Have you ever wondered how manufacturers, retailers, and large-scale production units ensure they always have the right materials at the right time? The answer lies in direct procurement—a critical process that involves sourcing raw materials, components, and goods essential for production.

Unlike indirect procurement, which deals with office supplies or maintenance services, direct procurement directly impacts a company's supply chain efficiency, production timelines, and overall profitability.

A well-structured direct procurement strategy helps businesses minimize costs, optimize inventory levels, and build strong relationships with suppliers. However, challenges like supplier reliability, fluctuating material costs, and unexpected supply chain disruptions can significantly affect operations.

To stay competitive, companies must embrace technology-driven solutions that streamline procurement, enhance visibility, and improve decision-making.

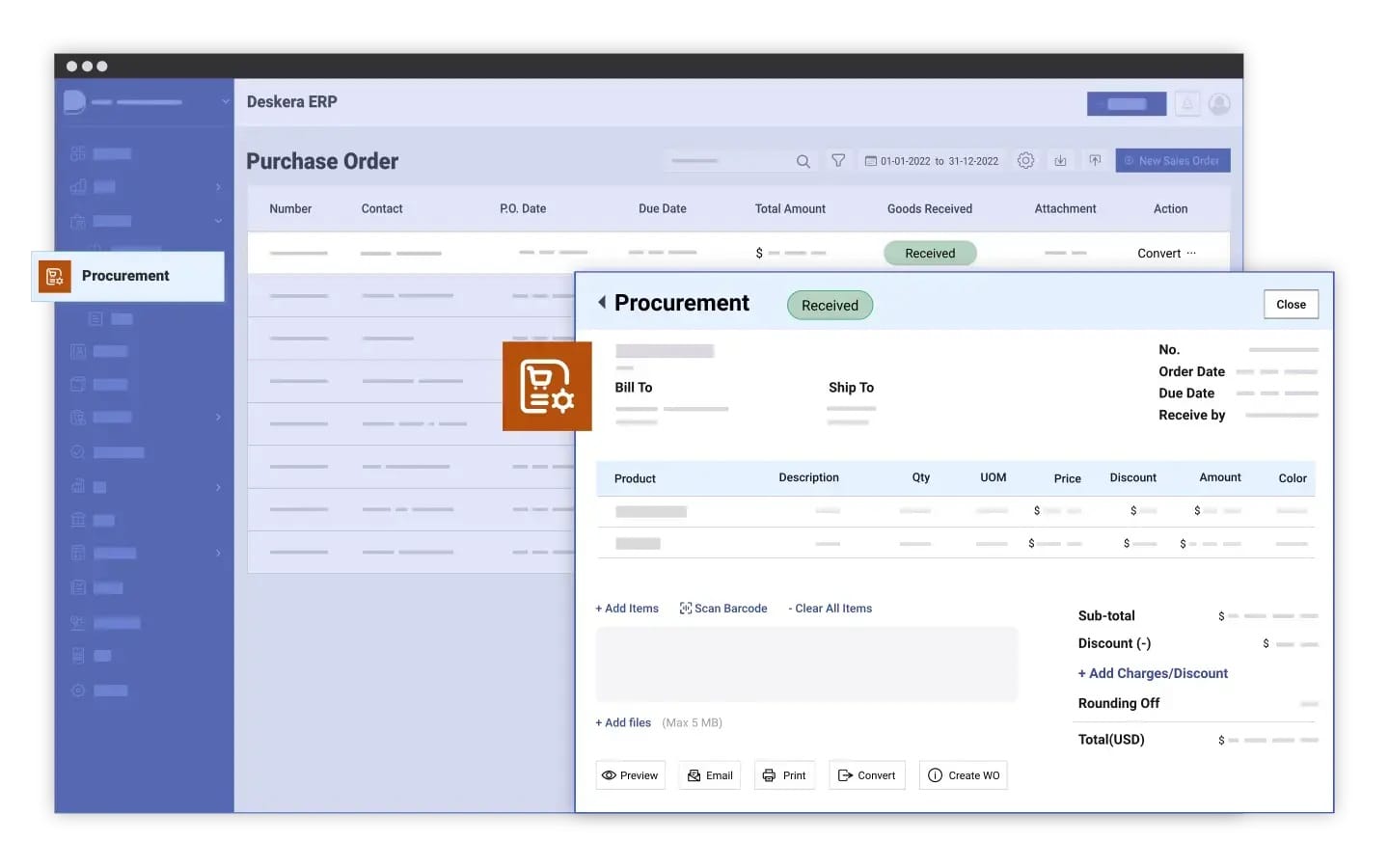

This is where Deskera ERP comes in. With its automated procurement workflows, real-time inventory tracking, AI-driven demand forecasting, and seamless supplier management, Deskera ERP helps businesses manage their procurement operations efficiently.

By integrating purchase orders, supplier contracts, and financial transactions into a single platform, companies can reduce costs, eliminate inefficiencies, and ensure smooth supply chain operations.

In this guide, we will take a deep dive into direct procurement, exploring its key processes, challenges, best practices, and the role of modern technology.

Whether you’re looking to improve supplier collaboration, reduce procurement costs, or enhance operational efficiency, this comprehensive guide will provide you with practical insights to optimize your procurement strategy.

What is Direct Procurement?

Direct procurement, also known as direct spend, refers to the process of acquiring essential raw materials, components, and goods required for producing a company’s core products or services.

This procurement type directly impacts production efficiency, cost management, and supply chain stability, making it a critical function for businesses in manufacturing, construction, retail, and other product-driven industries.

Unlike indirect procurement, which covers office supplies, utilities, and administrative expenses, direct procurement focuses solely on materials that go into the final product.

A well-managed direct procurement process ensures that businesses maintain a steady flow of high-quality materials at optimal costs, avoiding production delays and meeting customer demand. This involves supplier selection, price negotiations, quality assurance, and risk mitigation.

Companies must also monitor market conditions, anticipate supply chain disruptions, and adapt procurement strategies to maintain efficiency.

For example, an automobile manufacturer relies on direct procurement for sourcing steel, electrical components, and rubber, while a food processing company depends on suppliers for ingredients like wheat, dairy, and packaging materials.

To optimize direct procurement, businesses increasingly rely on technology-driven solutions. Advanced ERP and procurement management software, such as Deskera ERP, plays a crucial role in streamlining procurement workflows.

With features like real-time inventory tracking, automated purchase order generation, supplier performance monitoring, and AI-driven demand forecasting, Deskera ERP helps businesses reduce procurement inefficiencies and improve cost control.

These digital solutions provide greater visibility into the supply chain, allowing companies to quickly adapt to market fluctuations, supplier issues, or demand shifts.

Direct vs. Indirect Procurement: Key Differences

Procurement is generally divided into direct and indirect procurement, each serving a distinct function within a business. Understanding their differences is crucial for optimizing supply chain operations, cost efficiency, and overall business strategy.

1. Purpose and Impact

- Direct Procurement involves acquiring raw materials, components, or goods that are directly used in the production of a company’s final products. It directly influences manufacturing efficiency, product quality, and customer satisfaction.

- Indirect Procurement covers purchases that support business operations but are not part of the final product. These include office supplies, marketing services, IT software, and maintenance expenses. While indirect procurement does not affect production output, it impacts workforce productivity, infrastructure, and operational efficiency.

2. Supplier Relationships

- Direct Procurement requires long-term, strategic supplier partnerships to ensure consistent quality, timely deliveries, and cost stability. Companies often negotiate long-term contracts, focusing on supplier reliability, risk management, and demand forecasting.

- Indirect Procurement involves more short-term, transactional relationships, as purchases are often made on an as-needed basis. There is less emphasis on long-term contracts, and procurement teams prioritize cost savings and convenience.

3. Budget and Cost Management

- Direct Procurement typically involves a higher budget allocation since materials and components directly affect production. Procurement teams must ensure cost efficiency, bulk purchasing, and supplier performance monitoring to avoid cost overruns.

- Indirect Procurement spending is more discretionary and varies based on business needs. While important, cost control in indirect procurement is often less structured and more flexible than in direct procurement.

4. Role of Technology

- Direct Procurement relies on advanced procurement and supply chain management software, such as ERP systems like Deskera ERP, to optimize supplier management, automate purchase orders, and track inventory levels in real time.

- Indirect Procurement often utilizes procurement platforms or expense management tools to track business expenses, vendor payments, and approval workflows.

5. Risk Factors and Challenges

- Direct Procurement faces higher risks due to supply chain disruptions, raw material shortages, and price fluctuations. Any failure in this process can result in production delays, increased costs, or loss of customers.

- Indirect Procurement presents fewer risks, but inefficiencies in managing contracts, services, or operational expenses can still affect profitability and productivity.

Key Categories of Direct Procurement

Direct procurement encompasses various categories, each crucial for ensuring efficient production, cost control, and supply chain stability.

The following are the primary categories of direct procurement:

1. Raw Materials

Raw materials are the fundamental building blocks used in manufacturing and production. These materials undergo processing or assembly to create finished products.

Examples:

- Metals (steel, aluminum, copper) for automotive and construction

- Plastics & Polymers for packaging and consumer goods

- Textiles (cotton, wool, synthetic fibers) for apparel production

- Chemicals for pharmaceuticals and industrial applications

2. Components and Parts

This category includes pre-manufactured components that are assembled into final products. Industries such as electronics, automotive, and machinery rely heavily on these components.

Examples:

- Semiconductors & Microchips for electronics and computing

- Mechanical parts (gears, bearings, motors) for industrial equipment

- Batteries & Electrical components for automotive and consumer electronics

- Glass & Optical lenses for medical devices and smartphones

3. Packaging Materials

Packaging is essential for product protection, branding, and logistics. Businesses procure different packaging materials based on product requirements and sustainability goals.

Examples:

- Cardboard boxes & Paperboard for e-commerce and retail

- Plastic containers & Bottles for food and beverage packaging

- Biodegradable packaging for sustainable manufacturing

- Labels & Barcodes for inventory tracking and compliance

4. Equipment and Machinery

Manufacturing processes depend on specialized machinery, tools, and equipment to enhance production efficiency and product quality.

Examples:

- CNC machines & Robotics for automated manufacturing

- Injection molding machines for plastic product manufacturing

- Industrial ovens & Refrigeration units for food processing

- Printing presses for large-scale production of packaging and publications

5. Specialized Services

Certain professional services are directly linked to product development, production, or supply chain management. These services enhance efficiency, innovation, and compliance.

Examples:

- Engineering and Product Design Services for prototyping and development

- Quality Control and Testing Services to ensure compliance with industry standards

- Logistics and Freight Services for transportation of raw materials and components

- Maintenance and Repair Services for machinery upkeep

Advantages of Direct Procurement

Direct procurement plays a vital role in ensuring business continuity, cost efficiency, and supply chain stability.

Below are the key advantages of implementing an effective direct procurement strategy:

1. Cost Optimization and Bulk Purchasing

- Direct procurement enables businesses to negotiate bulk discounts and long-term contracts, reducing per-unit costs.

- Strategic supplier relationships help minimize price fluctuations and ensure cost predictability.

- Efficient procurement practices reduce waste, storage costs, and production inefficiencies.

2. Improved Supply Chain Efficiency

- Ensures a steady supply of raw materials and components, preventing production delays.

- Optimized inventory management reduces stockouts and excess inventory, balancing supply and demand.

- Integrating ERP solutions like Deskera enhances real-time tracking of procurement and inventory.

3. Better Product Quality and Consistency

- Businesses can control material quality by selecting trusted, high-standard suppliers.

- Consistent sourcing leads to uniform product quality, enhancing customer satisfaction and brand reputation.

- Regular supplier audits and performance evaluations help maintain quality compliance.

4. Stronger Supplier Relationships and Collaboration

- Long-term supplier partnerships lead to better pricing, priority service, and innovation opportunities.

- Collaborative efforts allow businesses to develop new products faster and respond to market changes effectively.

- Suppliers become more invested in meeting business needs, offering customized solutions.

5. Reduced Production Risks and Disruptions

- A well-managed direct procurement strategy mitigates supply chain risks, such as material shortages or delays.

- Multi-supplier sourcing and diversified procurement strategies enhance business resilience.

- Advanced procurement software helps forecast demand and plan purchases accordingly.

6. Increased Competitive Advantage

- Companies with streamlined direct procurement processes can offer competitive pricing and faster delivery.

- Improved supply chain agility allows businesses to adapt quickly to market shifts and consumer demands.

- Efficient procurement practices result in higher profitability and stronger market positioning.

7. Enhanced Production Planning and Forecasting

- Direct procurement ensures accurate demand forecasting, helping businesses align material purchases with production schedules.

- Reduces the risk of overstocking or understocking, leading to better cash flow management.

- ERP systems like Deskera provide real-time data on inventory levels, supplier lead times, and production needs.

8. Sustainability and Compliance Benefits

- Businesses can source eco-friendly materials and work with sustainable suppliers, aligning with ESG (Environmental, Social, and Governance) goals.

- Direct procurement ensures regulatory compliance by maintaining supplier certifications, ethical sourcing practices, and industry standards.

- Reducing waste and optimizing transportation through direct supplier relationships helps lower the company’s carbon footprint.

9. Greater Supply Chain Transparency

- End-to-end visibility into procurement processes helps companies track orders, supplier performance, and material quality.

- Digital procurement platforms provide data analytics for better decision-making and supply chain optimization.

- Automated workflows reduce manual errors, improving efficiency and accountability.

10. Faster Response to Market Changes

- Having strong supplier networks and real-time inventory tracking allows businesses to adapt quickly to shifts in consumer demand.

- Direct procurement enhances agility in production, enabling companies to introduce new products faster.

- Businesses can secure priority access to critical materials during supply chain disruptions or high-demand periods.

11. Better Negotiation Power with Suppliers

- Long-term supplier partnerships lead to better pricing, flexible payment terms, and exclusive deals.

- Early supplier involvement (ESI) in product development can result in cost-saving innovations and efficiency improvements.

- Direct procurement helps eliminate intermediaries, reducing extra costs and improving delivery timelines.

12. Integration with Digital Technologies for Efficiency

- AI-powered procurement tools optimize purchasing decisions by analyzing supplier performance, demand patterns, and cost trends.

- Automation in procurement reduces manual intervention, speeding up order processing and approvals.

- Using ERP solutions like Deskera, businesses can centralize procurement data, automate purchase orders, and enhance supplier collaboration.

Challenges in Direct Procurement

While direct procurement is essential for maintaining smooth production operations, businesses often face several challenges that can impact cost efficiency, supplier reliability, and overall supply chain stability.

Below are the key challenges:

1. Supply Chain Disruptions

- Unpredictable events like natural disasters, geopolitical conflicts, or pandemics can disrupt the supply chain, leading to material shortages and production delays.

- Supplier failures or unexpected shutdowns can create bottlenecks in manufacturing.

- Mitigation Strategy: Implement multi-supplier sourcing and use ERP solutions like Deskera to track supplier performance and inventory levels in real-time.

2. Rising Raw Material Costs

- Fluctuations in commodity prices impact the overall profitability and production costs.

- Increased demand for certain materials can drive up prices, making cost predictions difficult.

- Mitigation Strategy: Establish long-term contracts with key suppliers and explore alternative materials when possible.

3. Quality Control Issues

- Inconsistent material quality can lead to defective products, higher rejection rates, and customer dissatisfaction.

- Variations in supplier production processes may lead to non-compliance with quality standards.

- Mitigation Strategy: Implement regular supplier audits and use AI-driven quality monitoring tools for real-time quality checks.

4. Supplier Reliability and Performance Risks

- Dependence on a single supplier increases the risk of delays, quality issues, or sudden price hikes.

- Poor supplier communication can lead to misalignment in delivery schedules and material specifications.

- Mitigation Strategy: Develop supplier performance tracking systems, establish backup suppliers, and maintain strong supplier relationships.

5. Inventory Management Complexities

- Overstocking leads to increased storage costs and waste, while understocking results in production delays and missed customer commitments.

- Inefficient procurement planning may cause excess inventory or material shortages.

- Mitigation Strategy: Use inventory optimization tools like Deskera ERP to balance stock levels based on real-time demand forecasting.

6. Compliance and Regulatory Challenges

- Global supply chains require adherence to various trade regulations, environmental laws, and ethical sourcing policies.

- Non-compliance with import/export regulations can lead to legal penalties and supply chain disruptions.

- Mitigation Strategy: Implement automated compliance tracking to ensure regulatory adherence across global suppliers.

7. Technology Integration and Data Visibility Issues

- Many companies still rely on manual processes for procurement, leading to inefficiencies and errors.

- Lack of real-time visibility makes it difficult to track supplier performance, procurement costs, and inventory movement.

- Mitigation Strategy: Implement digital procurement platforms like Deskera for automated order processing, supplier tracking, and spend analysis.

8. Logistics and Transportation Challenges

- Freight costs and shipping delays can impact production timelines, especially for businesses sourcing materials from multiple locations.

- Customs clearance delays or logistics failures can halt the entire supply chain.

- Mitigation Strategy: Optimize logistics planning, work with reliable third-party logistics (3PL) providers, and use real-time tracking systems.

9. Demand Volatility and Forecasting Errors

- Sudden market changes can make it difficult to predict material requirements accurately.

- Poor demand forecasting leads to excess procurement or insufficient stock, affecting production schedules.

- Mitigation Strategy: Use AI-driven forecasting tools integrated into ERP systems like Deskera to enhance demand accuracy.

10. Risk of Supplier Fraud or Ethical Sourcing Issues

- Some suppliers may misrepresent product quality, pricing, or sourcing methods.

- Ethical concerns, such as child labor, environmental violations, or unfair wages, can damage brand reputation.

- Mitigation Strategy: Conduct regular supplier audits, implement strict vetting processes, and ensure traceability in procurement.

How to Address Direct Procurement Challenges

Direct procurement is crucial for ensuring a steady supply of materials and components necessary for production. However, businesses often face challenges such as supply chain disruptions, cost fluctuations, supplier reliability issues, and compliance risks.

To mitigate these challenges, organizations need to adopt strategic procurement practices, advanced technology, and strong supplier relationships.

1. Strengthen Supplier Relationships & Diversification

- Why It Matters: Relying on a single supplier increases the risk of shortages and disruptions.

- How to Address:

- Develop multi-supplier strategies to reduce dependency on a single vendor.

- Build long-term relationships with key suppliers for better contract terms and reliability.

- Conduct regular performance evaluations and risk assessments to ensure supplier consistency.

2. Use ERP & Procurement Automation Tools

- Why It Matters: Manual procurement processes lead to inefficiencies, errors, and delays.

- How to Address:

- Implement ERP solutions like Deskera to automate order processing, supplier management, and inventory tracking.

- Use AI-powered analytics for better demand forecasting and procurement planning.

- Integrate real-time data tracking to monitor supplier performance and stock levels efficiently.

3. Implement Strategic Cost Management

- Why It Matters: Fluctuations in raw material prices impact procurement budgets.

- How to Address:

- Negotiate long-term contracts with suppliers to lock in stable pricing.

- Leverage bulk purchasing discounts when possible.

- Monitor global market trends to anticipate price shifts and adjust procurement strategies accordingly.

4. Optimize Inventory Management

- Why It Matters: Overstocking increases holding costs, while understocking leads to production delays.

- How to Address:

- Implement just-in-time (JIT) inventory systems to balance stock levels.

- Use automated demand forecasting to ensure optimal stock replenishment.

- Set up safety stock policies to prevent critical shortages.

5. Improve Supply Chain Resilience & Risk Mitigation

- Why It Matters: Unexpected disruptions (e.g., natural disasters, geopolitical issues) can halt production.

- How to Address:

- Develop a risk management plan to identify and mitigate vulnerabilities.

- Maintain buffer stock of critical materials.

- Strengthen supply chain visibility through digital tracking and predictive analytics.

6. Enhance Compliance & Ethical Sourcing

- Why It Matters: Non-compliance with regulations can lead to legal penalties and reputational damage.

- How to Address:

- Implement automated compliance tracking for procurement processes.

- Conduct regular supplier audits to ensure ethical sourcing and adherence to environmental laws.

- Use blockchain technology for improved traceability and transparency in sourcing.

7. Invest in Data-Driven Decision-Making

- Why It Matters: Poor forecasting and decision-making can lead to procurement inefficiencies.

- How to Address:

- Utilize real-time analytics tools to monitor procurement trends and supplier performance.

- Adopt predictive analytics for better procurement planning.

- Train procurement teams on data-driven decision-making strategies.

8. Strengthen Logistics & Transportation Planning

- Why It Matters: Delays in transportation impact production schedules and customer satisfaction.

- How to Address:

- Work with reliable third-party logistics (3PL) providers.

- Use route optimization software to streamline deliveries and reduce costs.

- Monitor shipments in real-time using IoT-based tracking solutions.

9. Foster Cross-Department Collaboration

- Why It Matters: Lack of communication between procurement, finance, and production teams can create inefficiencies.

- How to Address:

- Implement collaborative procurement planning to align purchasing with production schedules.

- Use cloud-based procurement platforms to enhance real-time communication across departments.

- Encourage regular meetings between procurement, logistics, and finance teams.

10. Leverage AI & Machine Learning for Smart Procurement

- Why It Matters: AI-driven procurement reduces human errors, optimizes decision-making, and improves efficiency.

- How to Address:

- Use AI-powered procurement platforms for automated supplier selection, contract negotiation, and spend analysis.

- Implement machine learning models to detect patterns in procurement data and enhance predictive forecasting.

- Integrate chatbots and AI assistants to streamline supplier communication and query resolution.

Best Practices for Efficient Direct Procurement

Efficient direct procurement ensures a steady supply of essential materials while minimizing costs and disruptions. Implementing best practices helps streamline operations, strengthen supplier relationships, and enhance overall efficiency.

1. Select and Evaluate Suppliers Strategically

- Diversify the supplier base to minimize risks associated with over-reliance on a few vendors.

- Establish a rigorous supplier evaluation process, considering financial stability, product quality, technical capabilities, and compliance.

- Utilize a structured scoring system to compare and rank potential suppliers objectively.

- Regularly reassess supplier performance based on factors such as on-time delivery, cost competitiveness, and adherence to quality standards.

- Leverage industry benchmarking and market intelligence to identify new sourcing opportunities.

2. Foster Strong Supplier Partnerships

- Maintain open and transparent communication with suppliers to align expectations and goals.

- Establish long-term contracts with key suppliers to secure pricing stability and supply continuity.

- Implement incentive programs that reward suppliers for superior performance and reliability.

- Collaborate with suppliers on innovation, cost-saving initiatives, and process improvements.

- Conduct regular supplier performance reviews and joint planning sessions to strengthen partnerships.

3. Use Technology and Automation

- Implement advanced procurement software to automate purchase orders, approvals, and contract management.

- Utilize AI-driven analytics to gain real-time insights into spending, supplier performance, and demand forecasting.

- Integrate e-procurement platforms to streamline vendor selection, bidding, and compliance tracking.

- Adopt robotic process automation (RPA) to eliminate manual tasks, reducing errors and procurement cycle times.

- Leverage cloud-based procurement solutions for improved collaboration and access to real-time data.

4. Conduct Regular Audits and Performance Reviews

- Establish a structured audit schedule to assess procurement efficiency and supplier performance.

- Review supplier compliance with contractual obligations, quality standards, and delivery timelines.

- Identify bottlenecks and inefficiencies in procurement workflows through internal audits.

- Use audit findings to refine procurement policies, mitigate risks, and drive continuous improvement.

- Ensure financial and operational due diligence when onboarding new suppliers.

5. Implement Sustainable Procurement Practices

- Set clear sustainability criteria when evaluating suppliers, considering environmental and ethical factors.

- Work with suppliers to develop eco-friendly sourcing strategies, such as reducing waste and carbon footprint.

- Incorporate sustainability targets into supplier contracts and performance assessments.

- Prioritize sourcing from suppliers that comply with fair labor practices and ethical manufacturing standards.

- Monitor and report on sustainability efforts to align procurement with corporate ESG goals.

6. Align Procurement Strategies With Business Objectives

- Ensure procurement goals support overall business priorities, such as market expansion or cost reduction.

- Maintain cross-functional collaboration between procurement, finance, and operations teams.

- Adapt procurement strategies based on evolving market trends, competitive positioning, and regulatory requirements.

- Align supplier selection with product innovation and customer expectations.

- Establish key performance indicators (KPIs) to measure procurement’s contribution to business success.

Key Metrics to Measure the Success of Direct Procurement

Measuring the success of direct procurement requires tracking key performance indicators (KPIs) that reflect cost efficiency, supplier performance, procurement process effectiveness, and alignment with business goals.

Here are the key ways to evaluate success:

1. Cost Savings and Cost Avoidance

- Purchase Price Variance (PPV): Compare actual purchase prices against standard or historical costs to track savings.

- Cost Reduction Initiatives: Measure the success of negotiated discounts, bulk purchasing, and supplier consolidation.

- Cost Avoidance: Identify cost increases prevented through proactive negotiations or alternative sourcing strategies.

2. Supplier Performance Metrics

- On-Time Delivery Rate: Percentage of purchase orders delivered within the agreed timeframe.

- Quality Performance: Track the defect rate, return rate, or non-conformance issues with received goods.

- Supplier Responsiveness: Measure how quickly suppliers respond to inquiries, changes, or issues.

- Contract Compliance: Assess adherence to agreed-upon terms, such as pricing, service levels, and sustainability commitments.

3. Procurement Efficiency and Cycle Time

- Procurement Cycle Time: Measure the time taken from purchase request to final delivery.

- Purchase Order (PO) Accuracy: Percentage of POs processed correctly without errors or rework.

- Automation Adoption: Track the percentage of procurement tasks automated through ERP or procurement software.

4. Inventory and Supply Chain Optimization

- Inventory Turnover Ratio: Measure how frequently inventory is used and replenished to minimize excess stock.

- Stockout and Backorder Rates: Track how often critical materials are unavailable, leading to production delays.

- Supplier Lead Time: Evaluate the average time between placing an order and receiving the goods.

5. Strategic Supplier Relationships

- Supplier Collaboration Index: Measure joint innovation efforts, process improvements, or shared cost savings.

- Supplier Risk Assessment: Track supplier financial stability, geopolitical risks, and contingency planning.

- Sustainability Compliance: Monitor adherence to ESG (Environmental, Social, and Governance) procurement goals.

6. Compliance and Risk Management

- Regulatory Compliance Rate: Ensure procurement aligns with industry and government regulations.

- Contract Adherence: Percentage of contracts fully executed as per agreed terms.

- Disruption Response Time: Measure how quickly procurement mitigates supply chain disruptions.

7. Business Impact and Alignment

- Contribution to Revenue Growth: Assess procurement’s role in supporting product innovation or market expansion.

- Internal Stakeholder Satisfaction: Gather feedback from production, finance, and R&D teams on procurement effectiveness.

- Procurement ROI (Return on Investment): Compare procurement cost savings and efficiency gains against the department’s operating costs.

By regularly tracking and analyzing these metrics, businesses can refine their procurement strategies, enhance supplier relationships, and drive long-term cost and operational efficiencies.

The Role of Technology in Direct Procurement

Technology has transformed direct procurement by enhancing efficiency, visibility, and supplier collaboration. Companies leveraging digital tools can streamline purchasing processes, reduce costs, and improve decision-making.

Below are the key ways technology plays a crucial role in direct procurement:

1. Automation for Efficiency

Modern procurement software automates routine tasks like purchase order creation, approvals, and invoice processing. This reduces manual errors, speeds up procurement cycles, and ensures compliance with company policies.

2. Enhanced Supplier Collaboration

Supplier portals and cloud-based procurement platforms enable real-time communication and data sharing. This fosters stronger relationships, improves transparency, and ensures timely deliveries of raw materials and components.

3. Data-Driven Decision Making

Advanced analytics and AI-driven insights help procurement teams analyze historical spending, forecast demand, and identify cost-saving opportunities. Data-driven strategies improve budgeting and resource allocation.

4. Supply Chain Visibility and Risk Management

Technologies like IoT, blockchain, and AI enhance supply chain visibility by tracking shipments, monitoring supplier performance, and detecting potential disruptions. This allows businesses to mitigate risks and ensure a steady supply of critical materials.

5. Integration with ERP and Other Systems

Seamless integration with ERP systems ensures that procurement activities align with production schedules, inventory levels, and financial planning. This synchronization optimizes cash flow and minimizes stockouts or over-purchasing.

6. Sustainable Procurement Practices

Technology supports sustainability by providing insights into supplier compliance, carbon footprints, and ethical sourcing. Digital tracking tools help businesses make responsible procurement choices.

How Deskera ERP Enhances Direct Procurement Efficiency

Direct procurement plays a critical role in ensuring a smooth supply chain by managing the acquisition of raw materials and essential components.

Deskera ERP streamlines this process by offering automation, real-time tracking, and advanced analytics, allowing businesses to optimize procurement efficiency while reducing costs.

1. Automated Procurement Workflows

Deskera ERP eliminates manual procurement tasks by automating purchase requisitions, approvals, and order processing. This speeds up the procurement cycle and ensures compliance with company policies.

2. Real-Time Supplier and Inventory Tracking

The system provides real-time visibility into inventory levels and supplier performance, preventing stockouts and over-purchasing. Businesses can track material availability and ensure timely replenishment.

3. Seamless Supplier Collaboration

With Deskera ERP’s cloud-based platform, procurement teams can easily communicate with suppliers, share purchase orders, and track shipments in real time. This fosters transparency and strengthens supplier relationships.

4. Cost Control and Budget Optimization

Deskera’s advanced analytics help businesses monitor procurement spending, compare supplier pricing, and identify cost-saving opportunities. Companies can negotiate better terms and reduce unnecessary expenditures.

5. Integration with Manufacturing and Finance

Deskera ERP seamlessly integrates procurement with manufacturing and financial modules. This ensures that material purchases align with production schedules and budgets, reducing waste and optimizing cash flow.

Key Takeaways

- Direct procurement involves acquiring raw materials and essential goods necessary for production. It directly impacts supply chain efficiency, cost management, and product quality.

- While direct procurement focuses on core production materials, indirect procurement deals with operational expenses like office supplies and services. Understanding both is key to effective cost control.

- Direct procurement enhances cost efficiency, strengthens supplier relationships, ensures a steady supply of critical materials, and improves production planning, ultimately driving business growth and profitability.

- Common challenges include supplier disruptions, fluctuating costs, and inventory mismanagement. Businesses can mitigate risks by diversifying suppliers, using demand forecasting tools, and implementing strong procurement policies.

- Optimizing supplier relationships, leveraging data analytics, and implementing automated approval processes help businesses achieve cost efficiency and supply chain resilience.

- Key performance indicators (KPIs) such as cost savings, supplier reliability, procurement cycle time, and inventory turnover help assess the effectiveness of direct procurement strategies.

- ERP and procurement software streamline direct procurement by automating workflows, improving supplier collaboration, and providing real-time insights for better decision-making.

- Deskera ERP automates procurement workflows, provides real-time supplier and inventory tracking, integrates with finance and manufacturing, and helps businesses optimize costs while ensuring compliance.

Related Articles