Is your manufacturing business struggling to keep up with evolving market demands and operational complexities? For many manufacturers, managing production schedules, inventory, and supply chain processes efficiently can feel like a daunting task.

This is where ERP (Enterprise Resource Planning) systems come into play. ERP solutions offer a unified platform to streamline operations, integrate various business functions, and provide real-time insights that drive better decision-making.

In the fast-paced world of manufacturing, an effective ERP system is more than just a luxury—it's a necessity. By automating critical processes and centralizing data, ERP systems help manufacturers overcome challenges such as inventory mismanagement, production delays, and supply chain disruptions. With a robust ERP solution, manufacturers can enhance operational efficiency, improve product quality, and achieve greater overall agility.

One standout option for manufacturers is Deskera ERP. Deskera offers a comprehensive suite designed specifically to address the unique needs of the manufacturing sector. Its features include advanced production planning, real-time inventory tracking, and seamless supply chain management.

Deskera ERP empowers manufacturers to streamline their operations, reduce costs, and stay ahead in a competitive market. Whether you're looking to optimize your production processes or gain deeper insights into your business performance, Deskera ERP provides the tools needed to drive success.

What is ERP for Manufacturers?

ERP (Enterprise Resource Planning) for manufacturers is a comprehensive software solution designed to integrate and streamline various aspects of manufacturing operations.

Unlike traditional management systems that may only focus on specific functions, an ERP system centralizes and automates processes across the entire manufacturing organization. This integration helps manufacturers efficiently manage production, inventory, supply chain, finance, and more from a single platform.

At its core, ERP for manufacturers enables the coordination of production scheduling, resource allocation, and inventory management. By providing real-time data and insights, it helps manufacturers optimize workflows, reduce operational inefficiencies, and improve decision-making. Key features typically include production planning and control, inventory tracking, quality management, procurement, and financial management.

For manufacturers, an ERP system is crucial in addressing challenges such as inventory inaccuracies, production bottlenecks, and fragmented data systems. It enhances visibility across the supply chain, ensures compliance with industry standards, and supports scalability as the business grows.

With ERP, manufacturers can achieve better control over their operations, leading to increased productivity, cost savings, and improved customer satisfaction.

Why ERP is Critical in Manufacturing?

In the dynamic world of manufacturing, staying competitive requires more than just producing quality products—it necessitates efficient and well-coordinated operations. This is where ERP (Enterprise Resource Planning) systems become crucial.

ERP is critical in manufacturing for several key reasons:

- Streamlined Operations: ERP systems integrate various functions such as production planning, inventory management, and procurement into a single platform. This integration eliminates the silos that often exist between departments, enabling seamless communication and coordination. By automating processes and centralizing data, ERP helps manufacturers streamline their operations, reduce manual errors, and enhance overall efficiency.

- Real-Time Data and Insights: One of the significant advantages of ERP in manufacturing is its ability to provide real-time data and insights. Manufacturers can access up-to-date information on production status, inventory levels, and supply chain activities. This real-time visibility allows for better decision-making, quicker response to issues, and the ability to adapt to changing market conditions more effectively.

- Improved Inventory Management: Accurate inventory management is critical for manufacturing success. ERP systems offer advanced inventory tracking and management features, helping manufacturers maintain optimal stock levels, reduce excess inventory, and avoid stockouts. By providing detailed visibility into inventory levels and movements, ERP enables more accurate demand forecasting and inventory planning.

- Enhanced Production Efficiency: ERP systems facilitate efficient production scheduling and resource allocation. By integrating production planning with other business processes, manufacturers can better manage production schedules, optimize resource use, and minimize downtime. This leads to improved production efficiency, reduced lead times, and increased capacity to meet customer demands.

- Cost Reduction and Financial Control: Effective financial management is essential for profitability in manufacturing. ERP systems integrate financial data with operational processes, providing a comprehensive view of costs and revenues. This integration helps manufacturers identify cost-saving opportunities, control expenses, and enhance financial accuracy and reporting.

- Compliance and Quality Management: Compliance with industry standards and regulations is a significant concern in manufacturing. ERP systems help ensure compliance by integrating quality management processes and maintaining accurate records. This not only helps manufacturers meet regulatory requirements but also improves product quality and reduces the risk of recalls and defects.

In summary, ERP is critical in manufacturing because it provides a unified platform that enhances operational efficiency, improves data accuracy, and supports better decision-making.

By integrating key business functions and offering real-time insights, ERP systems enable manufacturers to stay competitive, reduce costs, and meet the ever-changing demands of the market.

Key Features of ERP for Manufacturers

ERP (Enterprise Resource Planning) systems offer a range of features specifically designed to address the complex needs of manufacturing operations. These features enhance efficiency, streamline processes, and provide valuable insights.

Here are some key features of ERP for manufacturers:

Production Planning and Scheduling

- Detailed Scheduling: ERP systems provide tools for creating detailed production schedules, optimizing work orders, and managing production capacity.

- Resource Allocation: Efficiently allocate resources such as labor, machinery, and materials to ensure smooth production processes and minimize downtime.

Inventory Management

- Real-Time Tracking: Monitor inventory levels, track stock movements, and manage reorder points in real-time to prevent stockouts and overstocking.

- Automated Reordering: Set up automated reordering processes based on predefined thresholds to maintain optimal inventory levels.

Supply Chain Management

- Supplier Management: Manage supplier relationships, track procurement processes, and ensure timely delivery of raw materials.

- Demand Forecasting: Utilize historical data and predictive analytics to forecast demand and plan procurement and production accordingly.

Quality Management

- Quality Control: Implement quality control processes to monitor and maintain product quality, including inspections and testing.

- Compliance Tracking: Ensure compliance with industry standards and regulations by maintaining accurate records and documentation.

Financial Management

- Cost Tracking: Integrate financial data with production processes to track costs, manage budgets, and analyze profitability.

- Real-Time Financial Reporting: Generate real-time financial reports to monitor performance, manage cash flow, and support strategic decision-making.

Order Management

- Order Processing: Streamline order processing by integrating sales orders with production and inventory management.

- Customer Relationship Management: Manage customer interactions, track orders, and ensure timely fulfillment and delivery.

Data Analytics and Reporting

- Customizable Dashboards: Create customizable dashboards to visualize key performance indicators (KPIs) and operational metrics.

- Advanced Reporting: Generate detailed reports on various aspects of manufacturing operations, including production efficiency, inventory turnover, and financial performance.

Integration Capabilities

- Integration with Other Systems: Seamlessly integrate with other business systems, such as CRM (Customer Relationship Management) and MRP (Material Requirements Planning), to ensure data consistency and streamline processes.

- Mobile Access: Access ERP functionalities from mobile devices to enable remote management and real-time updates.

Compliance and Documentation

- Regulatory Compliance: Ensure compliance with industry regulations and standards by maintaining detailed records and documentation.

- Audit Trails: Track changes and maintain audit trails for transparency and accountability in manufacturing processes.

Scalability and Customization

- Scalable Solutions: Adapt to changing business needs and growth by choosing an ERP system that can scale with your operations.

- Customizable Modules: Customize ERP modules and features to fit the specific requirements of your manufacturing processes and industry.

These features collectively help manufacturers improve operational efficiency, reduce costs, and enhance overall business performance by providing a comprehensive and integrated approach to managing manufacturing operations.

Tailoring ERP Solutions: How Deskera ERP Meets the Needs of Various Manufacturing Sectors

In the diverse world of manufacturing, one size does not fit all. Different sectors have unique requirements and challenges, from automotive and electronics to food and beverage. Deskera ERP understands this diversity and offers tailored solutions to meet the specific needs of various manufacturing industries.

Here's how Deskera ERP adapts to different manufacturing sectors:

1. Automotive Manufacturing

The automotive industry demands precision, efficiency, and scalability. Deskera ERP supports automotive manufacturers with robust features like advanced production scheduling, real-time inventory management, and quality control. Its capabilities ensure seamless coordination of complex supply chains, compliance with stringent industry standards, and effective management of extensive parts inventories.

2. Electronics Manufacturing

Electronics manufacturing involves rapid technological advancements and high-quality standards. Deskera ERP provides tools for managing intricate production processes, tracking components and subassemblies, and ensuring regulatory compliance. The system's real-time data analytics and forecasting capabilities help electronics manufacturers stay agile and responsive to market changes.

3. Food and Beverage Manufacturing

For the food and beverage sector, regulatory compliance, quality control, and inventory management are critical. Deskera ERP offers specialized features for managing batch production, ensuring food safety standards, and tracking ingredient quality. The system also supports efficient supply chain management, helping manufacturers manage perishable goods and optimize production schedules.

4. Textile and Apparel Manufacturing

Textile and apparel manufacturers require efficient handling of raw materials, production scheduling, and order management. Deskera ERP provides solutions for managing fabric inventory, coordinating production runs, and tracking orders from design to delivery. Its integrated features help streamline operations and improve visibility across the supply chain.

5. Pharmaceutical Manufacturing

The pharmaceutical industry is governed by strict regulations and demands high standards for quality and traceability. Deskera ERP assists pharmaceutical manufacturers with features for compliance tracking, batch management, and quality assurance. The system helps ensure adherence to Good Manufacturing Practices (GMP) and supports detailed record-keeping for audits.

6. Machinery and Equipment Manufacturing

Machinery and equipment manufacturers benefit from Deskera ERP’s capabilities in managing complex production processes and large-scale projects. The system supports project management, production planning, and inventory control, helping manufacturers deliver high-quality machinery and equipment on time and within budget.

Deskera ERP’s Versatility and Customization

Deskera ERP stands out for its ability to adapt to the unique needs of different manufacturing sectors. With customizable modules and industry-specific solutions, Deskera ERP provides a flexible platform that supports diverse manufacturing processes.

Whether you're managing a high-tech electronics factory or a large-scale food production facility, Deskera ERP offers the tools and features necessary to optimize operations, ensure compliance, and drive business growth.

By leveraging Deskera ERP’s tailored solutions, manufacturers across various sectors can enhance their operational efficiency, improve product quality, and stay competitive in their respective industries.

Enhancing Manufacturing Efficiency: How Deskera ERP Optimizes Every Stage of the Production Lifecycle

Deskera ERP is designed to transform how manufacturers operate by enhancing efficiency across the entire manufacturing lifecycle. From initial planning to final delivery, Deskera ERP integrates key processes and provides valuable insights to streamline operations.

Here’s how Deskera ERP boosts efficiency throughout the manufacturing lifecycle:

1. Streamlined Production Planning

Deskera ERP simplifies production planning by providing advanced scheduling tools that optimize resource allocation and minimize downtime. The system’s ability to forecast demand and manage production orders helps manufacturers plan production runs more effectively, ensuring that resources are used efficiently and production goals are met.

2. Real-Time Inventory Management

Efficient inventory management is crucial for manufacturing success. Deskera ERP offers real-time inventory tracking, automated reordering, and comprehensive stock management. By providing accurate visibility into inventory levels, the system helps manufacturers reduce excess inventory, prevent stockouts, and maintain optimal stock levels, which ultimately leads to cost savings and improved production flow.

3. Integrated Supply Chain Management

Deskera ERP enhances supply chain management by integrating procurement, supplier management, and logistics into a unified platform. This integration ensures smooth coordination between suppliers and manufacturers, streamlining procurement processes and reducing lead times. By improving supply chain visibility and collaboration, Deskera ERP helps manufacturers avoid disruptions and maintain efficient operations.

4. Quality Control and Compliance

Maintaining high-quality standards and regulatory compliance is essential in manufacturing. Deskera ERP supports quality control processes with tools for managing inspections, testing, and compliance documentation. The system helps manufacturers adhere to industry regulations, track quality metrics, and address quality issues proactively, ensuring that products meet the required standards and minimizing the risk of recalls.

5. Data-Driven Decision Making

Deskera ERP provides advanced analytics and reporting capabilities that offer valuable insights into manufacturing performance. By analyzing data related to production efficiency, inventory turnover, and financial performance, manufacturers can make informed decisions that drive continuous improvement. The system’s customizable dashboards and reports help identify trends, monitor KPIs, and implement strategies to enhance overall efficiency.

6. Enhanced Order Fulfillment

Efficient order fulfillment is key to customer satisfaction. Deskera ERP streamlines the order management process by integrating sales orders with production and inventory management. This integration ensures accurate order processing, timely production, and on-time delivery. The system also supports customer relationship management, helping manufacturers maintain strong customer relationships and manage order expectations effectively.

7. Scalable and Flexible Solutions

As manufacturers grow and adapt to market changes, Deskera ERP’s scalability and flexibility provide the necessary support. The system can be customized to meet the evolving needs of different manufacturing processes and industries. Whether expanding production capabilities or entering new markets, Deskera ERP offers the tools to manage growth and adapt to new challenges.

In summary, Deskera ERP enhances efficiency across the entire manufacturing lifecycle by optimizing production planning, inventory management, supply chain coordination, quality control, and order fulfillment. By leveraging its integrated features and data-driven insights, manufacturers can streamline their operations, reduce costs, and achieve greater overall efficiency.

Addressing Manufacturing Challenges: How Deskera ERP Provides Solutions

Manufacturers face a variety of challenges, from inventory mismanagement to production inefficiencies. Deskera ERP offers comprehensive solutions designed to tackle these common issues and enhance overall operational efficiency.

Here’s how Deskera ERP addresses key manufacturing challenges:

1. Tackling Inventory Mismanagement

Challenge: Inaccurate inventory levels can lead to stockouts, overstocking, and inefficient use of resources.

Solution: Deskera ERP provides real-time inventory tracking and automated inventory management. The system ensures accurate visibility of stock levels, manages reorder points, and automates the replenishment process. This helps manufacturers maintain optimal inventory levels, reduce excess stock, and avoid disruptions in production.

2. Overcoming Production Inefficiencies

Challenge: Inefficient production scheduling and resource allocation can result in downtime, delays, and increased costs.

Solution: Deskera ERP offers advanced production planning and scheduling tools. The system optimizes production schedules, allocates resources effectively, and minimizes downtime by aligning production activities with demand. This improves overall production efficiency and helps manufacturers meet their production targets more consistently.

3. Managing Supply Chain Disruptions

Challenge: Disruptions in the supply chain can lead to delays, increased costs, and difficulty in meeting customer demands.

Solution: Deskera ERP enhances supply chain management by integrating procurement, supplier management, and logistics into a unified platform. The system provides visibility into supply chain activities, streamlines procurement processes, and facilitates better coordination with suppliers. This helps manufacturers mitigate disruptions and maintain a smooth supply chain.

4. Ensuring Quality and Compliance

Challenge: Meeting quality standards and regulatory requirements can be challenging and time-consuming.

Solution: Deskera ERP supports robust quality control and compliance management. The system enables manufacturers to implement quality checks, track compliance with industry regulations, and maintain detailed records. By ensuring consistent quality and regulatory adherence, Deskera ERP helps prevent defects and reduces the risk of non-compliance.

5. Enhancing Data Visibility and Decision-Making

Challenge: Lack of accurate and timely data can hinder decision-making and strategic planning.

Solution: Deskera ERP provides advanced analytics and reporting capabilities. The system offers real-time data visibility through customizable dashboards and detailed reports. By delivering actionable insights into production performance, inventory levels, and financial metrics, Deskera ERP supports informed decision-making and strategic planning.

6. Streamlining Order Fulfillment

Challenge: Inefficient order processing can lead to delays, errors, and poor customer satisfaction.

Solution: Deskera ERP integrates order management with production and inventory systems. This integration ensures accurate and timely processing of orders, improves coordination between sales and production teams, and enhances on-time delivery. By streamlining order fulfillment, Deskera ERP helps manufacturers meet customer expectations and improve satisfaction.

7. Supporting Scalability and Growth

Challenge: As manufacturing operations expand, managing increased complexity can be challenging.

Solution: Deskera ERP offers scalable and flexible solutions that grow with your business. The system’s modular design allows manufacturers to customize and expand their ERP capabilities as needed. This scalability ensures that Deskera ERP continues to support evolving business requirements and facilitates smooth transitions during periods of growth.

In summary, Deskera ERP effectively addresses common manufacturing challenges by offering solutions that improve inventory management, optimize production processes, enhance supply chain coordination, ensure quality and compliance, and support data-driven decision-making.

By leveraging Deskera ERP’s comprehensive features, manufacturers can overcome obstacles and achieve greater efficiency and success in their operations.

Harnessing the Power of Cloud-Based Deskera ERP: Enabling Remote and Scalable Manufacturing Operations

In today’s fast-paced manufacturing environment, flexibility and scalability are crucial for staying competitive. Cloud-based ERP systems like Deskera ERP offer significant advantages for manufacturers by facilitating remote access and supporting scalable operations.

Here’s how Deskera ERP’s cloud-based solution enhances manufacturing efficiency:

1. Seamless Remote Access

Advantage: With Deskera ERP’s cloud-based platform, manufacturers can access critical business data and applications from anywhere, at any time. This remote access is particularly valuable for teams working in multiple locations or managing operations across different time zones.

Benefit: Remote access allows for real-time collaboration, efficient management of manufacturing processes, and prompt decision-making. It ensures that teams can stay connected and informed, even when they are not on-site, thereby enhancing overall productivity and responsiveness.

2. Scalability to Support Growth

Advantage: Deskera ERP’s cloud-based architecture supports scalable operations, making it easier for manufacturers to adapt to changing business needs and growth. The system can be easily scaled up or down based on production requirements and business expansion.

Benefit: Scalability ensures that manufacturers can add new users, integrate additional modules, and manage increased data volumes without the need for significant infrastructure investments. This flexibility helps businesses grow and adapt to market demands efficiently.

3. Cost-Effective Solution

Advantage: Cloud-based ERP solutions, including Deskera ERP, often come with lower upfront costs compared to traditional on-premises systems. The subscription-based pricing model eliminates the need for significant capital expenditure on hardware and software.

Benefit: The cost-effective nature of cloud-based ERP reduces the financial burden on manufacturers, allowing them to allocate resources more effectively. Ongoing maintenance and upgrades are also managed by the ERP provider, further reducing operational costs.

4. Enhanced Data Security and Reliability

Advantage: Deskera ERP offers robust cloud security measures, including data encryption, regular backups, and compliance with industry standards. The cloud infrastructure ensures high availability and disaster recovery capabilities.

Benefit: Enhanced data security and reliability protect sensitive manufacturing information and ensure that operations can continue smoothly in the event of hardware failures or other disruptions. Manufacturers can trust that their data is secure and accessible when needed.

5. Integration and Flexibility

Advantage: Cloud-based Deskera ERP provides seamless integration with other business applications and systems. This integration allows for a unified view of operations and enhances overall efficiency.

Benefit: The flexibility to integrate with various tools and platforms ensures that manufacturers can customize their ERP environment to fit specific operational needs. This interconnected approach streamlines processes and improves data accuracy across different functions.

6. Real-Time Updates and Innovation

Advantage: Deskera ERP’s cloud-based solution enables continuous updates and access to the latest features and innovations. Manufacturers benefit from regular enhancements without the need for manual upgrades.

Benefit: Real-time updates ensure that manufacturers have access to the most current technologies and functionalities, helping them stay ahead of industry trends and maintain a competitive edge. The continuous innovation enhances operational efficiency and supports evolving business requirements.

In summary, Deskera ERP’s cloud-based solution provides significant advantages for manufacturers by enabling remote access, supporting scalability, reducing costs, enhancing data security, and offering integration flexibility. By leveraging these benefits, manufacturers can optimize their operations, adapt to growth, and stay competitive in a rapidly changing industry landscape.

Best Practices for Implementing Deskera ERP in Manufacturing

Implementing Deskera ERP effectively in manufacturing operations requires careful planning and execution. Adhering to best practices can help ensure a smooth transition, optimize system benefits, and enhance overall efficiency.

Here are key best practices for a successful Deskera ERP implementation:

1. Define Clear Objectives and Goals

Practice: Establish clear objectives and goals for the ERP implementation project. Identify specific business processes that need improvement and set measurable targets for what you hope to achieve with Deskera ERP.

Benefit: Clear objectives provide a roadmap for the implementation process and help align the ERP system with your manufacturing needs. This ensures that the system is tailored to address your specific challenges and goals.

2. Involve Key Stakeholders

Practice: Engage key stakeholders from different departments, including production, inventory management, finance, and IT. Their input is crucial for defining requirements and ensuring that the ERP system meets the needs of all users.

Benefit: Involving stakeholders helps in gathering comprehensive requirements and securing buy-in from users who will be interacting with the system. This collaborative approach facilitates smoother adoption and minimizes resistance to change.

3. Conduct Thorough Needs Assessment

Practice: Perform a detailed needs assessment to understand your current processes, pain points, and areas for improvement. This assessment should guide the customization and configuration of Deskera ERP to fit your specific manufacturing processes.

Benefit: A thorough needs assessment ensures that the ERP system is customized to address your unique operational challenges, resulting in a more effective and relevant solution.

4. Develop a Comprehensive Implementation Plan

Practice: Create a detailed implementation plan that outlines timelines, milestones, resource requirements, and risk management strategies. The plan should also include training schedules and a communication strategy.

Benefit: A well-defined implementation plan helps in managing the project efficiently, keeping it on track, and ensuring that all aspects of the ERP deployment are covered. This minimizes disruptions and enhances project success.

5. Invest in Training and Support

Practice: Provide thorough training for users to ensure they understand how to use Deskera ERP effectively. Offer ongoing support to address any issues and reinforce best practices.

Benefit: Effective training and support empower users to maximize the benefits of the ERP system, reduce errors, and enhance overall productivity. Continuous support helps in resolving issues promptly and maintaining system performance.

6. Monitor and Evaluate Performance

Practice: Continuously monitor and evaluate the performance of Deskera ERP against the defined objectives and goals. Use key performance indicators (KPIs) to assess the system’s impact on your manufacturing processes.

Benefit: Regular monitoring and evaluation help in identifying areas for improvement and ensuring that the ERP system delivers the expected benefits. This enables you to make data-driven adjustments and optimize system performance.

7. Ensure Data Accuracy and Integration

Practice: Focus on ensuring data accuracy during the migration process and verify that Deskera ERP integrates seamlessly with other existing systems, such as supply chain management and CRM tools.

Benefit: Accurate data migration and seamless integration prevent disruptions and ensure that the ERP system operates effectively within your existing IT infrastructure. This enhances data consistency and operational efficiency.

8. Plan for Scalability and Future Needs

Practice: Consider future growth and scalability when implementing Deskera ERP. Ensure that the system can accommodate increasing data volumes, additional users, and evolving business needs.

Benefit: Planning for scalability ensures that Deskera ERP can grow with your business and adapt to future requirements. This avoids the need for frequent system overhauls and supports long-term operational success.

9. Foster a Culture of Continuous Improvement

Practice: Encourage a culture of continuous improvement by regularly reviewing and refining ERP processes and practices. Solicit feedback from users and make iterative enhancements based on their input.

Benefit: A focus on continuous improvement ensures that Deskera ERP remains effective and aligned with changing business needs. It helps in optimizing processes and maintaining a competitive edge in the manufacturing industry.

In summary, implementing Deskera ERP in manufacturing requires careful planning, stakeholder involvement, and ongoing support. By following these best practices, manufacturers can achieve a successful ERP deployment, enhance operational efficiency, and drive continuous improvement.

Deskera ERP: Pioneering the Next Generation of Manufacturing

As the manufacturing industry evolves towards greater digitalization and innovation, Deskera ERP plays a pivotal role in shaping the future of manufacturing operations. By integrating advanced technologies and offering comprehensive solutions, Deskera ERP is at the forefront of driving the next generation of manufacturing excellence.

Here’s how Deskera ERP is leading the way:

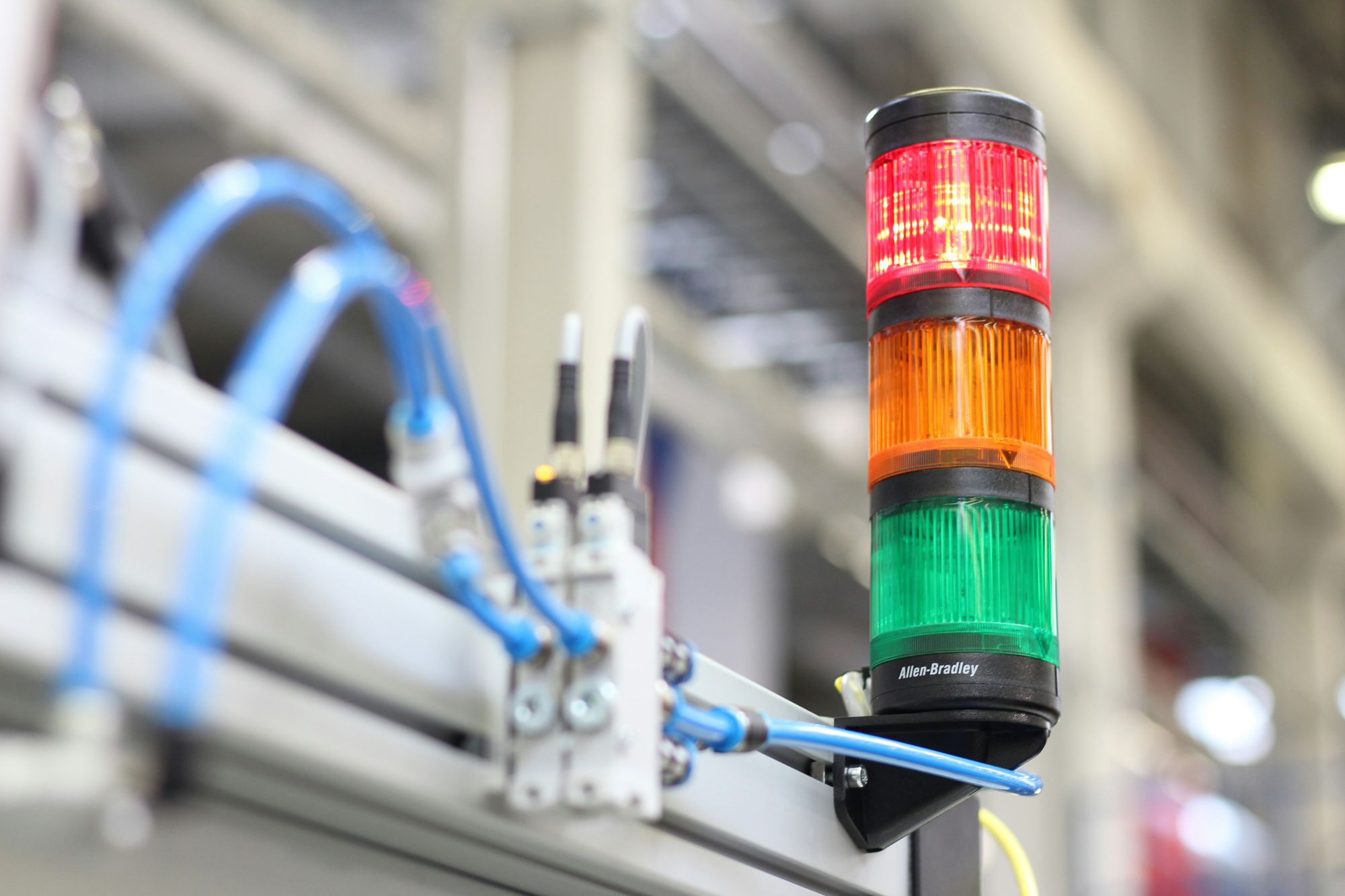

1. Enabling Smart Manufacturing

Role: Deskera ERP integrates with emerging technologies like IoT, AI, and machine learning to enable smart manufacturing practices. This integration allows for real-time monitoring, predictive maintenance, and automated decision-making.

Impact: By leveraging smart technologies, Deskera ERP helps manufacturers optimize their operations, reduce downtime, and enhance production efficiency. It transforms traditional manufacturing processes into highly responsive and intelligent systems.

2. Supporting Digital Transformation

Role: Deskera ERP acts as a central hub for digital transformation initiatives. It consolidates data across various functions, provides real-time analytics, and facilitates seamless integration with other digital tools and platforms.

Impact: Deskera ERP accelerates digital transformation by providing manufacturers with a unified platform for managing their operations. It enhances data visibility, supports data-driven decision-making, and fosters a culture of continuous improvement.

3. Enhancing Flexibility and Scalability

Role: With its cloud-based architecture, Deskera ERP offers unparalleled flexibility and scalability. Manufacturers can easily scale their operations, adapt to market changes, and manage growth without significant infrastructure investments.

Impact: The scalability of Deskera ERP ensures that manufacturers can expand their operations smoothly and efficiently. It supports the dynamic needs of modern manufacturing environments and enables businesses to stay agile and competitive.

4. Driving Sustainability and Efficiency

Role: Deskera ERP supports sustainable manufacturing practices by providing tools for efficient resource management, waste reduction, and energy optimization. It also helps track and report on sustainability metrics.

Impact: By promoting sustainability, Deskera ERP helps manufacturers reduce their environmental footprint and comply with regulatory standards. It enhances operational efficiency and supports corporate social responsibility initiatives.

5. Facilitating Collaboration and Innovation

Role: Deskera ERP fosters collaboration across departments and with external partners. It provides a centralized platform for communication, project management, and collaborative problem-solving.

Impact: Enhanced collaboration drives innovation and improves cross-functional coordination. Deskera ERP’s collaborative features enable manufacturers to streamline processes, accelerate product development, and respond effectively to market demands.

6. Offering Advanced Analytics and Insights

Role: Deskera ERP leverages advanced analytics and big data to provide actionable insights into manufacturing operations. It offers real-time dashboards, trend analysis, and predictive analytics.

Impact: Advanced analytics empower manufacturers to make informed decisions, identify trends, and anticipate potential issues. Deskera ERP’s insights enhance strategic planning and operational efficiency.

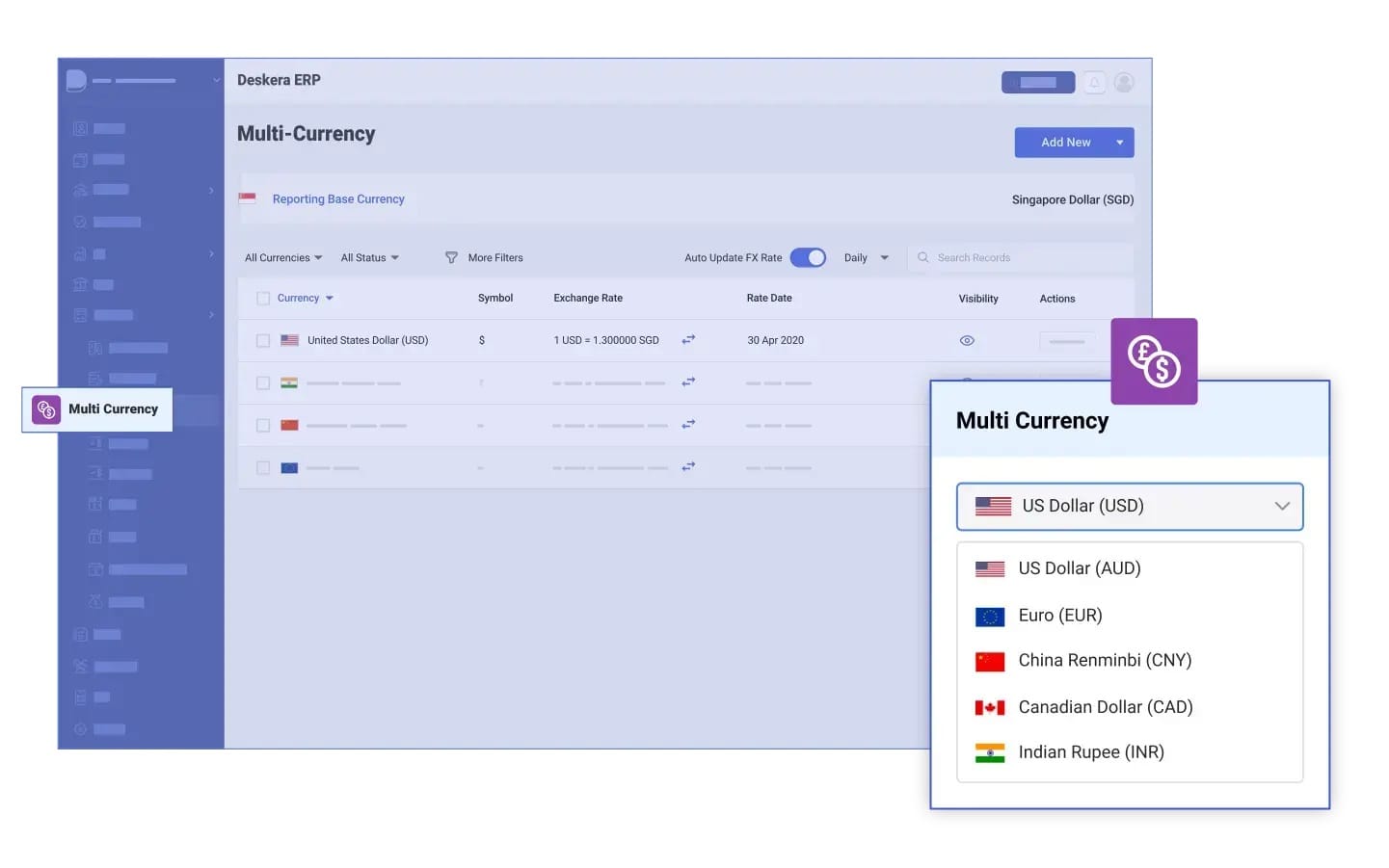

7. Supporting Global Operations

Role: Deskera ERP supports global manufacturing operations by offering multi-currency, multi-language, and multi-location capabilities. It enables seamless management of international supply chains and operations.

Impact: Global support ensures that manufacturers can manage their international operations efficiently and maintain consistency across different regions. Deskera ERP facilitates smooth coordination and integration of global manufacturing activities.

In summary, Deskera ERP is at the forefront of the next generation of manufacturing, driving smart manufacturing, digital transformation, and sustainability. By providing advanced tools and solutions, Deskera ERP empowers manufacturers to adapt to evolving industry trends, enhance operational efficiency, and achieve long-term success.

Integration Capabilities of Deskera ERP for Manufacturers

Deskera ERP offers robust integration capabilities that are essential for modern manufacturing operations. These integrations enhance operational efficiency, streamline processes, and ensure seamless connectivity across various systems. Here’s a closer look at the key integration capabilities of Deskera ERP for manufacturers:

1. Integration with IoT Devices

Capability: Deskera ERP integrates with Internet of Things (IoT) devices to gather real-time data from manufacturing equipment, sensors, and production lines.

Benefit: This integration provides manufacturers with live insights into machinery performance, production status, and environmental conditions. It enables proactive maintenance, reduces downtime, and enhances overall operational efficiency.

2. Connectivity with Supply Chain Management Systems

Capability: Deskera ERP seamlessly integrates with supply chain management (SCM) systems to manage and optimize the entire supply chain process.

Benefit: Integration with SCM systems ensures accurate tracking of inventory, supplier management, and order fulfillment. It improves coordination between procurement, production, and distribution, leading to a more efficient and responsive supply chain.

3. Integration with Customer Relationship Management (CRM) Tools

Capability: Deskera ERP connects with CRM tools to synchronize customer data, sales orders, and service requests.

Benefit: This integration provides a unified view of customer interactions and order history, improving customer service and sales management. It enhances collaboration between sales and manufacturing teams, leading to better customer satisfaction and streamlined order processing.

4. Connectivity with Financial Systems

Capability: Deskera ERP integrates with financial systems for seamless management of accounting, budgeting, and financial reporting.

Benefit: Integration with financial systems ensures accurate financial data, facilitates real-time financial analysis, and supports comprehensive reporting. It streamlines financial operations and helps maintain financial accuracy across manufacturing processes.

5. Integration with E-commerce Platforms

Capability: Deskera ERP connects with e-commerce platforms to manage online orders, inventory levels, and customer data.

Benefit: This integration enables manufacturers to efficiently handle online sales, synchronize inventory with e-commerce platforms, and track order fulfillment. It enhances the overall e-commerce experience and supports effective online business operations.

6. Integration with Human Resources (HR) Systems

Capability: Deskera ERP integrates with HR systems to manage employee data, payroll, and workforce scheduling.

Benefit: Integration with HR systems ensures accurate employee records, efficient payroll processing, and effective management of workforce scheduling. It supports better HR management and aligns human resources with manufacturing operations.

7. Connectivity with Advanced Analytics and BI Tools

Capability: Deskera ERP integrates with advanced analytics and business intelligence (BI) tools to provide deeper insights into manufacturing performance.

Benefit: Integration with BI tools enables manufacturers to analyze large volumes of data, generate actionable insights, and make informed decisions. It enhances data-driven decision-making and supports strategic planning.

8. Integration with Enterprise Asset Management (EAM) Systems

Capability: Deskera ERP connects with EAM systems to manage and maintain manufacturing assets and equipment.

Benefit: Integration with EAM systems supports asset tracking, maintenance scheduling, and lifecycle management. It improves asset utilization, reduces maintenance costs, and ensures optimal performance of manufacturing equipment.

9. Connectivity with Project Management Tools

Capability: Deskera ERP integrates with project management tools to manage manufacturing projects, timelines, and resources.

Benefit: Integration with project management tools facilitates effective planning, execution, and monitoring of manufacturing projects. It enhances project visibility, coordination, and resource allocation.

Top ERP Systems for Manufacturers

If you're looking for an ERP system tailored to manufacturing, several leading solutions cater specifically to this industry’s needs. Here’s a look at some of the best ERP systems for manufacturers, showcasing their key features and benefits.

1. Deskera ERP

Overview: Deskera ERP provides a comprehensive suite of tools designed for various manufacturing sectors. It is particularly well-suited for small to medium-sized manufacturers.

Key Features:

- Integrated Modules: Deskera ERP integrates crucial functions such as inventory management, production planning, and financial management into a single platform. This seamless integration helps eliminate data silos, ensuring cohesive operations across departments.

- Real-Time Analytics: The ERP system includes advanced data analytics and reporting tools that offer real-time insights into manufacturing processes. This feature aids in proactive decision-making and performance optimization by providing timely and actionable data.

- Cloud-Based Architecture: Being cloud-based, Deskera ERP provides remote access and ensures scalability. Manufacturers can manage their operations from anywhere, with the flexibility to adjust resources as their business needs evolve.

- Customization: Deskera ERP allows for extensive customization to cater to specific industry needs. Whether it’s for medical device manufacturing or food production, the system can be tailored to meet unique regulatory and operational requirements.

- Advanced Production Management: Includes tools for managing production schedules, tracking work orders, and optimizing resource utilization. This feature helps manufacturers streamline their production processes and improve efficiency.

- Supply Chain Integration: Facilitates seamless integration with supply chain management processes, enhancing coordination between procurement, production, and distribution. It improves inventory control and reduces lead times.

- Quality Management: Deskera ERP provides robust quality management tools to ensure product consistency and compliance with industry standards. This includes tracking quality metrics, managing inspections, and handling non-conformance issues.

- Customer Relationship Management (CRM): Integrated CRM features help manage customer interactions, track sales orders, and handle customer service requests. This integration supports better customer relationship management and improved sales processes.

- Mobile Accessibility: Deskera ERP offers mobile access, allowing users to manage manufacturing operations on the go. This feature supports remote work and ensures that key information is always within reach.

- Financial Management: Includes comprehensive financial management features such as budgeting, forecasting, and financial reporting. This ensures accurate financial oversight and aids in effective financial planning.

- Multi-Language and Multi-Currency Support: Deskera ERP supports multiple currencies, making it suitable for international operations and facilitating global business management.

- Integration with Third-Party Applications: Offers the capability to integrate with other third-party applications and systems, enhancing overall functionality and allowing manufacturers to leverage existing tools and technologies.

2. Oracle NetSuite

Overview: Oracle NetSuite is a leading cloud ERP solution known for its scalability and extensive functionality, making it ideal for manufacturers of all sizes.

Key Features:

- Comprehensive Manufacturing Modules: Includes advanced production management, supply chain management, and quality control.

- Global Business Management: Supports multi-currency and multi-language capabilities, useful for international operations.

- Real-Time Data Access: Provides real-time insights and reporting across all manufacturing processes.

- Integration: Easily integrates with other Oracle and third-party applications for enhanced functionality.

3. SAP Business One

Overview: SAP Business One is designed for small to medium-sized manufacturers, offering a robust set of features to streamline operations and improve efficiency.

Key Features:

- End-to-End Solution: Covers production planning, inventory management, and financials in a unified system.

- Industry-Specific Features: Tailored solutions for industries such as food manufacturing and medical devices.

- Scalability: Easily scalable to accommodate growing business needs and expanding operations.

- Integration: Seamlessly integrates with SAP’s broader ecosystem and third-party solutions.

4. Infor

Overview: Infor offers ERP solutions tailored for various manufacturing industries, including process and discrete manufacturing.

Key Features:

- Industry-Specific Functionality: Provides specialized features for process manufacturers, food manufacturers, and more.

- Advanced Analytics: Utilizes AI and machine learning to optimize production and supply chain processes.

- Cloud-Based: Flexible cloud deployment options for greater accessibility and scalability.

- User-Friendly Interface: Designed with a focus on user experience and ease of use.

5. Epicor

Overview: Epicor is renowned for its flexibility and scalability, making it suitable for both small manufacturers and large enterprises.

Key Features:

- Comprehensive Manufacturing ERP: Includes modules for production management, supply chain, and financials.

- Customization: Highly customizable to fit specific industry needs and manufacturing processes.

- Cloud and On-Premise Options: Offers both cloud-based and on-premise deployment options.

- Global Reach: Supports multi-national operations with global compliance and reporting.

6. Odoo

Overview: Odoo provides an open-source ERP solution with a modular approach, allowing manufacturers to build a system tailored to their specific needs.

Key Features:

- Modular Architecture: Choose from a wide range of modules, including manufacturing, inventory, and quality management.

- Cost-Effective: Offers a low-cost solution with extensive functionality suitable for small to medium-sized manufacturers.

- Customization: Highly customizable to meet various industry requirements.

- Integration: Easily integrates with other Odoo applications and third-party tools.

7. Acumatica

Overview: Acumatica is a cloud-based ERP solution designed to support a wide range of manufacturing processes and industries.

Key Features:

- Manufacturing Edition: Provides specialized features for production management, inventory control, and quality assurance.

- Cloud-Based: Offers flexible deployment with real-time access to data and applications.

- Scalability: Supports growing businesses with scalable solutions and modules.

- User-Friendly: Intuitive interface and easy-to-navigate dashboards for improved user experience.

8. Microsoft Dynamics 365

Overview: Microsoft Dynamics 365 offers a comprehensive ERP solution with a range of applications designed for various manufacturing needs.

Key Features:

- Integrated Applications: Combines ERP and CRM capabilities to provide a holistic view of manufacturing operations.

- Advanced Analytics: Utilizes AI and machine learning to enhance operational efficiency and decision-making.

- Cloud and On-Premise Options: Flexible deployment options to suit different business environments.

- Customization: Highly customizable to fit the specific needs of various manufacturing sectors.

9. Sage X3

Overview: Sage X3 is an ERP solution designed for mid-sized to large manufacturers, providing a comprehensive suite of features for managing manufacturing operations.

Key Features:

- Global Manufacturing Capabilities: Supports multi-country, multi-currency operations with comprehensive compliance features.

- Advanced Functionality: Includes modules for production, inventory, supply chain, and financial management.

- Cloud and On-Premise Deployment: Flexible deployment options to suit different business needs.

- Customization and Integration: Highly customizable with robust integration capabilities.

Each of these ERP systems offers unique features and benefits tailored to different manufacturing needs, from small manufacturers seeking cost-effective solutions to large enterprises requiring comprehensive and scalable systems. Choosing the best ERP for manufacturing involves evaluating your specific requirements and the capabilities of each system.

Key Takeaways

- ERP systems for manufacturers unify various business processes into a single platform, including production, inventory, and financial management. These systems provide a centralized database that enhances information accuracy and accessibility. They are designed to address the unique operational needs and challenges faced by manufacturing businesses.

- ERP systems streamline manufacturing operations, improving efficiency and reducing operational costs. They offer real-time visibility into production processes, enabling better decision-making and proactive management. By integrating various functions, ERP systems help eliminate data silos and enhance overall productivity.

- Integrated modules for inventory, production, and financial management enhance operational coherence. Advanced analytics and real-time reporting support data-driven decision-making. Customization and scalability ensure that ERP solutions can meet specific industry needs and business growth.

- Deskera ERP offers industry-specific features that address the unique requirements of different manufacturing sectors. It provides customizable modules to adapt to the specific processes and regulations of various industries. Deskera’s flexibility supports diverse manufacturing needs, from small businesses to large enterprises.

- Deskera ERP improves production planning and scheduling, leading to optimized resource utilization. The system streamlines inventory management and supply chain coordination, reducing lead times and costs. Real-time data access and reporting enhance operational efficiency and support continuous improvement.

- Deskera ERP addresses common manufacturing challenges such as inventory control, production delays, and quality management. It offers solutions for regulatory compliance and industry-specific requirements. The system’s integrated approach helps resolve issues related to data consistency and process inefficiencies.

- Deskera ERP’s cloud-based architecture provides remote access and supports scalable operations. It offers flexibility to adjust resources according to business needs and growth. Cloud-based deployment ensures accessibility and continuity in various operational environments.

- Effective planning and stakeholder engagement are crucial for successful ERP implementation. Customizing the ERP system to fit specific manufacturing processes enhances its effectiveness. Ongoing training and support are essential for maximizing the benefits of Deskera ERP.

- Deskera ERP is at the forefront of innovation, offering advanced features that align with the future of manufacturing. It incorporates emerging technologies and trends to support modern manufacturing practices. The system’s capabilities position it as a leader in the evolving landscape of manufacturing ERP solutions.

- Deskera ERP offers robust integration capabilities with other business tools and third-party applications. Its integration features enhance overall functionality and streamline various business processes. The system supports seamless data exchange and collaboration across different platforms.

- Leading ERP systems for manufacturers offer specialized features tailored to industry-specific needs. Key players include Deskera ERP, Oracle NetSuite, SAP Business One, Infor, Epicor, Odoo, Acumatica, Microsoft Dynamics 365, Fishbowl, and Sage X3. Each system provides unique functionalities and benefits, catering to various manufacturing requirements and business sizes.

Related Articles