Do you want to streamline the quality control processes of your food and beverage business? If your answer is yes, then you are on the right page.

In the bustling world of food and beverage production, maintaining impeccable quality control standards is not just a requisite but a cornerstone of success. As the industry evolves, so do the complexities surrounding quality assurance.

In this digital age, where efficiency and precision are paramount, the integration of food and beverage ERP systems emerges as a transformative force, reshaping the landscape of quality control practices.

In this insightful exploration, we delve into the strategic impact of food and beverage ERP solutions on quality control within the industry. From optimizing processes to ensuring compliance and fostering continuous improvement, these sophisticated systems revolutionize how companies manage and uphold their standards of quality.

Join us as we navigate through the myriad ways in which food and beverage ERP systems empower businesses to elevate their quality control initiatives, driving efficiency, reliability, and ultimately, delivering products of unparalleled excellence.

The topics covered in this article are:

- What is the Food and Beverage Industry?

- Importance of Quality Control in the Food and Beverage Industry

- What is Food and Beverage ERP?

- The Strategic Impact of Food and Beverage ERP on Quality Control

- How can Deskera as a Food and Beverage ERP Help with Quality Control?

- Key Takeaways

- Related Articles

What is the Food and Beverage Industry?

The food and beverage industry encompasses a wide range of businesses involved in the production, processing, distribution, and sale of food and drink products consumed by humans.

It is a diverse and multifaceted sector that includes various sub-industries and segments, each specializing in different aspects of food and beverage production and distribution.

Key components of the food and beverage industry include:

- Food Production: This involves the cultivation, harvesting, and farming of agricultural products such as fruits, vegetables, grains, and livestock for food production purposes.

- Food Processing: Food processing involves the conversion of raw agricultural products into processed or packaged food items through various methods such as cooking, preserving, canning, freezing, and packaging.

- Beverage Production: Beverage production includes the manufacturing of various types of drinks, including alcoholic beverages (such as beer, wine, and spirits) and non-alcoholic beverages (such as soft drinks, juices, and bottled water).

- Food Service and Hospitality: This sector involves restaurants, cafes, catering services, and other establishments that prepare and serve food and beverages to consumers for consumption on-site or off-site.

- Retail and Distribution: Retail and distribution encompass grocery stores, supermarkets, convenience stores, and other retail outlets that sell food and beverage products to consumers, as well as distribution channels such as wholesalers, distributors, and e-commerce platforms.

- Food Safety and Regulation: Food safety and regulation are critical aspects of the food and beverage industry, involving government agencies, regulatory bodies, and industry associations that establish and enforce standards and regulations related to food safety, labeling, packaging, and quality control.

- Research and Development: Research and development (R&D) activities in the food and beverage industry focus on innovation, product development, and improvement of manufacturing processes to meet consumer demands, enhance product quality, and address emerging trends and preferences.

Overall, the food and beverage industry plays a vital role in providing essential food and drink products to consumers worldwide, contributing significantly to the economy, employment, and societal well-being.

It is a dynamic and evolving sector driven by changing consumer preferences, technological advancements, and regulatory requirements.

Importance of Quality Control in the Food and Beverage Industry

Quality control in the food and beverage industry is of paramount importance due to several key reasons:

- Ensuring Consumer Safety: The primary objective of quality control in the food and beverage industry is to safeguard consumer health and safety. By adhering to strict quality standards and implementing rigorous testing and inspection processes, companies can minimize the risk of foodborne illnesses, contamination, and other health hazards.

- Maintaining Product Integrity: Quality control measures help maintain the integrity and consistency of food and beverage products. By monitoring factors such as taste, texture, appearance, and nutritional content, companies can ensure that their products meet or exceed consumer expectations, leading to increased customer trust and customer loyalty.

- Compliance with Regulations: The food and beverage industry is subject to stringent regulations and standards imposed by government agencies and regulatory bodies. Quality control practices ensure compliance with food safety regulations, labeling requirements, and industry standards, thereby avoiding legal issues, fines, and damage to reputation.

- Preventing Product Recalls: Effective quality control helps prevent product recalls, which can be costly and damaging to a company's reputation. By implementing robust quality assurance measures and traceability systems, companies can quickly identify and address quality issues before they escalate into full-blown recalls.

- Minimizing Waste and Losses: Quality control processes help minimize waste and losses by identifying and addressing issues such as product defects, spoilage, and inefficiencies in production. By optimizing processes and ensuring product quality, companies can reduce costs and maximize profitability.

- Meeting Customer Expectations: Consumers today are increasingly discerning and demand high-quality food and beverage products. Quality control enables companies to meet or exceed customer expectations for taste, freshness, safety, and nutritional value, enhancing customer satisfaction and loyalty.

- Protecting Brand Reputation: A strong reputation for quality is essential for success in the food and beverage industry. Quality control practices help protect and enhance brand reputation by ensuring consistent product quality, safety, and reliability, thereby building trust with consumers and stakeholders.

In summary, quality control is indispensable in the food and beverage industry for ensuring consumer safety, maintaining product integrity, complying with regulations, preventing recalls, minimizing waste, meeting customer expectations, and protecting brand reputation.

By prioritizing quality control, companies can achieve long-term success and sustainability in this competitive and dynamic industry.

What is Food and Beverage ERP?

Food and beverage ERP (Enterprise Resource Planning) is a specialized software solution designed specifically for the needs and requirements of the food and beverage industry.

It integrates various business processes and functions within a single unified platform, providing comprehensive tools and functionalities to manage and streamline operations across all aspects of food and beverage production, processing, distribution, and sales.

Key features of food and beverage ERP systems typically include:

- Inventory Management: Tracking and managing raw materials, ingredients, packaging materials, and finished products throughout the supply chain, including storage, procurement, and replenishment.

- Production Planning and Scheduling: Optimizing production processes, managing production schedules, and coordinating resources to meet demand while minimizing waste and downtime.

- Quality Control and Assurance: Implementing quality control measures, conducting inspections, testing, and analysis of raw materials and finished products to ensure compliance with regulatory standards and quality specifications.

- Recipe and Formulation Management: Managing recipes, formulas, and product specifications, including ingredient lists, nutritional information, allergen declarations, and packaging requirements.

- Lot Tracking and Traceability: Tracking the movement of materials and products throughout the production process and supply chain, enabling traceability in case of recalls or quality issues.

- Compliance Management: Ensuring compliance with food safety regulations, labeling requirements, and industry standards set by regulatory bodies such as the FDA (Food and Drug Administration) or the USDA (United States Department of Agriculture).

- Supplier and Vendor Management: Managing relationships with suppliers and vendors, including procurement, contract management, performance evaluation, and collaboration on quality control and supply chain management.

- Financial Management: Integrating financial processes such as accounting, budgeting, cost control, and reporting to monitor and manage financial performance and profitability.

- Sales and Distribution Management: Managing sales orders, pricing, promotions, and distribution channels, including sales forecasting, order processing, and delivery logistics.

- Customer Relationship Management (CRM): Managing customer interactions, preferences, and feedback to enhance customer satisfaction, customer loyalty, and customer retention.

Food and beverage ERP systems are tailored to meet the specific needs and challenges of the food and beverage industry, providing industry-specific functionalities, compliance features, and best practices to help businesses improve efficiency, ensure product quality, and maintain competitiveness in a highly regulated and dynamic market environment.

The Strategic Impact of Food and Beverage ERP on Quality Control

Implementing an Enterprise Resource Planning (ERP) system tailored to the food and beverage industry can have a profound strategic impact on quality control. Here's how:

Standardization of Processes

In the competitive landscape of the food and beverage industry, maintaining stringent quality control standards is paramount to success. Leveraging cutting-edge technology such as food and beverage ERP systems can revolutionize quality control processes, driving efficiency, consistency, and compliance.

Explore how the strategic implementation of food and beverage ERP systems impacts quality control, particularly through the standardization of processes.

- Enhanced Consistency: Food and beverage ERP systems facilitate the standardization of quality control processes across various departments and production facilities. By streamlining procedures for inspecting, testing, and ensuring product quality, manufacturers can achieve greater consistency in their operations.

- Optimized Resource Allocation: With manufacturing ERP solutions, companies can allocate resources more efficiently, ensuring that the right personnel and equipment are deployed for quality control tasks. Standardized processes enable organizations to minimize waste and optimize the use of materials, contributing to cost savings and improved profitability.

- Compliance Adherence: Food and beverage ERP software incorporates built-in functionalities to ensure compliance with industry regulations and standards, such as FDA guidelines and HACCP principles. By adhering to standardized quality control processes mandated by regulatory bodies, manufacturers can mitigate risks associated with non-compliance and avoid costly penalties.

- Integration Across Supply Chain: Manufacturing software integrates seamlessly with supply chain management modules, enabling end-to-end visibility and control over quality-related processes. Standardized quality control procedures extend beyond internal operations to include suppliers, fostering collaboration and accountability throughout the supply chain.

- Efficient Change Management: In a dynamic industry like food and beverage, agility is key to adapting to evolving market demands and regulations. Food and beverage ERP systems facilitate efficient change management by providing tools for documenting, communicating, and implementing updates to quality control processes, ensuring alignment with industry best practices and emerging standards.

In summary, the standardization of processes through food and beverage ERP systems is a strategic imperative for manufacturers seeking to uphold quality standards, ensure compliance, and gain a competitive edge in the marketplace.

By embracing standardized quality control practices enabled by MRP software, companies can elevate their operational excellence and deliver superior products to meet the demands of discerning consumers.

Traceability and Compliance

In the intricate landscape of the food and beverage industry, ensuring traceability and compliance throughout the supply chain is essential for upholding quality standards and meeting regulatory requirements.

Food and beverage ERP systems play a pivotal role in facilitating traceability and compliance initiatives, offering robust functionalities tailored to the unique needs of manufacturers in this sector.

- Comprehensive Traceability Solutions: Food and beverage ERP software provide end-to-end traceability solutions, enabling manufacturers to track ingredients, raw materials, and finished products at every stage of the production process. With manufacturing ERP, companies can trace the journey of products from procurement to distribution, ensuring transparency and accountability across the supply chain.

- Regulatory Compliance Management: Manufacturing software includes built-in features for managing regulatory compliance, helping companies navigate complex industry regulations such as FDA guidelines, FSMA (Food Safety Modernization Act), and GMP (Good Manufacturing Practices). Food and beverage ERP systems facilitate compliance with HACCP (Hazard Analysis and Critical Control Points) principles, allergen labeling requirements, and other regulatory mandates through automated workflows and documentation management capabilities.

- Real-time Monitoring and Reporting: Through food and beverage ERP solutions, manufacturers gain real-time visibility into quality control metrics, compliance status, and regulatory obligations. MRP software empowers companies to generate comprehensive reports and audits, demonstrating adherence to quality standards and regulatory requirements to stakeholders, customers, and regulatory authorities.

- Risk Mitigation and Contingency Planning: By leveraging manufacturing ERP for traceability and compliance, companies can proactively identify and mitigate risks associated with product recalls, contamination incidents, and supply chain disruptions. Food and beverage ERP systems enable swift response to quality issues, facilitating efficient recall management and crisis communication to protect brand reputation and consumer safety.

- Supply Chain Collaboration and Transparency: Manufacturing ERP fosters collaboration and transparency across the supply chain, allowing manufacturers to share quality data and compliance documentation with suppliers, distributors, and other stakeholders. Through integrated supply chain management modules, food and beverage ERP systems facilitate seamless communication and information exchange, ensuring alignment with quality standards and regulatory requirements throughout the extended enterprise.

In essence, the integration of traceability and compliance functionalities within food and beverage ERP systems is instrumental in safeguarding product integrity, ensuring regulatory compliance, and fostering trust and confidence among consumers and regulatory authorities.

By harnessing the power of MRP software for traceability and compliance initiatives, manufacturers can navigate the complexities of the industry landscape with confidence and resilience.

Real-Time Data Insights

In the fast-paced environment of the food and beverage industry, staying ahead of quality control challenges requires real-time insights and actionable data. Food and beverage ERP systems offer a strategic advantage by providing manufacturers with unparalleled access to real-time data insights.

Explore how leveraging these insights transforms quality control practices, driving efficiency, agility, and competitive advantage.

- Instantaneous Performance Monitoring: Food and beverage ERP systems enable manufacturers to monitor quality control performance in real time, tracking key metrics such as defect rates, production yields, and customer complaints. With manufacturing software, companies can identify trends, anomalies, and areas for improvement swiftly, empowering data-driven decision-making at every stage of the production process.

- Proactive Issue Identification: Real-time data insights provided by manufacturing ERP facilitate the proactive identification of quality issues before they escalate into larger problems. By analyzing quality control data as it emerges, companies can pinpoint potential issues, initiate corrective actions, and prevent costly quality incidents or recalls.

- Predictive Analytics for Quality Forecasting: Advanced food and beverage ERP systems leverage predictive analytics capabilities to forecast quality outcomes based on historical data, market trends, and external factors. With MRP software, manufacturers can anticipate potential quality issues, optimize production processes, and maintain high-quality standards across their product portfolio.

- Dynamic Resource Allocation: Manufacturing ERP solutions enable dynamic resource allocation based on real-time quality control data, ensuring that resources are allocated efficiently to address emerging quality concerns. By optimizing resource utilization, companies can minimize waste, reduce costs, and enhance overall operational efficiency without compromising on quality.

- Continuous Improvement Initiatives: Real-time data insights provided by food and beverage ERP systems serve as a catalyst for continuous improvement initiatives. By capturing data on quality control processes and outcomes, companies can identify opportunities for optimization, implement corrective actions, and monitor the effectiveness of quality improvement efforts over time.

The integration of real-time data insights within food and beverage ERP systems revolutionizes quality control practices, driving operational excellence, and fostering innovation.

By harnessing the power of manufacturing ERP, manufacturers can leverage actionable insights to enhance product quality, ensure regulatory compliance, and maintain a competitive edge in the dynamic landscape of the food and beverage industry.

Inventory Management

Efficient inventory management is critical for maintaining quality control in the dynamic food and beverage industry. Leveraging advanced technology such as food and beverage ERP systems revolutionizes inventory management practices, ensuring optimal stock levels, minimizing waste, and upholding quality standards.

Explore how integrating inventory management capabilities within food and beverage ERP systems enhances quality control processes, driving efficiency, and profitability.

- Streamlined Procurement and Replenishment: Food and beverage ERP systems streamline procurement processes by automating purchase orders, supplier management, and inventory replenishment. With manufacturing software, companies can maintain optimal stock levels of raw materials and ingredients, ensuring uninterrupted production and minimizing the risk of stockouts or overstocking.

- Quality Assurance in Incoming Materials: Manufacturing ERP solutions incorporate quality assurance functionalities to inspect and validate incoming materials and ingredients. By enforcing quality standards at the point of receipt, food, and beverage ERP systems mitigate the risk of using subpar materials in production, safeguarding product quality and consumer safety.

- Lot and Batch Tracking: Food and beverage ERP systems enable comprehensive lot and batch tracking, allowing manufacturers to trace the movement of materials and products throughout the supply chain. With MRP software, companies can quickly identify and isolate batches affected by quality issues, facilitating targeted recalls and minimizing the impact on product quality and brand reputation.

- Optimized Shelf-Life Management: Manufacturing ERP solutions include features for managing the shelf-life and expiration dates of perishable ingredients and finished products. By monitoring expiration dates in real-time, food and beverage ERP systems help prevent wastage and ensure that only fresh, high-quality products reach customers, enhancing brand reputation and customer satisfaction.

- Efficient Waste Reduction: Food and beverage ERP systems facilitate efficient waste reduction strategies by optimizing inventory turnover, minimizing excess inventory, and managing production yields. With manufacturing software, companies can identify and address inefficiencies in production processes, reducing waste and improving overall resource utilization without compromising on quality.

The integration of inventory management functionalities within food and beverage ERP systems is instrumental in enhancing quality control practices, driving operational efficiency, and maximizing profitability.

By harnessing the power of MRP software for inventory management, manufacturers can optimize stock levels, minimize waste, and uphold quality standards, positioning themselves for sustained success in the competitive landscape of the food and beverage industry.

Supplier Management

Effective supplier management is paramount for maintaining quality control standards and ensuring product integrity in the food and beverage industry. Food and beverage ERP systems offer robust supplier management functionalities that streamline processes, enforce quality standards, and foster collaboration with trusted suppliers.

Explore how integrating supplier management capabilities within food and beverage ERP systems enhances quality control practices, driving efficiency, and reliability.

- Supplier Evaluation and Selection: Food and beverage ERP systems facilitate comprehensive supplier evaluation processes, allowing companies to assess factors such as quality, reliability, and compliance history. With manufacturing software, companies can make informed decisions when selecting suppliers, ensuring alignment with quality control requirements and regulatory standards.

- Quality Assurance in Incoming Materials: Manufacturing ERP solutions enable seamless integration with supplier quality management systems, allowing manufacturers to enforce quality standards for incoming materials and ingredients. By collaborating closely with suppliers and establishing clear quality requirements, food and beverage ERP systems ensure that only high-quality materials are used in production, minimizing the risk of quality issues.

- Contract Management and Compliance: Food and beverage ERP systems include features for contract management, enabling companies to negotiate and manage contracts with suppliers efficiently. With MRP software, manufacturers can ensure compliance with contractual agreements, including pricing, delivery schedules, and quality specifications, fostering transparency and accountability in supplier relationships.

- Performance Monitoring and Improvement: Manufacturing ERP solutions provide tools for monitoring supplier performance metrics such as on-time delivery, quality ratings, and defect rates. By tracking supplier performance data in real-time, food and beverage ERP systems facilitate continuous improvement initiatives, enabling companies to address issues promptly, recognize top-performing suppliers, and optimize supply chain efficiency.

- Collaborative Relationship Building: Food and beverage ERP systems foster collaborative relationships with suppliers through seamless communication channels and information exchange. With manufacturing software, companies can share quality control requirements, specifications, and feedback with suppliers in real time, promoting transparency, alignment, and mutual success.

The integration of supplier management functionalities within food and beverage ERP systems is instrumental in enhancing quality control practices, ensuring product integrity, and mitigating supply chain risks.

By leveraging the power of manufacturing software for supplier management, manufacturers can establish strong partnerships, enforce quality standards, and maintain a competitive edge in the dynamic landscape of the food and beverage industry.

Batch Tracking and Recall Management

In the fast-paced and highly regulated environment of the food and beverage industry, effective batch tracking and recall management are paramount for maintaining quality control and ensuring consumer safety.

Food and beverage ERP systems provide comprehensive solutions for batch tracking and recall management, enabling manufacturers to swiftly identify, isolate, and address quality issues across the supply chain.

Explore how integrating these capabilities within food and beverage ERP systems enhances quality control practices, driving efficiency, and minimizing risk.

- Comprehensive Batch Tracking: Food and beverage ERP systems offer robust batch tracking functionalities, allowing manufacturers to trace the movement of materials and products from procurement to distribution. With manufacturing software, companies can track the production history, ingredients, and processing parameters associated with each batch, ensuring transparency and accountability throughout the supply chain.

- Swift Identification of Quality Issues: Manufacturing ERP solutions enable real-time monitoring of quality control metrics, enabling companies to quickly identify deviations, anomalies, or quality issues in production batches. By leveraging food and beverage ERP systems, manufacturers can take proactive measures to address quality issues before they escalate, minimizing the risk of product recalls or consumer safety incidents.

- Efficient Recall Management: Food and beverage ERP systems streamline recall management processes, enabling manufacturers to initiate, track, and execute recalls with speed and precision. With MRP software, companies can identify affected batches, notify customers and regulatory authorities, and manage the recall process seamlessly, minimizing the impact on brand reputation and consumer trust.

- Regulatory Compliance and Documentation: Manufacturing ERP solutions include built-in features for regulatory compliance management, ensuring that recall processes adhere to industry regulations and standards. By centralizing documentation and audit trails within food and beverage ERP systems, manufacturers can demonstrate compliance with recall procedures, mitigating regulatory risks and liabilities.

- Continuous Improvement and Prevention: Food and beverage ERP systems facilitate continuous improvement initiatives by capturing data on recall events and analyzing root causes of quality issues. With manufacturing software, companies can implement corrective actions, update standard operating procedures, and prevent the recurrence of quality issues, driving long-term improvements in quality control practices.

The integration of batch tracking and recall management functionalities within food and beverage ERP systems is instrumental in safeguarding product quality, ensuring regulatory compliance, and protecting consumer safety.

By leveraging the power of manufacturing ERP software for batch tracking and recall management, manufacturers can enhance their ability to respond swiftly to quality issues, minimize risk, and maintain a competitive edge in the dynamic food and beverage industry landscape.

Continuous Improvement

Continuous improvement is a cornerstone of quality control in the food and beverage industry, driving operational excellence and product innovation. Food and beverage ERP systems play a pivotal role in facilitating continuous improvement initiatives by providing manufacturers with valuable insights, analytics, and tools for optimization.

Explore how integrating continuous improvement capabilities within food and beverage ERP systems enhances quality control practices, driving efficiency, and fostering innovation.

- Data-Driven Insights: Food and beverage ERP systems offer real-time data insights into quality control metrics, production processes, and performance indicators. With manufacturing software, companies can analyze data trends, identify areas for improvement, and make informed decisions to enhance product quality and operational efficiency.

- Root Cause Analysis: Manufacturing ERP solutions enable root cause analysis of quality issues, helping companies identify underlying factors contributing to deviations or non-conformances. By pinpointing root causes, food and beverage ERP systems empower manufacturers to implement targeted corrective actions and prevent the recurrence of quality issues.

- Feedback Loops and Collaboration: Food and beverage ERP systems facilitate feedback loops and collaboration across departments, enabling cross-functional teams to share insights, best practices, and lessons learned. With MRP software, companies can foster a culture of continuous improvement, encouraging employees to contribute ideas for process optimization and innovation.

- Process Optimization: Manufacturing ERP solutions support process optimization initiatives by providing tools for workflow automation, standardization, and documentation management. By streamlining processes and eliminating inefficiencies, food and beverage ERP systems enhance operational performance and product quality.

- Performance Monitoring and Benchmarking: Food and beverage ERP systems enable performance monitoring and benchmarking against industry standards and best practices. With manufacturing software, companies can assess their performance relative to competitors, identify opportunities for improvement, and set goals for quality control excellence.

- Adaptability and Flexibility: Manufacturing ERP solutions offer adaptability and flexibility to accommodate evolving customer preferences, market trends, and regulatory requirements. By embracing change and innovation, food and beverage ERP systems empower manufacturers to stay ahead of the curve and continuously improve their quality control practices.

The integration of continuous improvement capabilities within food and beverage ERP systems is instrumental in driving quality control excellence, operational efficiency, and innovation.

By harnessing the power of MRP software for continuous improvement initiatives, manufacturers can optimize processes, enhance product quality, and maintain a competitive edge in the dynamic food and beverage industry landscape.

Customer Feedback Integration

In the customer-centric landscape of the food and beverage industry, integrating customer feedback into quality control processes is essential for delivering products that meet consumer expectations and preferences.

Food and beverage ERP systems offer sophisticated tools for customer feedback integration, enabling manufacturers to gather, analyze, and act upon feedback in real time.

Explore how leveraging customer feedback integration capabilities within food and beverage ERP systems enhances quality control practices, driving satisfaction, and loyalty.

- Real-Time Feedback Collection: Food and beverage ERP systems enable real-time collection of customer feedback through various channels such as surveys, reviews, and social media platforms. With manufacturing software, companies can capture customer sentiments, preferences, and quality perceptions directly, facilitating timely response and action.

- Data Analysis and Sentiment Analysis: Manufacturing ERP solutions include tools for analyzing customer feedback data and performing sentiment analysis to extract insights and trends. By leveraging food and beverage ERP systems, manufacturers can identify patterns, sentiments, and areas for improvement in product quality and customer satisfaction.

- Quality Improvement Initiatives: Food and beverage ERP systems facilitate quality improvement initiatives based on customer feedback insights, enabling companies to address issues and enhance product quality. With MRP software, manufacturers can prioritize quality control enhancements and allocate resources effectively to meet customer expectations and preferences.

- Product Innovation and Development: Manufacturing ERP solutions support product innovation and development by incorporating customer feedback into the design and formulation process. By integrating customer insights into food and beverage ERP systems, companies can identify new product opportunities, refine existing offerings, and differentiate themselves in the market.

- Brand Loyalty and Retention: Food and beverage ERP systems play a crucial role in fostering brand loyalty and customer retention by responding to feedback and delivering consistent quality products. With manufacturing software, companies can build trust and confidence among consumers, leading to repeat purchases and positive word-of-mouth referrals.

- Continuous Feedback Loop: Manufacturing ERP solutions establish a continuous feedback loop between customers and manufacturers, enabling ongoing dialogue and engagement. By incorporating customer feedback integration capabilities within food and beverage ERP systems, companies demonstrate their commitment to listening to customer needs and delivering exceptional quality products.

The integration of customer feedback into quality control processes within food and beverage ERP systems is instrumental in driving satisfaction, loyalty, and brand reputation.

By harnessing the power of MRP software for customer feedback integration, manufacturers can gain valuable insights, enhance product quality, and maintain a competitive edge in the dynamic food and beverage industry landscape.

Optimized Resource Allocation

Optimizing resource allocation is crucial for ensuring efficiency and effectiveness in quality control processes within the food and beverage industry. Food and beverage ERP systems play a pivotal role in streamlining resource allocation, enabling companies to allocate personnel, equipment, and materials efficiently.

Explore how leveraging optimized resource allocation capabilities within food and beverage ERP systems enhances quality control practices, driving productivity, cost-effectiveness, and overall performance.

- Real-Time Visibility: Food and beverage ERP systems provide real-time visibility into quality control metrics, inventory levels, and production schedules, enabling companies to make informed decisions regarding resource allocation. With manufacturing software, companies can identify bottlenecks, anticipate demand fluctuations, and allocate resources effectively to meet quality control requirements.

- Dynamic Resource Allocation: Manufacturing ERP solutions enable dynamic resource allocation based on fluctuating demand, production priorities, and quality control needs. By adjusting resource allocation in real-time, food and beverage ERP systems optimize production schedules, minimize downtime, and ensure the timely completion of quality control tasks.

- Personnel Management: Food and beverage ERP systems facilitate personnel management by assigning roles, responsibilities, and tasks based on skill levels, availability, and expertise. With MRP software, companies can optimize workforce utilization, improve communication, and enhance collaboration among quality control teams, driving efficiency and productivity.

- Equipment Utilization: Manufacturing ERP solutions optimize equipment utilization by scheduling maintenance, minimizing downtime, and maximizing uptime for quality control activities. By ensuring that equipment is available and operational when needed, food and beverage ERP systems enhance production efficiency and product quality.

- Inventory Optimization: Food and beverage ERP systems optimize inventory levels by aligning procurement, production, and quality control processes. With manufacturing software, companies can minimize excess inventory, reduce carrying costs, and ensure the availability of high-quality materials for production, enhancing overall efficiency and cost-effectiveness.

- Cost Management: Manufacturing ERP solutions support cost management initiatives by tracking expenses, analyzing costs, and identifying opportunities for savings in quality control processes. By optimizing resource allocation, food and beverage ERP systems help companies reduce overhead costs, improve profitability, and reinvest savings into quality improvement initiatives.

The integration of optimized resource allocation capabilities within food and beverage ERP systems is instrumental in driving efficiency, productivity, and cost-effectiveness in quality control processes.

By leveraging the power of MRP software for resource allocation, manufacturers can optimize production schedules, enhance product quality, and maintain a competitive edge in the dynamic food and beverage industry landscape.

Improved Collaboration and Transparency

Collaboration and transparency are integral to effective quality control practices in the food and beverage industry. Food and beverage ERP systems serve as centralized platforms that foster collaboration and transparency among various stakeholders involved in quality control processes.

Explore how leveraging improved collaboration and transparency capabilities within food and beverage ERP systems enhances communication, coordination, and accountability, ultimately driving superior product quality and customer satisfaction.

- Centralized Communication Hub: Food and beverage ERP systems act as centralized communication hubs, facilitating seamless communication and information exchange among quality control teams, production units, suppliers, and other stakeholders. With manufacturing software, companies can streamline communication channels, reduce information silos, and foster collaboration across departments, enhancing efficiency and effectiveness in quality control processes.

- Cross-Functional Collaboration: Manufacturing ERP solutions enable cross-functional collaboration by bringing together teams from different departments, such as quality assurance, production, procurement, and logistics. By promoting collaboration and knowledge sharing, food and beverage ERP systems enhance coordination, problem-solving, and decision-making, driving continuous improvement in quality control practices.

- Supplier Collaboration and Accountability: Food and beverage ERP systems facilitate collaboration with suppliers by providing visibility into quality requirements, specifications, and performance metrics. With MRP software, companies can establish transparent communication channels, set expectations, and hold suppliers accountable for meeting quality standards and regulatory requirements, ensuring product integrity and compliance.

- Real-Time Information Sharing: Manufacturing ERP solutions enable real-time information sharing, allowing stakeholders to access up-to-date data, reports, and analytics related to quality control processes. By providing timely insights and visibility, food and beverage ERP systems empower stakeholders to make informed decisions, identify issues, and take corrective actions promptly, enhancing overall performance and efficiency.

- Transparency in Process Documentation: Food and beverage ERP systems ensure transparency in process documentation by maintaining centralized repositories for standard operating procedures, work instructions, and quality control protocols. With manufacturing software, companies can ensure that all stakeholders have access to accurate and up-to-date documentation, fostering compliance, consistency, and accountability in quality control practices.

- Audit Trail and Compliance Management: Manufacturing ERP solutions provide audit trail functionalities, allowing companies to track changes, approvals, and deviations in quality control processes. By maintaining comprehensive audit trails, food and beverage ERP systems facilitate regulatory compliance, internal audits, and quality management certifications, demonstrating transparency and accountability to stakeholders.

The integration of improved collaboration and transparency capabilities within food and beverage ERP systems is instrumental in driving efficiency, effectiveness, and compliance in quality control processes.

By leveraging the power of MRP software for collaboration and transparency, manufacturers can enhance communication, coordination, and accountability, ultimately delivering superior product quality and customer satisfaction in the competitive food and beverage industry landscape.

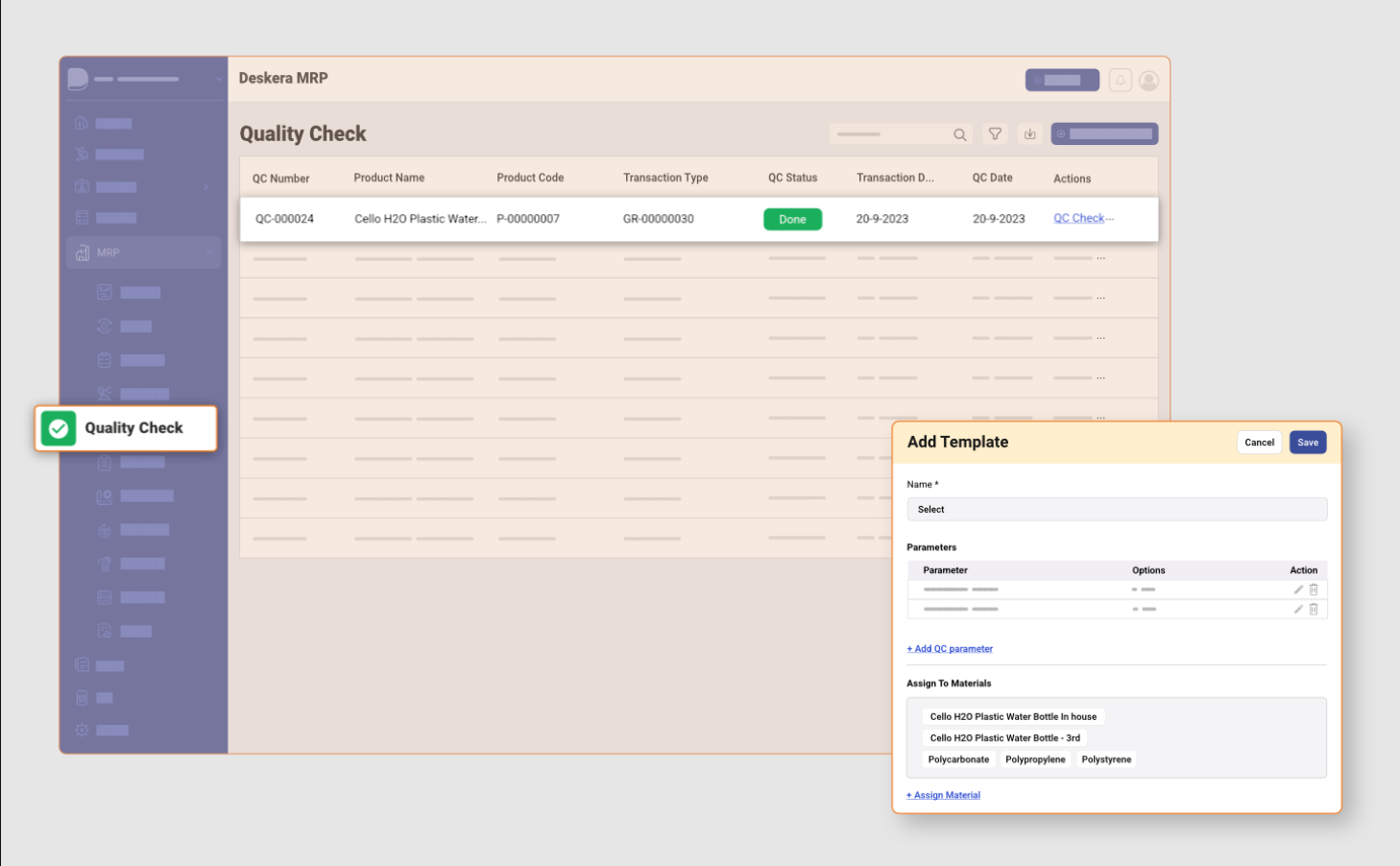

How can Deskera as a Food and Beverage ERP Help with Quality Control?

Deskera, as a food and beverage ERP solution, can significantly aid in improving quality control processes across various aspects of food and beverage production, processing, and distribution.

Here's how Deskera can help:

- Real-Time Monitoring and Tracking: Deskera enables real-time monitoring and tracking of quality control metrics, including product specifications, test results, and compliance status. Businesses can leverage dashboards and reporting tools to gain insights into quality performance across different stages of production and supply chain.

- Audit and Compliance Management: Deskera helps businesses streamline audit and compliance management processes by providing functionalities for scheduling audits, conducting inspections, and documenting findings. The solution facilitates compliance with food safety regulations, industry standards, and customer requirements through customizable audit templates and reporting capabilities.

- Continuous Improvement Initiatives: Deskera supports continuous improvement initiatives by providing tools for data analysis, trend identification, and performance monitoring. Businesses can analyze quality data, identify areas for improvement, and implement corrective actions to drive ongoing enhancements in quality control processes.

- Traceability and Recall Management: Deskera supports traceability and recall management by providing tools for lot tracking, batch management, and product tracing. In the event of quality issues or recalls, businesses can quickly identify affected products, trace their movement throughout the supply chain, and take appropriate corrective actions to mitigate risks.

- Supplier Management: Deskera streamlines supplier management processes, allowing businesses to manage vendor relationships, automate procurement workflows, and track supplier performance. Integration with supplier portals and automated reordering help businesses maintain optimal inventory levels of good quality and reduce stockouts.

Key Takeaways

In today's competitive food and beverage industry, maintaining stringent quality control standards is imperative for success. Food and Beverage ERP systems emerge as indispensable tools in this pursuit, offering a myriad of benefits that revolutionize how companies manage and uphold their standards of quality.

The 10 ways in which food and beverage ERP has a strategic impact on quality control are:

- Standardization of Processes: Food and Beverage ERP systems provide a centralized platform for standardizing processes across different departments and locations. In the context of quality control, this means establishing uniform procedures for inspecting, testing, and ensuring the quality of ingredients, products, and packaging materials.

- Traceability and Compliance: Food and beverage ERP systems often come equipped with features for traceability and compliance management. They enable companies to track ingredients and products throughout the supply chain, from procurement to distribution. This traceability is crucial for quickly identifying and addressing quality issues, as well as meeting regulatory requirements.

- Real-time Data Insights: Manufacturing software systems collect and analyze data in real time, offering valuable insights into quality control metrics such as defect rates, production yields, and customer complaints. By having access to this data, decision-makers can proactively identify trends, anticipate potential quality issues, and take corrective actions promptly.

- Inventory Management: Effective quality control requires tight management of inventory, particularly perishable ingredients and finished goods. Food and beverage ERP systems integrate inventory management functionalities, enabling companies to optimize stock levels, reduce waste, and ensure that only high-quality materials are used in production.

- Supplier Management: Quality control extends beyond the company's own operations to include its suppliers. ERP systems facilitate supplier management by providing tools for evaluating supplier performance, conducting audits, and enforcing quality standards throughout the supply chain. This ensures that only reliable and quality-assured suppliers are selected and retained.

- Batch Tracking and Recall Management: In the event of a quality issue or product recall, ERP systems streamline the process of identifying affected batches, notifying customers and regulatory authorities, and managing the recall process efficiently. This capability is essential for minimizing the impact on brand reputation and customer trust.

- Continuous Improvement: By capturing data on quality control processes and outcomes, ERP systems support continuous improvement initiatives. Companies can use this data to identify areas for optimization, implement corrective actions, and monitor the effectiveness of quality improvement efforts over time.

- Customer Feedback Integration: Customer feedback is a valuable source of information for improving product quality and customer satisfaction. Food and beverage ERP systems can integrate with customer feedback channels such as surveys, reviews, and social media platforms. This integration enables companies to capture, analyze, and act upon customer feedback in real time, allowing for swift adjustments to product formulations, packaging designs, or manufacturing processes to address emerging quality concerns and meet evolving consumer preferences. By incorporating customer insights into their quality control strategies, companies can enhance brand loyalty, drive product innovation, and gain a competitive edge in the marketplace.

- Optimized Resource Allocation: MRP software systems enable dynamic resource allocation based on real-time quality control data, ensuring efficient utilization of resources and cost optimization without compromising on quality.

- Improved Collaboration and Transparency: Manufacturing ERP systems foster collaboration and transparency across departments and stakeholders, facilitating information exchange, communication, and alignment of quality control efforts for enhanced efficiency and effectiveness.

In essence, food and beverage ERP systems serve as a strategic tool for enhancing quality control practices, driving operational efficiency, ensuring regulatory compliance, and ultimately safeguarding brand reputation and customer satisfaction.

Overall, Deskera serves as a comprehensive food and beverage ERP solution that empowers businesses to strengthen their quality control practices, ensure product safety and integrity, and maintain compliance with regulatory standards.

By leveraging Deskera's capabilities, businesses can enhance operational efficiency, reduce risks, and deliver high-quality products that meet customer expectations.

Related Articles