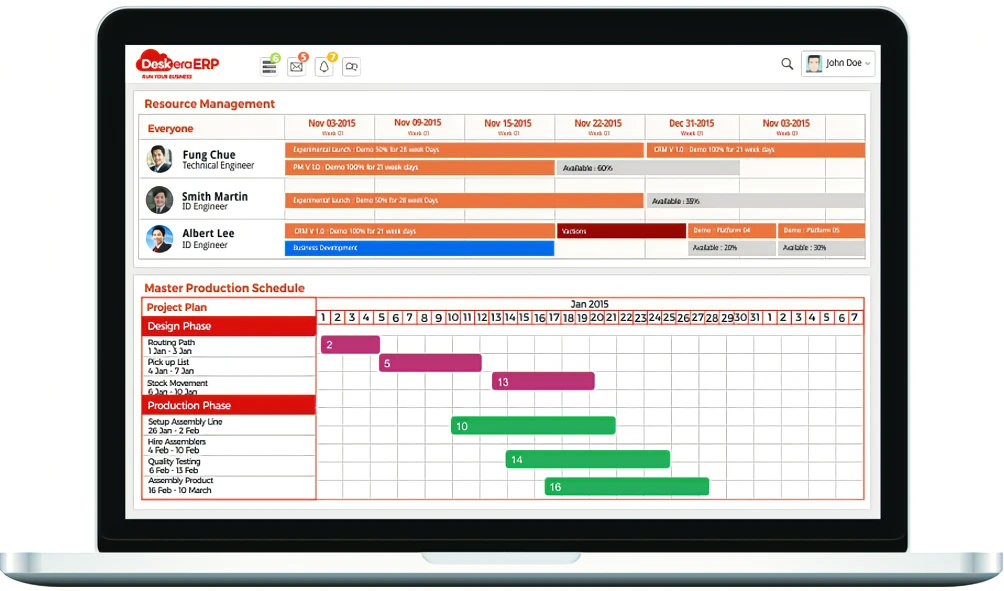

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Additives can enhance the durability, strength, color, texture, and flame retardancy of furniture materials. They can also protect furniture from decay, mold, and other environmental factors. In furniture manufacturing, additives are often used to customize the properties of raw materials to meet specific design and performance requirements.

- Wood protection additives can also extend the service life of wood products, reduce maintenance costs, and promote sustainable forestry practices by minimizing the need for replacement or disposal of damaged wood products.

- The use of these additives in furniture manufacturing can provide various benefits, such as enhancing the appearance and durability of the furniture, providing a protective layer against moisture and UV damage, and creating a unique, customized look. The selection of the right additives should be based on the specific type of wood, desired appearance, and intended use of the furniture.

- The purpose of flame retardant additives is to reduce the flammability of materials and slow down the spread of fire. They achieve this by interrupting the combustion process and creating a protective layer that prevents the material from catching fire.

- The use of additives in furniture manufacturing can have both positive and negative environmental impacts. Some additives can improve the sustainability of furniture by extending its lifespan and reducing the need for replacement. For example, the use of UV stabilizers can protect furniture from sun damage, while flame retardants can improve the safety of furniture and reduce the risk of fires.

- Nanoparticle additives can improve performance and reduce the amount of material needed, resulting in a reduced environmental impact. However, the production of nanoparticles may require energy-intensive processes, and their small size may make them difficult to remove from the environment if released.

- Recycled additives have a lower environmental impact compared to traditional additives since they are made from post-consumer waste. The use of recycled additives also helps to reduce waste sent to landfills. However, the production of recycled additives may require energy-intensive processes to transform waste into usable materials.

Related Articles