ERP (Enterprise Resource Planning) systems are software solutions designed to help companies manage their resources and business processes more efficiently. In the semiconductor industry, where precision and accuracy are critical, implementing an ERP system can be highly beneficial.

Semiconductor companies face unique challenges in managing their operations, including managing a complex supply chain, optimizing production processes, and tracking product quality and performance. By implementing an ERP system, semiconductor companies can streamline their operations, improve efficiency, and increase productivity.

In today's guide, we'll thoroughly learn and understand about ERP for semiconductor industry, features, advantages, and so much more. Before we dive in, let's take a look at the table of content ahead:

- About Semiconductor Industry

- ERP for Semiconductor Industry

- Important Features of ERP for Semiconductor Industry

- Advantages of ERP for Semiconductor Industry

- Disadvantages of ERP for Semiconductor Industry

- Challenges Faced by Semiconductor Industry Without An ERP Implementation

- Solutions ERP offers for Semiconductor Industry

- Future of ERP for Semiconductor Industry

- Frequently Asked Questions (FAQs) Associated with ERP for Semiconductor Industry

- Final Word

- How Deskera Can Assist You with ERP for Semiconductor Industry?

Let's get started!

About Semiconductor Industry

The semiconductor industry is the sector of the electronics industry that deals with the design, manufacture, and distribution of integrated circuits (ICs), also known as semiconductor chips or microchips. These chips are made up of semiconducting materials such as silicon and are the building blocks of modern electronics.

Semiconductors are crucial components in a wide range of products, including computers, smartphones, televisions, cars, medical equipment, and many more. As technology advances, the demand for more powerful and efficient chips continues to grow, making the semiconductor industry one of the fastest-growing and most important sectors in the global economy.

The semiconductor industry is characterized by rapid technological innovation, intense competition, and a high level of investment in research and development. Companies in this industry invest heavily in research and development in order to create new products, reduce manufacturing costs, and increase the performance and functionality of their chips.

Some of the largest companies in the semiconductor industry include Intel, Samsung Electronics, Qualcomm, Texas Instruments, and Broadcom. These companies have a significant impact on the global economy, with billions of dollars in revenue and thousands of employees around the world.

ERP for Semiconductor Industry

An Enterprise Resource Planning (ERP) system is a type of software application that is designed to manage and integrate various business processes and functions within an organization.

ERP software can be particularly useful in the semiconductor industry, where complex manufacturing processes, supply chain management, and inventory control are crucial to success.

Important Features of ERP for Semiconductor Industry

ERP software for the semiconductor industry typically includes features such as:

Product Lifecycle Management (PLM): This feature helps manage the various stages of a product's lifecycle, from design and development to production and end-of-life. It includes features such as engineering change orders, product configuration management, product data management, and collaboration tools to facilitate communication between teams.

Supply Chain Management (SCM):

SCM features help manage the flow of materials and products throughout the supply chain, from procurement to delivery. This includes features such as purchase order management, inventory tracking, demand forecasting, and logistics management.

Manufacturing Execution System (MES):

This feature is designed to manage and optimize the manufacturing process, from raw materials to finished products. It includes features such as scheduling, work order management, quality control, and production tracking.

Quality Management System (QMS):

QMS features help ensure that products meet quality standards and that production processes are compliant with industry regulations. This includes features such as non-conformance management, corrective and preventive actions, and document control.

Inventory Management:

This feature helps manage inventory levels and track the movement of materials and products within the organization. It includes features such as real-time inventory tracking, reorder point setting, and stock level management.

Financial Management:

ERP systems can also include features for managing financial processes such as accounting, invoicing, and purchasing. This includes features such as accounts payable and receivable, general ledger management, and financial reporting.

Business Intelligence:

An ERP system can provide business intelligence tools that help users gain insights into their organization's performance. This includes features such as analytics, reporting, and dashboards to help users make informed decisions.

Some of the leading ERP software providers for the semiconductor industry include SAP, Oracle, and more. These companies offer industry-specific solutions that are tailored to the unique needs of semiconductor manufacturers, with features and functionality that can help improve operational efficiency, reduce costs, and enhance overall performance.

Process History Tracking

Process history tracking is an important aspect of quality control and regulatory compliance in the semiconductor industry. It involves tracking and documenting the various steps involved in the manufacturing process, from the initial design to the final product.

An ERP system can help with process history tracking by providing a centralized database that stores all relevant information related to the manufacturing process. Here are a few ways that ERP can help in process history tracking:

Recording and Tracking data:

ERP systems can capture and store data on each stage of the manufacturing process, including design, production, testing, and shipping. This data can be used to track performance metrics, identify trends, and identify any issues or defects in the process.

Real-Time Tracking:

With real-time data capture, an ERP system can provide instant updates on the status of each stage of the process. This can help identify bottlenecks or other issues that may be delaying production and can help managers make informed decisions about how to address these issues.

Document Management:

An ERP system can help manage documents related to the manufacturing process, including design specifications, product drawings, and test reports. This ensures that all relevant documents are available and easily accessible and helps to ensure that regulatory compliance requirements are met.

Quality Control:

ERP systems can include quality control modules that help ensure that each stage of the manufacturing process meets the necessary quality standards. This can include features such as automated testing, inspection workflows, and non-conformance management.

Regulatory Compliance:

ERP systems can help ensure that the manufacturing process meets regulatory compliance requirements, by providing tools to track and document compliance with regulations such as ISO 9001, RoHS, and REACH.

In summary, an ERP system can help with process history tracking by providing a centralized database for storing and tracking information related to the manufacturing process, and by providing tools for quality control, regulatory compliance, and document management. By using an ERP system, semiconductor companies can improve their manufacturing processes, reduce costs, and ensure regulatory compliance.

Specific Product Identification

In the semiconductor industry, identifying specific products by lot number or date code is critical for quality control and regulatory compliance. This information is used to track the production history of a particular product and to ensure that it meets the necessary quality standards. An ERP system can help with specific product identification by lot number or date code in several ways:

- Lot Traceability: An ERP system can enable lot traceability by assigning unique lot numbers to each batch of products that are manufactured. This makes it easy to track the production history of each product and to identify any issues or defects that may arise.

- Date Code Tracking: An ERP system can track the date of production for each product, enabling managers to quickly identify products that were manufactured within a specific timeframe.

- Inventory Management: An ERP system can help manage inventory by tracking the quantity of each product that is in stock and the location of each product. This makes it easy to identify specific products by lot number or date code when needed.

Track Detailed Product Attributes

In the semiconductor industry, tracking detailed product attributes is crucial for quality control and regulatory compliance. Product attributes may include parameters such as product dimensions, materials used, and electrical characteristics.

An ERP system can help track these detailed product attributes by providing a centralized database for storing and tracking information related to the manufacturing process.

Here are a few ways that an ERP system can help track detailed product attributes in the semiconductor industry:

- Product Data Management: An ERP system can provide product data management (PDM) capabilities, which enable tracking of detailed product attributes such as materials used, component specifications, and physical dimensions. This ensures that all relevant product data is available in a centralized database, making it easy to retrieve and analyze when needed.

- Configurable Product Attributes: An ERP system can enable configurable product attributes, which enable users to customize products according to specific customer requirements. This makes it easy to track and manage product variations, ensuring that each variation is manufactured to the necessary quality standards.

- Inventory Management: An ERP system can help manage inventory by tracking the quantity of each product that is in stock and the location of each product. This makes it easy to identify specific products by their attributes when needed.

Process Cost History

In the semiconductor industry, tracking process cost history is essential for optimizing manufacturing processes and improving cost-efficiency. An ERP system can help track process cost history by providing a centralized database for storing and tracking information related to the manufacturing process.

Following, we've listed few ways that an ERP system can help track process cost history in the semiconductor industry:

- Cost Tracking: An ERP system can provide tools for tracking process costs, such as labor, raw materials, and overhead expenses. By tracking these costs in real-time, managers can identify inefficiencies in the manufacturing process and make data-driven decisions to improve cost-efficiency.

- Material Management: An ERP system can help manage raw materials by tracking inventory levels, ordering materials, and tracking usage. This ensures that materials are used efficiently and reduces waste.

- Production Planning: An ERP system can provide production planning capabilities, enabling managers to schedule production based on resource availability and demand. This helps ensure that resources are utilized efficiently and reduces the risk of overproduction or underproduction.

- Process Optimization: An ERP system can provide tools for process optimization, such as process analysis and workflow automation. This can help identify bottlenecks and inefficiencies in the manufacturing process and streamline processes to improve efficiency and reduce costs.

- Financial Reporting: An ERP system can provide financial reporting capabilities, enabling managers to track costs and revenue for each process. This helps identify profitable and unprofitable processes and make informed decisions about which processes to optimize or eliminate.

Reclamation Handling

Reclamation handling is an important aspect of semiconductor manufacturing, as it involves handling and processing returned products or materials that did not meet quality standards or customer requirements.

An ERP system can help in reclamation handling by providing tools to manage the process of handling and disposing of these materials in a way that minimizes environmental impact and maximizes cost recovery.

Following, we've discussed some crucial ways that an ERP system can help in reclamation handling in the semiconductor industry:

- Tracking and Documenting: An ERP system can provide tools for tracking and documenting the reclamation process, including identifying the products or materials being reclaimed, the reason for the reclamation, and the steps taken to handle and dispose of them.

- Quality Control: An ERP system can provide quality control capabilities for reclamation handling, such as automated testing and inspection workflows. This ensures that the reclaimed products or materials meet the necessary quality standards before they are either reworked, scrapped, or sold as scrap materials.

- Inventory Management: An ERP system can help manage inventory of the reclaimed products or materials, ensuring that they are accurately tracked, and that their disposition status is updated in real-time.

- Financial Reporting: An ERP system can provide financial reporting capabilities for reclamation handling, allowing managers to track the costs and revenue associated with the reclamation process, and make informed decisions about the disposition of the reclaimed products or materials.

- Compliance Management: An ERP system can help ensure that the reclamation process complies with environmental regulations and standards, by providing tools to track and document the disposal of hazardous materials or products.

Integrate with Operations Management

Integration with operations management is an essential requirement for an ERP system in the semiconductor industry. An ERP system can help integrate with operations management by providing real-time visibility into production, inventory, and supply chain operations, allowing managers to monitor and control all aspects of the manufacturing process.

Furthermore, an ERP system can provide real-time reporting and analysis capabilities, allowing managers to track key performance indicators (KPIs) and monitor the performance of the manufacturing process. This helps identify inefficiencies and areas for improvement and allows managers to make data-driven decisions.

Advantages of ERP for Semiconductor Industry

There are several advantages of using an ERP (Enterprise Resource Planning) system in the semiconductor industry. Here are some of the key benefits:

Improved Efficiency:

An ERP system can help streamline processes and improve efficiency by automating repetitive tasks, reducing manual data entry, and providing real-time data for decision making. This can lead to faster production cycles and reduced lead times.

Better Supply Chain Management:

ERP systems provide tools for managing suppliers, tracking orders, and managing inbound logistics. This can help semiconductor companies better manage their supply chain operations, reduce inventory costs, and improve delivery times.

Enhanced Product Quality:

An ERP system can help improve product quality by providing tools for tracking and managing product attributes, specifications, and test results. This can help identify quality issues early in the production process, leading to fewer defects and better product performance.

Improved Data Management:

ERP systems provide a central repository for all production data, including product data, manufacturing instructions, test results, and process parameters. This can help semiconductor companies better manage their data, reduce errors, and improve data integrity.

Better Financial Management:

ERP systems provide tools for managing cash flow, tracking expenses, and generating financial reports. This can help semiconductor companies better manage their finances, reduce costs, and improve profitability.

Improved Customer Service:

An ERP system can help semiconductor companies better manage customer orders, track delivery times, and respond quickly to customer inquiries. This can lead to improved customer satisfaction and better customer retention.

Disadvantages of ERP for Semiconductor Industry

While there are many benefits of using an ERP (Enterprise Resource Planning) system in the semiconductor industry, there are also some potential disadvantages to consider. Here are some of the key challenges associated with ERP systems in the semiconductor industry:

Implementation Complexity:

ERP systems can be complex to implement, especially in highly regulated industries like semiconductors. Furthermore, it may take significant time and resources to configure the system to meet the specific needs of the semiconductor company.

Integration Challenges:

Many semiconductor companies have unique IT systems and processes that may not easily integrate with an ERP system. This can create challenges in data integration and require custom development work to achieve integration.

Cost:

ERP systems can be expensive to implement, especially for smaller semiconductor companies. There may be significant up-front costs associated with licensing the software, configuring the system, and training employees to use it.

Staff Training:

An ERP system can be complex to use, and employees may require significant training to become proficient in using the system. This can create a learning curve that may impact productivity in the short term.

System Performance:

The size and complexity of an ERP system can impact system performance, especially in large organizations with complex processes. This can impact productivity and lead to frustration among employees.

Security and Data Privacy:

ERP systems contain sensitive data that must be protected against unauthorized access. Semiconductors companies, especially those involved in the design and manufacture of sensitive technology, must take extra precautions to ensure the security and privacy of their data.

Challenges Faced by Semiconductor Industry Without ERP Implementation

The semiconductor industry is a complex and fast-paced industry with a large number of moving parts. Without an ERP (Enterprise Resource Planning) system, semiconductor companies may face several challenges, including:

Data Management:

The semiconductor industry generates a large amount of data, including product specifications, manufacturing instructions, test results, and process parameters. Without an ERP system, managing this data can be challenging, leading to data inaccuracies, data silos, and increased risk of errors and quality issues.

Poor Supply Chain Management:

The semiconductor industry relies on a complex network of suppliers, contract manufacturers, and logistics providers to deliver raw materials and finished products. Without an ERP system, managing the supply chain can be difficult, leading to increased inventory costs, longer lead times, and lower customer satisfaction.

Inefficient Processes:

The semiconductor industry involves a large number of processes, from design to manufacturing to testing and packaging. Without an ERP system, managing these processes can be challenging, leading to inefficient workflows, redundant work, and a lack of visibility into the entire process.

Limited Visibility:

Without an ERP system, semiconductor companies may have limited visibility into their operations, including production capacity, inventory levels, and order status. This can make it difficult to make informed decisions and respond quickly to changes in demand or supply.

Inability to Scale:

As semiconductor companies grow, managing their operations becomes more complex. Without an ERP system, managing growth can be difficult, leading to a lack of scalability and the need for manual processes that can limit productivity and efficiency.

Solutions ERP offers for Semiconductor Industry

An ERP (Enterprise Resource Planning) system can provide many solutions for the semiconductor industry, including:

Centralized Data Management:

An ERP system can provide a centralized platform for managing data, including product specifications, manufacturing instructions, test results, and process parameters. This can help ensure data accuracy, reduce data silos, and improve data visibility across the organization.

Streamlined Supply Chain Management:

An ERP system can help semiconductor companies improve their supply chain management by providing real-time visibility into inventory levels, order status, and production capacity. This can help optimize inventory levels, reduce lead times, and improve customer satisfaction.

Improved Process Efficiencies:

An ERP system can help semiconductor companies streamline their processes by automating manual tasks, improving workflow visibility, and reducing redundancies. This can help reduce errors, improve quality, and increase productivity.

Real-time Visibility:

An ERP system can provide real-time visibility into key performance indicators (KPIs), such as production volume, yield rates, and cycle times. This can help semiconductor companies make informed decisions, respond quickly to changes in demand or supply, and identify areas for process improvement.

Scalability:

An ERP system can provide a scalable platform that can grow with the needs of the semiconductor company. This can help support growth, reduce the need for manual processes, and increase productivity and efficiency.

Compliance:

An ERP system can help semiconductor companies meet regulatory compliance requirements by providing a platform for tracking and reporting on compliance activities.

Future of ERP for Semiconductor Industry

The future of ERP (Enterprise Resource Planning) for the semiconductor industry looks promising, as new technology advancements and industry trends continue to shape the way semiconductor companies operate. Here are some potential future developments for ERP in the semiconductor industry:

Integration with IoT and AI: The integration of ERP systems with IoT (Internet of Things) and AI (Artificial Intelligence) technologies can enable real-time data collection, predictive maintenance, and more efficient production processes. This integration can help semiconductor companies optimize their operations, reduce costs, and increase productivity.

Cloud-based ERP Systems: Cloud-based ERP systems can offer several advantages over on-premise systems, including scalability, cost-effectiveness, and flexibility. As the semiconductor industry continues to grow and change, cloud-based ERP systems can provide the necessary agility and scalability to meet new demands.

Increased Use of Analytics: The use of analytics in ERP systems can help semiconductor companies make better business decisions by providing insights into trends, patterns, and opportunities. With the increasing amount of data generated by the semiconductor industry, analytics can play an important role in optimizing operations and improving decision-making.

More Emphasis on Security: With the growing threat of cyber attacks, security will continue to be a top priority for semiconductor companies. ERP systems will need to integrate robust security features to protect sensitive data and prevent cyber threats.

Greater Focus on Sustainability: As the demand for sustainable practices increases, ERP systems will need to support sustainability initiatives, such as tracking carbon emissions and reducing waste. This will require more comprehensive tracking and reporting capabilities within the ERP system.

Frequently Asked Questions (FAQs) Associated with ERP for Semiconductor Industry

Following, we've discussed some important frequently asked questions (FAQs) that might pops up in your mind while learning semiconductor industry ERP. Let's discuss:

Que1: What is the Meaning of Fabless Semiconductor Companies?

Ans: A fabless semiconductor company is a type of semiconductor company that focuses on the design and marketing of semiconductor chips but does not have its own manufacturing facilities.

Instead, fabless semiconductor companies outsource the fabrication of their chips to specialized foundries, which have the equipment and expertise to produce semiconductors on a large scale.

Fabless semiconductor companies typically focus on the design and development of integrated circuits (ICs) for a wide range of applications, such as consumer electronics, telecommunications, and computing. They work closely with foundries to ensure that their designs are optimized for manufacturing, and to ensure that the finished chips meet their performance and quality specifications.

By outsourcing manufacturing, fabless semiconductor companies can focus their resources on research and development, and on building strong relationships with customers and partners. They can also benefit from the economies of scale offered by foundries, which can produce chips at a lower cost than fabless companies could achieve on their own.

Fabless semiconductor companies have become an increasingly important part of the semiconductor industry, as they have enabled a large number of startups and smaller companies to enter the market without the need for significant capital investments in manufacturing facilities. Many of the largest and most successful semiconductor companies today, such as Qualcomm, Broadcom, and Nvidia, are fabless companies.

In summary, fabless semiconductor companies are focused on the design and marketing of semiconductor chips, but outsource their manufacturing to specialized foundries. They play an important role in the semiconductor industry by enabling startups and smaller companies to enter the market without the need for significant capital investments in manufacturing facilities.

Que 2: How Fabless Semiconductor Companies Rely on ERP Software?

Ans: Fabless semiconductor companies rely on ERP (Enterprise Resource Planning) software to manage their operations, from design and development to manufacturing and distribution. Here are some ways that fabless semiconductor companies rely on ERP software:

Product development: Fabless semiconductor companies rely on ERP software to manage the product development process, from design and prototyping to testing and validation. ERP systems provide tools for managing the product lifecycle, tracking design revisions, and managing engineering change orders (ECOs).

Supply chain management: Fabless semiconductor companies rely on ERP software to manage their supply chain operations, from sourcing raw materials to managing inventory levels. ERP systems provide tools for managing suppliers, tracking orders, and managing inbound logistics.

Manufacturing: Fabless semiconductor companies rely on ERP software to manage their manufacturing operations, from production planning and scheduling to quality control and testing. ERP systems provide tools for managing production workflows, tracking work-in-progress, and managing production capacity.

Financial management: Fabless semiconductor companies rely on ERP software to manage their financial operations, from budgeting and forecasting to accounting and reporting. ERP systems provide tools for managing cash flow, tracking expenses, and generating financial reports.

Business intelligence: Fabless semiconductor companies rely on ERP software to provide business intelligence, such as real-time analytics and dashboards, to help them make informed business decisions. ERP systems provide tools for monitoring key performance indicators (KPIs), such as production efficiency and inventory turnover, and identifying areas for improvement.

Que 3: What are some of the features to look for when choosing an ERP system for the semiconductor industry?

Ans: Key features to look for include advanced planning and scheduling, production management, inventory management, quality control, supply chain management, financial management, and reporting and analytics.

Que 4: Can ERP be customized to fit the specific needs of a semiconductor company?

Ans: Yes, ERP systems can be customized to fit the specific needs of a semiconductor company. However, customization can add complexity and cost to the implementation process, so it's important to carefully consider the level of customization required.

Final Word

In conclusion, ERP (Enterprise Resource Planning) systems are highly beneficial for the semiconductor industry. By providing real-time data on inventory management, production planning, supply chain, and financials, ERP systems can help semiconductor companies improve their operational efficiency, reduce costs, and make better-informed decisions.

However, implementing an ERP system can also be challenging and may require significant resources and investment. To ensure successful implementation, semiconductor companies should carefully evaluate the features and customization options of different ERP systems and ensure that the chosen system aligns with their specific business needs.

Overall, with proper planning and implementation, ERP systems can help semiconductor companies stay competitive and achieve their business goals.

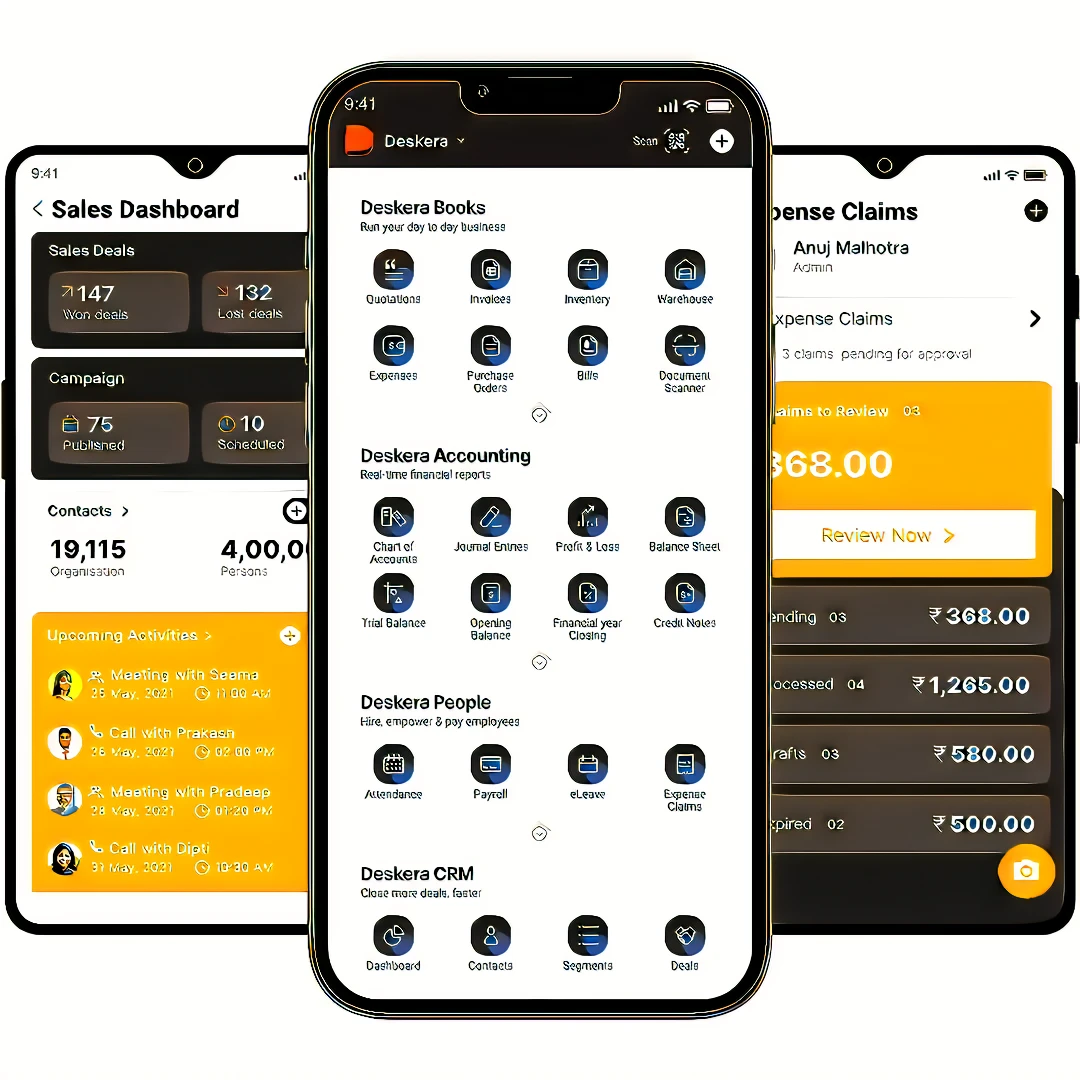

How Deskera Can Assist You with ERP for Semiconductor Industry?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- The semiconductor industry is the sector of the electronics industry that deals with the design, manufacture, and distribution of integrated circuits (ICs), also known as semiconductor chips or microchips. These chips are made up of semiconducting materials such as silicon, and are the building blocks of modern electronics.

- An Enterprise Resource Planning (ERP) system is a type of software application that is designed to manage and integrate various business processes and functions within an organization. ERP software can be particularly useful in the semiconductor industry, where complex manufacturing processes, supply chain management, and inventory control are crucial to success.

- SCM features help manage the flow of materials and products throughout the supply chain, from procurement to delivery. This includes features such as purchase order management, inventory tracking, demand forecasting, and logistics management.

- ERP systems can capture and store data on each stage of the manufacturing process, including design, production, testing, and shipping. This data can be used to track performance metrics, identify trends, and identify any issues or defects in the process.

- An ERP system can enable lot traceability by assigning unique lot numbers to each batch of products that are manufactured. This makes it easy to track the production history of each product and to identify any issues or defects that may arise.

- An ERP system can provide product data management (PDM) capabilities, which enable tracking of detailed product attributes such as materials used, component specifications, and physical dimensions. This ensures that all relevant product data is available in a centralized database, making it easy to retrieve and analyze when needed.

- Reclamation handling is an important aspect of semiconductor manufacturing, as it involves handling and processing returned products or materials that did not meet quality standards or customer requirements. An ERP system can help in reclamation handling by providing tools to manage the process of handling and disposing of these materials in a way that minimizes environmental impact and maximizes cost recovery.

Related Articles