The field of discrete manufacturing technologies is developing quickly. Enterprise systems improvements and the expanding availability of ERP solutions enable firms to maximize the value of their data and streamline procedures.

Discrete manufacturing ERP solutions reduce redundancy and errors while fostering integration and efficiency because they have a single integrated source of information. Real-time information updates make reporting and analytics simpler than ever.

Modernizing your manufacturing solutions and methods can help you take advantage of exciting new opportunities, despite the fact that change is usually challenging. Businesses who are prepared to move ahead into this uncharted territory will gain an advantage over rivals and attract customers in today's market.

ERP solutions for discrete manufacturing assist manufacturers in maintaining control and visibility over each stage of their workflows. These systems collect a variety of data and information, including customer and inventory data, and keep it organized, searchable, and central.

In this article, we'll describe discrete manufacturing, examine the steps involved, and discuss some of the benefits of this method of production. Following are the topics covered:

- What is Discrete Manufacturing?

- Types of Manufacturing Process

- 3 Key Features of Discrete Manufacturing

- Discrete vs Process Manufacturing

- Discrete Manufacturing Process Flow

- 5 Benefits of Discrete Manufacturing

- 5 Trends in Discrete Manufacturing

- Discrete Manufacturing and ERP Systems

- Conclusion

- Key Takeaways

What is Discrete Manufacturing?

The term "discrete manufacturing" refers to the process of creating final goods that can be easily counted, touched, or seen. Parts and systems including nuts and bolts, brackets, cables, assemblies, and specific items are produced through discrete manufacturing.

- Auto-mobiles, furniture, airplanes, toys, smartphones, and military systems are a few examples of things created using discrete manufacturing.

- Theoretically, a discrete product can be disassembled at the end of its lifespan so that its constituent parts can be recycled.

- By utilizing intelligent edge solutions, Industry 4.0 technologies can be implemented in discrete production at lower prices, higher efficiency, and new benefits.

- Businesses are capturing, evaluating, and acting on data throughout their operations more quickly and efficiently as discrete manufacturing becomes more sophisticated and automated.

What Are Some Examples of Discrete Manufacturing?

Almost every product that is purchased from a store is a product of discrete production. Discrete manufacturing refers to the process where each separate unit of the final product is produced. Non-distinct goods, like oil, can be divided into any number of sizes. A mug is a singular unit and cannot be divided into two parts.

Discrete manufacturing examples could include:

- Clothing

- Vehicles

- Cabling

- Aircraft

- Smartphones

- Computers

- Cookware

Additionally, it could consist of component pieces like:

- Nuts

- Bolts

- Brackets

These constituent parts can each be counted as a unit or recognized as a number. Usually, once something is produced, it cannot be disassembled back into its constituent parts.

Unit production can be used to describe discrete manufacturing. Units can be manufactured in high complexity and low volume, like computers or aircraft, or in low complexity and high volume, like nuts or bolts.

Types of Manufacturing Process

Four other manufacturing techniques are available in addition to discrete manufacture. But first, let's take a short look at some alternative methods:

Repetitive Manufacturing

The continuous manufacture of the same product over a lengthy period of time is known as repetitive manufacturing. Normally, the product is put together in a production line, where a number of operations are carried out sequentially by humans and/or machines.

- There is no cap on the amount generated at which point production halts. Instead, a specific amount is planned for production during each subsequent quarter.

- This circumstance most frequently occurs when a company receives a constant flow of orders that do not change over time.

- In a repetitious manufacturing process, some variation can be introduced to allow various products from the same family to exit the same production line.

- Components can be regularly staged next to the production line as existing component amounts are used up as part of the materials management for repetitive manufacturing.

- The majority of production routes are quite straightforward, allowing for a continuous conversion of raw materials into finished goods without a gap in which incomplete goods are transported to a temporary storage location.

Job Shop Manufacturing

Job shop manufacturing describes itself as a shop with equipment, tools, and facilities that execute identical tasks. The distinct workstations carry out various activities while a product is being manufactured. Small batches of the final items are created (of varying quantities).

- Customers alter their orders to suit their own requirements. This implies that a company will create a small number of non-standardized products.

- Shop floors have a distinct configuration and set of procedural processes because of the level of customization provided by the work shop process.

- A company's products might not all take the same course. Meaning that objects will proceed to the subsequent phase differently and might even visit the same workstation repeatedly.

- Everything is based on how the product is manufactured. Manufacturers who operate job shops can either sell their products directly to consumers, through a wholesaler, or by making parts for other companies.

- Just-in-time (JIT) workflow is frequently used by companies that use job shop production to complete customer orders.

Process Manufacturing

Process manufacturing is the term used to describe the production of goods utilizing formulas or recipes to combine materials, components, and raw resources.

- Chemical or thermal conversion is the usual method used by manufacturers to make things in large quantities.

- This process results in goods that cannot be reversed or divided into smaller components.

- For instance, once ice cream is produced, you cannot remove the ingredients from it. In addition, processed items can often be measured by volume or weight, like a liter of ice cream, as opposed to distinct product units, like a car.

- Recipes that specify the precise proportions of substances to be combined with heat, time, and pressure are used in the production of processed items.

- Precision at every stage of the production process is essential to its success.

- Manufacturers may rely on software and technology to guarantee accuracy and uniformity across all completed products.

- Production processes can be divided into two categories: batch manufacturing and continuous manufacturing.

Batch Manufacturing

A technique called "batch production" allows for the simultaneous production of a number of identical products (rather than one at a time). The manufacturer determines the size of the batch and the frequency of production of these batches.

- Each batch experiences the various manufacturing steps in concert. Meaning that if the previous batch is still in that stage of the cycle, another batch cannot start that step.

- Manufacturers may choose to alter the specifications from one group of products to the next, resulting in variations between each batch.

- It could be essential to alter the size or color of that specific group (depending on the preferences specified in a particular order).

- Each stage of the production cycle can be followed by a quality check. And to make sure there are no performance issues, machinery can be inspected in between batches.

- Other ways make it impossible to have this level of flexibility.

It's crucial to research these competing approaches to determine which best serves the demands of your company. However, it's accurate to claim that small- to medium-sized enterprises are ideally suited for batch manufacturing.

3 Key Features of Discrete Manufacturing

Discrete manufacturing systems have their own special set of accessories, just as conventional manufacturing software. However, when looking for this kind of program, there are a few typical aspects to take into account.

Recognize that not all businesses will benefit equally from common features. BOM, inventory, and serial number management are the top discrete manufacturing features.

Focus on Serial Numbers

- It can be like searching for a needle in a haystack to find specific camera models, lenses, or other accessories that are in or out of your factory.

- If your parts and items include serial numbers, you may easily find them with the help of a serial number management feature.

- In the event of a product recall, this attribute might be useful for identifying changes in parts, such as those related to size or color.

Create and Maintain BOMs

- BOMs are essential to discrete manufacturing because they provide an exhaustive inventory of the parts, assemblies, materials, and other components required to complete an order.

- Orders can be automatically converted into BOMs using BOM management tools, and you are then able to make any necessary revisions.

- You can replicate particular BOMs and store others for record-keeping purposes.

Monitor Inventory

- Keeping an eye on your inventory allows you to stay informed about the materials you have available both at your work site and at other locations.

- When you are running low on stock, common inventory management features let you know.

- With certain inventory management software, you may also set minimum stock levels for each item so that when you reach those levels, you'll know it's time to restock.

Discrete vs Process Manufacturing

Discrete manufacturing is the rival of process manufacturing. In process manufacturing, raw materials are refined according to a formula or recipe to create the completed product; the end product cannot be broken down into its component parts. Contrary to discrete production, process manufacturing produces things that can be identified by individual units.

Pharmaceuticals, food and drink, refined oil, and paints are a few examples of products made through process manufacturing.

Process manufacturing employs a recipe, and the ingredients are combined or improved in batches, as opposed to discrete manufacturing, which uses a bill of materials (BOM) and production routes like an assembly line.

Good examples of products made by process manufacturing include:

- Chemicals

- Food

- Plastics

- Beverages

- Pharmaceuticals

Discrete vs Process Manufacturing Market Requirements

It is crucial to keep in mind that while both process and discrete manufacturers may prefer either make to stock or make to order production strategies, the former is typically more prevalent for process manufacturers and the latter is more prevalent in discrete manufacturing.

In general, once production has begun, the qualities of the commodities produced in process manufacturing and in bulk cannot be changed. Discrete manufacturers, on the other hand, have a tendency to choose make-to-order (as well as engineer to order or configure to order) production processes since the markets they serve value customization.

- This is especially true for products that are highly complex and engineered to order, where manufacturers need to have the flexibility to continuously modify work orders based on back-and-forth communication with the client, ensuring also that the product complies with industry requirements and regulations.

- The majority of vertical markets where discrete manufacturing is used include: machinery (appliances, machine tools, farm equipment, watches, etc.); electronics (computers, televisions, smartphones, tablets, etc.); defense and aerospace (fighters, tanks, submarines, drones, etc.); high-tech (industrial robots, industrial telecommunication arrays, etc.); and automotive and transportation (cars, trucks, buses, vessels, etc.).

- The following industries have the highest concentration of process manufacturing firms: foods and drinks, food processing, paints and coatings, tyres, semiconductor fabrication, steel, aluminum, and other metal fabrication, cosmetics and pharmaceuticals, textiles, plastics, petrochemicals, etc.

What Differentiates Manufacturing From Assembly?

Manufacturing is the process of creating a part or component out of raw materials. A business may produce springs using hardened steel. The act of taking parts, frequently created through manufacturing, and placing them in a predetermined arrangement is called assembly. Computer mouse, for instance, might have steel springs assembled by a machine.

Discrete Manufacturing Process Flow

The following workflows are supported by the discrete manufacturing process:

1. Make to stock: Make-to-stock (MTS) is a manufacturing technique where production scheduling and planning are based on anticipated demand for the product. Orders placed during one manufacturing period are filled using products produced during the following production period.

- In make-to-stock production planning, this means that manufacturing is started beforehand and independently of particular customer orders.

- Make-to-stock is seen as a push-type operation, meaning that supplies, such as raw materials and components delivered by suppliers, are "pushed" through the manufacturing process.

- Planning begins with the availability of supplies and moves forward to the final product.

- Accurate demand forecasting and technologies that enable quick adjustments to shifting projections are two essential components of effective MTS planning.

The increasing number of products for which a manufacturer must forecast demand, as well as naturally unpredictable factors affecting demand, such as natural disasters, health crises, and specific seasonal variations (such as geopolitical or weather-related shortages of raw materials), have made demand forecasting more difficult in almost every market.

2. Make to order: Making a product "to order" (also known as "make to order, or MTO) means that the manufacturer waits until the consumer placed an order before beginning production. In this situation, goods are made specifically for the consumer based on their requirements.

- The MTO production method is best suited for specialized industries like manufacturing aircraft, building, etc.

- The term "Pull Supply Chain" is another name for MTO.

- A pull supply chain approach is one in which actual consumer demand drives the whole production, assembly, and distribution of any commodity.

- Only once a consumer has placed an order does the process of making the product begin, and the number of units produced also depends on the buyer's instructions.

3. Assemble to order: A mixture of the make-to-stock strategy (MTS) and the make-to-order (MTO) strategy is the assemble-to-order approach. When using a make-to-stock technique, all of the product is made up front.

- The goal is to create an inventory that corresponds to projected or guessed consumer demand.

- The steps in this process would be to set a production level, accumulate inventory, and then try to sell as much assembled product as you can.

- It is primarily used for high-volume products, consumables, and commodities that can be purchased individually or in large quantities.

- Making things when customers order them is known as a "make-to-order" technique. Demand drives production, and products are only made after verified orders.

- To put it another way, the supply chain activity doesn't start until there is sufficient proof of client demand. For high-end products or commodities produced in small batches or individually, this tactic is frequently used.

The ATO strategy aims to combine the advantages of both make-to-order and make-to-stock by delivering goods to consumers promptly while enabling the product to be customized or updated in specific ways in response to client requests.

Vertical Markets for Discrete Manufacturing

Discrete manufacturing allows for the production of an exceptionally broad range of goods. The most complex items are sold in key markets, which are supported by supply chains with numerous moving parts and complex global sources.

The following top five markets make significant investments in innovative technologies and discrete manufacturing to enable high-quality and productive output:

- Machinery and heavy equipment

- Automobiles and auto parts

- Aerospace, aviation, and defense

- Electronics and computers

- Consumer goods

The industrial intelligent edge is influencing each of these sectors in different ways. Every day, their operations generate significant amounts of data that may be used using near-real-time analytics to uncover methods to enhance business outcomes.

Assembly Required

The manufacturing of the components itself as well as their assemblage into subsystems and completed goods are all included in discrete manufacturing. Some discrete manufacturing techniques have a lengthy history, such as the Ford Motor Company's assembly line, which was developed one hundred years ago.

Even while assembly lines are still widely used in the automotive industry today, AI-enabled robots and other high-precision CAM systems and tools are increasingly used to complete—or at least support—the majority of the assembly operations.

One example of the current method to auto manufacturing is Audi. For Audi's automated production, Intel developed a scalable, adaptable machine learning platform in close collaboration with Audi engineers and technicians. This lays the groundwork for upcoming breakthroughs, allowing the business to boost productivity and cut costs.

5 Benefits of Discrete Manufacturing

There are remarkable perks that come with discrete manufacturing that you should consider as you choose whether or not to look for one:

Maintain Customer Satisfaction

- Your ultimate goal should be to keep your customers happy because they decide whether or not your things are valuable. They also impact how much money your business makes.

- Make sure the discrete manufacturing ERP you choose has a customer relationship management (CRM) tool or interfaces with your current CRM program.

- A good CRM tool may display precise customer data along with order status, product details, and progress reports.

- It can also maintain proper organization of your consumer data and information and even make precise sales predictions.

Intensify Productivity

Real-time KPI dashboards are a common feature of ERP software, and they can display any possible production bottlenecks.

With an automatic data capture (ADC) tool, they provide a real-time snapshot of operations for discrete manufacturing, including suppliers, transportation costs, market demand, and rivals among others.

Make quality a top priority

- Your primary priority should always be producing high-quality products for your customers. Products of superior quality result in happy customers.

- A discrete manufacturing ERP with a quality management attribute can guarantee that your products are flawless

- It helps with thorough verification and corrective action components to prevent flaws for current and future jobs as well as compliance control to make sure you're adhering to standard manufacturing regulations.

- Most quality management systems have an SPC (statistical process control) feature as well.

- This program measures the output of a process by identifying minute but statistically significant variations so that fixes can be made before errors occur.

Cut down on machine downtime

When you're creating 200 separate macro lens orders and the arm that holds the glass to your lens malfunctions in the middle of production, it's the worst feeling in the world. You now have to spend anything from 30 minutes to two hours or more diagnosing the issue and fixing the mechanical arm, which puts you behind schedule.

To prevent your machines from abruptly failing on you while you're working on a project, preventative maintenance scheduling and alert modules can let you know when it's time to perform normal maintenance tasks and checks.

Keep Supplier Associations Active

When determining whether your vendors are trustworthy, discrete manufacturing software with performance and historical analytics might be useful. This will allow you to avoid problems and boost your company's earnings.

The following are some crucial areas where an ERP or MRP (Material Requirements Planning) system can be helpful in:

- Monitor carrying costs

- Control production

- Evaluate work-in-progress costs

These solutions allow you to quickly view your manufacturing and material expenses. This simplifies your selling price computation in the end.

5 Trends in Discrete Manufacturing

New technologies and trends are applied to every industry to increase productivity. Manufacturing that is discrete is also included. A few of the most recent trends that are becoming more popular include the internet of things (IoT), utilizing your supply chain, cloud-based technologies, and examining business intelligence (BI).

IoT's advantages in discrete manufacturing

As manufacturers raise the amount of automation made possible by AI, machine learning, real-time data analytics, and high performance computing in the cloud and at the edge, discrete manufacturing is moving quickly. Through IoT, these and other cutting-edge technologies connect physical items to the digital world.

- The IoT enables numerous sophisticated manufacturing functions at the core of the Fourth Industrial Revolution, or Industry 4.0, beginning with data collecting and processing at the edge.

- Manufacturers may connect data to operational systems in real time and coordinate supply chain, order management, and delivery operations with production systems thanks to the convergence of information technology (IT) and operational technology (OT) in these new platforms.

- Manufacturers are able to link critical processes that were previously restricted to data silos by creating a software-defined infrastructure that combines IT and OT.

- By making crucial data more widely accessible, they are able to increase product quality through automated quality control procedures, decrease waste through careful process analysis, optimize prices, and create new business prospects.

- Artificial intelligence (AI), machine learning, sophisticated robotics, and real-time data analytics are all used in discrete manufacturing in smart factories to optimize everything from part stocks and labor scheduling to quality control and testing.

- In place of set option packages, the scalable, adaptable strategy enables auto-makers to offer fully customizable vehicles and to develop swiftly in response to consumer demand or regulatory needs.

Although there is still an assembly line in the auto factory of the future, the promise of mass customization is what makes innovative enterprises stand out.

Customer Relationship Management

Although discrete manufacturers have long used CRM technologies, there has been a long-standing absence of processes that adequately support an integrated sales and customer service approach.

This behavior has changed as a result of the advent of the knowledgeable customer. Businesses are starting to implement new tactics to give customers' experiences top priority.

- Customers are interacting and obtaining information more quickly than ever before, therefore businesses must learn to anticipate customer needs.

- Software integration is one method that contemporary technology has made it possible for discrete manufacturers to boost CRM utilization.

- Software integration has advanced significantly since the early days of laborious coding.

- Today's solutions come pre-built and offer quick platform installation along with flawless, two-way data synchronizations.

- For makers of discrete goods, this means that CRM and ERP systems can be linked in order to present a comprehensive perspective of consumers and enhance the buyer's experience.

Management of Your Supply Chain

In discrete manufacturing, maintaining your supply chain is essential. If you don't keep an eye out for production inconsistencies, resources, people, and other things may go unchecked and harm your business in the long term.

There are numerous advantages to purchasing a supply chain management package or discrete ERP with a supply chain management module, including:

- Increasing your logistics

- Cutting costs throughout your entire business

- Streamlining the distribution of goods and materials from point A to point B

- Keeping track of data on standard procedures

- Assessing and maintaining supplier relationships.

Implementing the Cloud

Another growing trend is the incorporation of cloud computing applications. The advantages of cloud programs over on-premise systems are numerous. You don't have to worry about keeping your important documents, files, and data on a real computer, for starters.

- When something is stored in the cloud, it can be accessed from any computer or mobile device that has a steady internet connection.

- The majority of cloud companies also include additional security features like two-step authentication and other safeguards to protect your data in their solutions.

- When it comes to implementation, certain cloud systems are less expensive than those installed on-premise.

Finally, you can collaborate with your provider to include the necessary updates and additions.

BI adoption

Integrating business intelligence (BI) into your discrete manufacturing software can provide you complete visibility of your KPIs and logistics, allowing you to identify any operational bottlenecks. Investing in a discrete manufacturing ERP with a BI tool or BI solution provides benefits like:

- Producing reports with information on costs, practices, staff, and customer interactions

- Creating thorough data visualizations using graphs, charts, films, infographics, animations, and other methods.

- Helping you in negotiations and commercial decisions by providing you with all the necessary data and analytics to support your claims.

- Assuming routine jobs like organizing data, removing duplicate entries, and other things so you and your team can concentrate on high-quality activities.

Discrete Manufacturing and ERP Systems

ERP systems were initially created to manage discrete manufacturing operations under the name manufacturing resource planning (MRP). By giving businesses control and insight over the manufacturing process, these ERP systems help cut down on waste and speed up the production of goods.

- These systems typically perform tasks including managing inventories or supplies, sales orders, the supply chain, finances, and customer relationship management.

- The needs of discrete manufacturing in a variety of industries, including automotive, aerospace, defense, industrial equipment, and electronics, are frequently catered for by ERP systems. The solutions are then often tailored to match the unique requirements of a company.

- Additionally, it is crucial that a business select the best discrete manufacturing software to aid in effective inventory management so that it doesn't lose time obtaining supplies for unforeseen demand.

- It must watch out for overstocking, which would make the products obsolete and raise costs. To handle discrete manufacturing processes, ERP systems are created.

- These ERP systems assist the business in maintaining control over the manufacturing process, cutting waste, shortening the time needed to manufacture products, and gaining a comprehensive understanding of the manufacturing process.

- There are numerous advantages to increased productivity, which is crucial in a sector like discrete manufacturing where output reigns supreme.

- A discrete production method reduces costs and enables quick market adaptability.

- Additionally, it promotes and aids in future business expansion. These are but a few benefits of ERP systems.

Even with all of the potential justifications for using discrete manufacturing ERP systems, transitioning to this type of technology may be a huge undertaking.

The decision is not whether or not to invest in an ERP, but rather what data you require to maximize the return on your investment.

Selecting an ERP System for Discrete Manufacturing

Finding the ideal discrete manufacturing ERP system is typically where this quest begins. And it's one of the more important choices you'll have to make when putting an ERP into place.

Every ERP system for discrete manufacturing should contain a few standard components. These include planning for materials requirements, barcode scanning, production scheduling, and supply chain tools. The requirements of your business come next.

- Every organization faces unique difficulties, and the ERP you choose should attempt to address these issues for you specifically. Integration and customization may also be advantageous.

- They can make sure your system is functional for your needs and that it interfaces with other software your business utilizes.

- Finding out more information about the solution supplier is also a smart option.

- It is a good idea to work with an ERP vendor who is knowledgeable about the manufacturing sector.

- Generalized ERPs and manufacturing ERPs are very distinct from one another.

- Choose a business that is aware of your demands and will make an effort to accommodate them.

Discrete Manufacturing ERP System Implementation

Inside an already intricate enterprise, the ERP deployment process is a complicated series of processes. Because of this, it's crucial to execute plans correctly the first time. It keeps time, money, and other resources from being wasted.

Installing the software is only one part of implementing an ERP system. Long before a user even opens the program, an ERP system for discrete manufacturing is being implemented.

Following the selection of your ERP, the implementation process begins with a thorough analysis of your company, the formation of an implementation team, and the development of a plan that includes:

- Communication with clients, users, and stakeholders

- Budgeting

- A projected timeline

- Training

The following phase is usually migrating data, which entails cleaning and confirming all data, deciding what to do with historical data, backing it all up, moving it, testing it, and verifying it once more. You should budget for an extended time of review once your organization deploys the ERP.

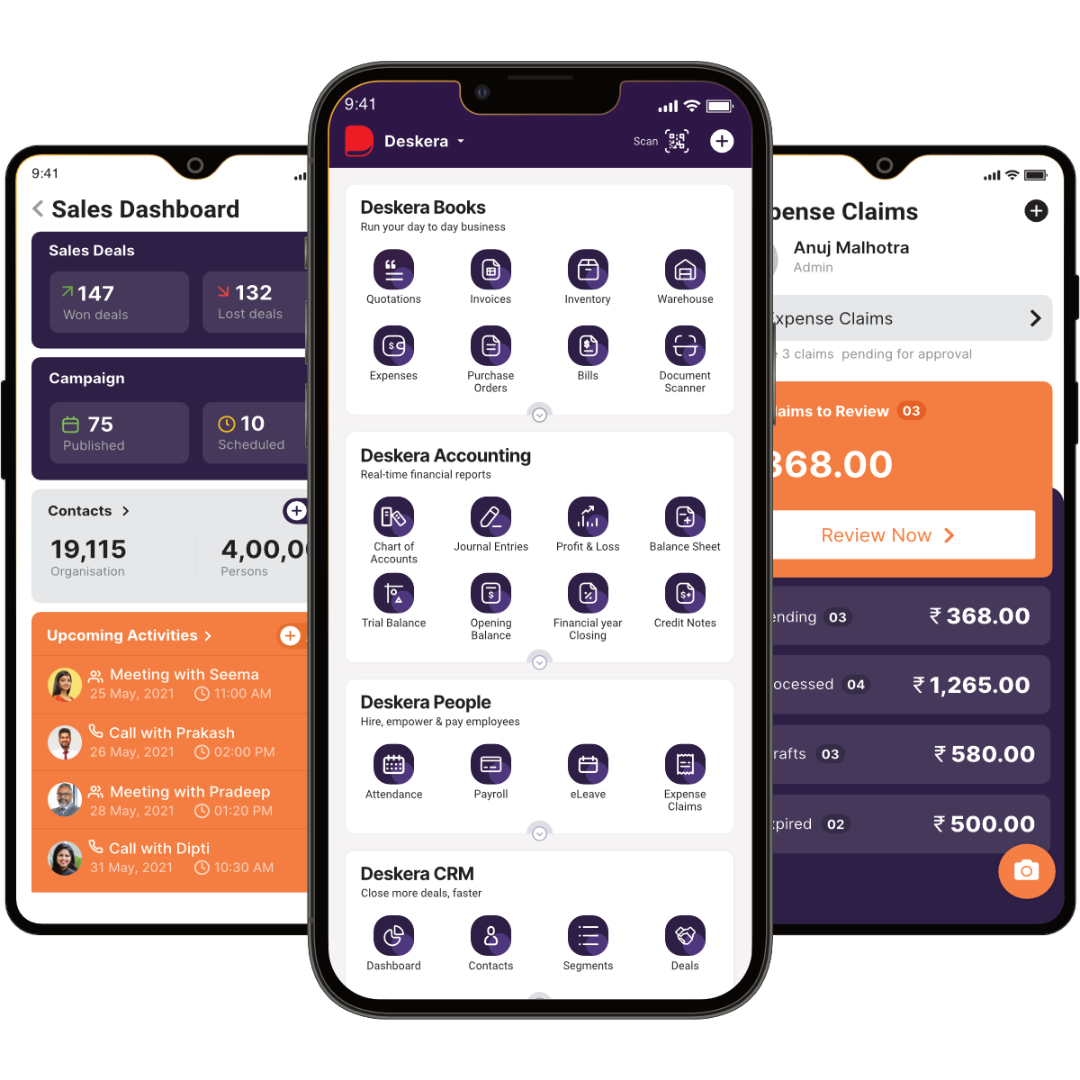

How can Deskera Help You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning, people and machinery use, and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your own dashboard.

Deskera ERP is a complete solution that allows you to manage suppliers, track supply chain activity in real time, and streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Conclusion

A production method known as discrete manufacturing involves creating one product at a time. It makes sense because it requires less capital than mass-producing items in big quantities. The difference between discrete and process manufacturing ought to be obvious by this point.

Hopefully, you were able to determine the type of manufacturing you currently conduct or intend to start. You are able to define discrete manufacturing. At the upcoming meeting of modern manufacturers in your area, you can even discuss different types of manufacturing.

Additionally, you might have learned some new information or learned why your production flow is configured the way it is.

Being an independent manufacturer has both rewards and challenges, one of which is figuring out what is best for your business. Every company is different, and manufacturers are constantly coming up with new strategies.

Key Takeaways

- The manufacturing of items and the kind of manufacturing process a company has established are both described by the terms "discrete manufacturing" and "process manufacturing."

- Individual products made by discrete producers require assembly and are composed of numerous different components.

- Process manufacturers use substances that must be combined chemically through mixing, boiling, or another method to create things in large quantities.

- Unlike processed goods, discretely manufactured goods can typically be disassembled.

- Process manufacturing focuses on formulas and recipes, whereas discrete manufacturing uses bills of materials and routing to specify the components and order of assembly of finished objects.

Related Articles