Are inefficiencies in your inventory management impacting your business performance? ERP software for inventory management provides a powerful solution to streamline operations, reduce costs, and enhance overall efficiency.

By integrating various business processes into a unified system, ERP software helps manage inventory more effectively, ensuring that your business stays competitive in a dynamic market.

ERP (Enterprise Resource Planning) software is designed to optimize inventory management through real-time data and advanced features. It automates routine tasks, improves demand forecasting, and enhances operational efficiency. With ERP systems, businesses can achieve precise inventory control, minimize waste, and improve decision-making processes.

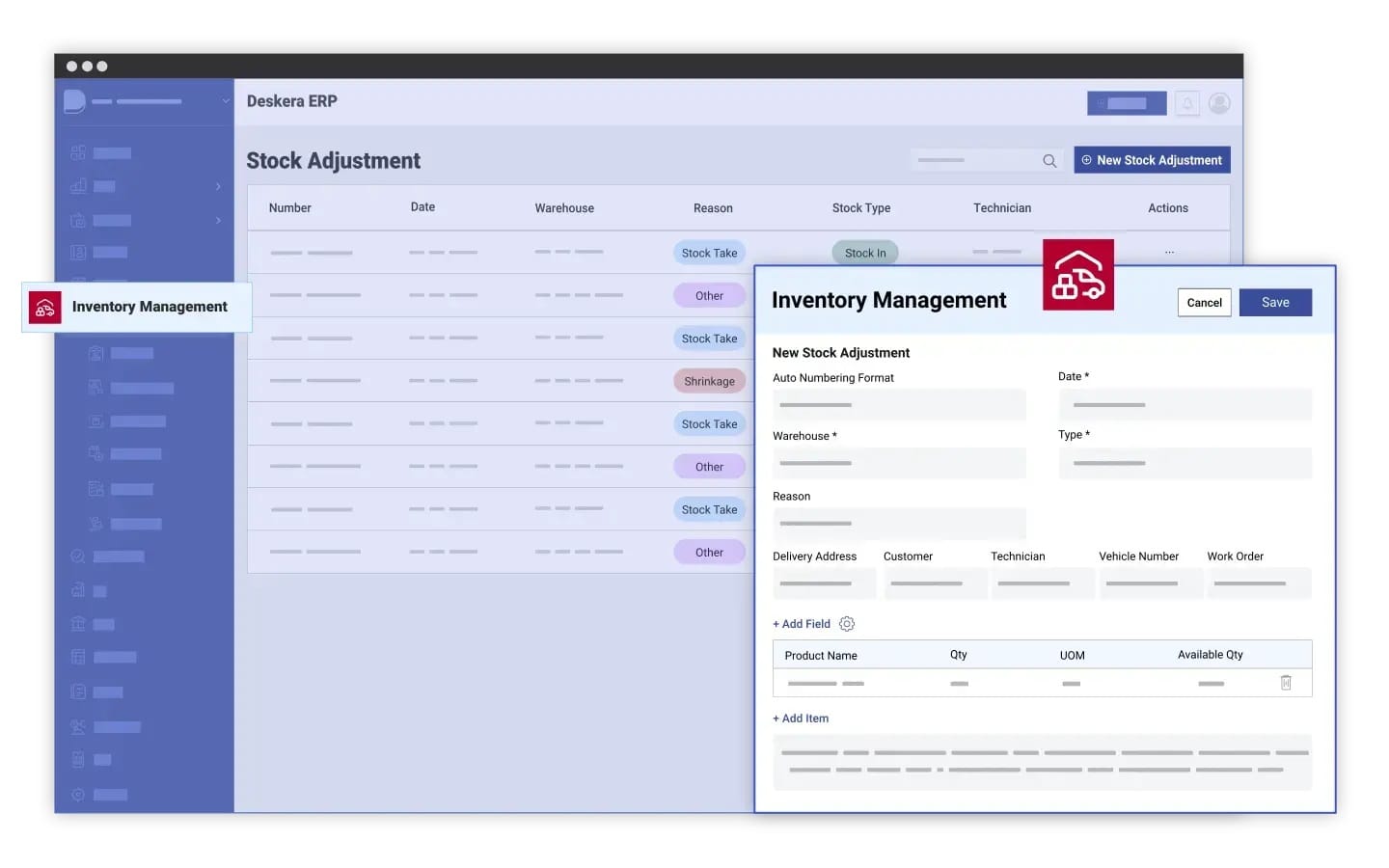

A prime example of effective ERP software is Deskera ERP, which offers a comprehensive suite of tools specifically for inventory management. Deskera ERP excels with features like real-time tracking, automated replenishment, and demand forecasting, helping businesses streamline their inventory operations. By adopting Deskera ERP, you can leverage advanced technology to drive growth and efficiency in your inventory management processes.

This guide will delve into how ERP systems can transform your inventory management practices, ensuring your business remains competitive and agile.

What is ERP Software for Inventory Management?

ERP (Enterprise Resource Planning) software is a comprehensive suite of integrated applications designed to manage and automate various business processes within an organization.

ERP software for inventory management is a specialized subset of ERP systems that focuses on optimizing inventory control and management. By centralizing inventory data and automating processes, ERP software helps businesses streamline their inventory operations, ensuring accurate stock levels, improved order fulfillment, and efficient resource utilization.

ERP systems for inventory management function by integrating inventory data with other business processes, such as procurement, sales, and production. This integration provides real-time visibility into inventory levels, enabling businesses to make informed decisions and respond swiftly to changes in demand.

For manufacturing operations, inventory management ERP software for manufacturing is crucial as it supports complex inventory needs, such as managing raw materials, work-in-progress, and finished goods.

The ERP system automates key tasks like stock tracking, order processing, and demand forecasting, thereby enhancing overall efficiency and reducing the risk of errors. ERP software for inventory management is essential for businesses looking to optimize their inventory processes and drive operational success.

Key Features of ERP Software for Inventory Management

1. Real-Time Inventory Tracking: ERP software provides continuous visibility into inventory levels across all locations. This feature helps businesses monitor stock quantities, track movements, and view the current inventory status instantaneously, preventing issues such as stockouts or overstocking.

2. Automated Replenishment: ERP systems automate inventory reordering based on predefined thresholds and forecast data. This automation minimizes manual intervention, ensuring inventory levels are replenished accurately and timely without constant manual checks.

3. Demand Forecasting: ERP software uses historical data and market trends to predict future inventory requirements. This forecasting capability allows businesses to prepare for fluctuations in demand and plan inventory levels accordingly.

4. Integration with Other Business Functions: ERP systems integrate inventory management with sales, procurement, and financial modules. This integration ensures that changes in inventory affect related business processes, providing a cohesive operational view and improving decision-making.

5. Inventory Valuation and Reporting: Comprehensive valuation tools and reporting features in ERP software support methods like FIFO (First-In-First-Out) and LIFO (Last-In-First-Out). These tools generate detailed reports on inventory metrics, helping in financial analysis and strategic planning.

6. Barcode and RFID Scanning: ERP systems often support barcode and RFID technology, enhancing the speed and accuracy of inventory tracking. Scanning tools help automate stocktaking and reduce errors associated with manual entry.

7. Multi-Location Management: For businesses with several locations, ERP software centralizes inventory management, allowing for synchronization of stock levels across multiple sites. This feature simplifies managing inventory transfers and maintaining consistent records.

Tailoring ERP Systems for Manufacturing: Key Inventory Management Considerations

When it comes to manufacturing, effective inventory management is not just about tracking raw materials and finished goods—it’s about optimizing the entire production process.

Inventory management ERP software for manufacturing is designed to address the unique challenges that manufacturers face, offering tailored solutions that integrate inventory control with production planning, procurement, and quality management.

Complex Inventory Needs

Manufacturing industries often deal with complex inventory structures, including raw materials, work-in-progress (WIP), and finished products. ERP systems help manage these complexities by providing real-time visibility across all stages of production.

For instance, a manufacturer of automotive parts can use ERP software to track the availability of each component, ensuring that the right materials are in place at the right time to meet production schedules.

Demand-Driven Production

Manufacturers must respond quickly to changing customer demands, which requires precise demand forecasting and inventory planning. ERP systems enable manufacturers to forecast demand accurately based on historical data and market trends, ensuring that inventory levels are aligned with production requirements.

For example, a furniture manufacturer might use ERP software to anticipate seasonal demand spikes and adjust inventory levels accordingly, minimizing the risk of overproduction or stockouts.

Integration with Production Planning

Inventory management in manufacturing is closely tied to production planning and scheduling. ERP systems integrate these functions, allowing manufacturers to plan production runs based on current inventory levels and anticipated demand.

This integration helps in reducing lead times, optimizing resource allocation, and improving overall production efficiency.

For instance, a pharmaceutical manufacturer could use ERP software to synchronize raw material procurement with production schedules, ensuring that production is not delayed due to material shortages.

Quality Management and Compliance

In industries like food and beverage or pharmaceuticals, maintaining high-quality standards and complying with regulations is critical.

ERP systems support quality management by tracking inventory throughout the production process, from raw materials to finished goods. This tracking ensures that all products meet quality standards and regulatory requirements.

For example, a food manufacturer can use ERP software to trace the origin of raw materials, monitor production processes, and maintain records for regulatory compliance.

Cost Control and Waste Reduction

Managing costs and reducing waste are key priorities in manufacturing. ERP systems help manufacturers achieve these goals by optimizing inventory levels, reducing excess stock, and minimizing production waste.

For instance, a manufacturer of electronics might use ERP software to monitor inventory turnover rates and identify slow-moving items, allowing for better inventory management and cost control.

In summary, inventory management ERP software for manufacturing provides manufacturers with the tools needed to manage complex inventory requirements, integrate production planning, ensure quality and compliance, and control costs.

By tailoring ERP solutions to the specific needs of manufacturing, businesses can enhance their production efficiency, reduce waste, and improve their overall competitiveness in the market.

ERP Inventory Management Example

Scenario: A mid-sized fashion retailer uses ERP software to manage inventory across multiple store locations and a central warehouse.

Application of Features:

- Real-Time Inventory Tracking: The ERP system updates stock levels in real-time across all store locations and the central warehouse. For example, when a store sells a jacket, the system immediately adjusts the inventory count at that store and in the central warehouse, ensuring accurate stock information.

- Automated Replenishment: As the jacket inventory at a store reaches a predefined minimum level, the ERP software automatically generates a purchase order to restock the item. This automated process ensures the store does not run out of popular items without manual oversight.

- Demand Forecasting: The ERP software analyzes past sales data and seasonal trends to forecast future demand for different apparel items. This helps the retailer anticipate high demand periods, such as during seasonal sales, and adjust inventory levels in advance.

- Integration with Other Business Functions: When a sale is processed, the ERP system integrates with the financial module to update sales records and adjust financial reports automatically. This integration ensures that inventory changes are reflected in financial statements and budgeting.

- Inventory Valuation and Reporting: The ERP system uses FIFO to manage the inventory valuation of the jackets, ensuring that older stock is sold before newer stock. It also generates comprehensive reports on sales performance and inventory turnover to guide inventory management strategies.

- Barcode and RFID Scanning: Store employees use barcode scanners to quickly check in new jacket shipments and update inventory records. This technology speeds up inventory processes and minimizes manual errors during stock counts.

- Multi-Location Management: The ERP system manages inventory across various store locations and the central warehouse from a unified platform. For instance, if the central warehouse needs to transfer jackets to a specific store, the ERP system tracks the transfer and updates inventory levels at both locations.

This example illustrates how ERP software's key features can be applied in a real-world scenario to enhance inventory management, improve accuracy, and streamline operations across multiple locations.

Benefits of ERP Inventory Management Systems

Implementing an ERP inventory management system can revolutionize how businesses handle their inventory, leading to substantial improvements across various operational areas.

Enhanced Accuracy and Reduced Errors

ERP inventory management systems automate various inventory processes, reducing the likelihood of manual errors. Real-time data updates and automated reconciliation ensure that inventory records are accurate, which helps prevent issues such as stock discrepancies and order fulfillment errors.

Improved Operational Efficiency

By integrating inventory management with other business functions like sales, finance, and procurement, ERP systems streamline workflows and eliminate redundant tasks. This integration facilitates smoother operations, faster order processing, and better coordination across departments.

Better Demand Forecasting

ERP systems use advanced algorithms and historical data to predict future inventory needs. Accurate demand forecasting helps businesses plan inventory levels more effectively, reduce excess stock, and avoid stockouts, leading to more efficient inventory management.

Cost Savings

Efficient inventory management through ERP systems can lead to significant cost savings. Automated replenishment reduces the need for manual intervention and minimizes the risk of overstocking or stockouts. This optimization helps lower carrying costs, reduce waste, and improve cash flow.

Real-Time Visibility

ERP systems provide real-time visibility into inventory levels, sales, and order status. This immediate access to information enables businesses to make informed decisions, respond quickly to changes in demand, and maintain optimal inventory levels.

Streamlined Compliance and Reporting

ERP systems simplify compliance with industry regulations and reporting requirements. Detailed inventory reports and accurate tracking help businesses adhere to standards, perform audits efficiently, and ensure financial transparency.

Scalability and Flexibility

ERP inventory management systems are designed to scale with your business as it grows. They offer flexibility to accommodate increasing inventory volumes, additional locations, and expanded product lines, ensuring that the system continues to meet evolving business needs.

Enhanced Customer Service

By maintaining accurate inventory levels and improving order fulfillment processes, ERP systems help enhance customer service. Businesses can better meet customer expectations, reduce lead times, and provide reliable product availability.

Integrated Supply Chain Management

ERP systems offer comprehensive supply chain management capabilities, including supplier management, procurement, and logistics. This integration helps optimize the entire supply chain, from ordering raw materials to delivering finished products to customers.

Data-Driven Decision Making

With access to detailed inventory data and analytics, ERP systems enable businesses to make strategic, data-driven decisions. Insights into inventory performance, sales trends, and operational metrics help businesses refine their strategies and drive growth.

Overall, ERP inventory management systems provide numerous benefits that enhance accuracy, efficiency, and decision-making, ultimately contributing to improved business performance and growth.

Challenges Associated with Inventory Management and How ERP Software Helps

Inventory management can be fraught with challenges that impact operational efficiency and business performance. ERP software offers solutions to many of these issues, enhancing overall management.

Inaccurate Inventory Data

Maintaining accurate inventory records is crucial, but manual processes often lead to errors and discrepancies. ERP software mitigates this challenge by automating data entry and updates, ensuring real-time accuracy and reducing the risk of stock discrepancies.

Inefficient Reordering Processes

Manual reordering can result in stockouts or excess inventory, impacting customer satisfaction and financial performance. ERP systems automate replenishment based on predefined thresholds and demand forecasts, ensuring timely reorders and optimal inventory levels.

Poor Demand Forecasting

Inaccurate demand predictions can lead to overstocking or stockouts, affecting profitability. ERP software uses historical data and advanced analytics to provide accurate demand forecasts, helping businesses plan inventory more effectively and align with market trends.

Complex Supply Chain Coordination

Managing inventory across multiple suppliers, warehouses, and locations can be challenging. ERP systems offer integrated supply chain management features, allowing businesses to coordinate inventory across all touchpoints, streamline procurement, and optimize logistics.

Lack of Real-Time Visibility

Without real-time insights, businesses may struggle to make informed decisions and respond quickly to changes. ERP software provides real-time visibility into inventory levels, sales, and order status, enabling proactive management and timely decision-making.

Compliance and Reporting Issues

Meeting regulatory requirements and generating accurate reports can be cumbersome with manual systems. ERP systems simplify compliance by automating reporting and providing detailed inventory data, ensuring adherence to standards and efficient audits.

Scalability Challenges

As businesses grow, managing increased inventory volumes and additional locations becomes more complex. ERP software is designed to scale with business growth, offering flexible solutions to handle expanding inventory needs and multi-location operations.

Ineffective Integration

Lack of integration between inventory management and other business functions can lead to inefficiencies. ERP systems integrate inventory management with sales, finance, and procurement, ensuring seamless operations and improved coordination across departments.

How to Choose the Right ERP System for Your Business?

Selecting the right ERP system for your business is crucial for optimizing inventory management and overall operational efficiency. With numerous options available, it’s essential to consider various factors to ensure you choose a system that meets your specific needs.

Here are some key considerations to guide your decision-making process:

Define Your Business Requirements

Start by identifying your business needs and inventory management requirements. Consider factors such as the size of your business, the complexity of your supply chain, and specific functionalities you need.

For businesses with basic requirements, free ERP software for inventory management may provide sufficient features, while larger enterprises might need more comprehensive solutions.

Evaluate Key Features

Look for ERP systems that offer robust inventory management features, including real-time tracking, automated replenishment, and demand forecasting. Assess how well each system aligns with your needs and whether it supports integration with other business functions like sales and finance.

Consider Scalability and Flexibility

Choose an ERP system that can scale with your business as it grows. Ensure the system offers flexibility to accommodate increasing inventory volumes, additional locations, and evolving business processes. A scalable solution will help you avoid the need for frequent system upgrades or replacements.

Assess Usability and Support

The ERP system should be user-friendly and easy to implement. Evaluate the level of training and support provided by the vendor, including documentation, customer service, and technical support. An intuitive interface and reliable support can significantly ease the transition and ongoing use of the system.

Compare Costs and Value

Consider the total cost of ownership, including initial investment, implementation, and ongoing maintenance. While some ERP systems offer free ERP software for inventory management, assess whether these options provide the features and support you need. Compare costs against the value and benefits each system offers.

Test and Validate

If possible, request a demo or trial version of the ERP software to test its functionality and compatibility with your business processes. This hands-on experience will help you evaluate how well the system performs and whether it meets your expectations.

Seek Vendor Recommendations

Consult with industry peers, read reviews, and seek recommendations from vendors or consultants. Learning from others’ experiences can provide valuable insights and help you make a more informed decision.

Choosing the right ERP system is a strategic decision that can significantly impact your business’s efficiency and growth. By carefully evaluating your needs, features, scalability, usability, costs, and vendor support, you can select an ERP system that will enhance your inventory management and support your business objectives.

How to Implement ERP Software for Inventory Management

Implementing ERP software for inventory management is a strategic process that requires careful planning, execution, and ongoing support.

Here’s a step-by-step guide to help you successfully integrate ERP software into your inventory management processes:

Define Your Objectives and Requirements

Begin by identifying the specific goals you want to achieve with your ERP implementation. Are you looking to improve inventory accuracy, streamline order processing, or enhance demand forecasting? Clearly defining your objectives will help guide the selection and customization of the ERP software to meet your inventory management needs.

Choose the Right ERP System

Select an ERP system that aligns with your business requirements, scalability needs, and budget. Consider factors such as the complexity of your inventory, the size of your business, and the level of integration required with other business functions. If cost is a concern, explore options for ERP inventory management software free download that may meet your initial needs.

Assemble an Implementation Team

Form a cross-functional team that includes representatives from inventory management, IT, finance, and other relevant departments. This team will be responsible for overseeing the implementation process, ensuring that all aspects of the ERP system are tailored to meet the specific needs of your business.

Plan the Implementation Process

Develop a detailed implementation plan that includes timelines, milestones, and resource allocation. Consider the scope of the project, including data migration, system customization, and integration with existing processes. Break down the implementation into manageable phases to minimize disruptions to daily operations.

Customize the ERP System

Work with the ERP vendor or implementation partner to customize the software according to your inventory management requirements. This may include configuring workflows, setting up automated replenishment processes, and integrating the system with other business functions like sales and procurement. Ensure that the system is tailored to support your specific inventory structure and operational processes.

Migrate Data

Data migration is a critical step in the implementation process. Ensure that all existing inventory data is accurately transferred to the new ERP system. Cleanse and validate the data to eliminate any errors or discrepancies before migration. This will help ensure the accuracy and reliability of your inventory management processes post-implementation.

Train Your Team

Provide comprehensive training for all users of the ERP system, focusing on how to effectively use the software for inventory management. Ensure that staff members understand how to input data, generate reports, and use the system’s features to manage inventory. Ongoing training and support will help maximize the benefits of the ERP system.

Test the System

Before fully rolling out the ERP software, conduct thorough testing to identify and resolve any issues. Test the system’s functionality, data accuracy, and integration with other business processes. This step will help ensure that the ERP system is ready for full deployment and can handle your inventory management needs effectively.

Go Live and Monitor Performance

Once the system is tested and ready, proceed with the full implementation. Monitor the system’s performance closely during the initial stages of use to identify any issues or areas for improvement.

Regularly review key performance indicators (KPIs) such as inventory accuracy, order fulfillment rates, and stock levels to assess the impact of the ERP system on your inventory management.

Provide Ongoing Support and Optimization

ERP implementation is an ongoing process that requires continuous support and optimization. Regularly update the system, address any technical issues, and refine processes as needed to ensure the ERP system continues to meet your evolving inventory management needs.

By following these steps, businesses can effectively implement ERP software for inventory management, leading to improved accuracy, efficiency, and overall operational performance.

Key Indicators for Deploying Inventory Management Software

Deploying inventory management software is a strategic decision that can significantly impact a business’s efficiency, accuracy, and profitability. However, understanding the right time to implement such a system is crucial.

Here are key indicators that suggest it’s time to deploy inventory management software:

Rapid Business Growth

If your business is experiencing rapid growth, managing inventory manually or with basic tools becomes increasingly difficult. As order volumes increase and your product range expands, inventory management software can help you maintain control and ensure that stock levels meet customer demand without overstocking.

Complex Inventory Needs

Businesses dealing with complex inventory structures—such as multiple warehouses, diverse product lines, or variable lead times—can benefit from inventory management software.

The software provides real-time visibility across locations, automates stock tracking, and helps manage inventory with precision, reducing errors and inefficiencies.

Frequent Stock Outs or Overstocking

If your business frequently encounters stock outs or overstock situations, it’s a clear sign that your current inventory management process is inadequate.

Inventory management software helps optimize stock levels by providing accurate demand forecasting, automated reordering, and real-time stock monitoring, preventing such costly issues.

Increasing Operational Costs

Rising operational costs related to inventory management—such as excess inventory carrying costs, storage fees, or labor costs—indicate that your current system is not efficient.

Deploying inventory management software can streamline processes, reduce waste, and lower these costs by automating and optimizing inventory control.

Inaccurate Inventory Data

If your inventory data is often inaccurate, leading to discrepancies between actual stock and recorded levels, it’s time to consider inventory management software. The software enhances data accuracy through real-time updates and integration with other business systems, ensuring that your inventory records reflect the true state of your stock.

Regulatory Compliance Requirements

In industries with strict regulatory requirements, such as pharmaceuticals or food and beverage, accurate inventory tracking is essential. Inventory management software helps ensure compliance by providing traceability, accurate record-keeping, and the ability to generate reports for audits and regulatory submissions.

Difficulty in Scaling Operations

As your business grows, scaling operations with manual processes or basic tools becomes challenging. Inventory management software is designed to scale with your business, accommodating increased order volumes, expanded product lines, and additional locations without compromising efficiency.

Integration with Other Systems

If your business relies on multiple systems (e.g., ERP, CRM, accounting software), deploying inventory management software that integrates with these systems can streamline operations. Integration ensures that inventory data is consistent across all platforms, enhancing decision-making and operational efficiency.

Best Practices for Improved Inventory Management in ERP

Implementing best practices for inventory management within an ERP system can significantly enhance operational efficiency and accuracy. By following these guidelines, businesses can optimize their inventory processes, reduce costs, and improve overall performance.

Maintain Accurate Data

Ensure that all inventory data entered into the ERP system is accurate and up-to-date. Regularly audit inventory records to identify and correct discrepancies. Accurate data entry is crucial for effective inventory tracking, demand forecasting, and reporting.

Utilize Real-Time Tracking

Leverage the ERP system’s real-time tracking capabilities to monitor inventory levels, movements, and sales. This visibility allows for prompt adjustments and helps prevent issues such as stock outs or overstocking. Real-time data also supports better decision-making and responsiveness to market changes.

Implement Automated Replenishment

Set up automated replenishment processes within the ERP system to manage inventory levels efficiently. Define reorder points and trigger automatic purchase orders when stock reaches predefined thresholds. This practice helps ensure that inventory levels are maintained optimally without manual intervention.

Optimize Demand Forecasting

Use the ERP system’s demand forecasting tools to predict future inventory needs based on historical data and market trends. Accurate forecasts help prevent excess inventory and stockouts, improving overall inventory management and reducing carrying costs.

Integrate Inventory with Other Functions

Ensure that inventory management is seamlessly integrated with other business functions such as sales, finance, and procurement. This integration facilitates synchronized operations, accurate financial reporting, and streamlined order processing.

Monitor and Analyze Key Metrics

Regularly review key inventory metrics such as turnover rates, carrying costs, and order accuracy. Use the ERP system’s reporting tools to generate insights and identify trends. Analyzing these metrics helps in making informed decisions and implementing improvements.

Use Barcode and RFID Technology

Incorporate barcode and RFID technology to enhance inventory accuracy and streamline stocktaking processes. These technologies reduce manual entry errors and speed up inventory tracking and audits.

Train Your Team

Provide comprehensive training for staff members on how to effectively use the ERP system for inventory management. Ensure that team members understand system functionalities, data entry procedures, and reporting tools to maximize the benefits of the ERP system.

Regularly Review and Update Processes

Periodically assess and update inventory management processes to align with changing business needs and industry best practices. Continuous improvement helps maintain efficiency and adapt to new challenges.

Ensure Data Security

Protect inventory data within the ERP system by implementing robust security measures. Control access to sensitive information, regularly back up data, and ensure compliance with data protection regulations.

By adhering to these best practices, businesses can enhance their inventory management processes, improve accuracy, reduce costs, and achieve better operational efficiency with their ERP system.

How Can Deskera ERP Help You with Inventory Management?

Deskera ERP stands out as one of the best ERP for inventory management by offering a comprehensive suite of tools designed to streamline and optimize your inventory processes.

Whether you're a small business or a large enterprise, Deskera ERP provides the flexibility and functionality you need to maintain accurate stock levels, reduce costs, and improve overall efficiency.

Real-Time Inventory Tracking

Deskera ERP allows you to monitor your inventory in real-time across multiple locations. This feature ensures that you always have accurate data on stock levels, helping you avoid stockouts and overstocking. With real-time updates, you can make informed decisions about reordering and inventory allocation.

Automated Reordering

The system includes an automated reordering function that triggers orders when inventory levels fall below predefined thresholds. This ensures that you maintain optimal stock levels without the risk of running out of essential items. By automating this process, Deskera ERP saves time and reduces the likelihood of human error.

Integrated Demand Forecasting

Deskera ERP’s advanced demand forecasting tools analyze historical data and current trends to predict future inventory needs. This feature helps you plan your inventory more effectively, ensuring that you have the right products available when your customers need them, while minimizing excess inventory.

Comprehensive Reporting and Analytics

Deskera ERP provides in-depth reporting and analytics, giving you valuable insights into your inventory performance. These reports help you identify trends, track inventory turnover, and assess the efficiency of your supply chain. With this data, you can make strategic decisions to further optimize your inventory management processes.

Seamless Integration with Other Business Functions

Deskera ERP integrates seamlessly with other essential business functions, such as accounting, sales, and procurement. This integration ensures that your inventory data is consistent and up-to-date across all departments, enhancing collaboration and reducing the risk of errors.

By leveraging these features, Deskera ERP helps you achieve greater control and efficiency in managing your inventory, making it an ideal solution for businesses seeking the best ERP for inventory management.

Key Takeaways

ERP software for inventory management is a transformative solution that drives efficiency, control, and growth in today’s dynamic business environment.

- ERP software for inventory management integrates and automates inventory-related processes, providing businesses with real-time visibility, accuracy, and control over their stock levels across all locations.

- The key features of ERP software, such as real-time tracking, automated reordering, and demand forecasting, are designed to optimize inventory management, reduce costs, and enhance operational efficiency.

- Manufacturing-specific ERP solutions address the unique challenges of managing complex inventory needs, such as coordinating raw materials, production schedules, and just-in-time inventory to maximize production efficiency.

- ERP inventory management systems offer significant benefits, including improved accuracy, cost savings, and scalability, all of which contribute to better overall business performance and competitiveness.

- ERP software addresses common inventory management challenges such as stock discrepancies, demand fluctuations, and inefficiencies by providing automated, data-driven solutions that enhance accuracy and responsiveness.

- Choosing the right ERP system involves evaluating your business’s specific needs, such as scalability, integration capabilities, and industry-specific features, to ensure the system aligns with your long-term goals.

- Successful implementation of ERP software for inventory management requires careful planning, employee training, and ongoing support to ensure the system is fully integrated and delivers its intended benefits.

- Key indicators for deploying inventory management software include rapid business growth, complex inventory needs, and rising operational costs, signaling that it’s time to upgrade from manual processes to a more sophisticated solution.

- Adopting best practices such as regular system updates, continuous employee training, and leveraging data analytics can significantly enhance the effectiveness of your ERP system in managing inventory and driving business success.

- Deskera ERP is a powerful tool for inventory management, offering real-time tracking, automated reordering, and demand forecasting to streamline your operations. Its user-friendly interface and robust features make it one of the best ERP solutions for managing complex inventory needs across various industries. With Deskera ERP, businesses can achieve greater accuracy, reduce costs, and scale efficiently as they grow.

As companies continue to grow and face more complex inventory challenges, implementing an ERP system becomes not just an option but a necessity for sustained success.

Whether you are a small business or a large enterprise, the right ERP software can be the key to achieving better control over your inventory and supporting your business's long-term goals.

Related Articles